|

Kelvin–Voigt Material

A Kelvin-Voigt material, also called a Voigt material, is the most simple model viscoelastic material showing typical rubbery properties. It is purely elastic on long timescales (slow deformation), but shows additional resistance to fast deformation. It is named after the British physicist and engineer Lord Kelvin and German physicist Woldemar Voigt. Definition The Kelvin-Voigt model, also called the Voigt model, is represented by a purely viscous damper and purely elastic spring connected in parallel as shown in the picture. If, instead, we connect these two elements in series we get a model of a Maxwell material. Since the two components of the model are arranged in parallel, the strains in each component are identical: : \varepsilon_\text = \varepsilon_S = \varepsilon_D. where the subscript D indicates the stress-strain in the damper and the subscript S indicates the stress-strain in the spring. Similarly, the total stress will be the sum of the stress in each component: ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Viscoelastic

In materials science and continuum mechanics, viscoelasticity is the property of materials that exhibit both viscous and elastic characteristics when undergoing deformation. Viscous materials, like water, resist shear flow and strain linearly with time when a stress is applied. Elastic materials strain when stretched and immediately return to their original state once the stress is removed. Viscoelastic materials have elements of both of these properties and, as such, exhibit time-dependent strain. Whereas elasticity is usually the result of bond stretching along crystallographic planes in an ordered solid, viscosity is the result of the diffusion of atoms or molecules inside an amorphous material.Meyers and Chawla (1999): "Mechanical Behavior of Materials", 98-103. Background In the nineteenth century, physicists such as Maxwell, Boltzmann, and Kelvin researched and experimented with creep and recovery of glasses, metals, and rubbers. Viscoelasticity was further examined in ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Retardation Time

Retardation is the delayed response to an applied force or stress and can be described as "delay of the elasticity". Ideal elastic materials show an immediate deformation after applying a jump-like stress, and an immediate reformation after removing the stress afterwards in the jump-like form again. For viscoelastic samples, this elastic behaviour occurs with a certain time delay. The term "relaxation time" has been described. It is used in combination with tests presetting the strain (deformation) or strain rate (shear rate In physics, shear rate is the rate at which a progressive shearing deformation is applied to some material. Simple shear The shear rate for a fluid flowing between two parallel plates, one moving at a constant speed and the other one stationary ...), eg, when performing relaxation tests. On the other hand, the term "retardation time" is used for tests when presetting the stress, eg, when performing creep tests. See also * Creep-testing machine Refer ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Non-Newtonian Fluids

A non-Newtonian fluid is a fluid that does not follow Newton's law of viscosity, i.e., constant viscosity independent of stress. In non-Newtonian fluids, viscosity can change when under force to either more liquid or more solid. Ketchup, for example, becomes runnier when shaken and is thus a non-Newtonian fluid. Many salt solutions and molten polymers are non-Newtonian fluids, as are many commonly found substances such as custard, toothpaste, starch suspensions, corn starch, paint, blood, melted butter, and shampoo. Most commonly, the viscosity (the gradual deformation by shear or tensile stresses) of non-Newtonian fluids is dependent on shear rate or shear rate history. Some non-Newtonian fluids with shear-independent viscosity, however, still exhibit normal stress-differences or other non-Newtonian behavior. In a Newtonian fluid, the relation between the shear stress and the shear rate is linear, passing through the origin, the constant of proportionality being the coeffic ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Generalized Maxwell Model

The Generalized Maxwell model also known as the Maxwell–Wiechert model (after James Clerk Maxwell and E WiechertWiechert, E (1889); "Ueber elastische Nachwirkung", Dissertation, Königsberg University, GermanyWiechert, E (1893); "Gesetze der elastischen Nachwirkung für constante Temperatur", Annalen der Physik, Vol. 286issue 10, p. 335–348anissue 11, p. 546–570/ref>) is the most general form of the linear model for viscoelasticity In materials science and continuum mechanics, viscoelasticity is the property of materials that exhibit both viscous and elastic characteristics when undergoing deformation. Viscous materials, like water, resist shear flow and strain linearl .... In this model several Maxwell elements are assembled in parallel. It takes into account that the relaxation does not occur at a single time, but in a set of times. Due to the presence of molecular segments of different lengths, with shorter ones contributing less than longer ones, there is a ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Burgers Material

A Burgers material is a viscoelastic material having the properties both of elasticity and viscosity. It is named after the Dutch physicist Johannes Martinus Burgers. Overview Maxwell representation Given that one Maxwell material has an elasticity E_1 and viscosity \eta_1, and the other Maxwell material has an elasticity E_2 and viscosity \eta_2, the Burgers model has the constitutive equation : \sigma + \left( \frac + \frac \right) \dot\sigma + \frac \ddot\sigma = \left( \eta_1 + \eta_2 \right) \dot\varepsilon + \frac \ddot\varepsilon where \sigma is the stress and \varepsilon is the strain. Kelvin representation Given that the Kelvin material has an elasticity E_1 and viscosity \eta_1, the spring has an elasticity E_2 and the dashpot has a viscosity \eta_2, the Burgers model has the constitutive equation : \sigma + \left( \frac + \frac + \frac \right) \dot\sigma + \frac \ddot\sigma = \eta_2\dot\varepsilon + \frac \ddot\varepsilon where \sigma is the ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Dynamic Modulus

Dynamic modulus (sometimes complex modulusThe Open University (UK), 2000. ''T838 Design and Manufacture with Polymers: Solid properties and design'', page 30. Milton Keynes: The Open University.) is the ratio of stress to strain under ''vibratory conditions'' (calculated from data obtained from either free or forced vibration tests, in shear, compression, or elongation). It is a property of viscoelastic materials. Viscoelastic stress–strain phase-lag Viscoelasticity is studied using dynamic mechanical analysis where an oscillatory force (stress) is applied to a material and the resulting displacement (strain) is measured. *In purely elastic materials the stress and strain occur in phase, so that the response of one occurs simultaneously with the other. *In purely viscous materials, there is a phase difference between stress and strain, where strain lags stress by a 90 degree (\pi/2 radian) phase lag. *Viscoelastic materials exhibit behavior somewhere in between that of purely ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Solid

Solid is one of the State of matter#Four fundamental states, four fundamental states of matter (the others being liquid, gas, and Plasma (physics), plasma). The molecules in a solid are closely packed together and contain the least amount of kinetic energy. A solid is characterized by structural rigidity and resistance to a force applied to the surface. Unlike a liquid, a solid object does not flow to take on the shape of its container, nor does it expand to fill the entire available volume like a gas. The atoms in a solid are bound to each other, either in a regular geometric lattice (crystal, crystalline solids, which include metals and ordinary ice), or irregularly (an amorphous solid such as common window glass). Solids cannot be compressed with little pressure whereas gases can be compressed with little pressure because the molecules in a gas are loosely packed. The branch of physics that deals with solids is called solid-state physics, and is the main branch of condens ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Kelvin Deformation 2

The kelvin, symbol K, is the primary unit of temperature in the International System of Units (SI), used alongside its prefixed forms and the degree Celsius. It is named after the Belfast-born and University of Glasgow-based engineer and physicist William Thomson, 1st Baron Kelvin (1824–1907). The Kelvin scale is an absolute thermodynamic temperature scale, meaning it uses absolute zero as its null (zero) point. Historically, the Kelvin scale was developed by shifting the starting point of the much-older Celsius scale down from the melting point of water to absolute zero, and its increments still closely approximate the historic definition of a degree Celsius, but since 2019 the scale has been defined by fixing the Boltzmann constant to be exactly . Hence, one kelvin is equal to a change in the thermodynamic temperature that results in a change of thermal energy by . The temperature in degree Celsius is now defined as the temperature in kelvins minus 273.15, meaning tha ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Normal Stress

In continuum mechanics, stress is a physical quantity. It is a quantity that describes the magnitude of forces that cause deformation. Stress is defined as ''force per unit area''. When an object is pulled apart by a force it will cause elongation which is also known as deformation, like the stretching of an elastic band, it is called tensile stress. But, when the forces result in the compression of an object, it is called compressive stress. It results when forces like tension or compression act on a body. The greater this force and the smaller the cross-sectional area of the body on which it acts, the greater the stress. Therefore, stress is measured in newton per square meter (N/m2) or pascal (Pa). Stress expresses the internal forces that neighbouring particles of a continuous material exert on each other, while strain is the measure of the deformation of the material. For example, when a solid vertical bar is supporting an overhead weight, each particle in the bar pushes o ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

William Thomson, 1st Baron Kelvin

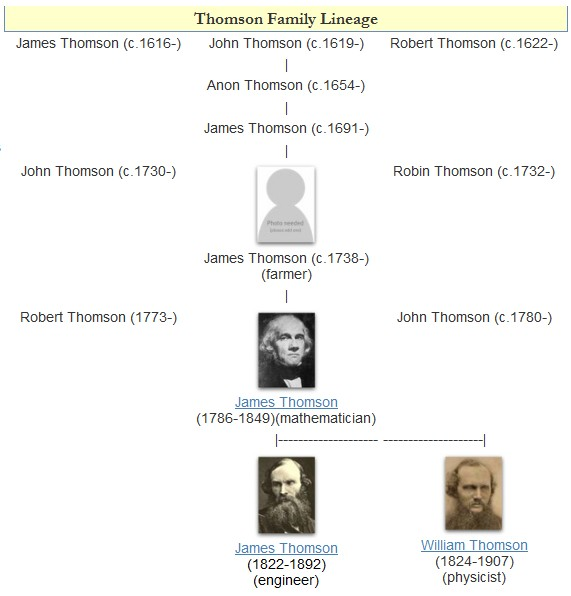

William Thomson, 1st Baron Kelvin, (26 June 182417 December 1907) was a British mathematician, mathematical physicist and engineer born in Belfast. Professor of Natural Philosophy at the University of Glasgow for 53 years, he did important work in the mathematical analysis of electricity and formulation of the first and second laws of thermodynamics, and did much to unify the emerging discipline of physics in its contemporary form. He received the Royal Society's Copley Medal in 1883, was its president 1890–1895, and in 1892 was the first British scientist to be elevated to the House of Lords. Absolute temperatures are stated in units of kelvin in his honour. While the existence of a coldest possible temperature ( absolute zero) was known prior to his work, Kelvin is known for determining its correct value as approximately −273.15 degrees Celsius or −459.67 degrees Fahrenheit. The Joule–Thomson effect is also named in his honour. He worked closely with mathematics ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Shear Stress

Shear stress, often denoted by (Greek: tau), is the component of stress coplanar with a material cross section. It arises from the shear force, the component of force vector parallel to the material cross section. ''Normal stress'', on the other hand, arises from the force vector component perpendicular to the material cross section on which it acts. General shear stress The formula to calculate average shear stress is force per unit area.: : \tau = , where: : = the shear stress; : = the force applied; : = the cross-sectional area of material with area parallel to the applied force vector. Other forms Wall shear stress Wall shear stress expresses the retarding force (per unit area) from a wall in the layers of a fluid flowing next to the wall. It is defined as: \tau_w:=\mu\left(\frac\right)_ Where \mu is the dynamic viscosity, u the flow velocity and y the distance from the wall. It is used, for example, in the description of arterial blood flow in which case which ther ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |