|

Suspension Polymerization

Suspension polymerization is a heterogeneous radical polymerization process that uses mechanical agitation to mix a monomer or mixture of monomers in a liquid phase, such as water, while the monomers polymerize, forming spheres of polymer. The monomer droplets (size of the order 10-1000 μm) are suspended in the liquid phase. The individual monomer droplets can be considered as undergoing bulk polymerization. The liquid phase outside these droplets help in better conduction of heat and thus tempering the increase in temperature. While choosing a liquid phase for suspension polymerization, low viscosity, high thermal conductivity and low temperature variation of viscosity are generally preferred. The primary advantage of suspension polymerization over other types of polymerization is that a higher degree of polymerization can be achieved without monomer boil-off. During this process, there is often a possibility of these monomer droplets to stick to each other and cause creaming i ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

International Union Of Pure And Applied Chemistry

The International Union of Pure and Applied Chemistry (IUPAC ) is an international federation of National Adhering Organizations working for the advancement of the chemical sciences, especially by developing nomenclature and terminology. It is a member of the International Science Council (ISC). IUPAC is registered in Zürich, Switzerland, and the administrative office, known as the "IUPAC Secretariat", is in Research Triangle Park, North Carolina, United States. This administrative office is headed by IUPAC's executive director, currently Lynn Soby. IUPAC was established in 1919 as the successor of the International Congress of Applied Chemistry for the advancement of chemistry. Its members, the National Adhering Organizations, can be national chemistry societies, national academies of sciences, or other bodies representing chemists. There are fifty-four National Adhering Organizations and three Associate National Adhering Organizations. IUPAC's Inter-divisional Committee on ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

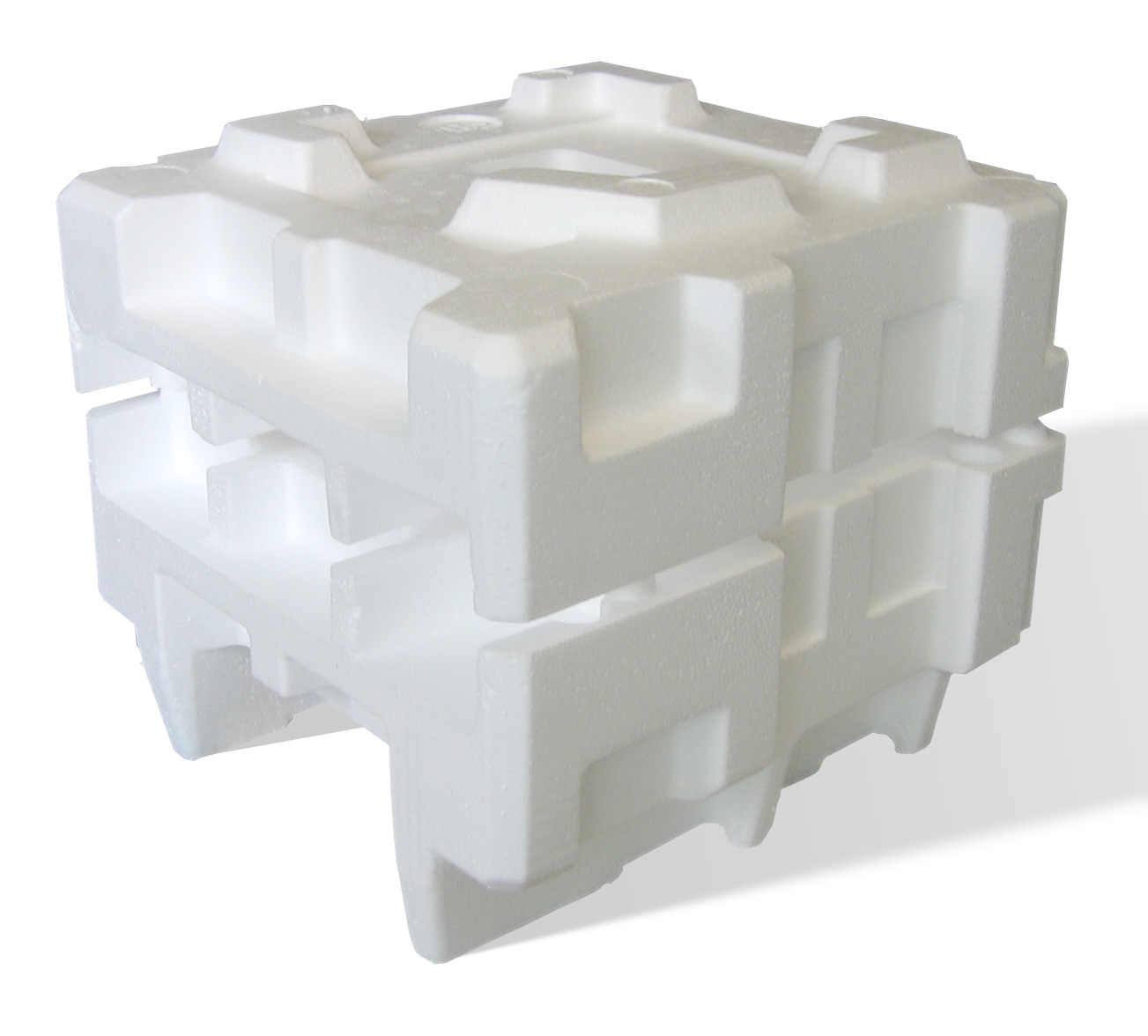

Polystyrene

Polystyrene (PS) is a synthetic polymer made from monomers of the aromatic hydrocarbon styrene. Polystyrene can be solid or foamed. General-purpose polystyrene is clear, hard, and brittle. It is an inexpensive resin per unit weight. It is a poor barrier to oxygen and water vapour and has a relatively low melting point. Polystyrene is one of the most widely used plastics, the scale of its production being several million tonnes per year. Polystyrene can be naturally transparent, but can be colored with colorants. Uses include protective packaging (such as packing peanuts and in the jewel cases used for storage of optical discs such as CDs and occasionally DVDs), containers, lids, bottles, trays, tumblers, disposable cutlery, in the making of models, and as an alternative material for phonograph records. As a thermoplastic polymer, polystyrene is in a solid (glassy) state at room temperature but flows if heated above about 100 °C, its glass transition temperature. I ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Suspension Polymerization Equipment

Suspension or suspended may refer to: Science and engineering * Suspension (topology), in mathematics * Suspension (dynamical systems), in mathematics * Suspension of a ring, in mathematics * Suspension (chemistry), small solid particles suspended in a liquid **Colloidal suspension * Cell suspension or suspension culture, in biology * Suspension (mechanics), system allowing a machine to move smoothly with reduced shock * The superstructure of a suspension bridge * Suspensory behavior, arboreal locomotion of primates * Magnetic suspension, a method by which an object is suspended with no support other than magnetic fields * Car suspension Temporary revocation of privileges * Suspension (punishment), temporary exclusion as a punishment ** Suspension from the UK parliament ** Suspension (Catholic canonical penalty) * Suspension of driving privileges ("suspended driver's license") * Administrative License Suspension (ALS), US, driving license suspension without a court hearing ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Superabsorbent Polymer

A superabsorbent polymer (SAP) (also called slush powder) is a water-absorbing hydrophilic homopolymers or copolymers that can absorb and retain extremely large amounts of a liquid relative to its own mass. Water-absorbing polymers, which are classified as hydrogels when mixed, absorb aqueous solutions through hydrogen bonding with water molecules. A SAP's ability to absorb water depends on the ionic concentration of the aqueous solution. In deionized and distilled water, a SAP may absorb 300 times its weight (from 30 to 60 times its own volume) and can become up to 99.9% liquid, and when put into a 0.9% saline solution the absorbency drops to approximately 50 times its weight. The presence of valence cations in the solution impedes the polymer's ability to bond with the water molecule. The SAP's total absorbency and swelling capacity are controlled by the type and degree of cross-linkers used to make the gel. Low-density cross-linked SAPs generally have a higher absorbent capaci ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Emulsion Polymerization

Emulsion polymerization is a type of radical polymerization that usually starts with an emulsion incorporating water, monomer, and surfactant. The most common type of emulsion polymerization is an oil-in-water emulsion, in which droplets of monomer (the oil) are emulsified (with surfactants) in a continuous phase of water. Water-soluble polymers, such as certain polyvinyl alcohols or hydroxyethyl celluloses, can also be used to act as emulsifiers/stabilizers. The name "emulsion polymerization" is a misnomer that arises from a historical misconception. Rather than occurring in emulsion droplets, polymerization takes place in the latex/colloid particles that form spontaneously in the first few minutes of the process. These latex particles are typically 100 nm in size, and are made of many individual polymer chains. The particles are prevented from coagulating with each other because each particle is surrounded by the surfactant ('soap'); the charge on the surfactant repels other pa ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Step-growth Polymerization

Step-growth polymerization refers to a type of polymerization mechanism in which bi-functional or multifunctional monomers react to form first dimers, then trimers, longer oligomers and eventually long chain polymers. Many naturally occurring and some synthetic polymers are produced by step-growth polymerization, e.g. polyesters, polyamides, polyurethanes, etc. Due to the nature of the polymerization mechanism, a high extent of reaction is required to achieve high molecular weight. The easiest way to visualize the mechanism of a step-growth polymerization is a group of people reaching out to hold their hands to form a human chain—each person has two hands (= reactive sites). There also is the possibility to have more than two reactive sites on a monomer: In this case branched polymers production take place. IUPAC deprecates the term step-growth polymerization and recommends use of the terms polyaddition, when the propagation steps are addition reactions and no molecules are ev ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Polymerization

In polymer chemistry, polymerization (American English), or polymerisation (British English), is a process of reacting monomer, monomer molecules together in a chemical reaction to form polymer chains or three-dimensional networks. There are many forms of polymerization and different systems exist to categorize them. In chemical compounds, polymerization can occur via a variety of reaction mechanisms that vary in complexity due to the functional groups present in the reactants and their inherent steric effects. In more straightforward polymerizations, alkenes form polymers through relatively simple free-radical reaction, radical reactions; in contrast, reactions involving substitution at a carbonyl group require more complex synthesis due to the way in which reactants polymerize. Alkanes can also be polymerized, but only with the help of strong acids. As alkenes can polymerize in somewhat straightforward radical reactions, they form useful compounds such as polyethylene and p ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

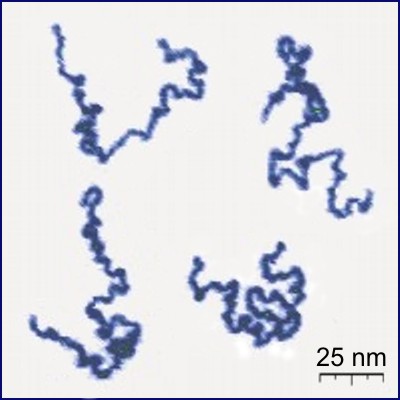

Polymer

A polymer (; Greek '' poly-'', "many" + ''-mer'', "part") is a substance or material consisting of very large molecules called macromolecules, composed of many repeating subunits. Due to their broad spectrum of properties, both synthetic and natural polymers play essential and ubiquitous roles in everyday life. Polymers range from familiar synthetic plastics such as polystyrene to natural biopolymers such as DNA and proteins that are fundamental to biological structure and function. Polymers, both natural and synthetic, are created via polymerization of many small molecules, known as monomers. Their consequently large molecular mass, relative to small molecule compounds, produces unique physical properties including toughness, high elasticity, viscoelasticity, and a tendency to form amorphous and semicrystalline structures rather than crystals. The term "polymer" derives from the Greek word πολύς (''polus'', meaning "many, much") and μέρος (''meros'' ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Radical Polymerization

In polymer chemistry, free-radical polymerization (FRP) is a method of polymerization by which a polymer forms by the successive addition of free-radical building blocks (repeat units). Free radicals can be formed by a number of different mechanisms, usually involving separate initiator molecules. Following its generation, the initiating free radical adds (nonradical) monomer units, thereby growing the polymer chain. Free-radical polymerization is a key synthesis route for obtaining a wide variety of different polymers and materials composites. The relatively non-specific nature of free-radical chemical interactions makes this one of the most versatile forms of polymerization available and allows facile reactions of polymeric free-radical chain ends and other chemicals or substrates. In 2001, 40 billion of the 110 billion pounds of polymers produced in the United States were produced by free-radical polymerization. Free-radical polymerization is a type of chain-growth polymeriz ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Diluent

A diluent (also referred to as a filler, dilutant or thinner) is a Concentration, diluting agent. Certain fluids are too Viscosity, viscous to be pumped easily or too density, dense to flow from one particular point to the other. This can be problematic, because it might not be economically feasible to transport such fluids in this state. To ease this restricted movement, diluents are added. This decreases the viscosity of the fluids, thereby also decreasing the pumping/transportation costs. One industrial application is the transport of crude oil via pipelines. Heavy crude oil/bitumen are fluids with high viscosity, especially at low temperatures. The addition of a diluent enables the diluted fluid (dilbit in the case of bitumen) to meet pipeline specifications in order for it to be efficiently transported. Typical diluent in this case is naphtha or Natural gas condensate, condensate. Types of diluents more familiar to the general public include paint thinner and nail polish ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Poly(methyl Methacrylate)

Poly(methyl methacrylate) (PMMA) belongs to a group of materials called engineering plastics. It is a transparent thermoplastic. PMMA is also known as acrylic, acrylic glass, as well as by the trade names and brands Crylux, Plexiglas, Acrylite, Astariglas, Lucite, Perclax, and Perspex, among several others ( see below). This plastic is often used in sheet form as a lightweight or shatter-resistant alternative to glass. It can also be used as a casting resin, in inks and coatings, and for many other purposes. Although not a type of familiar silica-based glass, the substance, like many thermoplastics, is often technically classified as a type of glass, in that it is a non-crystalline vitreous substance—hence its occasional historic designation as ''acrylic glass''. Chemically, it is the synthetic polymer of methyl methacrylate. It was developed in 1928 in several different laboratories by many chemists, such as William Chalmers, Otto Röhm, and Walter Bauer, and first brought ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Styrene-acrylonitrile Resin

Styrene acrylonitrile resin is a copolymer plastic consisting of styrene and acrylonitrile. It is also known as SAN. It is widely used in place of polystyrene owing to its greater thermal resistance. The chains of between 70 and 80% by weight styrene and 20 to 30% acrylonitrile. Larger acrylonitrile content improves mechanical properties and chemical resistance, but also adds a yellow tint to the normally transparent plastic. Properties SAN is similar in use to polystyrene. Like polystyrene itself, it is optically transparent and brittle in mechanical behavior. The copolymer has a glass transition temperature greater than 100 °C owing to the acrylonitrile units in the chain, thus making the material resistant to boiling water. It is structurally related to ABS plastic, where polybutadiene is copolymerised with SAN to give a much tougher material. The rubber chains form separate phases which are 10-20 micrometers in diameter. When the product is stressed, crazing from th ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |