|

Pig-iron

Pig iron, also known as crude iron, is an intermediate product of the iron industry in the production of steel which is obtained by smelting iron ore in a blast furnace. Pig iron has a high carbon content, typically 3.8–4.7%, along with silica and other constituents of dross, which makes it brittle and not useful directly as a material except for limited applications. The traditional shape of the molds used for pig iron ingots is a branching structure formed in sand, with many individual ingots at right angles to a central channel or "runner", resembling a litter of piglets being nursed by a sow. When the metal had cooled and hardened, the smaller ingots (the "pigs") were simply broken from the runner (the "sow"), hence the name "pig iron". As pig iron is intended for remelting, the uneven size of the ingots and the inclusion of small amounts of sand cause only insignificant problems considering the ease of casting and handling them. History Smelting and producing wrough ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Blast Furnace

A blast furnace is a type of metallurgical furnace used for smelting to produce industrial metals, generally pig iron, but also others such as lead or copper. ''Blast'' refers to the combustion air being "forced" or supplied above atmospheric pressure. In a blast furnace, fuel ( coke), ores, and flux (limestone) are continuously supplied through the top of the furnace, while a hot blast of air (sometimes with oxygen enrichment) is blown into the lower section of the furnace through a series of pipes called tuyeres, so that the chemical reactions take place throughout the furnace as the material falls downward. The end products are usually molten metal and slag phases tapped from the bottom, and waste gases (flue gas) exiting from the top of the furnace. The downward flow of the ore along with the flux in contact with an upflow of hot, carbon monoxide-rich combustion gases is a countercurrent exchange and chemical reaction process. In contrast, air furnaces (such as reverbera ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Ferrous Metallurgy

Ferrous metallurgy is the metallurgy of iron and its alloys. The earliest surviving prehistoric iron artifacts, from the 4th millennium BC in Egypt, were made from meteoritic iron-nickel. It is not known when or where the smelting of iron from ores began, but by the end of the 2nd millennium BC iron was being produced from iron ores in the region from Greece to India,Riederer, Josef; Wartke, Ralf-B.: "Iron", Cancik, Hubert; Schneider, Helmuth (eds.): Brill's New Pauly, Brill 2009Early Antiquity By I.M. Drakonoff. 1991. University of Chicago Press. . p. 372 and Sub-Saharan Africa. The use of wrought iron (worked iron) was known by the 1st millennium BC, and its spread defined the Iron Age. During the medieval period, smiths in Europe found a way of producing wrought iron from cast iron (in this context known as pig iron) using finery forges. All these processes required charcoal as fuel. By the 4th century BC southern India had started exporting Wootz steel (with a carbon conten ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Pig Iron

Pig iron, also known as crude iron, is an intermediate product of the iron industry in the production of steel which is obtained by smelting iron ore in a blast furnace. Pig iron has a high carbon content, typically 3.8–4.7%, along with silica and other constituents of dross, which makes it brittle and not useful directly as a material except for limited applications. The traditional shape of the molds used for pig iron ingots is a branching structure formed in sand, with many individual ingots at right angles to a central channel or "runner", resembling a litter of piglets being nursed by a sow. When the metal had cooled and hardened, the smaller ingots (the "pigs") were simply broken from the runner (the "sow"), hence the name "pig iron". As pig iron is intended for remelting, the uneven size of the ingots and the inclusion of small amounts of sand cause only insignificant problems considering the ease of casting and handling them. History Smelting and producing wroug ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Wrought Iron

Wrought iron is an iron alloy with a very low carbon content (less than 0.08%) in contrast to that of cast iron (2.1% to 4%). It is a semi-fused mass of iron with fibrous slag Inclusion (mineral), inclusions (up to 2% by weight), which give it a wood-like "grain" that is visible when it is etched, rusted, or bent to structural failure, failure. Wrought iron is tough, malleable, ductile, corrosion resistant, and easily forge welding, forge welded, but is more difficult to welding, weld electrically. Before the development of effective methods of steelmaking and the availability of large quantities of steel, wrought iron was the most common form of malleable iron. It was given the name ''wrought'' because it was hammered, rolled, or otherwise worked while hot enough to expel molten slag. The modern functional equivalent of wrought iron is Carbon steel#Mild or low-carbon steel, mild steel, also called low-carbon steel. Neither wrought iron nor mild steel contain enough carbon to be ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Gray Iron

Gray iron, or grey cast iron, is a type of cast iron that has a graphitic microstructure. It is named after the gray color of the fracture it forms, which is due to the presence of graphite.. It is the most common cast iron and the most widely used cast material based on weight.. It is used for housings where the stiffness of the component is more important than its tensile strength, such as internal combustion engine cylinder blocks, pump housings, valve bodies, electrical boxes, and decorative castings. Grey cast iron's high thermal conductivity and specific heat capacity are often exploited to make cast iron cookware and disc brake rotors. Its former widespread use on brakes in freight trains has been greatly reduced in the European Union over concerns regarding noise pollution. Deutsche Bahn for example had replaced grey iron brakes on 53,000 of its freight cars (85% of their fleet) with newer, quieter models by 2019—in part to comply with a law that came into force in ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Puddling Furnace

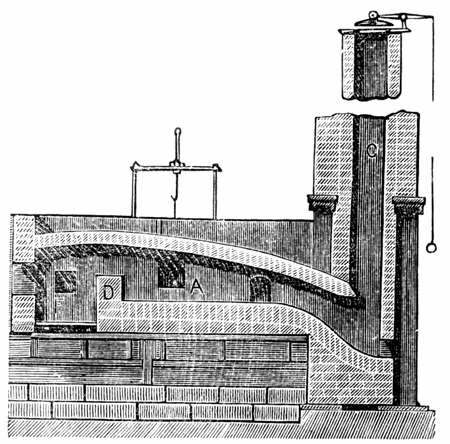

Puddling is the process of converting pig iron to bar (wrought) iron in a coal fired reverberatory furnace. It was developed in England during the 1780s. The molten pig iron was stirred in a reverberatory furnace, in an oxidizing environment, resulting in wrought iron. It was one of the most important processes of making the first appreciable volumes of valuable and useful bar iron (malleable wrought iron) without the use of charcoal. Eventually, the furnace would be used to make small quantities of specialty steels. Though it was not the first process to produce bar iron without charcoal, puddling was by far the most successful, and replaced the earlier potting and stamping processes, as well as the much older charcoal finery and bloomery processes. This enabled a great expansion of iron production to take place in Great Britain, and shortly afterwards, in North America. That expansion constitutes the beginnings of the Industrial Revolution so far as the iron industry is co ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Finery Forge

A finery forge is a forge used to produce wrought iron from pig iron by decarburization in a process called "fining" which involved liquifying cast iron in a fining hearth and removing carbon from the molten cast iron through oxidation. Finery forges were used as early as the 3rd century BC in China. The finery forge process was replaced by the puddling process and the roller mill, both developed by Henry Cort in 1783–4, but not becoming widespread until after 1800. History A finery forge was used to refine wrought iron at least by the 3rd century BC in ancient China, based on the earliest archaeological specimens of cast and pig iron fined into wrought iron and steel found at the early Han Dynasty (202 BC – 220 AD) site at Tieshengguo.Pigott, Vincent C. (1999). ''The Archaeometallurgy of the Asian Old World''. Philadelphia: University of Pennsylvania Museum of Archaeology and Anthropology. , p. 186-187. Pigott speculates that the finery forge existed in the previous ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Decarburization

