|

Race (bearing)

The rolling-elements of a rolling-element bearing ride on races. The large race that goes into a bore is called the ''outer race'', and the small race that the shaft rides in is called the ''inner race''. Design In the case of ball bearings, the bearing has inner and outer ''races'' and a set of balls. Each race is a ring with a groove where the balls rest. The groove is usually shaped so the ball is a slightly loose fit in the groove. Thus, in principle, the ball contacts each race at a single point. However, a load on an infinitely small point would cause infinitely high contact pressure. In practice, the ball deforms (flattens) slightly where it contacts each race, much as a tire flattens where it touches the road. The race also dents slightly where each ball presses on it. Thus, the contact between ball and race is of finite size and has finite pressure. The deformed ball and race do not roll entirely smoothly because different parts of the ball are moving at different spe ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Outer Race Of Bearing

{{Short pages monitor ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Rolling-element Bearing

In mechanical engineering, a rolling-element bearing, also known as a rolling bearing, is a bearing which carries a load by placing rolling elements (such as balls or rollers) between two concentric, grooved rings called races. The relative motion of the races causes the rolling elements to roll with very little rolling resistance and with little sliding. One of the earliest and best-known rolling-element bearings are sets of logs laid on the ground with a large stone block on top. As the stone is pulled, the logs roll along the ground with little sliding friction. As each log comes out the back, it is moved to the front where the block then rolls on to it. It is possible to imitate such a bearing by placing several pens or pencils on a table and placing an item on top of them. See " bearings" for more on the historical development of bearings. A rolling element rotary bearing uses a shaft in a much larger hole, and cylinders called "rollers" tightly fill the space between t ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Ball (bearing)

Bearing balls are special highly spherical and smooth balls, most commonly used in ball bearings, but also used as components in things like freewheel mechanisms. The balls come in many different ''grades''. These grades are defined by bodies such as the American Bearing Manufacturers Association (ABMA), a body which sets standards for the precision of bearing balls. They are manufactured in machines designed specially for the job. In 2008, the United States produced 5.778 billion bearing balls. Grade Bearing balls are manufactured to a specific grade, which defines its geometric tolerances. The grades range from 2000 to 3, where the smaller the number the higher the precision. Grades are written "GXXXX", i.e. grade 100 would be "G100". Lower grades also have fewer defects, such as flats, pits, soft spots, and cuts. The surface smoothness is measured in two ways: surface roughness and waviness. Size refers to the farthest possible distance between two points on the ball's ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Tire

A tire (American English) or tyre (British English) is a ring-shaped component that surrounds a wheel's rim to transfer a vehicle's load from the axle through the wheel to the ground and to provide traction on the surface over which the wheel travels. Most tires, such as those for automobiles and bicycles, are pneumatically inflated structures, which also provide a flexible cushion that absorbs shock as the tire rolls over rough features on the surface. Tires provide a footprint, called a contact patch, that is designed to match the weight of the vehicle with the bearing strength of the surface that it rolls over by providing a bearing pressure that will not deform the surface excessively. The materials of modern pneumatic tires are synthetic rubber, natural rubber, fabric, and wire, along with carbon black and other chemical compounds. They consist of a tread and a body. The tread provides traction while the body provides containment for a quantity of compressed ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

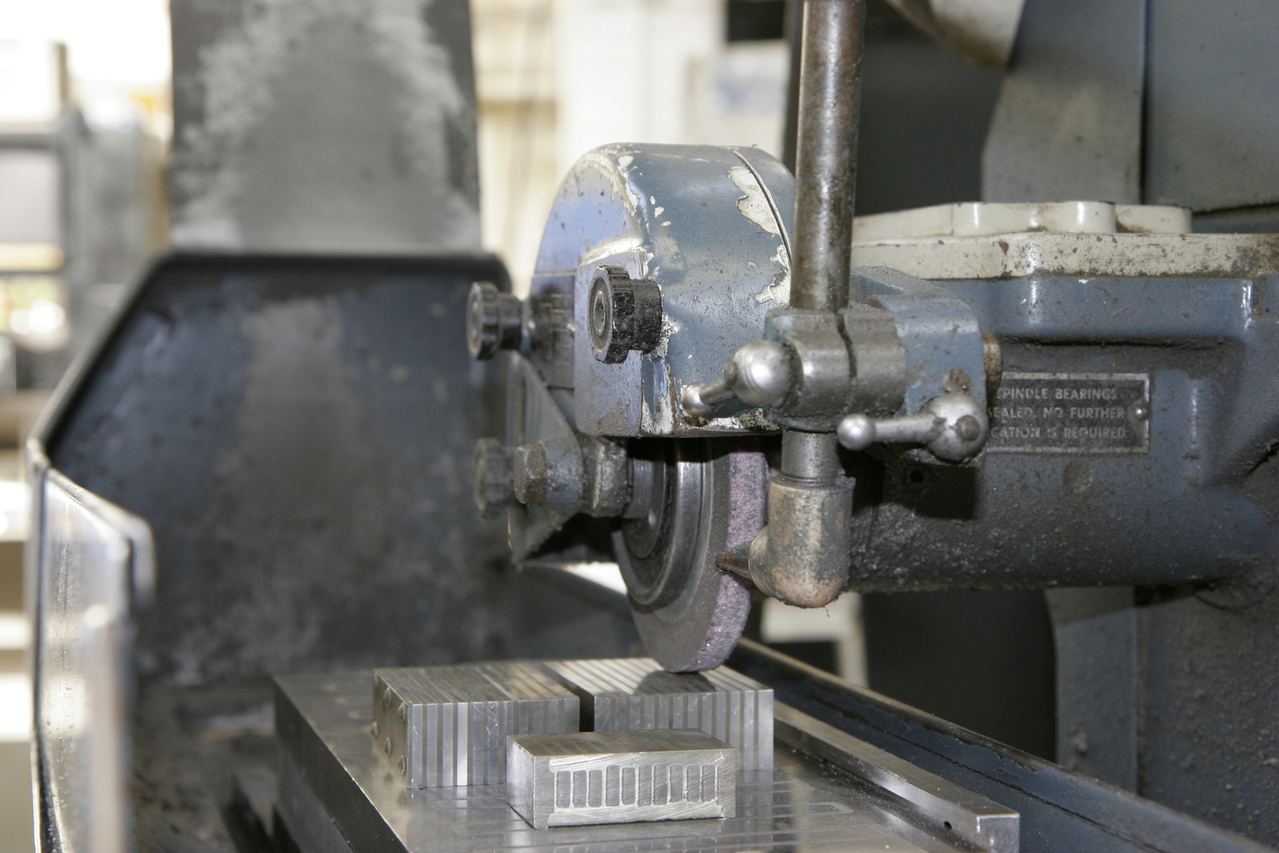

Centerless Ground

Centerless grinding is a machining process that uses abrasive cutting to remove material from a workpiece. Centerless grinding differs from centered grinding operations in that no spindle or fixture is used to locate and secure the workpiece; the workpiece is secured between two rotary grinding wheels, and the speed of their rotation relative to each other determines the rate at which material is removed from the workpiece. Centerless grinding is typically used in preference to other grinding processes for operations where many parts must be processed in a short time. Working principle In centerless grinding, the workpiece is held between two wheels, rotating in the same direction at different speeds, and a workholding platform. One wheel, known as the grinding wheel (stationary wheel in the diagram), is on a fixed axis and rotates such that the force applied to the workpiece is directed downward, against the workholding platform. This wheel usually performs the grinding action ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Dial Indicator

In various contexts of science, technology, and manufacturing (such as machining, fabricating, and additive manufacturing), an indicator is any of various instruments used to accurately measure small distances and angles, and amplify them to make them more obvious. The name comes from the concept of '' indicating'' to the user that which their naked eye cannot discern; such as the presence, or exact quantity, of some small distance (for example, a small height difference between two flat surfaces, a slight lack of concentricity between two cylinders, or other small physical deviations). The classic mechanical version, called a dial indicator, provides a dial display similar to a clock face with clock hands; the hands point to graduations in a circular scales on the dial which represent the distance of the probe tip from a zero setting. The internal works of a mechanical dial indicator are similar to the precision clockworks of a mechanical wristwatch, employing a rack and pini ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Micrometre

The micrometre ( international spelling as used by the International Bureau of Weights and Measures; SI symbol: μm) or micrometer ( American spelling), also commonly known as a micron, is a unit of length in the International System of Units (SI) equalling (SI standard prefix " micro-" = ); that is, one millionth of a metre (or one thousandth of a millimetre, , or about ). The nearest smaller common SI unit is the nanometre, equivalent to one thousandth of a micrometre, one millionth of a millimetre or one billionth of a metre (). The micrometre is a common unit of measurement for wavelengths of infrared radiation as well as sizes of biological cells and bacteria, and for grading wool by the diameter of the fibres. The width of a single human hair ranges from approximately 20 to . The longest human chromosome, chromosome 1, is approximately in length. Examples Between 1 μm and 10 μm: * 1–10 μm – length of a typical bacterium * 3–8 μm � ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Grinding Wheel Wear

Grinding wheel wear is an important measured factor of grinding in the manufacturing process of engineered parts and tools. Grinding involves the removal process of material and modifying the surface of a workpiece to some desired finish which might otherwise be unachievable through conventional machining processes. The grinding process itself has been compared to machining operations which employ multipoint cutting tools. The abrasive grains which make up the entire geometry of wheel act as independent small cutting tools. The quality, characteristics, and rate of grinding wheel wear can be affected by contributions of the characteristics of the material of the workpiece, the temperature increase of the workpiece, and the rate of wear of the grinding wheel itself. Moderate wear rate allows for more consistent material size. Maintaining stable grinding forces is preferred rather than high wheel wear rate which can decrease the effectiveness of material removal from the workpiece. M ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

.jpg)