|

LLDPE

Linear low-density polyethylene (LLDPE) is a substantially linear polymer (polyethylene), with significant numbers of short branches, commonly made by copolymerization of ethylene with longer-chain olefins. Linear low-density polyethylene differs structurally from conventional low-density polyethylene (LDPE) because of the absence of long chain branching. The linearity of LLDPE results from the different manufacturing processes of LLDPE and LDPE. In general, LLDPE is produced at lower temperatures and pressures by copolymerization of ethylene and such higher alpha-olefins as butene, hexene, or octene. The copolymerization process produces an LLDPE polymer that has a narrower molecular weight distribution than conventional LDPE and in combination with the linear structure, significantly different rheological properties. Production and properties The production of LLDPE is initiated by transition metal catalysts, particularly Ziegler or Philips types of catalyst. The actual polyme ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Polyethylene

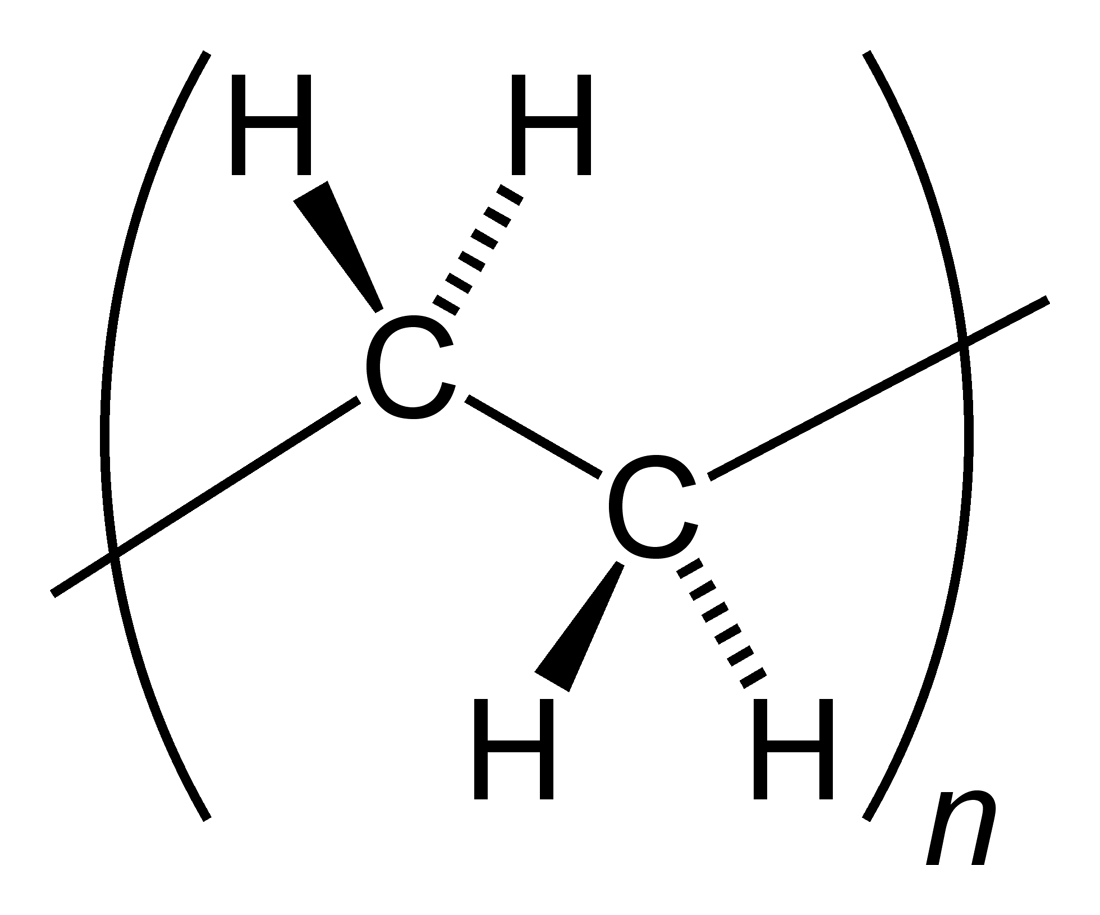

Polyethylene or polythene (abbreviated PE; IUPAC name polyethene or poly(methylene)) is the most commonly produced plastic. It is a polymer, primarily used for packaging (plastic bags, plastic films, geomembranes and containers including bottles, etc.). , over 100 million tonnes of polyethylene resins are being produced annually, accounting for 34% of the total plastics market. Many kinds of polyethylene are known, with most having the chemical formula (C2H4)''n''. PE is usually a mixture of similar polymers of ethylene, with various values of ''n''. It can be ''low-density'' or ''high-density'': low-density polyethylene is extruded using high pressure () and high temperature (), while high-density polyethylene is extruded using low pressure () and low temperature (). Polyethylene is usually thermoplastic, but it can be modified to become thermosetting instead, for example, in cross-linked polyethylene. History Polyethylene was first synthesized by the German ch ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Ziegler–Natta Catalyst

A Ziegler–Natta catalyst, named after Karl Ziegler and Giulio Natta, is a catalyst used in the synthesis of polymers of 1-alkenes ( alpha-olefins). Two broad classes of Ziegler–Natta catalysts are employed, distinguished by their solubility: * Heterogeneous supported catalysts based on titanium compounds are used in polymerization reactions in combination with cocatalysts, organoaluminum compounds such as triethylaluminium, Al(C2H5)3. This class of catalyst dominates the industry. * Homogeneous catalysts usually based on complexes of the group 4 metals titanium, zirconium or hafnium. They are usually used in combination with a different organoaluminum cocatalyst, methylaluminoxane (or methylalumoxane, MAO). These catalysts traditionally contain metallocenes but also feature multidentate oxygen- and nitrogen-based ligands. Ziegler–Natta catalysts are used to polymerize terminal alkenes (ethylene and alkenes with the vinyl double bond): :''n'' CH2=CHR → − H2� ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Geomembranes

A geomembrane is very low permeability (earth sciences), permeability synthetic membrane liner or barrier used with any geotechnical engineering related material so as to control fluid (liquid or gas) migration in a human-made project, structure, or system. Geomembranes are made from relatively thin continuous polymeric sheets, but they can also be made from the impregnation of geotextiles with asphalt, elastomer or polymer, polymer sprays, or as multilayered bitumen geocomposites. Continuous polymer sheet geomembranes are, by far, the most common. Manufacturing The manufacturing of geomembranes begins with the production of the raw materials, which include the polymer resin, and various additives such as antioxidants, plasticizers, fillers, carbon black, and lubricants (as a processing aid). These raw materials (i.e., the "formulation") are then processed into sheets of various widths and thickness by extrusion, calendering, and/or spread coating. Geomembranes dominate the sa ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Low-density Polyethylene

Low-density polyethylene (LDPE) is a thermoplastic made from the monomer ethylene. It was the first grade of polyethylene, produced in 1933 by Imperial Chemical Industries (ICI) using a high pressure process via free radical polymerization. Its manufacture employs the same method today. The EPA estimates 5.7% of LDPE ( resin identification code 4) is recycled in the United States. Despite competition from more modern polymers, LDPE continues to be an important plastic grade. In 2013 the worldwide LDPE market reached a volume of about US$33 billion. Despite its designation with the recycling symbol, it cannot be as commonly recycled as No. 1 (polyethylene terephthalate) or 2 plastics (high-density polyethylene). Properties LDPE is defined by a density range of 917–930 kg/m3. At room temperature it is not reactive, except to strong oxidizers; some solvents cause it to swell. It can withstand temperatures of continuously and for a short time. Made in translucent and opaqu ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Plastic Wrap

Plastic wrap, cling film, Saran wrap, cling wrap, Glad wrap or food wrap is a thin plastic film typically used for sealing food items in containers to keep them fresh over a longer period of time. Plastic wrap, typically sold on rolls in boxes with a cutting edge, clings to many smooth surfaces and can thus remain tight over the opening of a container without adhesive. Common plastic wrap is roughly 0.0005 inches (12.7 μm) thick. The trend has been to produce thinner plastic wrap, particularly for household use (where very little stretch is needed), so now the majority of brands on shelves around the world are 8, 9 or 10 μm thick. Materials used Plastic wrap was initially created from polyvinyl chloride (PVC), which remains the most common component globally. PVC has an acceptably-low permeability to water vapor and oxygen, helping to preserve the freshness of food. There are concerns about the transfer of plasticizers from PVC into food. Pliofilm was made of various kinds o ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Low-density Polyethylene

Low-density polyethylene (LDPE) is a thermoplastic made from the monomer ethylene. It was the first grade of polyethylene, produced in 1933 by Imperial Chemical Industries (ICI) using a high pressure process via free radical polymerization. Its manufacture employs the same method today. The EPA estimates 5.7% of LDPE ( resin identification code 4) is recycled in the United States. Despite competition from more modern polymers, LDPE continues to be an important plastic grade. In 2013 the worldwide LDPE market reached a volume of about US$33 billion. Despite its designation with the recycling symbol, it cannot be as commonly recycled as No. 1 (polyethylene terephthalate) or 2 plastics (high-density polyethylene). Properties LDPE is defined by a density range of 917–930 kg/m3. At room temperature it is not reactive, except to strong oxidizers; some solvents cause it to swell. It can withstand temperatures of continuously and for a short time. Made in translucent and opaqu ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

High-density Polyethylene

High-density polyethylene (HDPE) or polyethylene high-density (PEHD) is a thermoplastic polymer produced from the monomer ethylene. It is sometimes called "alkathene" or "polythene" when used for HDPE pipes. With a high strength-to-density ratio, HDPE is used in the production of plastic bottles, corrosion-resistant piping, geomembranes and plastic lumber. HDPE is commonly recycled, and has the number "2" as its resin identification code. In 2007, the global HDPE market reached a volume of more than 30 million tons. Properties HDPE is known for its high strength-to-density ratio. The density of HDPE ranges from 930 to 970 kg/m3. The standard method to test plastic density is ISO 1183 part 2 (gradient columns), alternatively ISO 1183 part 1MVS2PRO density analyzer. Although the density of HDPE is only marginally higher than that of low-density polyethylene, HDPE has little branching, giving it stronger intermolecular forces and tensile strength (38 MPa versus 21 M ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Cross-linked Polyethylene

Cross-linked polyethylene, commonly abbreviated PEX, XPE or XLPE, is a form of polyethylene with cross-links. It is used predominantly in building services pipework systems, hydronic radiant heating and cooling systems, domestic water piping, insulation for high tension (high voltage) electrical cables, and baby play mats. It is also used for natural gas and offshore oil applications, chemical transportation, and transportation of sewage and slurries. PEX is an alternative to polyvinyl chloride (PVC), chlorinated polyvinyl chloride (CPVC) or copper tubing for use as residential water pipes. Properties Low-temperature impact strength, abrasion resistance and environmental stress cracking resistance can be increased significantly by crosslinking, whereas hardness and rigidity are somewhat reduced. Compared to thermoplastic polyethylene, PEX does not melt (analogous to elastomers) and is thermally resistant (over longer periods of up to 120 °C, for short periods without e ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Stretch Wrap

Stretch wrap or stretch film is a highly stretchable plastic film that is wrapped around items. The elastic recovery keeps the items tightly bound. In contrast, shrink wrap is applied loosely around an item and shrinks tightly with heat. While it is visually similar to plastic food wrap, it is not usually made of material rated as safe for food contact. It is frequently used to secure pallet loads to one another but also may be used for bundling smaller items. Types of stretch film include bundling stretch film, hand stretch film, extended core stretch film, machine stretch film and static dissipative film. Materials The most common stretch wrap material is linear low-density polyethylene (LLDPE), which is produced by copolymerization of ethylene with alpha-olefins, the most common of which are butene, hexene and octene. The use of higher alpha-olefins (hexene or octene) gives rise to enhanced stretch film characteristics, particularly in respect of elongation at break ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Plastic Bags

A plastic bag, poly bag, or pouch is a type of container made of thin, flexible, plastic film, nonwoven fabric, or plastic textile. Plastic bags are used for containing and transporting goods such as foods, produce, powders, ice, magazines, chemicals, and waste. It is a common form of packaging. Most plastic bags are heat sealed at the seams, while some are bonded with adhesives or are stitched. Many countries are introducing legislation to phase-out lightweight plastic bags, because plastic never fully breaks down, causing everlasting pollution of plastics and environmental impacts. Every year, about 1 to 5 trillion plastic bags are used and discarded around the world. From point of sale to destination, plastic bags have a lifetime of 12 minutes. Approximately 320 bags per capita were used in 2014 in the United States of America. Package Several design options and features are available. Some bags have gussets to allow a higher volume of contents, special stand- ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Heat Sealer

A heat sealer is a machine used to seal products, packaging, and other thermoplastic materials using heat. This can be with uniform thermoplastic monolayers or with materials having several layers, at least one being thermoplastic. Heat sealing can join two similar materials together or can join dissimilar materials, one of which has a thermoplastic layer. Heat sealing process Heat sealing is the process of sealing one thermoplastic to another similar thermoplastic using heat and pressure. The direct contact method of heat sealing utilizes a constantly heated die or sealing bar to apply heat to a specific contact area or path to seal or weld the thermoplastics together. Heat sealing is used for many applications, including heat seal connectors, thermally activated adhesives, film media, plastic ports or foil sealing. Applications for the heat sealing process Heat seal connectors are used to join LCD A liquid-crystal display (LCD) is a flat-panel display or other ele ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |