|

Steel Abrasive

Steel abrasives are steel particles that are used as abrasive or peening media. They are usually available in two different shapes (shot and grit) that address different industrial applications. Steel shot refers to spherical grains made of molten steel through an atomization ("granulation") process, available in different sizes and hardnesses. Steel grit characterizes grains with a predominantly angular shape. These grains are obtained by crushing steel shot, therefore they exhibit sharp edges and broken sections. Harder than steel shot, it is also available in different sizes and hardnesses. Properties Most steel abrasives are made of a high-carbon steel composition, the best compromise between mechanical properties, efficiency and durability. The most important properties for steel abrasives are hardness, grain size and shape, toughness and cleanliness (lack of oxides, contaminants, etc.). Recyclability and environmental impact The recyclability of steel shot and grit ranges ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

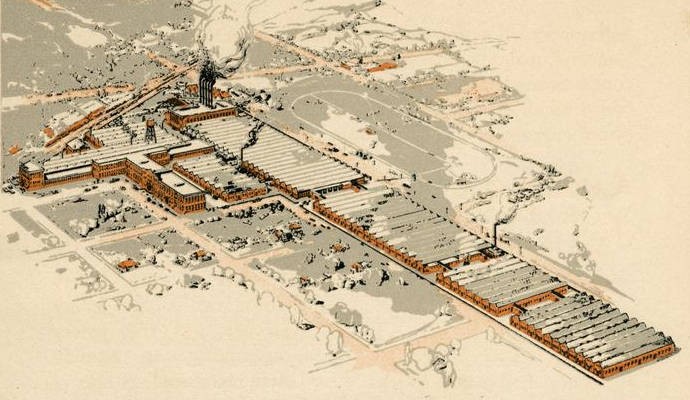

Steel Shot Abrasive Media

Steel is an alloy made up of iron with added carbon to improve its strength and fracture resistance compared to other forms of iron. Many other elements may be present or added. Stainless steels that are corrosion- and oxidation-resistant typically need an additional 11% chromium. Because of its high tensile strength and low cost, steel is used in buildings, infrastructure, tools, ships, trains, cars, machines, electrical appliances, weapons, and rockets. Iron is the base metal of steel. Depending on the temperature, it can take two crystalline forms (allotropic forms): body-centred cubic and face-centred cubic. The interaction of the allotropes of iron with the alloying elements, primarily carbon, gives steel and cast iron their range of unique properties. In pure iron, the crystal structure has relatively little resistance to the iron atoms slipping past one another, and so pure iron is quite ductile, or soft and easily formed. In steel, small amounts of carb ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Granite

Granite () is a coarse-grained ( phaneritic) intrusive igneous rock composed mostly of quartz, alkali feldspar, and plagioclase. It forms from magma with a high content of silica and alkali metal oxides that slowly cools and solidifies underground. It is common in the continental crust of Earth, where it is found in igneous intrusions. These range in size from dikes only a few centimeters across to batholiths exposed over hundreds of square kilometers. Granite is typical of a larger family of ''granitic rocks'', or '' granitoids'', that are composed mostly of coarse-grained quartz and feldspars in varying proportions. These rocks are classified by the relative percentages of quartz, alkali feldspar, and plagioclase (the QAPF classification), with true granite representing granitic rocks rich in quartz and alkali feldspar. Most granitic rocks also contain mica or amphibole minerals, though a few (known as leucogranites) contain almost no dark minerals. Granite is ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Steel

Steel is an alloy made up of iron with added carbon to improve its strength and fracture resistance compared to other forms of iron. Many other elements may be present or added. Stainless steels that are corrosion- and oxidation-resistant typically need an additional 11% chromium. Because of its high tensile strength and low cost, steel is used in buildings, infrastructure, tools, ships, trains, cars, machines, electrical appliances, weapons, and rockets. Iron is the base metal of steel. Depending on the temperature, it can take two crystalline forms (allotropic forms): body-centred cubic and face-centred cubic. The interaction of the allotropes of iron with the alloying elements, primarily carbon, gives steel and cast iron their range of unique properties. In pure iron, the crystal structure has relatively little resistance to the iron atoms slipping past one another, and so pure iron is quite ductile, or soft and easily formed. In steel, small amounts of ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Abrasives

An abrasive is a material, often a mineral, that is used to shape or finish a workpiece through rubbing which leads to part of the workpiece being worn away by friction. While finishing a material often means polishing it to gain a smooth, reflective surface, the process can also involve roughening as in satin, matte or beaded finishes. In short, the ceramics which are used to cut, grind and polish other softer materials are known as abrasives. Abrasives are extremely commonplace and are used very extensively in a wide variety of industrial, domestic, and technological applications. This gives rise to a large variation in the physical and chemical composition of abrasives as well as the shape of the abrasive. Some common uses for abrasives include grinding, polishing, buffing, honing, cutting, drilling, sharpening, lapping, and sanding (see abrasive machining). (For simplicity, "mineral" in this article will be used loosely to refer to both minerals and mineral-like substanc ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Footnotes

A note is a string of text placed at the bottom of a page in a book or document or at the end of a chapter, volume, or the whole text. The note can provide an author's comments on the main text or citations of a reference work in support of the text. Footnotes are notes at the foot of the page while endnotes are collected under a separate heading at the end of a chapter, volume, or entire work. Unlike footnotes, endnotes have the advantage of not affecting the layout of the main text, but may cause inconvenience to readers who have to move back and forth between the main text and the endnotes. In some editions of the Bible, notes are placed in a narrow column in the middle of each page between two columns of biblical text. Numbering and symbols In English, a footnote or endnote is normally flagged by a superscripted number immediately following that portion of the text the note references, each such footnote being numbered sequentially. Occasionally, a number between brac ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Abrasive Machining

Abrasive machining is a machining process where material is removed from a workpiece using a multitude of small abrasive particles. Common examples include grinding, honing, and polishing. Abrasive processes are usually expensive, but capable of tighter tolerances and better surface finish than other machining processes Mechanics of abrasive machining Abrasive machining works by forcing the abrasive particles, or grains, into the surface of the workpiece so that each particle cuts away a small bit of material. Abrasive machining is similar to conventional machining, such as milling or turning, because each of the abrasive particles acts like a miniature cutting tool. However, unlike conventional machining the grains are much smaller than a cutting tool, and the geometry and orientation of individual grains are not well defined. As a result, abrasive machining is less power efficient and generates more heat. The grain size may be different based on the machining. For rough grinding, ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Abrasive Blasting

Sandblasting, sometimes known as abrasive blasting, is the operation of forcibly propelling a stream of abrasive material against a surface under high pressure to smooth a rough surface, roughen a smooth surface, shape a surface or remove surface contaminants. A pressurised fluid, typically compressed air, or a centrifugal wheel is used to propel the blasting material (often called the ''media''). The first abrasive blasting process was patented by Benjamin Chew Tilghman on 18 October 1870. There are several variants of the process, using various media; some are highly abrasive, whereas others are milder. The most abrasive are shot blasting (with metal shot) and sandblasting (with sand). Moderately abrasive variants include glass bead blasting (with glass beads) and plastic media blasting (PMB) with ground-up plastic stock or walnut shells and corncobs. Some of these substances can cause anaphylactic shock to individuals allergic to the media. A mild version is sodablasting ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Petrochemical Industry

The petrochemical industry is concerned with the production and trade of petrochemicals. A major part is constituted by the plastics (polymer) industry. It directly interfaces with the petroleum industry, especially the downstream sector. Companies The top ten global petrochemical companies based on the 2008 revenues – excludes state-owned companies: Countries and sites *Marun petrochemical complex Technology Conferences *Asia Petrochemical Industry Conference *International Petrochemical Conference by the AFPM Associations *American Fuel and Petrochemical Manufacturers (AFPM) *European Petrochemical Association *Gulf Petrochemicals and Chemicals Association Awards *Medal "For the Tapping of the Subsoil and Expansion of the Petrochemical Complex of Western Siberia" *Petrochemical Heritage Award See also *Aqueous Wastes from Petroleum and Petrochemical Plants ''Aqueous Wastes from Petroleum and Petrochemical Plants'' is a book about the composition and treatment of ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Metallurgy

Metallurgy is a domain of materials science and engineering that studies the physical and chemical behavior of metallic elements, their inter-metallic compounds, and their mixtures, which are known as alloys. Metallurgy encompasses both the science and the technology of metals; that is, the way in which science is applied to the production of metals, and the engineering of metal components used in products for both consumers and manufacturers. Metallurgy is distinct from the craft of metalworking. Metalworking relies on metallurgy in a similar manner to how medicine relies on medical science for technical advancement. A specialist practitioner of metallurgy is known as a metallurgist. The science of metallurgy is further subdivided into two broad categories: chemical metallurgy and physical metallurgy. Chemical metallurgy is chiefly concerned with the reduction and oxidation of metals, and the chemical performance of metals. Subjects of study in chemical metallurgy include m ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Construction

Construction is a general term meaning the art and science to form objects, systems, or organizations,"Construction" def. 1.a. 1.b. and 1.c. ''Oxford English Dictionary'' Second Edition on CD-ROM (v. 4.0) Oxford University Press 2009 and comes from Latin ''constructio'' (from ''com-'' "together" and ''struere'' "to pile up") and Old French ''construction''. To construct is the verb: the act of building, and the noun is construction: how something is built, the nature of its structure. In its most widely used context, construction covers the processes involved in delivering buildings, infrastructure, industrial facilities and associated activities through to the end of their life. It typically starts with planning, financing, and design, and continues until the asset is built and ready for use; construction also covers repairs and maintenance work, any works to expand, extend and improve the asset, and its eventual demolition, dismantling or decommissioning. The con ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Automotive Industry

The automotive industry comprises a wide range of companies and organizations involved in the design, development, manufacturing, marketing, and selling of motor vehicles. It is one of the world's largest industries by revenue (from 16 % such as in France up to 40 % to countries like Slovakia). It is also the industry with the highest spending on research & development per firm. The word ''automotive'' comes from the Greek ''autos'' (self), and Latin ''motivus'' (of motion), referring to any form of self-powered vehicle. This term, as proposed by Elmer Sperry (1860-1930), first came into use with reference to automobiles in 1898. History The automotive industry began in the 1860s with hundreds of manufacturers that pioneered the horseless carriage. For many decades, the United States led the world in total automobile production. In 1929, before the Great Depression, the world had 32,028,500 automobiles in use, and the U.S. automobile industry produced over 90% ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Shot Peening

Shot peening is a cold working process used to produce a compressive residual stress layer and modify the mechanical properties of metals and composites. It entails striking a surface with shot (round metallic, glass, or ceramic particles) with force sufficient to create plastic deformation."Shot Peening," ''Tool and Manufacturing Engineers Handbook'' (TMEH), Volume 3, Society of Manufacturing Engineers, 1985 In machining, shot peening is used to strengthen and relieve stress in components like steel automobile crankshafts and connecting rods. In architecture it provides a muted finish to metal. Shot peening is similar mechanically to sandblasting, though its purpose is not to remove material, but rather it employs the mechanism of plasticity to achieve its goal, with each particle functioning as a ball-peen hammer. Details Peening a surface spreads it plastically, causing changes in the mechanical properties of the surface. Its main application is to avoid the propagati ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |