|

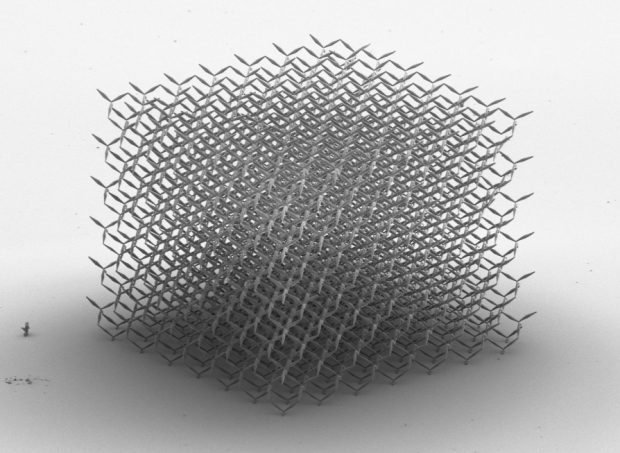

Nanolattices

A nanolattice is a synthetic porous material consisting of nanometer-size members patterned into an ordered lattice structure, like a space frame. The nanolattice is a newly emerged material class that has been rapidly developed over the last decade. Nanolattices redefine the limits of the material property space. Despite being composed of 50-99% of air, nanolattices are very mechanically robust because they take advantage of size-dependent properties that we generally see in nanoparticles, nanowires, and thin films. The most typical mechanical properties of nanolattices include ultrahigh strength, damage tolerance, and high stiffness. Thus, nanolattices have a wide range of applications. Driven by the evolution of 3D printing techniques, nanolattices aiming to exploit beneficial material size effects through miniaturized lattice designs were first developed in the mid-2010s,. Nanolattices are the smallest man-made lattice truss structures and a class of metamaterials that derive ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Metallic Microlattice

A metallic microlattice is a synthetic porous metallic material consisting of an ultra-light metal foam. With a density as low as 0.99 mg/cm3 (0.00561 lb/ft3), it is one of the lightest structural materials known to science. It was developed by a team of scientists from California-based HRL Laboratories, in collaboration with researchers at University of California, Irvine and Caltech, and was first announced in November 2011. The prototype samples were made from a nickel-phosphorus alloy. In 2012, the microlattice prototype was declared one of 10 World-Changing Innovations by ''Popular Mechanics''. Metallic microlattice technology has numerous potential applications in automotive and aeronautical engineering. A detailed comparative review study among other types of metallic lattice structures showed them to be beneficial for light-weighting purposes but expensive to manufacture. Synthesis To produce their metallic microlattice, the HRL/UCI/Caltech team first prepared a ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Atomic Layer Deposition

Atomic layer deposition (ALD) is a thin-film deposition technique based on the sequential use of a gas-phase chemical process; it is a subclass of chemical vapour deposition. The majority of ALD reactions use two chemicals called precursors (also called "reactants"). These precursors react with the surface of a material one at a time in a sequential, self-limiting, manner. A thin film is slowly deposited through repeated exposure to separate precursors. ALD is a key process in fabricating semiconductor devices, and part of the set of tools for synthesising nanomaterials. Introduction During atomic layer deposition a film is grown on a substrate by exposing its surface to alternate gaseous species (typically referred to as precursors or reactants). In contrast to chemical vapor deposition, the precursors are never present simultaneously in the reactor, but they are inserted as a series of sequential, non-overlapping pulses. In each of these pulses the precursor molecules react wit ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Nanomaterials

* Nanomaterials describe, in principle, materials of which a single unit is sized (in at least one dimension) between 1 and 100 nm (the usual definition of nanoscale). Nanomaterials research takes a materials science-based approach to nanotechnology, leveraging advances in materials metrology and synthesis which have been developed in support of microfabrication research. Materials with structure at the nanoscale often have unique optical, electronic, thermo-physical or mechanical properties. Nanomaterials are slowly becoming commercialized and beginning to emerge as commodities. Definition In ISO/TS 80004, ''nanomaterial'' is defined as the "material with any external dimension in the nanoscale or having internal structure or surface structure in the nanoscale", with ''nanoscale'' defined as the "length range approximately from 1 nm to 100 nm". This includes both ''nano-objects'', which are discrete pieces of material, and ''nanostructured materials'', which have inte ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Metamaterials

A metamaterial (from the Ancient Greek, Greek word Meta, μετά ''meta'', meaning "beyond" or "after", and the Latin word ''materia'', meaning "matter" or "material") is any material engineered to have a property that is not found in naturally occurring materials. They are made from assemblies of multiple elements fashioned from composite materials such as metals and plastics. The materials are usually arranged in Periodic function, repeating patterns, at scales that are smaller than the wavelengths of the phenomena they influence. Metamaterials derive their properties not from the properties of the base materials, but from their newly designed structures. Their precise shape, geometry, dimensions, size, orientation (geometry), orientation and arrangement gives them their smart properties capable of manipulating Electromagnetism, electromagnetic waves: by blocking, absorbing, enhancing, or bending waves, to achieve benefits that go beyond what is possible with conventional materi ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Metamaterial Cloaking

Metamaterial cloaking is the usage of metamaterials in an cloaking device, invisibility cloak. This is accomplished by manipulating the paths traversed by light through a novel optical material. Metamaterials direct and control the Wave propagation, propagation and transmission of specified parts of the EM spectrum, light spectrum and demonstrate the potential to render an object seemingly wikt:invisible, invisible. Metamaterial cloaking, based on transformation optics, describes the process of shielding something from view by controlling electromagnetic radiation. Objects in the defined location are still present, but incident waves are guided around them without being affected by the object itself. Electromagnetic metamaterials ''Electromagnetic metamaterials'' respond to chosen parts of radiated light, also known as the electromagnetic spectrum, in a manner that is difficult or impossible to achieve with natural materials. In other words, these metamaterials can be further d ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Thermal Conductivity

The thermal conductivity of a material is a measure of its ability to conduct heat. It is commonly denoted by k, \lambda, or \kappa. Heat transfer occurs at a lower rate in materials of low thermal conductivity than in materials of high thermal conductivity. For instance, metals typically have high thermal conductivity and are very efficient at conducting heat, while the opposite is true for insulating materials like Rockwool or Styrofoam. Correspondingly, materials of high thermal conductivity are widely used in heat sink applications, and materials of low thermal conductivity are used as thermal insulation. The reciprocal of thermal conductivity is called thermal resistivity. The defining equation for thermal conductivity is \mathbf = - k \nabla T, where \mathbf is the heat flux, k is the thermal conductivity, and \nabla T is the temperature gradient. This is known as Fourier's Law for heat conduction. Although commonly expressed as a scalar, the most general form of th ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Mechanical Metamaterials

Mechanical metamaterials are artificial structures with mechanical properties defined by their structure rather than their composition. They can be seen as a counterpart to the rather well-known family of optical metamaterials. They are often also termed ''elastodynamic metamaterials'' and include acoustic metamaterials as a special case of vanishing shear. Their mechanical properties can be designed to have values which cannot be found in nature. Examples of mechanical metamaterials Acoustic / phononic metamaterials Acoustic metamaterials, Acoustic or phononic metamaterials can exhibit acoustic properties not found in nature, such as negative effective bulk modulus, negative effective mass density, or double negativity. They find use in (mostly still purely scientific) applications like acoustic subwavelength imaging, superlensing, negative refraction or transformation acoustics. Materials with negative Poisson's ratio (auxetics) Poisson's ratio defines how a material e ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Nanowires

A nanowire is a nanostructure in the form of a wire with the diameter of the order of a nanometre (10−9 metres). More generally, nanowires can be defined as structures that have a thickness or diameter constrained to tens of nanometers or less and an unconstrained length. At these scales, quantum mechanical effects are important—which coined the term "quantum wires". Many different types of nanowires exist, including superconducting (e.g. YBCO), metallic (e.g. Ni, Pt, Au, Ag), semiconducting (e.g. silicon nanowires (SiNWs), InP, GaN) and insulating (e.g. SiO2, TiO2). Molecular nanowires are composed of repeating molecular units either organic (e.g. DNA) or inorganic (e.g. Mo6S9−xIx). Characteristics upright=1.2, Crystalline 2×2-atom tin selenide nanowire grown inside a single-wall carbon nanotube (tube diameter ~1 nm). file:HgTe@SWCNT.png, A noise-filtered HRTEM image of a HgTe extreme nanowire embedded down the central pore of a SWCNT. The image is also accom ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Theoretical Strength Of A Solid

The theoretical strength of a solid is the maximum possible stress a perfect solid can withstand. It is often much higher than what current real materials can achieve. The lowered fracture stress is due to defects, such as interior or surface cracks. One of the goals for the study of mechanical properties of materials is to design and fabricate materials exhibiting strength close to the theoretical limit. Definition When a solid is in tension, its atomic bonds stretch, elastically. Once a critical strain is reached, all the atomic bonds on the fracture plane rupture and the material fails mechanically. The stress at which the solid fractures is the theoretical strength, often denoted as \sigma_. After fracture, the stretched atomic bonds return to their initial state, except that two surfaces have formed. The theoretical strength is often approximated as: :\sigma_ \cong \frac where *\sigma_ is the maximum theoretical stress the solid can withstand. * E is the Young's Modulus ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Electroless Plating

Electroless plating, also known as chemical plating or autocatalytic plating, is a class of industrial chemical processes that create metal coatings on various materials by autocatalytic chemical reduction of metal cations in a liquid bath. This class is contrasted with electroplating processes, where the reduction is achieved by an externally generated electric current. The main technical advantage of electroless plating is that it creates an even layer of metal regardless of the geometry of the surface—in contrast to electroplating, which suffers from uneven current density due to the effect of substrate shape on the electrical resistance of the bath. Moreover, electroless plating can be applied to non-conductive surfaces and parts of the object that cannot be connected to the current source. Electroless plating has many industrial applications, from merely decorative to the prevention of corrosion and wear. It can even be used to coat individual grains of powdered materials ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Electroplating

Electroplating, also known as electrochemical deposition or electrodeposition, is a process for producing a metal coating on a solid substrate through the reduction of cations of that metal by means of a direct electric current. The part to be coated acts as the cathode (negative electrode) of an electrolytic cell; the electrolyte is a solution of a salt of the metal to be coated; and the anode (positive electrode) is usually either a block of that metal, or of some inert conductive material. The current is provided by an external power supply. Electroplating is widely used in industry and decorative arts to improve the surface qualities of objects—such as resistance to abrasion and corrosion, lubricity, reflectivity, electrical conductivity, or appearance. It is used to build up thickness on undersized or worn-out parts, or to manufacture metal plates with complex shape, a process called electroforming. It is used to deposit copper and other conductors in forming printe ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |