|

Kirchweger Condenser

The purpose of the Kirchweger condenser (German: ''Kirchweger-Kondensationseinrichtung'' or ''Kirchwegersche Abdampfkondensation'') was to preheat feedwater in a steam locomotive using the exhaust steam from the engine. It was invented in 1850 by Heinrich Kirchweger. A similar system was developed by Rohrbeck. Overview Exhaust steam was extracted from the steam chest and fed through a 100 mm diameter pipe under the locomotive to the tender. There the steam was fed directly into the feedwater, which thus heated up to boiling point. The remaining steam was allowed to escape to atmosphere through a second chimney on the tender. The quantity of steam could be regulated using a cock on the tender. The Rohrbeck system differed in detail from the Kirchweger condenser, in which steam was removed at the blast pipe and led away along the top of the boiler. The system was regulated by a throttle valve on the blast pipe. Fuel savings Using such a system, fuel savings of between 10 and ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

LDE WURZEN

Long delayed echoes (LDEs) are radio echoes which return to the sender several seconds after a radio transmission has occurred. Delays of longer than 2.7 seconds are considered LDEs. ARRL: Stan Horzepa, ''Radio Ghosts'' (dead link. use https://web.archive.org/web/20031105155129/http://www.arrl.org/news/features/2003/10/31/1/) LDEs have a number of proposed scientific origins. History These echoes were first observed in 1927 by civil engineer and operator Jørgen Hals from his home near , |

Feedwater

Boiler feedwater is an essential part of boiler operations. The feed water is put into the steam drum from a feed pump. In the steam drum the feed water is then turned into steam from the heat. After the steam is used it is then dumped to the main condenser. From the condenser it is then pumped to the deaerated feed tank. From this tank it then goes back to the steam drum to complete its cycle. The feed water is never open to the atmosphere. This cycle is known as a closed system or Rankine cycle. History of feedwater treatment During the early development of boilers, water treatment was not so much of an issue, as temperatures and pressures were so low that high amounts of scale and rust would not form to such a significant extent, especially if the boiler was “ blown down”. It was general practice to install zinc plates and/or alkaline chemicals to reduce corrosion within the boiler. Many tests had been performed to determine the cause (and possible protection) from corrosi ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Steam Locomotive

A steam locomotive is a locomotive that provides the force to move itself and other vehicles by means of the expansion of steam. It is fuelled by burning combustible material (usually coal, oil or, rarely, wood) to heat water in the locomotive's boiler to the point where it becomes gaseous and its volume increases 1,700 times. Functionally, it is a steam engine on wheels. In most locomotives, the steam is admitted alternately to each end of its cylinders, in which pistons are mechanically connected to the locomotive's main wheels. Fuel and water supplies are usually carried with the locomotive, either on the locomotive itself or in a tender coupled to it. Variations in this general design include electrically-powered boilers, turbines in place of pistons, and using steam generated externally. Steam locomotives were first developed in the United Kingdom during the early 19th century and used for railway transport until the middle of the 20th century. Richard Trevithick ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Heinrich Kirchweger

Johann Gottfried Heinrich Kirchweger (12 June 1809 – 18 January 1899) was a German railway engineer. Heinrich Kirchweger was born on 12 June 1809 in Stettin, then part of the Kingdom of Prussia, now Szczecin in Poland. After attending the trade school in Berlin, Kirchweger worked with the industrialist Georg Henschel in Kassel. Career In 1838 he became the technical operations manager of the Leipzig–Dresden Railway Company and, later, the Saxon-Bavarian Railway Company. In 1843 he took up a post with the newly founded Royal Hanoverian State Railways. Here he was responsible for the mechanical engineering, operations, maintenance and the procurement of running and rolling stock. Thanks to him, an organised maintenance system and standardised railway operations emerged. He introduced feedwater preheating on locomotives using the ''Kirchweger condenser'' and introduced "Hanoverian standard locomotives" based on those built by Thomas Russell Crampton and Johann Friedrich Ludwig W ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Tender (rail)

A tender or coal-car (US only) is a special rail vehicle hauled by a steam locomotive containing its fuel (wood, coal, oil or torrefied biomass) and water. Steam locomotives consume large quantities of water compared to the quantity of fuel, so their tenders are necessary to keep them running over long distances. A locomotive that pulls a tender is called a tender locomotive. Locomotives that do not have tenders and carry all their fuel and water on board the locomotive itself are called tank locomotives. A corridor tender is a locomotive tender with a passageway to one side, allowing crew changes on the fly. A brake tender is a tender that is heavy and used (primarily) to provide greater braking efficiency. General functions The largest steam locomotives are semi-permanently coupled by a drawbar to a tender that carries the water and fuel. The fuel source used depends on what is economically available locally. In the UK and parts of Europe, a plentiful supply of coal made ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

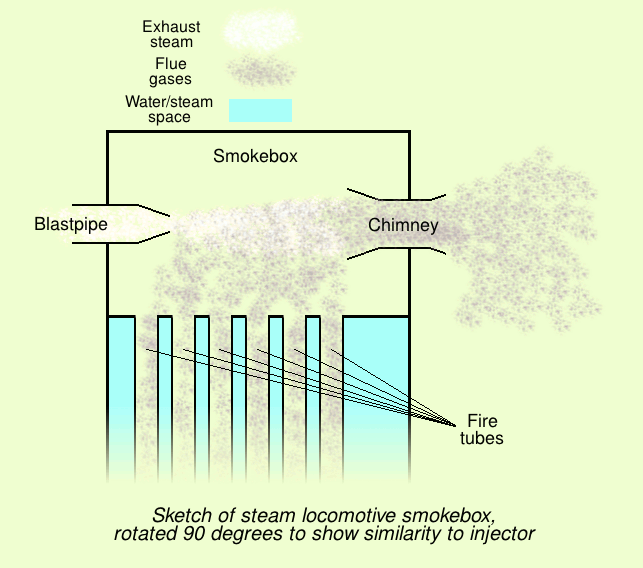

Blast Pipe

The blastpipe is part of the exhaust system of a steam locomotive that discharges exhaust steam from the cylinders into the smokebox beneath the chimney in order to increase the draught through the fire. History The primacy of discovery of the effect of directing the exhaust steam up the chimney as a means of providing draft through the fire is the matter of some controversy, Ahrons (1927) devoting significant attention to this matter. The exhaust from the cylinders on the first steam locomotive – built by Richard Trevithick – was directed up the chimney, and he noted its effect on increasing the draft through the fire at the time. At Wylam, Timothy Hackworth also employed a blastpipe on his earliest locomotives, but it is not clear whether this was an independent discovery or a copy of Trevithick's design. Shortly after Hackworth, George Stephenson also employed the same method, and again it is not clear whether that was an independent discovery or a copy of one of the oth ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Boiler

A boiler is a closed vessel in which fluid (generally water) is heated. The fluid does not necessarily boil. The heated or vaporized fluid exits the boiler for use in various processes or heating applications, including water heating, central heating, boiler-based power generation, cooking, and sanitation. Heat sources In a fossil fuel power plant using a steam cycle for power generation, the primary heat source will be combustion of coal, oil, or natural gas. In some cases byproduct fuel such as the carbon monoxide rich offgasses of a coke battery can be burned to heat a boiler; biofuels such as bagasse, where economically available, can also be used. In a nuclear power plant, boilers called steam generators are heated by the heat produced by nuclear fission. Where a large volume of hot gas is available from some process, a heat recovery steam generator or recovery boiler can use the heat to produce steam, with little or no extra fuel consumed; such a configuration is common ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Lower Silesian-Märkisch Railway

{{Disambiguation ...

Lower may refer to: *Lower (surname) *Lower Township, New Jersey *Lower Receiver (firearms) *Lower Wick Gloucestershire, England See also *Nizhny Nizhny (russian: Ни́жний; masculine), Nizhnyaya (; feminine), or Nizhneye (russian: Ни́жнее; neuter), literally meaning "lower", is the name of several Russian localities. It may refer to: * Nizhny Novgorod, a Russian city colloquial ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Boiler Feedwater

Boiler feedwater is an essential part of boiler operations. The feed water is put into the steam drum from a feed pump. In the steam drum the feed water is then turned into steam from the heat. After the steam is used it is then dumped to the main condenser. From the condenser it is then pumped to the deaerated feed tank. From this tank it then goes back to the steam drum to complete its cycle. The feed water is never open to the atmosphere. This cycle is known as a closed system or Rankine cycle. History of feedwater treatment During the early development of boilers, water treatment was not so much of an issue, as temperatures and pressures were so low that high amounts of scale and rust would not form to such a significant extent, especially if the boiler was “ blown down”. It was general practice to install zinc plates and/or alkaline chemicals to reduce corrosion within the boiler. Many tests had been performed to determine the cause (and possible protection) from corrosi ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Injector

An injector is a system of ducting and nozzles used to direct the flow of a high-pressure fluid in such a way that a lower pressure fluid is entrained in the jet and carried through a duct to a region of higher pressure. It is a fluid-dynamic pump with no moving parts except a valve to control inlet flow. A steam injector is a typical application of the principle used to deliver cold water to a boiler against its own pressure, using its own live or exhaust steam, replacing any mechanical pump. When first developed, its operation was intriguing because it seemed paradoxical, almost like perpetual motion, but it was later explained using thermodynamics. Other types of injector may use other pressurised motive fluids such as air. Depending on the application, an injector can also take the form of an ''eductor-jet pump'', a ''water eductor'' or an ''aspirator''. An '' ejector'' operates on similar principles to create a vacuum feed connection for braking systems etc. History The ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Condensing Steam Locomotive

A condensing steam locomotive is a type of locomotive designed to recover exhaust steam, either in order to improve range between taking on boiler water, or to reduce emission of steam inside enclosed spaces. The apparatus takes the exhaust steam that would normally be used to produce a draft for the firebox, and routes it through a heat exchanger, into the boiler water tanks. Installations vary depending on the purpose, design and the type of locomotive to which it is fitted. It differs from the usual closed cycle condensing steam engine, in that the function of the condenser is primarily either to recover water, or to avoid excessive emissions to the atmosphere, rather than maintaining a vacuum to improve both efficiency and power. Thermodynamics Unlike the surface condenser often used on a steam turbine or marine steam engine, the condensing apparatus on a steam locomotive does not normally increase the power output, rather it decreases due to a reduction of airflow to th ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Feedwater Heater

A feedwater heater is a power plant component used to pre-heat water delivered to a steam generating boiler. Preheating the feedwater reduces the irreversibilities involved in steam generation and therefore improves the thermodynamic efficiency of the system.Fundamentals of Steam Power by Kenneth Weston, University of Tulsa This reduces plant operating costs and also helps to avoid thermal shock to the boiler metal when the feedwater is introduced back into the steam cycle. In a steam power plant (usually modeled as a modified Rankine cycle), feedwater heaters allow the feedwater to be brought up to the saturation temperature very gradually. This minimizes the inevitable irreversibilities associated with heat transfer to the working fluid (water). See the article on the second law of thermodynamics for a fur ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |