|

Optical Proximity Correction

Optical proximity correction (OPC) is a photolithography enhancement technique commonly used to compensate for image errors due to diffraction or process effects. The need for OPC is seen mainly in the making of semiconductor devices and is due to the limitations of light to maintain the edge placement integrity of the original design, after processing, into the etched image on the silicon wafer. These projected images appear with irregularities such as line widths that are narrower or wider than designed, these are amenable to compensation by changing the pattern on the photomask used for imaging. Other distortions such as rounded corners are driven by the resolution of the optical imaging tool and are harder to compensate for. Such distortions, if not corrected for, may significantly alter the electrical properties of what was being fabricated. Optical proximity correction corrects these errors by moving edges or adding extra polygons to the pattern written on the photomask. This ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Photoresist

A photoresist (also known simply as a resist) is a light-sensitive material used in several processes, such as photolithography and photoengraving, to form a patterned coating on a surface. This process is crucial in the electronic industry. The process begins by coating a substrate with a light-sensitive organic material. A patterned mask is then applied to the surface to block light, so that only unmasked regions of the material will be exposed to light. A solvent, called a developer, is then applied to the surface. In the case of a positive photoresist, the photo-sensitive material is degraded by light and the developer will dissolve away the regions that were exposed to light, leaving behind a coating where the mask was placed. In the case of a negative photoresist, the photosensitive material is strengthened (either polymerized or cross-linked) by light, and the developer will dissolve away only the regions that were not exposed to light, leaving behind a coating in areas ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Phase-shift Mask

Phase-shift masks are photomasks that take advantage of the interference generated by phase differences to improve image resolution in photolithography. There exist alternating and attenuated phase shift masks. A phase-shift mask relies on the fact that light passing through a transparent media will undergo a phase change as a function of its optical thickness. Types and effects A conventional photomask is a transparent plate with the same thickness everywhere, parts of which are covered with non-transmitting material in order to create a pattern on the semiconductor wafer when illuminated. In ''alternating phase-shift masks'', certain transmitting regions are made thinner or thicker. That induces a phase-shift in the light traveling through those regions of the mask (see the illustration). When the thickness is suitably chosen, the interference of the phase-shifted light with the light coming from unmodified regions of the mask has the effect of improving the contrast ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Computational Lithography

Computational lithography (also known as computational scaling) is the set of mathematical and algorithmic approaches designed to improve the resolution attainable through photolithography. Computational lithography has come to the forefront of photolithography in 2008 as the semiconductor industry grappled with the challenges associated with the transition to 22 nanometer CMOS fabrication process technology and beyond. 193 nm deep UV photolithography The periodic enhancement in the resolution achieved through photolithography has been a driving force behind Moore's Law. Resolution improvements enable printing of smaller geometries on an integrated circuit. The minimum feature size that a projection system typically used in photolithography can print is given approximately by: :CD = k_1 \cdot\frac where *CD is the minimum feature size (also called the critical dimension). *\lambda is the wavelength of light used. *NA is the numerical aperture of the lens as seen from the wafe ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Defocus Of Subresolution Assist Features

In optics, defocus is the aberration in which an image is simply out of focus. This aberration is familiar to anyone who has used a camera, videocamera, microscope, telescope, or binoculars. Optically, defocus refers to a translation of the focus along the optical axis away from the detection surface. In general, defocus reduces the sharpness and contrast of the image. What should be sharp, high-contrast edges in a scene become gradual transitions. Fine detail in the scene is blurred or even becomes invisible. Nearly all image-forming optical devices incorporate some form of focus adjustment to minimize defocus and maximize image quality. In optics and photography The degree of image blurring for a given amount of focus shift depends inversely on the lens f-number. Low f-numbers, such as to 2.8, are very sensitive to defocus and have very shallow depths of focus. High f-numbers, in the 16 to 32 range, are highly tolerant of defocus, and consequently have large depth ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Assist Feature OPC

Assist or ASSIST may refer to: Sports Several sports have a statistic known as an "assist", generally relating to action by a player leading to a score by another player on their team: * Assist (basketball), a pass by a player that facilitates a basket by another *Assist (ice hockey), a pass by a player or players that helps set up a goal *Assist (association football), a pass by a player or players that helps set up a goal *Assist in Australian rules football, the last pass by a player that directly helps set up a goal *Assist (baseball), any touching of the ball by a defensive player after it has been hit by the batter and prior to the recording of a putout *Assist in water polo, the last pass by a player that directly helps set up a goal *Assist in ultimate, a pass by a player on which a goal is scored. Other * The World Health Organization's Alcohol, Smoking and Substance Involvement Screening Test (ASSIST) Project * ASSIST (computing), Assembler System for Student Instructio ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

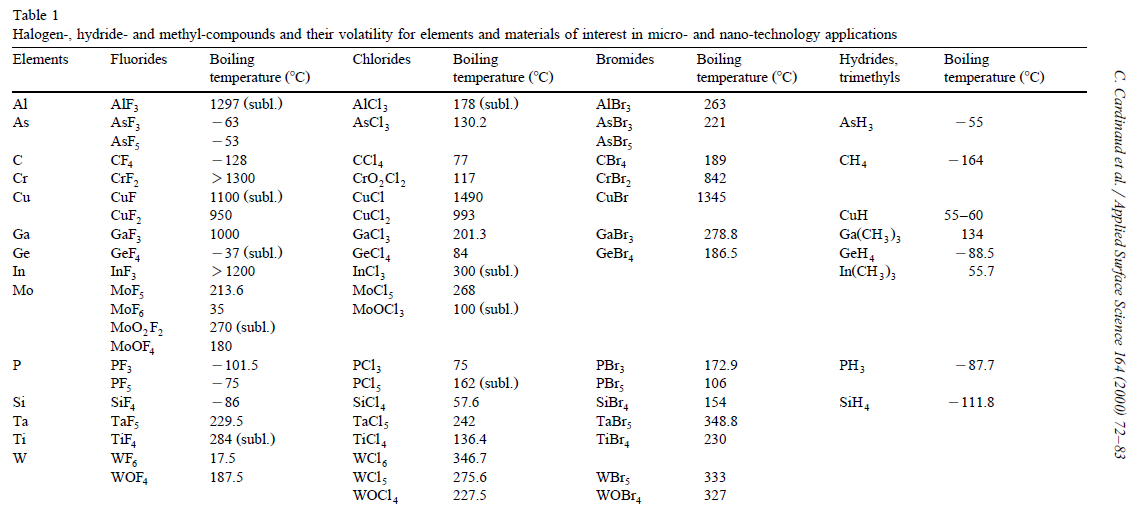

Plasma Etching

Plasma etching is a form of plasma processing used to fabricate integrated circuits. It involves a high-speed stream of glow discharge ( plasma) of an appropriate gas mixture being shot (in pulses) at a sample. The plasma source, known as etch species, can be either charged ( ions) or neutral (atoms and radicals). During the process, the plasma generates volatile etch products at room temperature from the chemical reactions between the elements of the material etched and the reactive species generated by the plasma. Eventually the atoms of the shot element embed themselves at or just below the surface of the target, thus modifying the physical properties of the target. Mechanisms Plasma generation A plasma is a high energetic condition in which a lot of processes can occur. These processes happen because of electrons and atoms. To form the plasma electrons have to be accelerated to gain energy. Highly energetic electrons transfer the energy to atoms by collisions. Three differen ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

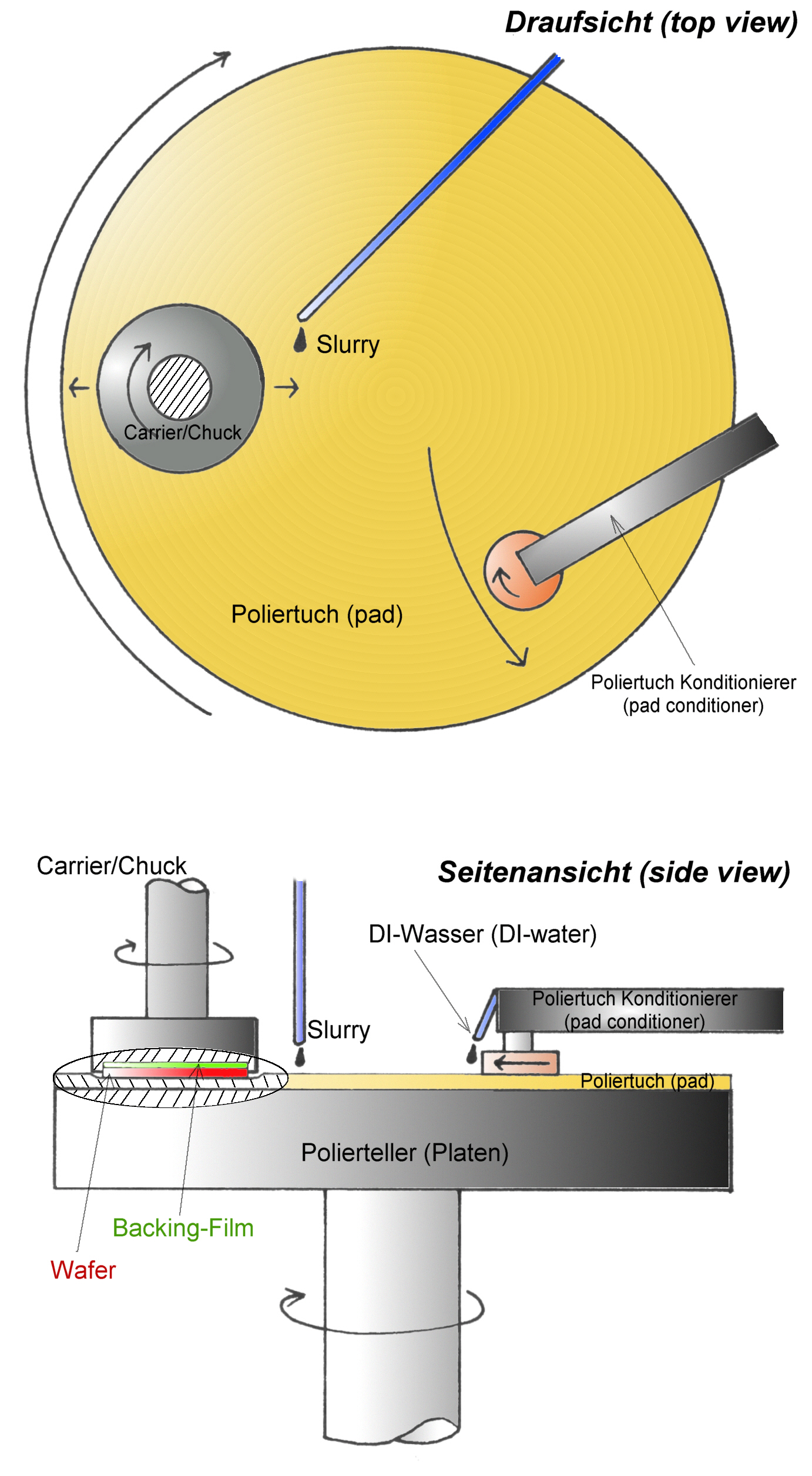

Chemical-mechanical Polishing

Chemical mechanical polishing (CMP) or planarization is a process of smoothing surfaces with the combination of chemical and mechanical forces. It can be thought of as a hybrid of chemical etching and free abrasive polishing. Description The process uses an abrasive and corrosive chemical slurry (commonly a colloid) in conjunction with a polishing pad and retaining ring, typically of a greater diameter than the wafer. The pad and wafer are pressed together by a dynamic polishing head and held in place by a plastic retaining ring. The dynamic polishing head is rotated with different axes of rotation (i.e., not concentric). This removes material and tends to even out any irregular topography, making the wafer flat or planar. This may be necessary to set up the wafer for the formation of additional circuit elements. For example, CMP can bring the entire surface within the depth of field of a photolithography system, or selectively remove material based on its position. Typical depth ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Electron Beam Lithography

Electron-beam lithography (often abbreviated as e-beam lithography, EBL) is the practice of scanning a focused beam of electrons to draw custom shapes on a surface covered with an electron-sensitive film called a resist (exposing). The electron beam changes the solubility of the resist, enabling selective removal of either the exposed or non-exposed regions of the resist by immersing it in a solvent (developing). The purpose, as with photolithography, is to create very small structures in the resist that can subsequently be transferred to the substrate material, often by etching. The primary advantage of electron-beam lithography is that it can draw custom patterns (direct-write) with sub-10 nm resolution. This form of maskless lithography has high resolution and low throughput, limiting its usage to photomask fabrication, low-volume production of semiconductor devices, and research and development. Systems Electron-beam lithography systems used in commercial applicatio ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Proximity Effect (electron Beam Lithography)

The proximity effect in electron beam lithography (EBL) is the phenomenon that the exposure dose distribution, and hence the developed pattern, is wider than the scanned pattern due to the interactions of the primary beam electrons with the resist and substrate. These cause the resist outside the scanned pattern to receive a non-zero dose. Important contributions to weak-resist polymer chain scission (for positive resists) or crosslinking (for negative resists) come from electron forward scattering and backscattering. The forward scattering process is due to electron-electron interactions which deflect the primary electrons by a typically small angle, thus statistically broadening the beam in the resist (and further in the substrate). The majority of the electrons do not stop in the resist but penetrate the substrate. These electrons can still contribute to resist exposure by scattering back into the resist and causing subsequent inelastic or exposing processes. This backscattering ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Electronic Design Automation

Electronic design automation (EDA), also referred to as electronic computer-aided design (ECAD), is a category of software tools for designing electronic systems such as integrated circuits and printed circuit boards. The tools work together in a design flow that chip designers use to design and analyze entire semiconductor chips. Since a modern semiconductor chip can have billions of components, EDA tools are essential for their design; this article in particular describes EDA specifically with respect to integrated circuits (ICs). History Early days Prior to the development of EDA, integrated circuits were designed by hand and manually laid out. Some advanced shops used geometric software to generate tapes for a Gerber photoplotter, responsible for generating a monochromatic exposure image, but even those copied digital recordings of mechanically drawn components. The process was fundamentally graphic, with the translation from electronics to graphics done manually; t ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |