|

Hopper Cooling

Hopper cooling is a simple form of water cooling used for small stationary engines. The defining feature of hopper cooling, amongst other water-cooled engines, is that there is no radiator. Cooling water is heated by the engine and evaporates from the surface of the hopper as steam. Operation Internal combustion engines are rather inefficient and require cooling to dispose of the waste heat they generate when running. Water-cooled engines remove this heat from around the cylinder head by surrounding it with a water jacket. In most familiar engines today, this water is circulated from the hot parts of the engine to a radiator, where it gives up its heat to the air. In early and low powered engines with hopper cooling there is little circulation. Water is instead slowly boiled off, with the heat of vaporisation needed to boil the water coming from the engine heat. The loss of heat with this departing water vapour is enough to cool the engine. As the heat of vaporisation (energy ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

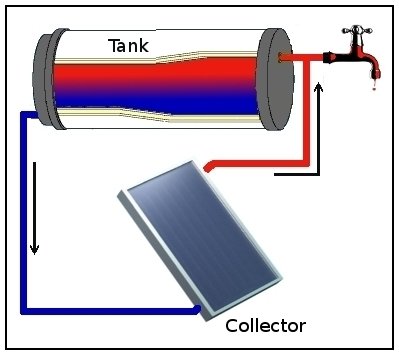

Thermosyphon

Thermosiphon (or thermosyphon) is a method of passive heat exchange, based on natural convection, which circulates a fluid without the necessity of a mechanical pump. Thermosiphoning is used for circulation of liquids and volatile gases in heating and cooling applications such as heat pumps, water heaters, boilers and furnaces. Thermosiphoning also occurs across air temperature gradients such as those utilized in a wood fire chimney or solar chimney. This circulation can either be open-loop, as when the substance in a holding tank is passed in one direction via a heated transfer tube mounted at the bottom of the tank to a distribution point—even one mounted above the originating tank—or it can be a vertical closed-loop circuit with return to the original container. Its purpose is to simplify the transfer of liquid or gas while avoiding the cost and complexity of a conventional pump. Simple thermosiphon Natural convection of the liquid starts when heat transfer to the liquid ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

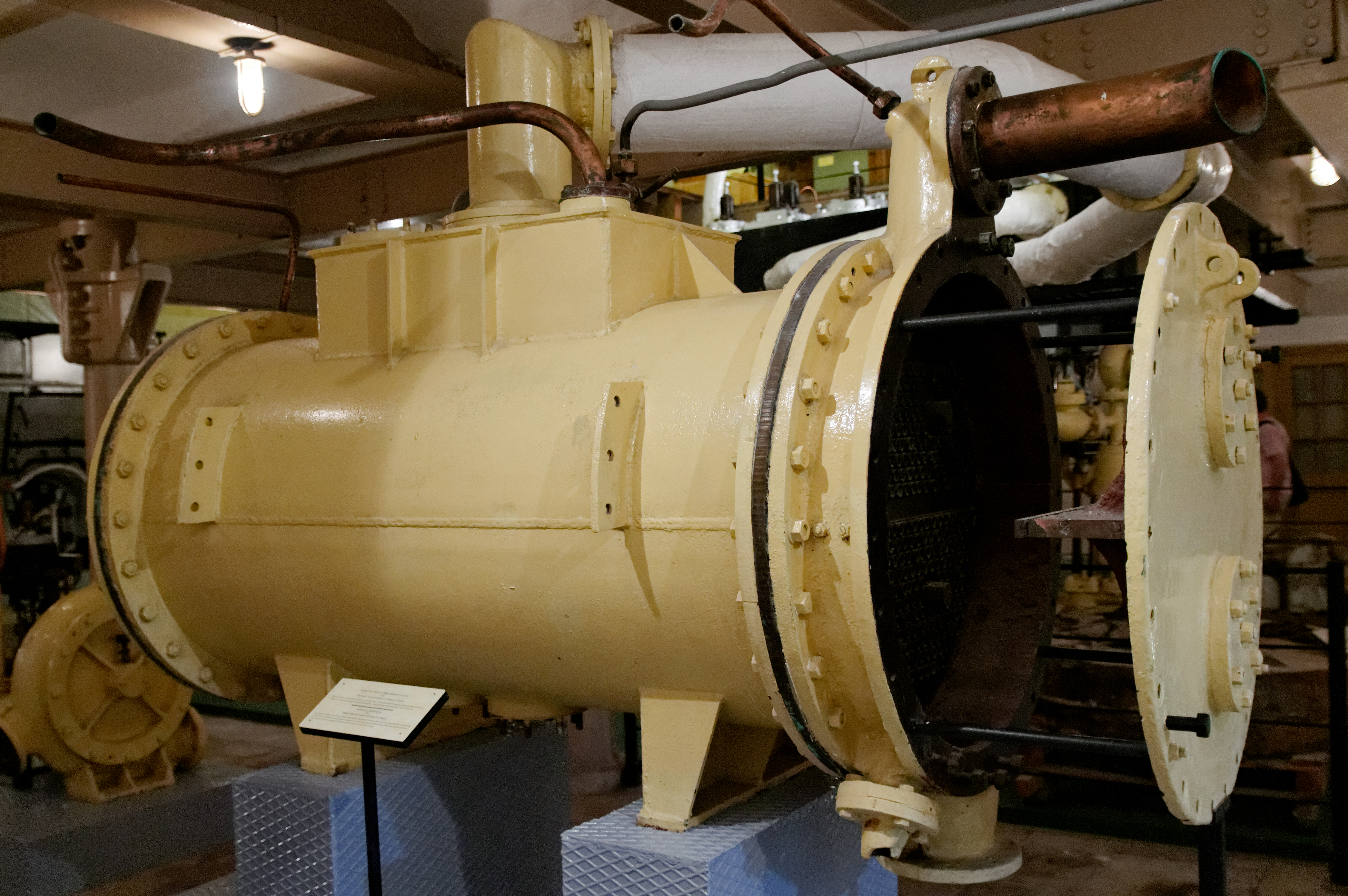

Surface Condenser

A surface condenser is a water-cooled shell and tube heat exchanger installed to condense exhaust steam from a steam turbine in thermal power stations. These condensers are heat exchangers which convert steam from its gaseous to its liquid state at a pressure below atmospheric pressure. Where cooling water is in short supply, an air-cooled condenser is often used. An air-cooled condenser is however, significantly more expensive and cannot achieve as low a steam turbine exhaust pressure (and temperature) as a water-cooled surface condenser. Surface condensers are also used in applications and industries other than the condensing of steam turbine exhaust in power plants. Purpose In thermal power plants, the purpose of a surface condenser is to condense the exhaust steam from a steam turbine to obtain maximum efficiency, and also to convert the turbine exhaust steam into pure water (referred to as steam condensate) so that it may be reused in the steam generator or boiler as boiler ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Rolls-Royce Heritage Trust

The Rolls-Royce Heritage Trust is an organisation that was founded in 1981 to preserve the history of Rolls-Royce Limited, Rolls-Royce Holdings and all merged or acquired companies. Five volunteer led branches exist, three in England, one in Scotland and a North American branch. Branches Derby and Hucknall The collection is located within the Company campus at Sinfin. The site at Osmaston Road is now permanently closed. A separate site with a smaller engine collection details the history of the Rolls-Royce Flight Test Establishment at Hucknall. Coventry and Ansty The Coventry and Ansty branch examples of Armstrong Siddeley rocket designs is kept at the Derby site. Bristol The Bristol branch engine collection is housed in the Sir Roy Fedden Heritage Centre. As well as Roy Fedden designed engines from the Bristol Aeroplane Company and products built by Bristol Siddeley a number of de Havilland and Blackburn types are displayed. Scotland The Scottish branch of the Rolls-Roy ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Rolls-Royce Goshawk

The Rolls-Royce Goshawk was a development of the Rolls-Royce Kestrel that used evaporative or steam cooling. In line with Rolls-Royce convention of naming piston engines after birds of prey, it was named after the goshawk. The engine first ran in 1933 and provided 660 horsepower (490 kW). Only a few engines were built as the aircraft designs intended to use it were not adopted by the Royal Air Force. The Goshawk was used to power the Short Knuckleduster, the Supermarine Type 224 (a predecessor to the Supermarine Spitfire) and other prototype aircraft. Design and development The Goshawk was developed from the Kestrel IV prototype engine, to use evaporative (also known as "steam") cooling. Rather than keep the cooling liquid below its boiling point in the cooling system, the coolant was allowed to boil; the phase change from liquid to vapour takes more heat from the engine, so less weight of coolant is needed. However, the radiator had to be bulkier to accommodate coola ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Aircraft Engine

An aircraft engine, often referred to as an aero engine, is the power component of an aircraft propulsion system. Most aircraft engines are either piston engines or gas turbines, although a few have been rocket powered and in recent years many small UAVs have used electric motors. Manufacturing industry In commercial aviation the major Western manufacturers of turbofan engines are Pratt & Whitney (a subsidiary of Raytheon Technologies), General Electric, Rolls-Royce, and CFM International (a joint venture of Safran Aircraft Engines and General Electric). Russian manufacturers include the United Engine Corporation, Aviadvigatel and Klimov. Aeroengine Corporation of China was formed in 2016 with the merger of several smaller companies. The largest manufacturer of turboprop engines for general aviation is Pratt & Whitney. General Electric announced in 2015 entrance into the market. Development history * 1848: John Stringfellow made a steam engine for a 10-foot wingspan mod ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Evaporative Cooling (engine)

Radiators are heat exchangers used for cooling internal combustion engines, mainly in #Automobiles and motorcycles, automobiles but also in #Aircraft, piston-engined aircraft, Diesel locomotive, railway locomotives, #Automobiles and motorcycles, motorcycles, Diesel generator, stationary generating plant or any similar use of such an engine. Internal combustion engine cooling, Internal combustion engines are often cooled by circulating a liquid called ''#Engine_coolant, engine coolant'' through the engine block, and cylinder head where it is heated, then through a radiator where it loses heat to the atmosphere, and then returned to the engine. Engine coolant is usually water-based, but may also be oil. It is common to employ a water pump to force the engine coolant to circulate, and also for an axial fan to force air through the radiator. Automobiles and motorcycles In automobiles and motorcycles with a liquid-cooled internal combustion engine, a radiator is connected to ch ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Rider-Ericsson Engine Company

The US Rider-Ericsson Engine Company was the successor of the DeLamater Iron Works and the Rider Engine Company, having bought from both companies their extensive plants and entire stocks of engines and patterns, covering all styles of Rider and Ericsson hot air pumping engines brought out by both of the old companies since 1844, excepting the original Ericsson engine, the patterns of which were burned in the DeLameter fire of 1888. Engines The company specialized in hot air pumping engines. A hot air engine is an external combustion engine. All hot air engines consist of a hot side and a cold side. Mechanical energy is derived from a hot air engine as air is repeatedly heated and cooled, expanding and contracting, and imparting pressure upon a reciprocating piston. Early hot air engines In his patent of 1759, Henry Wood was the first to document the powering an engine by the changing volume of air as it changed temperature. George Cayley was the first to build a working mode ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Hot Air Engine

A hot air engine (historically called an air engine or caloric engine) is any heat engine that uses the expansion and contraction of air under the influence of a temperature change to convert thermal energy into mechanical work. These engines may be based on a number of thermodynamic cycles encompassing both open cycle devices such as those of Sir George Cayley and John Ericsson and the closed cycle engine of Robert Stirling. Hot air engines are distinct from the better known internal combustion based engine and steam engine. In a typical implementation, air is repeatedly heated and cooled in a cylinder and the resulting expansion and contraction are used to move a piston and produce useful mechanical work. Definition The term "hot air engine" specifically excludes any engine performing a thermodynamic cycle in which the working fluid undergoes a phase transition, such as the Rankine cycle. Also excluded are conventional internal combustion engines, in which heat is added to ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Air Cooling

Air cooling is a method of dissipating heat. It works by expanding the surface area or increasing the flow of air over the object to be cooled, or both. An example of the former is to add cooling fins to the surface of the object, either by making them integral or by attaching them tightly to the object's surface (to ensure efficient heat transfer). In the case of the latter, it is done by using a fan blowing air into or onto the object one wants to cool. The addition of fins to a heat sink increases its total surface area, resulting in greater cooling effectiveness. There are two types of cooling pads that can used for air cooling: one is the honeycomb design and another one is excelsior. In all cases, the air has to be cooler than the object or surface from which it is expected to remove heat. This is due to the second law of thermodynamics, which states that heat will only move spontaneously from a hot reservoir (the heat sink) to a cold reservoir (the air). Derating at high ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Anti-freeze

An antifreeze is an additive which lowers the freezing point of a water-based liquid. An antifreeze mixture is used to achieve freezing-point depression for cold environments. Common antifreezes also increase the boiling point of the liquid, allowing higher coolant temperature. However, all common antifreeze additives also have lower heat capacities than water, and do reduce water's ability to act as a coolant when added to it. Because water has good properties as a coolant, water plus antifreeze is used in internal combustion engines and other heat transfer applications, such as HVAC chillers and solar water heaters. The purpose of antifreeze is to prevent a rigid enclosure from bursting due to expansion when water freezes. Commercially, both the ''additive'' (pure concentrate) and the ''mixture'' (diluted solution) are called antifreeze, depending on the context. Careful selection of an antifreeze can enable a wide temperature range in which the mixture remains in the liquid ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Diesel Engine

The diesel engine, named after Rudolf Diesel, is an internal combustion engine in which ignition of the fuel is caused by the elevated temperature of the air in the cylinder due to mechanical compression; thus, the diesel engine is a so-called compression-ignition engine (CI engine). This contrasts with engines using spark plug-ignition of the air-fuel mixture, such as a petrol engine (gasoline engine) or a gas engine (using a gaseous fuel like natural gas or liquefied petroleum gas). Diesel engines work by compressing only air, or air plus residual combustion gases from the exhaust (known as exhaust gas recirculation (EGR)). Air is inducted into the chamber during the intake stroke, and compressed during the compression stroke. This increases the air temperature inside the cylinder to such a high degree that atomised diesel fuel injected into the combustion chamber ignites. With the fuel being injected into the air just before combustion, the dispersion of the fuel is une ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |