|

Powder Bed Fusion

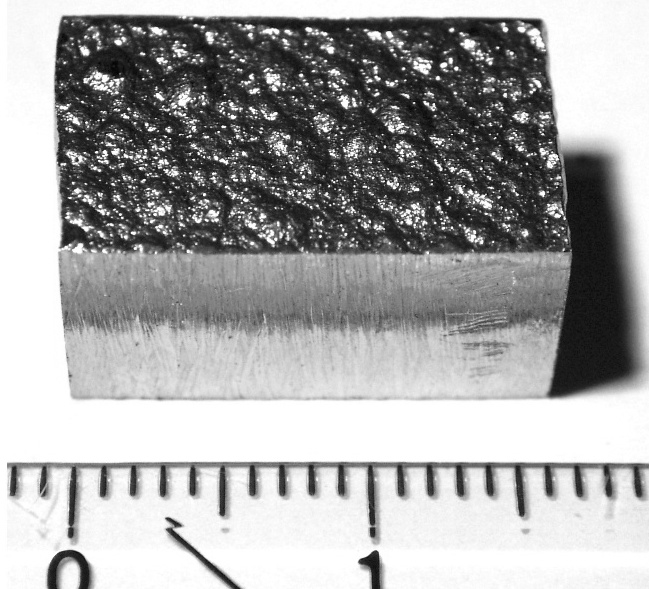

Selective laser melting (SLM) is one of many proprietary names for a metal additive manufacturing (AM) technology that uses a bed of powder with a source of heat to create metal parts. Also known as direct metal laser sintering (DMLS), the ASTM standard term is powder bed fusion (PBF). PBF is a rapid prototyping, 3D printing, or additive manufacturing technique designed to use a high power-density laser to melt and fuse metallic powders together. History Selective laser melting is one of many proprietary powder bed fusion technologies, started in 1995 at the Fraunhofer Institute ILT in Aachen, Germany. A research project run by Wilhelm Meiners, Konrad Wissenbach, and Andres Gasser resulted in the so-called basic ILT SLM patent. The ASTM International F42 standards committee has grouped selective laser melting into the category of "laser sintering", although this is an acknowledged misnomer because the process fully melts the metal into a solid homogeneous fully dense mass, unli ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Selective Laser Melting

Selective laser melting (SLM) is one of many proprietary names for a metal Additive Manufacturing, additive manufacturing (AM) technology that uses a bed of powder with a source of heat to create metal parts. Also known as direct metal laser sintering (DMLS), the ASTM standard term is powder bed fusion (PBF). PBF is a rapid prototyping, 3D printing, or additive manufacturing technique designed to use a high power-density laser to melt and fuse metallic powders together. History Selective laser melting is one of many proprietary powder bed fusion technologies, started in 1995 at the Fraunhofer Institute ILT in Aachen, Germany. A research project run by Wilhelm Meiners, Konrad Wissenbach, and Andres Gasser resulted in the so-called basic ILT SLM patent. The ASTM International F42 standards committee has grouped selective laser melting into the category of "laser sintering", although this is an acknowledged misnomer because the process fully melts the metal into a solid homogeneou ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Fiber Laser

A fiber laser (or fibre laser in Commonwealth English) is a laser in which the active gain medium is an optical fiber doped with rare-earth elements such as erbium, ytterbium, neodymium, dysprosium, praseodymium, thulium and holmium. They are related to doped fiber amplifiers, which provide light amplification without lasing. Fiber nonlinearities, such as stimulated Raman scattering or four-wave mixing, can also provide gain and thus serve as gain media for a fiber laser. Characteristics An advantage of fiber lasers over other types of lasers is that the laser light is both generated and delivered by an inherently flexible medium, which allows easier delivery to the focusing location and target. This can be important for laser cutting, welding, and folding of metals and polymers. Another advantage is high output power compared to other types of laser. Fiber lasers can have active regions several kilometers long, and so can provide very high optical gain. They can sup ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Microstructure

Microstructure is the very small scale structure of a material, defined as the structure of a prepared surface of material as revealed by an optical microscope above 25× magnification. The microstructure of a material (such as metals, polymers, ceramics or composites) can strongly influence physical properties such as strength, toughness, ductility, hardness, corrosion resistance, high/low temperature behaviour or wear resistance. These properties in turn govern the application of these materials in industrial practice. Microstructure at scales smaller than can be viewed with optical microscopes is often called nanostructure, while the structure in which individual atoms are arranged is known as crystal structure. The nanostructure of biological specimens is referred to as ultrastructure. A microstructure's influence on the mechanical and physical properties of a material is primarily governed by the different defects present or absent of the structure. These defects can ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Schematic Of Major Defects And Microstructural Phenomena Produced By SLM

A schematic, or schematic diagram, is a designed representation of the elements of a system using abstract, graphic symbols rather than realistic pictures. A schematic usually omits all details that are not relevant to the key information the schematic is intended to convey, and may include oversimplified elements in order to make this essential meaning easier to grasp, as well as additional organization of the information. For example, a subway map intended for passengers may represent a subway station with a dot. The dot is not intended to resemble the actual station at all but aims to give the viewer information without unnecessary visual clutter. A schematic diagram of a chemical process uses symbols in place of detailed representations of the vessels, piping, valves, pumps, and other equipment that compose the system, thus emphasizing the functions of the individual elements and the interconnections among them and suppresses their physical details. In an electronic circuit d ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Yield Strength

In materials science and engineering, the yield point is the point on a stress–strain curve that indicates the limit of elastic behavior and the beginning of plastic behavior. Below the yield point, a material will deform elastically and will return to its original shape when the applied stress is removed. Once the yield point is passed, some fraction of the deformation will be permanent and non-reversible and is known as plastic deformation. The yield strength or yield stress is a material property and is the stress corresponding to the yield point at which the material begins to deform plastically. The yield strength is often used to determine the maximum allowable load in a mechanical component, since it represents the upper limit to forces that can be applied without producing permanent deformation. For most metals, such as aluminium and cold-worked steel, there is a gradual onset of non-linear behavior, and no precise yield point. In such a case, the offset yield p ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Titanium

Titanium is a chemical element; it has symbol Ti and atomic number 22. Found in nature only as an oxide, it can be reduced to produce a lustrous transition metal with a silver color, low density, and high strength, resistant to corrosion in sea water, aqua regia, and chlorine. Titanium was discovered in Cornwall, Great Britain, by William Gregor in 1791 and was named by Martin Heinrich Klaproth after the Titans of Greek mythology. The element occurs within a number of minerals, principally rutile and ilmenite, which are widely distributed in the Earth's crust and lithosphere; it is found in almost all living things, as well as bodies of water, rocks, and soils. The metal is extracted from its principal mineral ores by the Kroll and Hunter processes. The most common compound, titanium dioxide (TiO2), is a popular photocatalyst and is used in the manufacture of white pigments. Other compounds include titanium tetrachloride (TiCl4), a component of smoke screens and cata ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

AlSi10Mg

AlSi10Mg is a lightweight, high-strength aluminium alloy that is widely used in the aerospace, automotive, and medical industries. Its unique combination of aluminium, silicon, and magnesium makes it an ideal material for additive manufacturing processes, such as 3D printing. Composition The composition of AlSi10Mg typically consists of approximately 90% aluminium, 9% silicon, and 1% magnesium. The alloy may also contain small amounts of other elements, such as iron, copper, and zinc, to improve its mechanical properties and corrosion resistance. The precise composition of AlSi10Mg may vary depending on the specific manufacturing process used and the intended application of the alloy. However, the general proportions of aluminum, silicon, and magnesium remain consistent in most formulations of the alloy. The addition of silicon to the alloy improves its strength and hardness, while magnesium enhances its ductility and corrosion resistance. The combination of these elements resul ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Aluminum

Aluminium (or aluminum in North American English) is a chemical element; it has chemical symbol, symbol Al and atomic number 13. It has a density lower than that of other common metals, about one-third that of steel. Aluminium has a great affinity towards oxygen, passivation (chemistry), forming a protective layer of aluminium oxide, oxide on the surface when exposed to air. It visually resembles silver, both in its color and in its great ability to reflect light. It is soft, magnetism, nonmagnetic, and ductility, ductile. It has one stable isotope, 27Al, which is highly abundant, making aluminium the abundance of the chemical elements, 12th-most abundant element in the universe. The radioactive decay, radioactivity of aluminium-26, 26Al leads to it being used in radiometric dating. Chemically, aluminium is a post-transition metal in the boron group; as is common for the group, aluminium forms compounds primarily in the +3 oxidation state. The aluminium cation Al3+ ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Inconel

Inconel is a nickel-chromium-based superalloy often utilized in extreme environments where components are subjected to high temperature, pressure or Mechanical load, mechanical loads. Inconel alloys are oxidation- and corrosion-resistant. When heated, Inconel forms a thick, stable, passivation (chemistry), passivating oxide layer protecting the surface from further attack. Inconel retains strength over a wide temperature range, attractive for high-temperature applications where aluminum and steel would succumb to creep (deformation), creep as a result of thermally-induced crystal vacancies. Inconel's high-temperature strength is developed by solid solution strengthening or precipitation hardening, depending on the alloy.Inconel alloy 718 , Special Metals Corporation Inconel all ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Chromium

Chromium is a chemical element; it has Symbol (chemistry), symbol Cr and atomic number 24. It is the first element in Group 6 element, group 6. It is a steely-grey, Luster (mineralogy), lustrous, hard, and brittle transition metal. Chromium is valued for its high corrosion resistance and hardness. A major development in steel production was the discovery that steel could be made highly resistant to corrosion and discoloration by adding metallic chromium to form stainless steel. Stainless steel and chrome plating (electroplating with chromium) together comprise 85% of the commercial use. Chromium is also greatly valued as a metal that is able to be highly polishing, polished while resisting tarnishing. Polished chromium reflects almost 70% of the visible spectrum, and almost 90% of infrared, infrared light. The name of the element is derived from the Ancient Greek, Greek word χρῶμα, ''chrōma'', meaning color, because many chromium compounds are intensely colored. Indust ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Cobalt

Cobalt is a chemical element; it has Symbol (chemistry), symbol Co and atomic number 27. As with nickel, cobalt is found in the Earth's crust only in a chemically combined form, save for small deposits found in alloys of natural meteoric iron. The free element, produced by reductive smelting, is a hard, lustrous, somewhat brittle, gray metal. Cobalt-based blue pigments (cobalt blue) have been used since antiquity for jewelry and paints, and to impart a distinctive blue tint to glass. The color was long thought to be due to the metal bismuth. Miners had long used the name ''kobold ore'' (German language, German for ''goblin ore'') for some of the blue pigment-producing minerals. They were so named because they were poor in known metals and gave off poisonous arsenic-containing fumes when smelted. In 1735, such ores were found to be reducible to a new metal (the first discovered since ancient times), which was ultimately named for the ''kobold''. Today, some cobalt is produced sp ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Maraging Steel

Maraging steels (a portmanteau of " martensitic" and "aging") are steels that possess superior strength and toughness without losing ductility. ''Aging'' refers to the extended heat-treatment process. These steels are a special class of very-low-carbon ultra-high-strength steels that derive their strength from precipitation of intermetallic compounds rather than from carbon. The principal alloying metal is 15 to 25 wt% nickel. Secondary alloying metals, which include cobalt, molybdenum and titanium, are added to produce intermetallic precipitates. The first maraging steel was developed by Clarence Gieger Bieber at Inco in the late 1950s. It produced 20 and 25 wt% Ni steels with small additions of aluminium, titanium, and niobium. The intent was to induce age-hardening with the aforementioned intermetallics in an iron-nickel martensitic matrix, and it was discovered that Co and Mo complement each other very well. Commercial production started in December 1960. A rise in the pr ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |