|

Snips

Snips, also known as shears, are hand tools used to cut sheet metal and other tough web (manufacturing), webs. It is a cutting tool. Workers use various types of snips, either straight or blend one be obtained. The straight or bent being not only for straight cuts but for inside of the curvature or concave curvature too. There are two broad categories: ''tinner's snips'', which are similar to common scissors, and ''compound-action'' snips, which use a compound leverage handle system to increase the mechanical advantage. Types Tinner snips Tinner's snips, also known as tinner snips or tin snips, are one of the most popular type of snips. They are defined by their long handles and short blades. They usually have extra wide jaws and are made of drop forging, drop forged carbon steel. Depending on the size of the blade, tin snips can cut between 24 and 16 gauge cold rolling, cold rolled low-carbon tin. They can be ranged in length from long. There are two main types: straight-patter ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Scissors

Scissors are hand-operated shearing tools. A pair of scissors consists of a pair of metal blades pivoted so that the sharpened edges slide against each other when the handles (bows) opposite to the pivot are closed. Scissors are used for cutting various thin materials, such as paper, cardboard, metal foil, cloth, rope, and wire. A large variety of scissors and shears all exist for specialized purposes. Hair-cutting shears and kitchen shears are functionally equivalent to scissors, but the larger implements tend to be called shears. Hair-cutting shears have specific blade angles ideal for cutting hair. Using the incorrect type of scissors to cut hair will result in increased damage or split ends, or both, by breaking the hair. Kitchen shears, also known as kitchen scissors, are intended for cutting and trimming foods such as meats. Inexpensive, mass-produced modern scissors are often designed ergonomically with composite thermoplastic and rubber handles. Terminology The noun ' ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Shear (sheet Metal)

There are many types of shears used to shear or cut sheet metal. Types Alligator shear An alligator shear, historically known as a lever shear and sometimes as a crocodile shear, is a metal-cutting shear with a hinged jaw, powered by a flywheel or hydraulic cylinder. Alligator shears are generally set up as stand-alone shears; however, there are types for excavators. The jaw size can range from 4 to 36 in (100 to 910 mm) long. They are generally used to cut ferrous members, such as rebar, pipe, angle iron, or I-beams. Bench shear A ''bench shear'', also known as a ''lever shear'', is a bench mounted shear with a compound mechanism to increase the mechanical advantage. It is usually used for cutting rough shapes out of medium-sized pieces of sheet metal, but cannot do delicate work. For the small shear, it mostly designed for a wide field of applications. Light weight and easy efficient operation, yet very sturdy in construction. The cutting blades fitted are carefully and accura ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Hand Tool

A hand tool is any tool that is powered by hand rather than a motor. Categories of hand tools include wrenches, pliers, cutters, files, striking tools, struck or hammered tools, screwdrivers, vises, clamps, snips, hacksaws, drills, and knives. Outdoor tools such as garden forks, pruning shears, and rakes are additional forms of hand tools. Portable power tools are not hand tools. History Hand tools have been used by humans since the Stone Age when stones were used for hammering and cutting. During the Bronze Age tools were made by casting the copper and tin alloys. Bronze tools were sharper and harder than those made of stone. During the Iron Age iron replaced bronze, and tools became even stronger and more durable. The Romans developed tools during this period which are similar to those being produced today. In the period since the industrial revolution, the manufacture of tools has transitioned from being craftsman made to being factory produced. A large collection of ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Metalworking Cutting Tools

Metalworking is the process of shaping and reshaping metals to create useful objects, parts, assemblies, and large scale structures. As a term it covers a wide and diverse range of processes, skills, and tools for producing objects on every scale: from huge ships, buildings, and bridges down to precise engine parts and delicate jewelry. The historical roots of metalworking predate recorded history; its use spans cultures, civilizations and millennia. It has evolved from shaping soft, native metals like gold with simple hand tools, through the smelting of ores and hot forging of harder metals like iron, up to highly technical modern processes such as machining and welding. It has been used as an industry, a driver of trade, individual hobbies, and in the creation of art; it can be regarded as both a science and a craft. Modern metalworking processes, though diverse and specialized, can be categorized into one of three broad areas known as forming, cutting, or joining processes. Mo ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Metalworking Hand Tools

Metalworking hand tools are hand tools that are used in the metalworking field. Hand tools are powered solely by the operator. Slapper Both metal and wood slappers are used for metalworking. Generally wood slappers are covered with a leather-face. Slappers can be used to shrink, contour, and planish (smooth) the panel without leaving rough marks to clean up. The salapper controls more surface with each blow than a hammer can and is very easy to use because it has the same angle of attack as a body hammer. This means the user does not need to change their arm and hand position when moving from hammer to slapper. The slapper can be far more effective than the hammer for shrinking because its leverage gives greater mechanical advantage over the rough spots. The slapper is great for working metal over a T-stake or for gouging and planishing. A good slapper can make radius bends and crowns quite well. A slapper works well with forming stakes and post dollies for lightly planishing and p ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Sheet Metal

Sheet metal is metal formed into thin, flat pieces, usually by an industrial process. Sheet metal is one of the fundamental forms used in metalworking, and it can be cut and bent into a variety of shapes. Thicknesses can vary significantly; extremely thin sheets are considered foil or leaf, and pieces thicker than 6 mm (0.25 in) are considered plate, such as plate steel, a class of structural steel. Sheet metal is available in flat pieces or coiled strips. The coils are formed by running a continuous sheet of metal through a roll slitter. In most of the world, sheet metal thickness is consistently specified in millimeters. In the U.S., the thickness of sheet metal is commonly specified by a traditional, non-linear measure known as its gauge. The larger the gauge number, the thinner the metal. Commonly used steel sheet metal ranges from 30 gauge to about 7 gauge. Gauge differs between ferrous ( iron-based) metals and nonferrous metals such as aluminum or copper. Cop ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Nibbler

A nibbler, or nibblers,Jeffery Zurschmeide Automotive Welding: A Practical Guide 2009 - Page 26 "Nibblers make a ragged cut and also leave thousands of little sheetmetal nibbles all over your shop. ... Power shears are the best tool going for cutting sheetmetal, but they cost more than a nibbler, and a lot more than a set of hand shears." is a tool for cutting sheet metal with minimal distortion. They may be used for nibbling. One type operates much like a punch and die, with a blade that moves in a linear fashion against a fixed die, removing small bits of metal and leaving a kerf approximately 6 mm wide. Another type operates similar to tin snips, but shears the sheet along two parallel tracks 3–6 mm apart, rolling up the waste in a tight spiral as it cuts. Nibblers may be manual (hand operated) or powered. Power nibblers are often powered by compressed air, though electrical types also exist. A common DIY nibbler tool is an electric drill A drill is a tool u ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

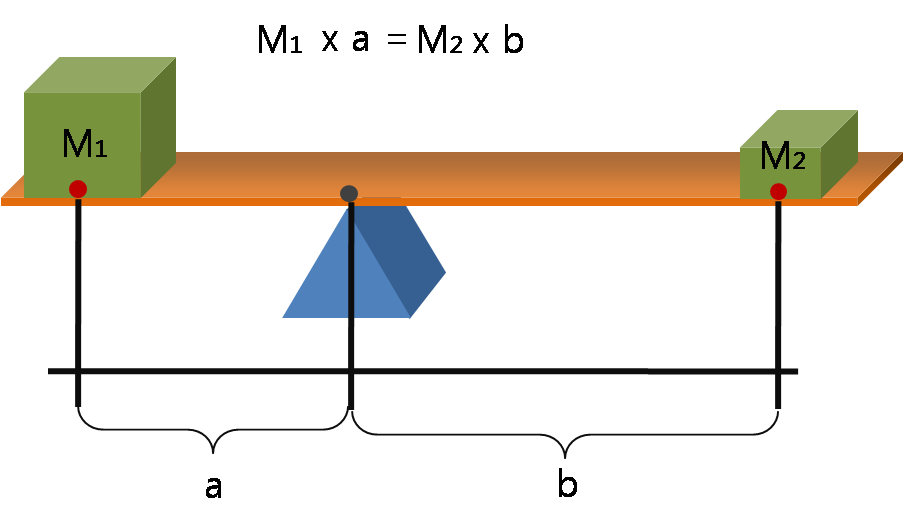

Mechanical Advantage

Mechanical advantage is a measure of the force amplification achieved by using a tool, mechanical device or machine system. The device trades off input forces against movement to obtain a desired amplification in the output force. The model for this is the ''law of the lever.'' Machine components designed to manage forces and movement in this way are called mechanisms. An ideal mechanism transmits power without adding to or subtracting from it. This means the ideal machine does not include a power source, is frictionless, and is constructed from rigid bodies that do not deflect or wear. The performance of a real system relative to this ideal is expressed in terms of efficiency factors that take into account departures from the ideal. Lever The lever is a movable bar that pivots on a fulcrum attached to or positioned on or across a fixed point. The lever operates by applying forces at different distances from the fulcrum, or pivot. The location of the fulcrum determines ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Siding (construction)

Siding or wall cladding is the protective material attached to the exterior side of a wall of a house or other building. Along with the roof, it forms the first line of defense against the elements, most importantly sun, rain/snow, heat and cold, thus creating a stable, more comfortable environment on the interior side. The siding material and style also can enhance or detract from the building's beauty. There is a wide and expanding variety of materials to side with, both natural and artificial, each with its own benefits and drawbacks. Masonry walls as such do not require siding, but any wall can be sided. Walls that are internally framed, whether with wood, or steel I-beams, however, must always be sided. Most siding consists of pieces of weather-resistant material that are smaller than the wall they cover, to allow for expansion and contraction of the materials due to moisture and temperature changes. There are various styles of joining the pieces, from board and batton, wher ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Web (manufacturing)

A web is a long, thin, and flexible material. Common webs include foil, metal, paper, textile, plastic film, and wire. Common processes carried out on webs include coating, plating, and laminating.. A web is generally processed by moving over rollers. Between processing stages, webs are stored and transported as rolls also known as coils, packages and doffs. The end result or use of web manufacturing is usually sheets. The primary motivation to work with webs instead of sheets is economics. Webs, being continuous, can be made at far higher speeds and do not have the start-stop issues of discrete sheet processing. The size of the web-handling industries is unknown. Related processes *Web processing Web processing is found in a wide variety of other manufacturing including electronics such as circuit boards, construction materials such as roofing, and pharmaceuticals such as drug patches. *Web handling Web handling refers to the processing of a web through a machine with maxi ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Lever

A lever is a simple machine consisting of a beam or rigid rod pivoted at a fixed hinge, or ''fulcrum''. A lever is a rigid body capable of rotating on a point on itself. On the basis of the locations of fulcrum, load and effort, the lever is divided into three types. Also, leverage is mechanical advantage gained in a system. It is one of the six simple machines identified by Renaissance scientists. A lever amplifies an input force to provide a greater output force, which is said to provide leverage. The ratio of the output force to the input force is the mechanical advantage of the lever. As such, the lever is a mechanical advantage device, trading off force against movement. Etymology The word "lever" entered English around 1300 from Old French, in which the word was ''levier''. This sprang from the stem of the verb ''lever'', meaning "to raise". The verb, in turn, goes back to the Latin ''levare'', itself from the adjective ''levis'', meaning "light" (as in "not heavy"). The ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Fatigue (material)

In materials science, fatigue is the initiation and propagation of cracks in a material due to cyclic loading. Once a fatigue crack has initiated, it grows a small amount with each loading cycle, typically producing striations on some parts of the fracture surface. The crack will continue to grow until it reaches a critical size, which occurs when the stress intensity factor of the crack exceeds the fracture toughness of the material, producing rapid propagation and typically complete fracture of the structure. Fatigue has traditionally been associated with the failure of metal components which led to the term metal fatigue. In the nineteenth century, the sudden failing of metal railway axles was thought to be caused by the metal ''crystallising'' because of the brittle appearance of the fracture surface, but this has since been disproved. Most materials, such as composites, plastics and ceramics, seem to experience some sort of fatigue-related failure. To aid in predicting t ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |