|

Hot Bulb Oil Engine

The hot-bulb engine is a type of internal combustion engine in which fuel ignites by coming in contact with a red-hot metal surface inside a bulb, followed by the introduction of air (oxygen) compressed into the hot-bulb chamber by the rising piston. There is some ignition when the fuel is introduced, but it quickly uses up the available oxygen in the bulb. Vigorous ignition takes place only when sufficient oxygen is supplied to the hot-bulb chamber on the compression stroke of the engine. Most hot-bulb engines were produced as one or two-cylinder, low-speed two-stroke crankcase scavenged units. History Four-stroke Hornsby-Akroyd oil engine The concept of this engine was established by Herbert Akroyd Stuart, an English inventor. The first prototypes were built in 1886 and production started in 1891 by Richard Hornsby & Sons of Grantham, Lincolnshire, England under the title Hornsby Akroyd Patent Oil Engine under licence.Herbert Akroyd Stuart, ''Improvements in Engines Op ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Bolinder-Munktell

AB Bolinder-Munktell (BM) was a tractor and machines manufacturer founded in Eskilstuna, Sweden in 1932 through the merger of the mechanical companies Bolinder and Munktell. Bolinder are also well known as manufacturers of 'Semi-Diesel' or 'Hot bulb' engines. In 1950 BM was bought by AB Volvo. In 1973 the company changed its name to Volvo BM AB and then in 1995 to Volvo Construction Equipment. The product range has changed with the times. Up to the beginning of the 20th century agricultural machines such as threshers were an important product. Products Marine engines Bolinder produced a wide range of marine engines, mostly of the semi-diesel hot bulb type. Some of those sizes proved to be ideal in narrow boats, and some Bolinder motors so used are still in use. When starting, the cylinder head has to be heated with a kerosene blowtorch to get the hot bulb heated, and to be able to start the combustion process. Tractors Tractor production commenced in 1913, with the type 3 ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Blackstone & Co

Blackstone & Co. was a farm implement maker at Stamford, Lincolnshire, United Kingdom. History Company History This business was established in 1837 as Smith & Ashby later known as Rutland Iron Works. Later still it came into the ownership of Ashby and G. E. Jeffery. In 1877 Edward Christopher Blackstone (1850-1916) was admitted to a new partnership owning Rutland Iron Works known as Jeffery and Blackstone. Blackstone and George Mills, a member of Blackstone's wife's family, bought out Jeffery in 1882. A limited liability company, Blackstone & Co Limited, was incorporated on 29 January 1889 to take ownership of the business. In 1895/1896 the Carter Brothers (Frank and Evershed) of Billingshurst joined the company. They had developed their 'Reliance' oil engine in 1894, and Blackstone started producing the engine in 1896. Frank Carter became works manager in 1904 where he remained until his death in 1934.Blackstone Oil Engine Inventor, Lincolnshire Standard and Boston Guardian, ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Four-stroke Engine

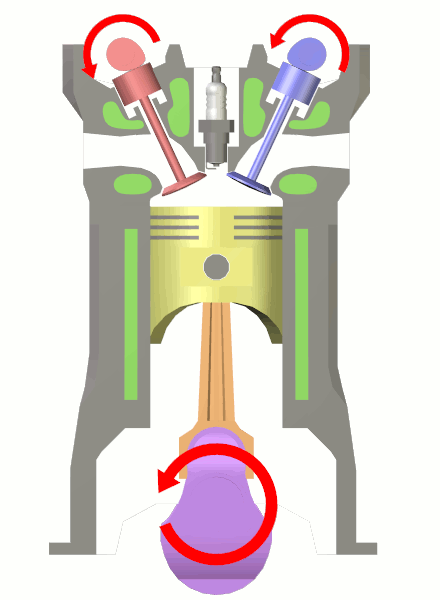

A four-stroke (also four-cycle) engine is an internal combustion (IC) engine in which the piston completes four separate strokes while turning the crankshaft. A stroke refers to the full travel of the piston along the cylinder, in either direction. The four separate strokes are termed: #Intake: Also known as induction or suction. This stroke of the piston begins at top dead center (T.D.C.) and ends at bottom dead center (B.D.C.). In this stroke the intake valve must be in the open position while the piston pulls an air-fuel mixture into the cylinder by producing vacuum pressure into the cylinder through its downward motion. The piston is moving down as air is being sucked in by the downward motion against the piston. #Compression: This stroke begins at B.D.C, or just at the end of the suction stroke, and ends at T.D.C. In this stroke the piston compresses the air-fuel mixture in preparation for ignition during the power stroke (below). Both the intake and exhaust valves are close ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Crankshaft

A crankshaft is a mechanical component used in a piston engine to convert the reciprocating motion into rotational motion. The crankshaft is a rotating shaft containing one or more crankpins, that are driven by the pistons via the connecting rods. The crankpins are also called ''rod bearing journals'', and they rotate within the "big end" of the connecting rods. Most modern crankshafts are located in the engine block. They are made from steel or cast iron, using either a forging, casting or machining process. Design The crankshaft located within the engine block, held in place via main bearings which allow the crankshaft to rotate within the block. The up-down motion of each piston is transferred to the crankshaft via connecting rods. A flywheel is often attached to one end of the crankshaft, in order to smoothen the power delivery and reduce vibration. A crankshaft is subjected to enormous stresses, in some cases more than per cylinder. Crankshafts for single-cylin ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Flywheel

A flywheel is a mechanical device which uses the conservation of angular momentum to store rotational energy; a form of kinetic energy proportional to the product of its moment of inertia and the square of its rotational speed. In particular, assuming the flywheel's moment of inertia is constant (i.e., a flywheel with fixed mass and second moment of area revolving about some fixed axis) then the stored (rotational) energy is directly associated with the square of its rotational speed. Since a flywheel serves to store mechanical energy for later use, it is natural to consider it as a kinetic energy analogue of an electrical inductor. Once suitably abstracted, this shared principle of energy storage is described in the generalized concept of an accumulator. As with other types of accumulators, a flywheel inherently smooths sufficiently small deviations in the power output of a system, thereby effectively playing the role of a low-pass filter with respect to the mechanical velocity ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Cylinder (engine)

In a reciprocating engine, the cylinder is the space in which a piston travels. The inner surface of the cylinder is formed from either a thin metallic liner (also called "sleeve") or a surface coating applied to the engine block. A piston is seated inside each cylinder by several metal piston rings, which also provide seals for compression and the lubricating oil. The piston rings do not actually touch the cylinder walls, instead they ride on a thin layer of lubricating oil. Steam engines The cylinder in a steam engine is made pressure-tight with end covers and a piston; a valve distributes the steam to the ends of the cylinder. Cylinders were cast in cast iron and later in steel. The cylinder casting can include other features such as valve ports and mounting feet. Internal combustion engines The cylinder is the space through which the piston travels, propelled to the energy generated from the combustion of the air/fuel mixture in the combustion chamber. In an ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Piston

A piston is a component of reciprocating engines, reciprocating pumps, gas compressors, hydraulic cylinders and pneumatic cylinders, among other similar mechanisms. It is the moving component that is contained by a cylinder and is made gas-tight by piston rings. In an engine, its purpose is to transfer force from expanding gas in the cylinder to the crankshaft via a piston rod and/or connecting rod. In a pump, the function is reversed and force is transferred from the crankshaft to the piston for the purpose of compressing or ejecting the fluid in the cylinder. In some engines, the piston also acts as a valve by covering and uncovering ports in the cylinder. __TOC__ Piston engines Internal combustion engines An internal combustion engine is acted upon by the pressure of the expanding combustion gases in the combustion chamber space at the top of the cylinder. This force then acts downwards through the connecting rod and onto the crankshaft. The connecting rod is att ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Dead Centre (engineering)

In a reciprocating engine, the dead centre is the position of a piston in which it is either farthest from, or nearest to, the crankshaft. The former is known as Top Dead Centre (TDC) while the latter is known as Bottom Dead Centre (BDC). More generally, the dead centre is any position of a crank where the applied force is straight along its axis, meaning no turning force can be applied. Many sorts of machines are crank driven, including unicycles, bicycles, tricycles, various types of machine presses, gasoline engines, diesel engines, steam locomotives, and other steam engines. Crank-driven machines rely on the energy stored in a flywheel to overcome the dead centre, or are designed, in the case of multi-cylinder engines, so that dead centres can never exist on all cranks at the same time. A steam locomotive is an example of the latter, the connecting rods being arranged such that the dead centre for each cylinder occurs out of phase with the other one (or more) cylinde ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Compression Ratio

The compression ratio is the ratio between the volume of the cylinder and combustion chamber in an internal combustion engine at their maximum and minimum values. A fundamental specification for such engines, it is measured two ways: the static compression ratio, calculated based on the relative volumes of the combustion chamber and the cylinder when the piston is at the bottom of its stroke, and the volume of the combustion chamber when the piston is at the top of its stroke. The dynamic compression ratio is a more advanced calculation which also takes into account gasses entering and exiting the cylinder during the compression phase. Effect and typical ratios A high compression ratio is desirable because it allows an engine to extract more mechanical energy from a given mass of air–fuel mixture due to its higher thermal efficiency. This occurs because internal combustion engines are heat engines, and higher compression ratios permit the same combustion temperature to ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Rudolf Diesel

Rudolf Christian Karl Diesel (, ; 18 March 1858 – 29 September 1913) was a German inventor and Mechanical engineering, mechanical engineer who is famous for having invented the diesel engine, which burns diesel fuel; both are named after him. Early life and education Diesel was born at 38 Rue Notre Dame de Nazareth in Paris, Second French Empire, France in 1858 the second of three children of Elise (née Strobel) and Theodor Diesel. His parents were Bavarian immigrants living in Paris... Theodor Diesel, a Bookbinding, bookbinder by trade, left his home town of Augsburg, Kingdom of Bavaria, Bavaria, in 1848. He met his wife, a daughter of a Nuremberg merchant, in Paris in 1855 and became a leather goods manufacturer there. Shortly after his birth, Diesel was given away to a Vincennes farmer family, where he spent his first nine months. When he was returned to his family, they moved into the flat 49 in the :fr:Rue de la Fontaine-au-Roi, Rue de la Fontaine-au-Roi. At the time, th ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Diesel Engine

The diesel engine, named after Rudolf Diesel, is an internal combustion engine in which ignition of the fuel is caused by the elevated temperature of the air in the cylinder due to mechanical compression; thus, the diesel engine is a so-called compression-ignition engine (CI engine). This contrasts with engines using spark plug-ignition of the air-fuel mixture, such as a petrol engine (gasoline engine) or a gas engine (using a gaseous fuel like natural gas or liquefied petroleum gas). Diesel engines work by compressing only air, or air plus residual combustion gases from the exhaust (known as exhaust gas recirculation (EGR)). Air is inducted into the chamber during the intake stroke, and compressed during the compression stroke. This increases the air temperature inside the cylinder to such a high degree that atomised diesel fuel injected into the combustion chamber ignites. With the fuel being injected into the air just before combustion, the dispersion of the fuel is une ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

.jpg)

.png)