Injector on:

[Wikipedia]

[Google]

[Amazon]

An injector is a system of ducting and nozzles used to direct the flow of a high-pressure fluid in such a way that a lower pressure fluid is entrained in the jet and carried through a duct to a region of higher pressure. It is a fluid-dynamic pump with no moving parts except a valve to control inlet flow.

A steam injector is a typical application of the principle used to deliver cold

An empirical application of the principle was in widespread use on steam locomotives before its formal development as the injector, in the form of the arrangement of the

An empirical application of the principle was in widespread use on steam locomotives before its formal development as the injector, in the form of the arrangement of the

Shallow well pumps are those in which the jet assembly is attached directly to the main pump and are limited to a depth of approximately 5-8m to prevent cavitation.

Deep well pumps are those in which the jet is located at the bottom of the well. The maximum depth for deep well pumps is determined by the inside diameter of and the velocity through the jet. The major advantage of jet pumps for deep well installations is the ability to situate all mechanical parts (e.g., electric/petrol motor, rotating impellers) at the ground surface for easy maintenance. The advent of the electrical

Shallow well pumps are those in which the jet assembly is attached directly to the main pump and are limited to a depth of approximately 5-8m to prevent cavitation.

Deep well pumps are those in which the jet is located at the bottom of the well. The maximum depth for deep well pumps is determined by the inside diameter of and the velocity through the jet. The major advantage of jet pumps for deep well installations is the ability to situate all mechanical parts (e.g., electric/petrol motor, rotating impellers) at the ground surface for easy maintenance. The advent of the electrical

Use of Eductor for Lifting Water

{{steam engine configurations Chemical equipment Fluid dynamics Pumps Locomotive parts Steam locomotive technologies

water

Water (chemical formula ) is an Inorganic compound, inorganic, transparent, tasteless, odorless, and Color of water, nearly colorless chemical substance, which is the main constituent of Earth's hydrosphere and the fluids of all known living ...

to a boiler against its own pressure, using its own live or exhaust steam, replacing any mechanical pump. When first developed, its operation was intriguing because it seemed paradoxical, almost like perpetual motion, but it was later explained using thermodynamics

Thermodynamics is a branch of physics that deals with heat, work, and temperature, and their relation to energy, entropy, and the physical properties of matter and radiation. The behavior of these quantities is governed by the four laws of th ...

. Other types of injector may use other pressurised motive fluids such as air.

Depending on the application, an injector can also take the form of an ''eductor-jet pump'', a ''water eductor A water eductor or water dredge is an eductor-jet pump-based tool used by underwater archaeologists to remove sediments from an underwater archaeological site. Airlifts may be used for the same purpose.

It consists of a large bore straight tube ...

'' or an ''aspirator''. An '' ejector'' operates on similar principles to create a vacuum feed connection for braking systems etc.

History

The injector was invented byHenri Giffard

Baptiste Jules Henri Jacques Giffard (8 February 182514 April 1882) was a French engineer. In 1852 he invented the steam injector and the powered Giffard dirigible airship.

Career

Giffard was born in Paris in 1825. He invented the injector a ...

in early 1850s and patented in 1858, for use on steam locomotives, and patented in the United Kingdom

The United Kingdom of Great Britain and Northern Ireland, commonly known as the United Kingdom (UK) or Britain, is a country in Europe, off the north-western coast of the European mainland, continental mainland. It comprises England, Scotlan ...

by Sharp, Stewart and Company

Sharp, Stewart and Company was a steam locomotive manufacturer, initially located in Manchester, England. The company was formed in 1843 upon the demise of Sharp, Roberts & Co.. It moved to Glasgow, Scotland, in 1888, eventually amalgamating wit ...

of Glasgow

Glasgow ( ; sco, Glesca or ; gd, Glaschu ) is the most populous city in Scotland and the fourth-most populous city in the United Kingdom, as well as being the 27th largest city by population in Europe. In 2020, it had an estimated popul ...

.

After some initial scepticism resulting from the unfamiliar and superficially paradoxical mode of operation, the injector became widely adopted for steam locomotives as an alternative to mechanical pumps.

Operation

The injector consists of a body filled with a secondary fluid, into which a motive fluid is injected. The motive fluid induces the secondary fluid to move. Injectors exist in many variations, and can have several stages, each repeating the same basic operating principle, to increase their overall effect. It uses theVenturi effect

The Venturi effect is the reduction in fluid pressure that results when a fluid flows through a constricted section (or choke) of a pipe. The Venturi effect is named after its discoverer, the 18th century Italian physicist, Giovanni Battista ...

of a converging-diverging nozzle on a steam jet to convert the pressure

Pressure (symbol: ''p'' or ''P'') is the force applied perpendicular to the surface of an object per unit area over which that force is distributed. Gauge pressure (also spelled ''gage'' pressure)The preferred spelling varies by country and e ...

energy of the steam to velocity

Velocity is the directional speed of an object in motion as an indication of its rate of change in position as observed from a particular frame of reference and as measured by a particular standard of time (e.g. northbound). Velocity i ...

energy, reducing its pressure to below that of the atmosphere, which enables it to entrain a fluid (e.g., water). After passing through the convergent "combining cone", the mixed fluid is fully condensed, releasing the latent heat

Latent heat (also known as latent energy or heat of transformation) is energy released or absorbed, by a body or a thermodynamic system, during a constant-temperature process — usually a first-order phase transition.

Latent heat can be underst ...

of evaporation of the steam which imparts extra velocity to the water. The condensate mixture then enters a divergent "delivery cone" which slows the jet, converting kinetic energy back into static pressure energy above the pressure of the boiler enabling its feed through a non-return valve.

Most of the heat energy in the condensed steam is returned to the boiler, increasing the thermal efficiency of the process. Injectors are therefore typically over 98% energy-efficient overall; they are also simple compared to the many moving parts in a feed pump.

The motive fluid may be a liquid, steam or any other gas. The entrained suction fluid may be a gas, a liquid, a slurry, or a dust-laden gas stream.

Key design parameters

Fluid feed rate and operating pressure range are the key parameters of an injector, and vacuum pressure and evacuation rate are the key parameters for an ejector. Compression ratio and the entrainment ratio may also be defined: The compression ratio of the injector, , is defined as ratio of the injector's outlet pressure to the inlet pressure of the suction fluid . The entrainment ratio of the injector, , is defined as the amount (in kg/h) of suction fluid that can be entrained and compressed by a given amount (in kg/h) of motive fluid.Lifting properties

Other key properties of an injector include the fluid inlet pressure requirements i.e. whether it is lifting or non-lifting. In a non-lifting injector, positive inlet fluid pressure is needed e.g. the cold water input is fed by gravity. The steam-cone minimal orifice diameter is kept larger than the combining cone minimal diameter. The non-lifting Nathan 4000 injector used on theSouthern Pacific 4294

Southern Pacific 4294 is a class " AC-12" 4-8-8-2 Cab forward type steam locomotive that was owned and operated by the Southern Pacific Railroad (SP). It was built by the Baldwin Locomotive Works in March 1944 and was used hauling SP's trains o ...

could push 12,000 US gallons (45,000 L) per hour at 250 psi (17 bar).

The lifting injector can operate with negative inlet fluid pressure i.e. fluid lying below the level of the injector. It differs from the non-lifting type mainly in the relative dimensions of the nozzles.

Overflow

An overflow is required for excess steam or water to discharge, especially during starting. If the injector cannot initially overcome boiler pressure, the overflow allows the injector to continue to draw water and steam.Check valve

There is at least one check valve (called a "clack valve" in locomotives because of the distinctive noise it makes) between the exit of the injector and the boiler to prevent back flow, and usually a valve to prevent air being sucked in at the overflow.Exhaust steam injector

Efficiency was further improved by the development of a multi-stage injector which is powered not by live steam from the boiler but by exhaust steam from the cylinders, thereby making use of the residual energy in the exhaust steam which would otherwise go to waste. However, an exhaust injector also cannot work when the locomotive is stationary; later exhaust injectors could use a supply of live steam if no exhaust steam was available.Problems

Injectors can be troublesome under certain running conditions, such as when vibration causes the combined steam and water jet to "knock off". Originally the injector had to be restarted by careful manipulation of the steam and water controls, and the distraction caused by a malfunctioning injector was largely responsible for the 1913 Ais Gill rail accident. Later injectors were designed to automatically restart on sensing the collapse in vacuum from the steam jet, for example with a spring-loaded delivery cone. Another common problem occurs when the incoming water is too warm and is less effective at condensing the steam in the combining cone. That can also occur if the metal body of the injector is too hot, e.g. from prolonged use.Vacuum ejectors

An additional use for the injector technology is in vacuum ejectors in continuous train braking systems, which were made compulsory in the UK by theRegulation of Railways Act 1889

The Regulation of Railways Act 1889 (52 & 53 Vict c 57) is an Act of the Parliament of the United Kingdom. It is one of the Railway Regulation Acts 1840 to 1893.The Short Titles Act 1896, section 2(1) and Schedule 2 It was enacted following th ...

. A vacuum ejector uses steam pressure to draw air out of the vacuum pipe and reservoirs of continuous train brake. Steam locomotives, with a ready source of steam, found ejector technology ideal with its rugged simplicity and lack of moving parts. A steam locomotive usually has two ejectors: a large ejector for releasing the brakes when stationary and a small ejector for maintaining the vacuum against leaks. The exhaust from the ejectors is invariably directed to the smokebox, by which means it assists the blower in draughting the fire. The small ejector is sometimes replaced by a reciprocating pump driven from the crosshead because this is more economical of steam and is only required to operate when the train is moving.

Vacuum brakes have been superseded by air brakes in modern trains, which allow the use of smaller brake cylinders and/or higher braking force due to the greater difference from atmospheric pressure.

Earlier application of the principle

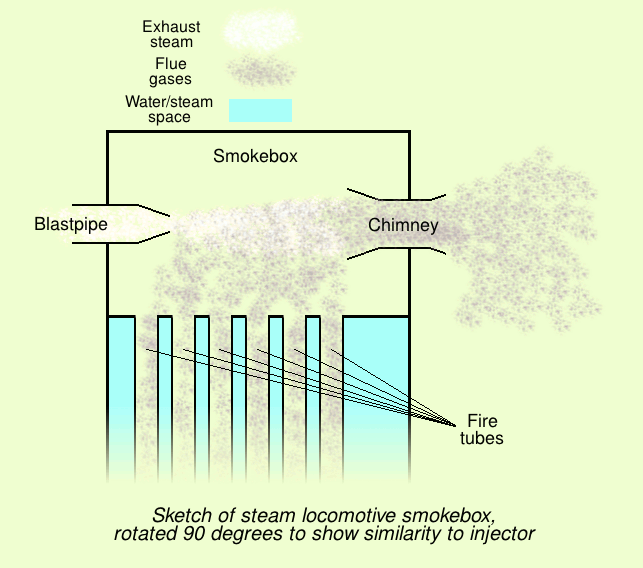

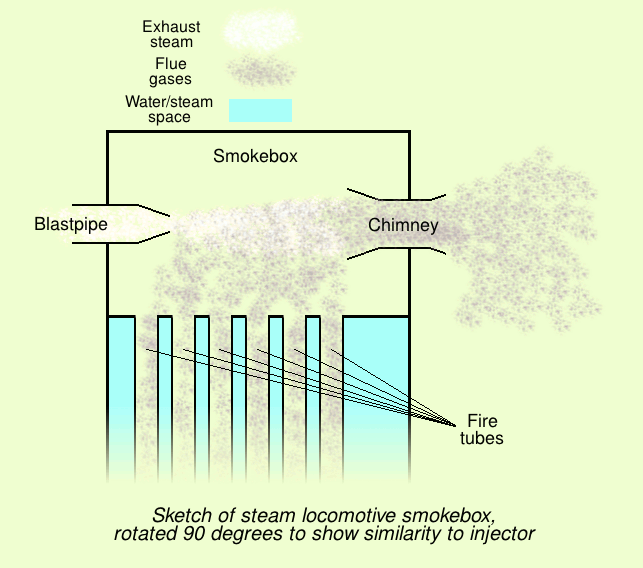

An empirical application of the principle was in widespread use on steam locomotives before its formal development as the injector, in the form of the arrangement of the

An empirical application of the principle was in widespread use on steam locomotives before its formal development as the injector, in the form of the arrangement of the blastpipe The blastpipe is part of the exhaust system of a steam locomotive that discharges exhaust steam from the cylinders into the smokebox beneath the chimney in order to increase the draught through the fire.

History

The primacy of discovery of th ...

and chimney in the locomotive smokebox. The sketch on the right shows a cross section through a smokebox, rotated 90 degrees; it can be seen that the same components are present, albeit differently named, as in the generic diagram of an injector at the top of the article. Exhaust steam from the cylinders is directed through a nozzle on the end of the blastpipe, to reduce pressure inside the smokebox by entraining the flue gases from the boiler which are then ejected via the chimney. The effect is to increase the draught on the fire to a degree proportional to the rate of steam consumption, so that as more steam is used, more heat is generated from the fire and steam production is also increased. The effect was first noted by Richard Trevithick

Richard Trevithick (13 April 1771 – 22 April 1833) was a British inventor and mining engineer. The son of a mining captain, and born in the mining heartland of Cornwall, Trevithick was immersed in mining and engineering from an early age. He w ...

and subsequently developed empirically by the early locomotive engineers; Stephenson's Rocket made use of it, and this constitutes much of the reason for its notably improved performance in comparison with contemporary machines.

Modern uses

The use of injectors (or ejectors) in various industrial applications has become quite common due to their relative simplicity and adaptability. For example: * To injectchemicals

A chemical substance is a form of matter having constant chemical composition and characteristic properties. Some references add that chemical substance cannot be separated into its constituent elements by physical separation methods, i.e., wit ...

into the boiler drums of small, stationary, low pressure boilers. In large, high-pressure modern boilers, usage of injectors for chemical dosing is not possible due to their limited outlet pressures.

* In thermal power station

A thermal power station is a type of power station in which heat energy is converted to electrical energy. In a steam-generating cycle heat is used to boil water in a large pressure vessel to produce high-pressure steam, which drives a stea ...

s, they are used for the removal of the boiler bottom ash, the removal of fly ash from the hoppers of the electrostatic precipitator

An electrostatic precipitator (ESP) is a filterless device that removes fine particles, like dust and smoke, from a flowing gas using the force of an induced electrostatic charge minimally impeding the flow of gases through the unit.

In con ...

s used to remove that ash from the boiler flue gas, and for drawing a vacuum pressure in steam turbine exhaust condensers.

* Jet pumps have been used in boiling water nuclear reactors to circulate the coolant fluid.

* For use in producing a vacuum pressure in steam jet cooling systems.

* For expansion work recovery in air conditioning and refrigeration systems.

* For enhanced oil recovery processes in the oil & gas Industry.

* For the bulk handling of grains

A grain is a small, hard, dry fruit (caryopsis) – with or without an attached hull layer – harvested for human or animal consumption. A grain crop is a grain-producing plant. The two main types of commercial grain crops are cereals and legumes ...

or other granular or powdered materials.

* The construction industry uses them for pumping turbid

Turbidity is the cloudiness or haziness of a fluid caused by large numbers of individual particles that are generally invisible to the naked eye, similar to smoke in air. The measurement of turbidity is a key test of water quality.

Fluids can ...

water and slurries

A slurry is a mixture of denser solids suspended in liquid, usually water. The most common use of slurry is as a means of transporting solids or separating minerals, the liquid being a carrier that is pumped on a device such as a centrifugal pu ...

.

* Eductors are used in ships to pump residual ballast

Ballast is material that is used to provide stability to a vehicle or structure. Ballast, other than cargo, may be placed in a vehicle, often a ship or the gondola of a balloon or airship, to provide stability. A compartment within a boat, ship ...

water, or cargo oil which cannot be removed using centrifugal pumps due to loss of suction head and may damage the centrifugal pump if run dry, which may be caused due to trim or list

A ''list'' is any set of items in a row. List or lists may also refer to:

People

* List (surname)

Organizations

* List College, an undergraduate division of the Jewish Theological Seminary of America

* SC Germania List, German rugby unio ...

of the ship.

* Eductors are used on-board ships to pump out bilges, since using centrifugal pump would not be feasible as the suction head may be lost frequently.

* Some aircraft (mostly earlier designs) use an ejector attached to the fuselage to provide vacuum for gyroscopic instruments such as an attitude indicator

The attitude indicator (AI), formerly known as the gyro horizon or artificial horizon, is a flight instrument that informs the pilot of the aircraft orientation relative to Earth's horizon, and gives an immediate indication of the smallest o ...

(artificial horizon).

* Eductors are used in aircraft fuel systems as transfer pumps; fluid flow from an engine-mounted mechanical pump can be delivered to a fuel tank-mounted eductor to transfer fuel from that tank.

* Aspirators are vacuum pumps based on the same operating principle and are used in laboratories to create a partial vacuum and for medical use in suction of mucus or bodily fluids.

* Water eductor A water eductor or water dredge is an eductor-jet pump-based tool used by underwater archaeologists to remove sediments from an underwater archaeological site. Airlifts may be used for the same purpose.

It consists of a large bore straight tube ...

s are water pumps used for dredging silt and panning for gold, they're used because they can handle the highly abrasive mixtures quite well.

* To create vacuum system in vacuum distillation unit (oil refinery).

* Vacuum autoclaves use an ejector to pull a vacuum, generally powered by the cold water supply to the machine.

* Low weight jet pumps can be made out of paper mache.

Well pumps

Jet pumps are commonly used to extract water fromwater well

A well is an excavation or structure created in the ground by digging, driving, or drilling to access liquid resources, usually water. The oldest and most common kind of well is a water well, to access groundwater in underground aquifers. T ...

s. The main pump, often a centrifugal pump

Centrifugal pumps are used to transport fluids by the conversion of rotational kinetic energy to the hydrodynamic energy of the fluid flow. The rotational energy typically comes from an engine or electric motor. They are a sub-class of dynamic ...

, is powered and installed at ground level. Its discharge is split, with the greater part of the flow leaving the system, while a portion of the flow is returned to the jet pump installed below ground in the well. This recirculated part of the pumped fluid is used to power the jet. At the jet pump, the high-energy, low-mass returned flow drives more fluid from the well, becoming a low-energy, high-mass flow which is then piped to the inlet of the main pump.

submersible pump

A submersible pump (or electric submersible pump (ESP)) is a device which has a hermetically sealed motor close-coupled to the pump body. The whole assembly is submerged in the fluid to be pumped. The main advantage of this type of pump is that i ...

has partly replaced the need for jet type well pumps, except for driven point wells or surface water intakes.

Multi-stage steam vacuum ejectors

In practice, for suction pressure below 100mbar

The bar is a metric unit of pressure, but not part of the International System of Units (SI). It is defined as exactly equal to 100,000 Pa (100 kPa), or slightly less than the current average atmospheric pressure on Earth at sea lev ...

absolute, more than one ejector is used, usually with condensers between the ejector stages. Condensing of motive steam greatly improves ejector set efficiency; both barometric

A barometer is a scientific instrument that is used to measure air pressure in a certain environment. Pressure tendency can forecast short term changes in the weather. Many measurements of air pressure are used within surface weather analysis ...

and shell-and-tube surface condenser

A surface condenser is a water-cooled shell and tube heat exchanger installed to condense exhaust steam from a steam turbine in thermal power stations. These condensers are heat exchangers which convert steam from its gaseous to its liquid stat ...

s are used.

In operation a two-stage system consists of a primary high-vacuum (HV) ejector and a secondary low-vacuum (LV) ejector. Initially the LV ejector is operated to pull vacuum down from the starting pressure to an intermediate pressure. Once this pressure is reached, the HV ejector is then operated in conjunction with the LV ejector to finally pull vacuum to the required pressure.

In operation a three-stage system consists of a primary booster, a secondary high-vacuum (HV) ejector, and a tertiary low-vacuum (LV) ejector. As per the two-stage system, initially the LV ejector is operated to pull vacuum down from the starting pressure to an intermediate pressure. Once this pressure is reached, the HV ejector is then operated in conjunction with the LV ejector to pull vacuum to the lower intermediate pressure. Finally the booster is operated (in conjunction with the HV & LV ejectors) to pull vacuum to the required pressure.

Construction materials

Injectors or ejectors are made of carbon steel, stainless steel,brass

Brass is an alloy of copper (Cu) and zinc (Zn), in proportions which can be varied to achieve different mechanical, electrical, and chemical properties. It is a substitutional alloy: atoms of the two constituents may replace each other wit ...

, titanium

Titanium is a chemical element with the Symbol (chemistry), symbol Ti and atomic number 22. Found in nature only as an oxide, it can be reduced to produce a lustrous transition metal with a silver color, low density, and high strength, resista ...

, PTFE, carbon

Carbon () is a chemical element with the symbol C and atomic number 6. It is nonmetallic and tetravalent—its atom making four electrons available to form covalent chemical bonds. It belongs to group 14 of the periodic table. Carbon mak ...

, and other materials.

See also

*Aspirator (pump)

A vacuum ejector, or simply ejector is a type of vacuum pump, which produces vacuum by means of the Venturi effect.

In an ejector, a working fluid (liquid or gaseous) flows through a jet nozzle into a tube that first narrows and then expands in ...

*De Laval nozzle

A de Laval nozzle (or convergent-divergent nozzle, CD nozzle or con-di nozzle) is a tube which is pinched in the middle, making a carefully balanced, asymmetric hourglass shape. It is used to accelerate a compressible fluid to supersonic speeds ...

* Diffusion pump

* Giovanni Battista Venturi

*Gustaf de Laval

Karl Gustaf Patrik de Laval (; 9 May 1845 – 2 February 1913) was a Swedish engineer and inventor who made important contributions to the design of steam turbines and centrifugal separation machinery for dairy.

Life

Gustaf de Laval was born at ...

* Nozzle

*Surface condenser

A surface condenser is a water-cooled shell and tube heat exchanger installed to condense exhaust steam from a steam turbine in thermal power stations. These condensers are heat exchangers which convert steam from its gaseous to its liquid stat ...

*Venturi effect

The Venturi effect is the reduction in fluid pressure that results when a fluid flows through a constricted section (or choke) of a pipe. The Venturi effect is named after its discoverer, the 18th century Italian physicist, Giovanni Battista ...

References

Further reading

* *External links

Use of Eductor for Lifting Water

{{steam engine configurations Chemical equipment Fluid dynamics Pumps Locomotive parts Steam locomotive technologies