Decarburization (or decarbonization) is the process of decreasing carbon content, which is the opposite of carburization. The term is typically used in metallurgy, describing the decrease of the content of carbon in metals (usually steel). Decarburization occurs when the metal is heated to temperatures of 700 °C or above when carbon in the metal reacts with gases containing oxygen or hydrogen. The removal of carbon removes hard carbide phases resulting in a softening of the metal, primarily at the surfaces which are in contact with the decarburizing gas. Decarburization can be either advantageous or detrimental, depending on the application for which the metal will be used. It is thus both something that can be done intentionally as a step in a manufacturing process, or something that happens as a side effect of a process (such as rolling) and must be either prevented or later reversed (such as via a carburization step). The decarburization mechanism can be described as t ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Silk Road

The Silk Road () was a network of Eurasian trade routes active from the second century BCE until the mid-15th century. Spanning over 6,400 kilometers (4,000 miles), it played a central role in facilitating economic, cultural, political, and religious interactions between the Eastern world, East and Western world, West. The name "Silk Road", first coined in the late 19th century, has fallen into disuse among some modern historians in favor of Silk Routes, on the grounds that it more accurately describes the intricate web of land and sea routes connecting East Asia, East and Southeast Asia, the South Asia, Indian subcontinent, Central Asia, the Middle East, East Africa and Southern Europe, Europe. The Silk Road derives its name from the highly lucrative trade of silk, silk textiles that were Silk industry in China, produced almost exclusively in China. The network began with the Han dynasty, Han dynasty's expansion into Central Asia around 114 BCE, Protectorate of the Western Regio ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Westphalia

Westphalia (; german: Westfalen ; nds, Westfalen ) is a region of northwestern Germany and one of the three historic parts of the state of North Rhine-Westphalia. It has an area of and 7.9 million inhabitants. The territory of the region is almost identical with the historic Province of Westphalia, which was a part of the Kingdom of Prussia from 1815 to 1918 and the Free State of Prussia from 1918 to 1946. In 1946, Westphalia merged with North Rhine, another former part of Prussia, to form the newly created state of North Rhine-Westphalia. In 1947, the state with its two historic parts was joined by a third one: Lippe, a former principality and free state. The seventeen districts and nine independent cities of Westphalia and the single district of Lippe are members of the Westphalia-Lippe Regional Association (''Landschaftsverband Westfalen-Lippe''). Previous to the formation of Westphalia as a province of Prussia and later state part of North Rhine-Westphalia, the ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

County Of Mark

The County of Mark (german: Grafschaft Mark, links=no, french: Comté de La Marck, links=no colloquially known as ) was a county and state of the Holy Roman Empire in the Lower Rhenish–Westphalian Circle. It lay on both sides of the Ruhr River along the Volme and Lenne rivers. The Counts of the Mark were among the most powerful and influential Westphalian lords in the Holy Roman Empire. The name ''Mark'' is recalled in the present-day district in lands south of the Ruhr in North Rhine-Westphalia, Germany. The northern portion (north of the Lippe river) is still called ("Higher Mark"), while the former "Lower Mark" (between the Ruhr and Lippe Rivers) is—for the most part—merged in the present Ruhr area. Geography The County of the Mark enclosed an area of approximately 3,000 km² and extended between the Lippe and Aggers rivers (north-south) and between Gelsenkirchen and Bad Sassendorf (west-east) for about 75 km. The east-west flowing Ruhr separated the cou ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Lapphyttan

Lapphyttan or Lapphyttejarn in Norberg Municipality, Sweden, may be regarded as the type site for the Medieval Blast Furnace. Its date is probably between 1150 and 1350. It produced cast iron, which was then fined to make ferritic wrought iron cake or bun-like blooms. These were then cut into lumps for trade. It is thought that they correspond to the iron pieces known as osmonds. Osmonds occur in English Customs records in the 1250s and seem to be alluded to in a commercial treaty with Novgorod in 1203. Lapphyttan is a part of Ecomuseum Bergslagen. Furnaces of this type have also been identified in Mark (Märkische Sauerland) in Westphalia and north of the Schwäbische Alb both in Germany Germany,, officially the Federal Republic of Germany, is a country in Central Europe. It is the second most populous country in Europe after Russia, and the most populous member state of the European Union. Germany is situated betwe .... Further reading * N. Björkenstam, 'The ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |