|

Pipe Fittings

A fitting or adapter is used in pipe systems to connect straight sections of pipe (fluid conveyance), pipe or tube (fluid conveyance), tube, adapt to different sizes or shapes, and for other purposes such as regulating (or measuring) fluid flow. These fittings are used in plumbing to manipulate the conveyance of water, gas, or liquid waste in domestic or commercial environments, within a system of pipes or tubes. Fittings (especially uncommon types) require money, time, materials, and tools to install and are an important part of piping and plumbing systems. Valves are technically fittings, but are usually discussed separately. Standards Standard codes are followed when designing (or manufacturing) a piping system. Organizations which promulgate piping standards include: * ASME: American Society of Mechanical Engineers ** A112.19.1 Enameled cast-iron and steel plumbing fixtures standards ** A112.19.2 Ceramic plumbing fixtures standard * ASTM International: American Society ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Compressed Gas Association

The Compressed Gas Association (CGA) is an American trade association for the industrial and medical gas supply industries. The CGA publishes standards and practices that codify industry practices. In cases where government regulation is inspecific, CGA documents are considered authoritative. CGA falls into a group of trade associations whose publications are relied on by government. These groups include the National Fire Protection Association (NFPA) and ASTM International. For example, the state of Montana, the U.S. Army, and OSHA point to CGA documents for regulatory guidance. Cylinder valve openings The CGA provides detail specifications for the outlet connections of gas containers. They are based on the characteristics of the gas and the storage pressure. flammability, toxicity, state (permanent gas or liquified) and corrosiveness of the gas. These connections are identified by a 3-digit number, such as CGA-555. The range of available connection standards covers the majo ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Chlorinated Polyvinyl Chloride

Chlorinated polyvinyl chloride (CPVC) is a thermoplastic produced by chlorination of polyvinyl chloride (PVC) resin. CPVC is significantly more flexible than PVC, and can also withstand higher temperatures. Uses include hot and cold water delivery pipes and industrial liquid handling. CPVC, like PVC, is deemed safe for the transport and use of potable water. History Genova Products located in Michigan initially created the first CPVC tubing and fittings for hot- and cold-water distribution systems in the early 1960s. The original tetrahydrofuran (THF) / methyl ethyl ketone (MEK) formulas for CPVC cements were developed by Genova in conjunction with the B.F. Goodrich Company, the original developer of the CPVC resin. Production process Chlorinated polyvinyl chloride (CPVC) is PVC that has been chlorinated via a free radical chlorination reaction. This reaction is typically initiated by application of thermal or UV energy utilizing various approaches. In the process, chlor ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

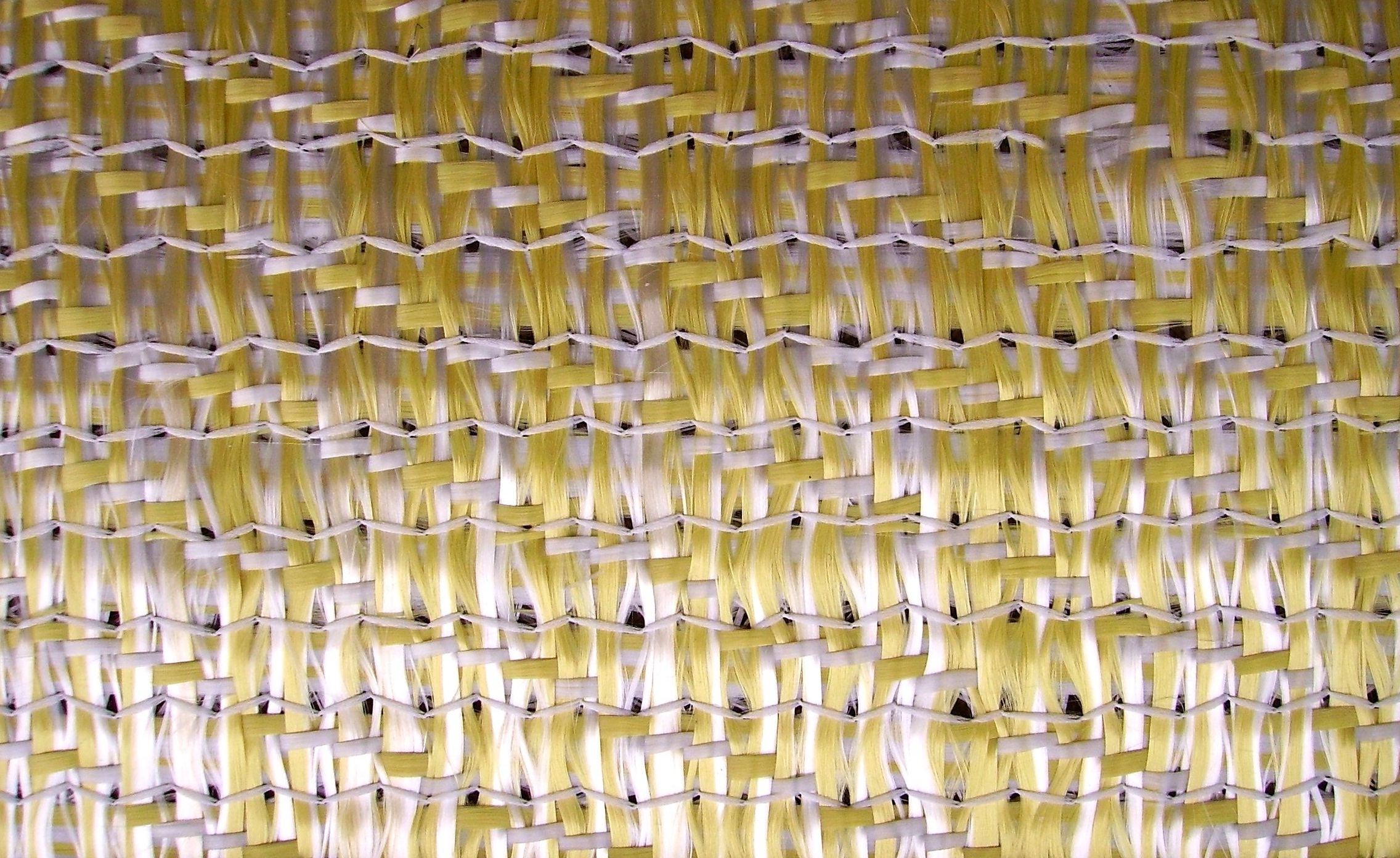

Fibre-reinforced Plastic

Fibre-reinforced plastic (FRP; also called fibre-reinforced polymer, or in American English ''fiber'') is a composite material made of a polymer matrix reinforced with fibres. The fibres are usually glass (in fibreglass), carbon (in carbon-fibre-reinforced polymer), aramid, or basalt. Rarely, other fibres such as paper, wood, or asbestos have been used. The polymer is usually an epoxy, vinyl ester, or polyester thermosetting plastic, though phenol formaldehyde resins are still in use. FRPs are commonly used in the aerospace, automotive, marine, and construction industries. They are commonly found in ballistic armour and cylinders for self-contained breathing apparatuses. Process definition A polymer is generally manufactured by step-growth polymerization or addition polymerization. When combined with various agents to enhance or in any way alter the material properties of polymers, the result is referred to as a plastic. Composite plastics refers to those types of plastic ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Acrylonitrile Butadiene Styrene

Acrylonitrile butadiene styrene (ABS) (chemical formula (C8H8)''x''·(C4H6)''y''·(C3H3N)''z'' is a common thermoplastic polymer. Its glass transition temperature is approximately . ABS is amorphous and therefore has no true melting point. ABS is a terpolymer made by polymerizing styrene and acrylonitrile in the presence of polybutadiene. The proportions can vary from 15% to 35% acrylonitrile, 5% to 30% butadiene and 40% to 60% styrene. The result is a long chain of polybutadiene crisscrossed with shorter chains of poly(styrene-co-acrylonitrile). The nitrile groups from neighboring chains, being polar, attract each other and bind the chains together, making ABS stronger than pure polystyrene. The acrylonitrile also contributes chemical resistance, fatigue resistance, hardness, and rigidity, while increasing the heat deflection temperature. The styrene gives the plastic a shiny, impervious surface, as well as hardness, rigidity, and improved processing ease. The polybutadiene ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Cupronickel

Cupronickel or copper-nickel (CuNi) is an alloy of copper that contains nickel and strengthening elements, such as iron and manganese. The copper content typically varies from 60 to 90 percent. (Monel is a nickel-copper alloy that contains a minimum of 52 percent nickel.) Despite its high copper content, cupronickel is silver in colour. Cupronickel is highly resistant to corrosion by salt water, and is therefore used for piping, heat exchangers and condensers in seawater systems, as well as for marine hardware. It is sometimes used for the propellers, propeller shafts, and hulls of high-quality boats. Other uses include military equipment and chemical, petrochemical, and electrical industries. Another common 20th-century use of cupronickel was silver-coloured coins. For this use, the typical alloy has 3:1 copper to nickel ratio, with very small amounts of manganese. In the past, true silver coins were debased with cupronickel, such as coins of the pound sterling from 1947 onwar ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Incoloy

Incoloy refers to a range of superalloys now produced by the Special Metals Corporation (SMC) group of companies and created with a trademark by the Inco company in 1952. Originally Inco protected these alloys by patent. In 2000, the SMC published a 61-page document entitled "High-Performance Alloys for Resistance to Aqueous Corrosion" highlighting Incoloy, as well as Monel and Inconel products, and their use in fluid environments such as sulfuric acid, hydrochloric acid, hydrofluoric acid, phosphoric acid, nitric acid, other acids as well as freshwater environments. Incoloy products are mostly chromium-based and mostly nickel-based, and designed for corrosion resistance as well as strength at high temperatures. Incoloy alloys belong to the category of super austenitic stainless steels. One advantage is that Incoloy alloys do not have to be heat treated after welding to restore the corrosion resistance. There are specific alloys for resistance to particular chemical attacks. For ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Inconel

Inconel is a registered trademark of Special Metals Corporation for a family of austenitic nickel-chromium-based superalloys. Inconel alloys are oxidation-corrosion-resistant materials well suited for service in extreme environments subjected to pressure and heat. When heated, Inconel forms a thick, stable, passivating oxide layer protecting the surface from further attack. Inconel retains strength over a wide temperature range, attractive for high-temperature applications where aluminium and steel would succumb to creep as a result of thermally-induced crystal vacancies. Inconel's high-temperature strength is developed by solid solution strengthening or precipitation hardening, depending on the alloy.INCONEL alloy 718 Special Metals Corporation Inconel alloys are typical ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Copper

Copper is a chemical element with the symbol Cu (from la, cuprum) and atomic number 29. It is a soft, malleable, and ductile metal with very high thermal and electrical conductivity. A freshly exposed surface of pure copper has a pinkish-orange color. Copper is used as a conductor of heat and electricity, as a building material, and as a constituent of various metal alloys, such as sterling silver used in jewelry, cupronickel used to make marine hardware and coins, and constantan used in strain gauges and thermocouples for temperature measurement. Copper is one of the few metals that can occur in nature in a directly usable metallic form ( native metals). This led to very early human use in several regions, from circa 8000 BC. Thousands of years later, it was the first metal to be smelted from sulfide ores, circa 5000 BC; the first metal to be cast into a shape in a mold, c. 4000 BC; and the first metal to be purposely alloyed with another metal, tin, to create ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Malleable Iron

Malleable iron is cast as white iron, the structure being a metastable carbide in a pearlitic matrix. Through an annealing heat treatment, the brittle structure as first cast is transformed into the malleable form. Carbon agglomerates into small roughly spherical aggregates of graphite, leaving a matrix of ferrite or pearlite according to the exact heat treatment used. Three basic types of malleable iron are recognized within the casting industry: ''blackheart'' malleable iron, ''whiteheart'' malleable iron and ''pearlitic'' malleable iron. History Malleable iron was used as early as the 4th century BCE, and archaeologists have found malleable iron artifacts made in China between 4th century BCE and 9th century CE. By the Tang Dynasty, the use of malleable iron in China waned, although there are malleable iron artifacts dating to the 9th century. Malleable iron is mentioned in England in a patent dating to the 1670s. Réaumur conducted extensive research on malleable iron in 1 ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Stainless Steel

Stainless steel is an alloy of iron that is resistant to rusting and corrosion. It contains at least 11% chromium and may contain elements such as carbon, other nonmetals and metals to obtain other desired properties. Stainless steel's corrosion resistance, resistance to corrosion results from the chromium, which forms a Passivation (chemistry), passive film that can protect the material and self-healing material, self-heal in the presence of oxygen. The alloy's properties, such as luster and resistance to corrosion, are useful in many applications. Stainless steel can be rolled into Sheet metal, sheets, plates, bars, wire, and tubing. These can be used in cookware, cutlery, surgical instruments, major appliances, vehicles, construction material in large buildings, industrial equipment (e.g., in paper mills, chemical plants, water treatment), and storage tanks and tankers for chemicals and food products. The biological cleanability of stainless steel is superior to both alumi ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |