|

Suzuki K Engine

The Suzuki K engine family is a series of all aluminium inline-three or four cylinder automobile engines from Suzuki, introduced in 1994. The displacement is ranging from 0.7 L to 1.5 L. This is a timing chain head driven DOHC 4-valve per cylinder engine with VVT, using multipoint fuel injection or direct injection fuel system, turbocharged for some variants and also available with hybrid electric technology. Since 2013, some of the K engines range has been upgraded with Dualjet technology. The upgrades including new two injectors per cylinder, smaller compression chamber, increasing the compression ratio, improving the thermal efficiency, redesigned water jacket shape, adding piston cooling oil jets, adoption of water-cooled EGR system and several other changes for fuel efficiency. The turbocharged variant with direct injection fuel system is called Boosterjet. Furthermore, a mild hybrid technology with 12 or 48-volt Integrated Motor Generator (ISG) dubbed as ''S ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Suzuki

is a Japan, Japanese multinational corporation headquartered in Minami-ku, Hamamatsu, Japan. Suzuki manufactures automobiles, motorcycles, All-terrain vehicle, all-terrain vehicles (ATVs), outboard motor, outboard marine engines, wheelchairs and a variety of other small internal combustion engines. In 2016, Suzuki was the Automotive industry#By manufacturer, eleventh biggest automaker by production worldwide. Suzuki has over 45,000 employees and has 35 production facilities in 23 countries, and 133 distributors in 192 countries. The worldwide sales volume of automobiles is the world's tenth largest, while domestic sales volume is the third largest in the country. Suzuki's domestic motorcycle sales volume is the third largest in Japan. History In 1909, Michio Suzuki (inventor), Michio Suzuki (1887–1982) founded the Suzuki Loom Works in the small seacoast village of Hamamatsu, Japan. Business boomed as Suzuki built loom, weaving looms for Japan's giant silk industry. In 1929 ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Suzuki R Engine

The Suzuki R engine is an inline-three engine that has been produced by Suzuki since 2011. Initially introduced in the third-generation MR Wagon, and intended as a replacement for the K6A engine, the R engine has since been used in various Suzuki's, such as the Alto, the Wagon R, and the Carry. Overview For the release of the third-generation MR Wagon in 2011, Suzuki introduced a brand-new inline-three petrol engine. The new engine, known as the R06A, was available in naturally-aspirated and turbocharged forms, which produced respectively. Introduced as a replacement to the K6A that had been in production since 1994, the R06A features four valves per cylinder (for a total of 12), dual overhead camshafts, with a bore and stroke of respectively. In addition, the size and weight of the engine were reduced by adopting a cylinder head integrated into the exhaust manifold and a simpler catalyst case structure. While this is good for fuel economy and emissions, the exhaust is mor ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Powertrain Of Suzuki Wagon R Stingray T

A drivetrain (also frequently spelled as drive train or sometimes drive-train) is the group of components that deliver mechanical power from the prime mover to the driven components. In automotive engineering, the drivetrain is the components of a motor vehicle that deliver power to the drive wheels. This excludes the engine or motor that generates the power. In marine applications, the drive shaft will drive a propeller, thruster, or waterjet rather than a drive axle, while the actual engine might be similar to an automotive engine. Other machinery, equipment and vehicles may also use a drivetrain to deliver power from the engine(s) to the driven components. In contrast, the powertrain is considered to include both the automotive engine, engine and/or motor(s) as well as the drivetrain. Function The function of the drivetrain is to couple the engine that produces the power to the driving wheels that use this mechanical power to rotate the axle. This connection involves phys ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Motor–generator

A motor–generator (an M–G set) is a device for converting electrical power to another form. Motor–generator sets are used to convert frequency, voltage, or phase of power. They may also be used to isolate electrical loads from the electrical power supply line. Large motor–generators were widely used to convert industrial amounts of power while smaller motor–generators (such as the one shown in the picture) were used to convert battery power to higher DC voltages. While a motor–generator set may consist of distinct motor and generator machines coupled together, a single unit dynamotor (for dynamo–motor) has the motor coils and the generator coils wound around a single rotor; both the motor and generator therefore share the same outer field coils or magnets.Radio Amateur's Handbook 1976, pub. |

Hybrid Vehicle Drivetrain

Hybrid vehicle drivetrains transmit power to the driving wheels for hybrid vehicles. A hybrid vehicle has multiple forms of motive power. Hybrids come in many configurations. For example, a hybrid may receive its energy by burning gasoline, but switch between an electric motor and a combustion engine. Electrical vehicles have a long history combining internal combustion and electrical transmission as in a diesel–electric power-train although they have mostly been used for rail locomotives. A diesel–electric powertrain fails the definition of hybrid because the electric drive transmission directly replaces the mechanical transmission rather than being a supplementary source of motive power. One of the earliest forms of hybrid land vehicle was the 'trackless' trolleybus experiment in The United States (New Jersey) that ran from 1935 to 1948, which normally used traction current delivered by wire. The trolleybus was fitted with an internal combustion engine (ICE) to power the m ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Start-stop System

A vehicle start-stop system or stop-start system automatically shuts down and restarts the internal combustion engine to reduce the amount of time the engine spends idling, thereby reducing fuel consumption and emissions. This is most advantageous for vehicles which spend significant amounts of time waiting at traffic lights or frequently come to a stop in traffic jams. Start-stop technology may become more common with more stringent government fuel economy and emissions regulations.Johnson Controls expands global production of Start-Stop batteries to meet rising automaker demand |

Mild Hybrid

Mild hybrids (also known as power-assist hybrids, battery-assisted hybrid vehicles or BAHVs) are generally cars with an internal combustion engine equipped with an electric machine (one motor/generator in a parallel hybrid configuration) allowing the engine to be turned off whenever the car is coasting, braking, or stopped, and then quickly restarted once power is again required. Mild hybrids may employ regenerative braking and some level of power assist to the internal combustion engine (ICE), but mild hybrids do not have an electric-only mode of propulsion. Overview The mild hybrid's electric motor provides greater efficiency through the use of a single device that is essentially an integrated starter/alternator sometimes known as a generator-motor unit. A typical mild-hybrid setup uses a belt-powered generator-motor unit driven off the engine to supply power to a small battery. The generator is also powered through regenerative braking, enabling power that would otherwise be dis ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Exhaust Gas Recirculation

In internal combustion engines, exhaust gas recirculation (EGR) is a nitrogen oxide () emissions reduction technique used in petrol/gasoline, diesel engines and some hydrogen engines. EGR works by recirculating a portion of an engine's exhaust gas back to the engine cylinders. The exhaust gas displaces atmospheric air and reduces in the combustion chamber. Reducing the amount of oxygen reduces the amount of fuel that can burn in the cylinder thereby reducing peak in-cylinder temperatures. The actual amount of recirculated exhaust gas varies with the engine operating parameters. In the combustion cylinder, is produced by high-temperature mixtures of atmospheric nitrogen and oxygen, and this usually occurs at cylinder peak pressure. In a spark-ignition engine, an ancillary benefit of recirculating exhaust gases via an external EGR valve is an increase in efficiency, as charge dilution allows a larger throttle position and reduces associated pumping losses. Mazda's turbocharge ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Water Jacket

A water jacket is a water-filled casing surrounding a device, typically a metal sheath having intake and outlet vents to allow water to be pumped through and circulated. The flow of water to an external heating or cooling device allows precise temperature control of the device. Applications Water jackets are often used in watercooling. They are also used in laboratory glassware: Liebig, Graham, and Allihn condensers. Water jackets were used to cool the barrels of machine guns until several years after the First World War, but modern machine guns are air-cooled to conserve weight and hence increase portability. In a reciprocating piston internal combustion engine the water jacket is a series of holes either cast or bored through the main engine block and connected by inlet and outlet valves to a radiator. Equipment such as tissue culture Tissue culture is the growth of tissues or cells in an artificial medium separate from the parent organism. This technique is also called mi ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Injector

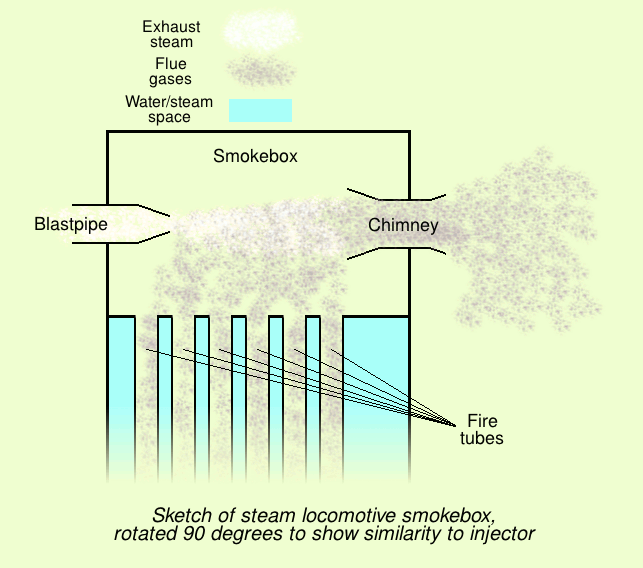

An injector is a system of ducting and nozzles used to direct the flow of a high-pressure fluid in such a way that a lower pressure fluid is entrained in the jet and carried through a duct to a region of higher pressure. It is a fluid-dynamic pump with no moving parts except a valve to control inlet flow. A steam injector is a typical application of the principle used to deliver cold water to a boiler against its own pressure, using its own live or exhaust steam, replacing any mechanical pump. When first developed, its operation was intriguing because it seemed paradoxical, almost like perpetual motion, but it was later explained using thermodynamics. Other types of injector may use other pressurised motive fluids such as air. Depending on the application, an injector can also take the form of an ''eductor-jet pump'', a ''water eductor'' or an ''aspirator''. An '' ejector'' operates on similar principles to create a vacuum feed connection for braking systems etc. History The ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Hybrid Electric Vehicle

A hybrid electric vehicle (HEV) is a type of hybrid vehicle that combines a conventional internal combustion engine (ICE) system with an electric propulsion system ( hybrid vehicle drivetrain). The presence of the electric powertrain is intended to achieve either better fuel economy than a conventional vehicle or better performance. There is a variety of HEV types and the degree to which each function as an electric vehicle (EV) also varies. The most common form of HEV is the hybrid electric car, although hybrid electric trucks (pickups and tractors), buses, boats and aircraft also exist. Modern HEVs make use of efficiency-improving technologies such as regenerative brakes which convert the vehicle's kinetic energy to electric energy, which is stored in a battery or supercapacitor. Some varieties of HEV use an internal combustion engine to turn an electrical generator, which either recharges the vehicle's batteries or directly powers its electric drive motors; this combinatio ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Turbo

In an internal combustion engine, a turbocharger (often called a turbo) is a forced induction device that is powered by the flow of exhaust gases. It uses this energy to compress the intake gas, forcing more air into the engine in order to produce more power for a given displacement. The current categorisation is that a turbocharger is powered by the kinetic energy of the exhaust gasses, whereas a is mechanically powered (usually by a belt from the engine's crankshaft). However, up until the mid-20th century, a turbocharger was called a "turbosupercharger" and was considered a type of supercharger. History Prior to the invention of the turbocharger, |

_(cropped).jpg)