|

Release Liner

A release liner or ''release paper'' is a paper or plastic-based film sheet (usually applied during the manufacturing process) used to prevent a sticky surface from prematurely adhering. It is coated on one or both sides with a release agent, which provides a release effect against any type of a sticky material such as an adhesive or a mastic. Release liners are available in different colors, with or without printing under the low surface energy coating or on the backside of the liner. ''Release'' is separation of the liner from a sticky material; ''liner'' is the carrier for the release agent. Industry segmentation Globally there are between 400 and 500 companies involved in making or dealing with release liner products on an industrial scale. In general there are two types of companies which are manufacturing release liner. Liner producer Commercial coating companies deal with a lot of different end uses of this industry. They provide unique solutions to their customers, ba ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Polyolefin

A polyolefin is a type of polymer with the general formula (CH2CHR)n where R is an alkyl group. They are usually derived from a small set of simple olefins (alkenes). Dominant in a commercial sense are polyethylene and polypropylene. More specialized polyolefins include polyisobutylene and polymethylpentene. They are all colorless or white oils or solids. Many copolymers are known, such as polybutene, which derives from a mixture of different butene isomers. The name of each polyolefin indicates the olefin from which it is prepared; for example, polyethylene is derived from ethylene, and polymethylpentene is derived from 4-methyl-1-pentene. Polyolefins are not olefins themselves because the double bond of each olefin monomer is opened in order to form the polymer. Monomers having more than one double bond such as butadiene and isoprene yield polymers that contain double bonds ( polybutadiene and polyisoprene) and are usually not considered polyolefins. Polyolefins are the foundat ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Artificial Leather

Artificial leather, also called synthetic leather, is a material intended to substitute for leather in upholstery, clothing, footwear, and other uses where a leather-like finish is desired but the actual material is cost prohibitive or unsuitable. Artificial leather is known under many names, including ''leatherette'', ''imitation leather'', ''faux leather'', ''vegan leather'', ''PU leather'', and ''pleather''. Manufacture Many different methods for the manufacture of imitation leathers have been developed. A current method is to use an embossed release paper known as ''casting paper'' as a form for the surface finish, often mimicking the texture of top-grain leather. This embossed release paper holds the final texture in negative. For the manufacture, the release paper is coated with several layers of plastic e.g. pvc or polyurethane, possibly including a surface finish, a colour layer, a foam layer, an adhesive, a fabric layer, a reverse finish. Depending on the spec ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Bicast Leather

Bicast leather (also spelled as bi-cast leather or bycast leather) is a material made with a split leather backing covered with an embossed layer of polyurethane or vinyl. Bicast leather was originally made for the apparel industry for glossy shoes, and was later adopted by the furniture industry. Production and features The hide material used in the making of bicast is usually a portion of the fibrous, lower grade of leather that remains when the higher-grade grain layer is split off. Bicast leather is produced by building up a layer of plastic (typically polyurethane) on top of an embossed release paper known as ''casting paper''. The embossing is usually giving the appearance of top grain leather, although it may be smooth depending on the desired finish. The plastic layer may optionally include: pigment, foams of various consistencies, and adhesives. Split leather is then applied and pressed onto the plastic, which may have been dried. After the resultant bicast leather ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Self-adhesive Plastic Sheet

Self-adhesive plastic sheet, known in the United Kingdom as sticky-backed plastic, is wide plastic sheet or film with an adhesive layer on one side, used as a surface coating for decorative purposes. It is typically smooth and shiny, but can also come in textured varieties, in which case it can sometimes be used as a cheap alternative to veneer. The plastic is often PVC. The sheeting is typically sold with a removable paper release liner to prevent it from adhering prematurely. Self-adhesive vinyl sheet was introduced to the UK market in the 1960s under the brand name Fablon. It was extensively used in DIY at the time, and notably featured in children's DIY projects on the British TV show ''Blue Peter'', but always under the generic name "sticky-backed plastic." Smooth self-adhesive plastic sheet is typically used to cover the studio floor for shiny-floor shows, thus giving them their name. See also * Vinyl lettering * Pressure-sensitive tape Pressure-sensitive tape, known ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Pressure-sensitive Tape

Pressure-sensitive tape, known also in various countries as PSA tape, adhesive tape, self-stick tape, sticky tape, Sellotape, or just tape, is an adhesive tape that will stick with application of pressure, without the need for a solvent (such as water) or heat for activation. PSA tape consists of three components: *the tape itself, which often is cellophane, cellulose acetate, or polyvinyl chloride. Other materials include paper, plastic film, cloth, or metal foil.coated onto a backing material such as paper, plastic film, cloth, or metal foil. *a pressure-sensitive adhesive. *release liner, which keeps the tape from sticking to itself. Some have layers of adhesives, primers, release agents, filaments, printing, etc. made for specific functions. It will stick without the need for a solvent such as water or heat for activation. By contrast, "gummed" or "water activated" adhesive tapes require warm water for activation and "heat activated" tapes require heat. Single-sided ta ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Label

A label (as distinct from signage) is a piece of paper, plastic film, cloth, metal, or other material affixed to a container or product, on which is written or printed information or symbols about the product or item. Information printed directly on a container or article can also be considered labelling. Labels have many uses, including promotion and providing information on a product's origin, the manufacturer (e.g., brand name), use, safety, shelf-life and disposal, some or all of which may be governed by legislation such as that for food in the UK or United States. Methods of production and attachment to packaging are many and various and may also be subject to internationally recognised standards. In many countries, hazardous products such as poisons or flammable liquids must have a warning label. Uses Labels may be used for any combination of identification, information, warning, instructions for use, environmental advice or advertising. They may be stickers, perma ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Silicone

A silicone or polysiloxane is a polymer made up of siloxane (−R2Si−O−SiR2−, where R = organic group). They are typically colorless oils or rubber-like substances. Silicones are used in sealants, adhesives, lubricants, medicine, cooking utensils, thermal insulation, and electrical insulation. Some common forms include silicone oil, silicone grease, silicone rubber, silicone resin, and silicone caulk. Chemistry More precisely called polymerized siloxanes or polysiloxanes, silicones consist of an inorganic silicon–oxygen backbone chain (⋯−Si−O−Si−O−Si−O−⋯) with two organic groups attached to each silicon center. Commonly, the organic groups are methyl. The materials can be cyclic or polymeric. By varying the −Si−O− chain lengths, side groups, and crosslinking, silicones can be synthesized with a wide variety of properties and compositions. They can vary in consistency from liquid to gel to rubber to hard plastic. The most common siloxan ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

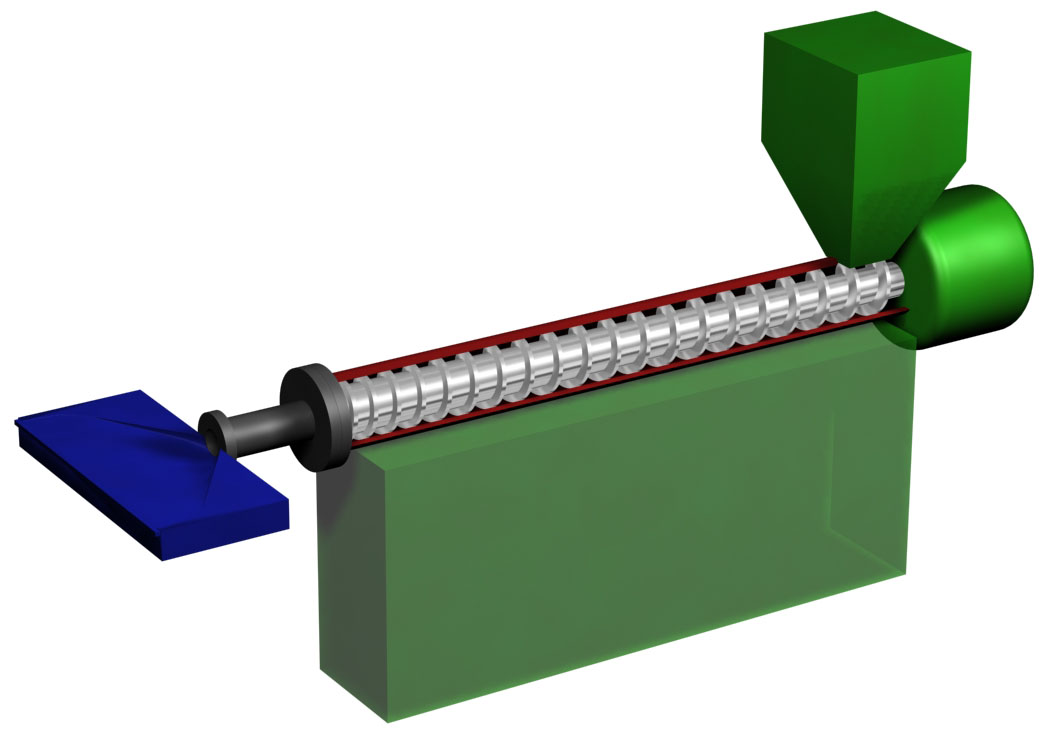

Plastics Extrusion

Plastics extrusion is a high-volume manufacturing process in which raw plastic is melted and formed into a continuous profile. Extrusion produces items such as pipe/tubing, weatherstripping, fencing, deck railings, window frames, plastic films and sheeting, thermoplastic coatings, and wire insulation. This process starts by feeding plastic material (pellets, granules, flakes or powders) from a hopper into the barrel of the extruder. The material is gradually melted by the mechanical energy generated by turning screws and by heaters arranged along the barrel. The molten polymer is then forced into a die, which shapes the polymer into a shape that hardens during cooling. History The first precursors to the modern extruder were developed in the early 19th century. In 1820, Thomas Hancock invented a rubber "masticator" designed to reclaim processed rubber scraps, and in 1836 Edwin Chaffee developed a two-roller machine to mix additives into rubber. The first thermoplastic extrus ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Low Density Polyethylene

Low-density polyethylene (LDPE) is a thermoplastic made from the monomer ethylene. It was the first grade of polyethylene, produced in 1933 by Imperial Chemical Industries (ICI) using a high pressure process via free radical polymerization. Its manufacture employs the same method today. The EPA estimates 5.7% of LDPE ( resin identification code 4) is recycled in the United States. Despite competition from more modern polymers, LDPE continues to be an important plastic grade. In 2013 the worldwide LDPE market reached a volume of about US$33 billion. Despite its designation with the recycling symbol, it cannot be as commonly recycled as No. 1 (polyethylene terephthalate) or 2 plastics (high-density polyethylene). Properties LDPE is defined by a density range of 917–930 kg/m3. At room temperature it is not reactive, except to strong oxidizers; some solvents cause it to swell. It can withstand temperatures of continuously and for a short time. Made in translucent and opaque v ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

High Density Polyethylene

High-density polyethylene (HDPE) or polyethylene high-density (PEHD) is a thermoplastic polymer produced from the monomer ethylene. It is sometimes called "alkathene" or "polythene" when used for HDPE pipes. With a high strength-to-density ratio, HDPE is used in the production of plastic bottles, corrosion-resistant piping, geomembranes and plastic lumber. HDPE is commonly recycled, and has the number "2" as its resin identification code. In 2007, the global HDPE market reached a volume of more than 30 million tons. Properties HDPE is known for its high strength-to-density ratio. The density of HDPE ranges from 930 to 970 kg/m3. The standard method to test plastic density is ISO 1183 part 2 (gradient columns), alternatively ISO 1183 part 1MVS2PRO density analyzer. Although the density of HDPE is only marginally higher than that of low-density polyethylene, HDPE has little branching, giving it stronger intermolecular forces and tensile strength (38 MPa versus 21 MPa) than ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Polypropylene

Polypropylene (PP), also known as polypropene, is a thermoplastic polymer used in a wide variety of applications. It is produced via chain-growth polymerization from the monomer propylene. Polypropylene belongs to the group of polyolefins and is partially crystalline and non-polar. Its properties are similar to polyethylene, but it is slightly harder and more heat-resistant. It is a white, mechanically rugged material and has a high chemical resistance. Bio-PP is the bio-based counterpart of polypropylene (PP). Polypropylene is the second-most widely produced commodity plastic (after polyethylene). In 2019, the global market for polypropylene was worth $126.03 billion. Revenues are expected to exceed US$145 billion by 2019. The sales of this material are forecast to grow at a rate of 5.8% per year until 2021. History Phillips Petroleum chemists J. Paul Hogan and Robert Banks first demonstrated the polymerization of propylene in 1951. The stereoselective polymerization t ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |