|

Honyaki

Honyaki (本焼) (literally true-fired) is the name for the Japanese traditional method of metalwork construction most often seen in kitchen knives (but also other tools) by forging a blade, with a technique most similar to the tradition of nihonto, from a single piece of high-carbon steel covered with clay to yield upon quench a soft, resilient spine, a hamon (or temper line), and a hard, sharp edge. Honyaki as a term alone can refer to either ''mizu honyaki'' (water-quench) or ''abura honyaki'' (oil quench). The goal is to produce a sharper, longer lasting edge than is usually achievable with the lamination method. The term has been adapted to describe high-end mono-stainless in Japan and carbon blades by non-Japanese bladesmiths that have a hamon but are made with Western steel, heat treat, equipment, finishing (etching and polishing), and design. Traditional process Fuel and steel: Pine charcoal is cut to size for use in the fire as gentle heat for the blade before quench. ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Nihonto

A is one of several types of traditionally made swords from Japan. Bronze swords were made as early as the Yayoi period (1000 BC – 300 AD), though most people generally refer to the curved blades made from the Heian period (794 – 1185) to the present day when speaking of "Japanese swords". There are many types of Japanese swords that differ by size, shape, field of application and method of manufacture. Some of the more commonly known types of Japanese swords are the ''katana'', ''tachi'', '' odachi'', ''wakizashi'', and ''tantō''. Classification Classification by shape and usage In modern times the most commonly known type of Japanese sword is the ''Shinogi-Zukuri'' ''katana'', which is a single-edged and usually curved longsword traditionally worn by samurai from the 15th century onwards. Western historians have said that Japanese katana were among the finest cutting weapons in world military history, for their intended use. Other types of Japanese swords inclu ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

High-carbon Steel

Carbon steel is a steel with carbon content from about 0.05 up to 2.1 percent by weight. The definition of carbon steel from the American Iron and Steel Institute (AISI) states: * no minimum content is specified or required for chromium, cobalt, molybdenum, nickel, niobium, titanium, tungsten, vanadium, zirconium, or any other element to be added to obtain a desired alloying effect; * the specified minimum for copper does not exceed 0.40%; * or the maximum content specified for any of the following elements does not exceed the percentages noted: manganese 1.65%; silicon 0.60%; copper 0.60%. The term ''carbon steel'' may also be used in reference to steel which is not stainless steel; in this use carbon steel may include alloy steels. High carbon steel has many different uses such as milling machines, cutting tools (such as chisels) and high strength wires. These applications require a much finer microstructure, which improves the toughness. Carbon steel is a popular metal choic ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Quench

In materials science, quenching is the rapid cooling of a workpiece in water, oil, polymer, air, or other fluids to obtain certain material properties. A type of heat treating, quenching prevents undesired low-temperature processes, such as phase transformations, from occurring. It does this by reducing the window of time during which these undesired reactions are both thermodynamically favorable, and kinetically accessible; for instance, quenching can reduce the crystal grain size of both metallic and plastic materials, increasing their hardness. In metallurgy, quenching is most commonly used to harden steel by inducing a martensite transformation, where the steel must be rapidly cooled through its eutectoid point, the temperature at which austenite becomes unstable. In steel alloyed with metals such as nickel and manganese, the eutectoid temperature becomes much lower, but the kinetic barriers to phase transformation remain the same. This allows quenching to start at a lower ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Hamon (swordsmithing)

In swordsmithing, (from Japanese, literally "edge pattern") is a visible effect created on the blade by the hardening process. The hamon is the outline of the hardened zone (''yakiba'') which contains the cutting edge (''ha''). Blades made in this manner are known as differentially hardened, with a harder cutting edge than spine (''mune'') (for example: spine 40 HRC vs edge 58 HRC). This difference in hardness results from clay being applied on the blade (''tsuchioki'') prior to the cooling process (quenching). Less or no clay allows the edge to cool faster, making it harder but more brittle, while more clay allows the center (''hira'') and spine to cool slower, thus retaining its resilience.''A History of Metallography'' By Cyril Stanley Smith -- MIT Press 1968 Page 40--57 Introduction The hamon of a blade is created during the quenching process (''yakiire''). During the differential heat treatment, the clay coating on the back of the sword reduces the cooling speed of the ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Eutectoid

A eutectic system or eutectic mixture ( ) is a homogeneous mixture that has a melting point lower than those of the constituents. The lowest possible melting point over all of the mixing ratios of the constituents is called the ''eutectic temperature''. On a phase diagram, the eutectic temperature is seen as the eutectic point (see plot on the right). Non-eutectic mixture ratios would have different melting temperatures for their different constituents, since one component's lattice will melt at a lower temperature than the other's. Conversely, as a non-eutectic mixture cools down, each of its components would solidify (form a lattice) at a different temperature, until the entire mass is solid. Not all binary alloys have eutectic points, since the valence electrons of the component species are not always compatible, in any mixing ratio, to form a new type of joint crystal lattice. For example, in the silver-gold system the melt temperature (liquidus) and freeze temperature ( ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Laminated

Lamination is the technique/process of manufacturing a Raw material, material in multiple layers, so that the composite material achieves improved strength of materials, strength, stability, sound insulation, visual appearance, appearance, or other properties from the use of the differing materials, such as plastic. A laminate is a permanently assembled object created using thermal energy, heat, pressure, welding, or adhesives. Various coating machines, machine presses and calendering equipment are used. Materials There are different lamination processes, depending primarily on the type or types of materials to be laminated. The materials used in laminates can be identical or different, depending on the process and the object to be laminated. Textile Laminated fabric are widely used in different fields of human activity, including medical and military. Woven fabrics (organic and inorganic based) are usually laminated by different chemical polymers to give them useful proper ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Sakai, Osaka

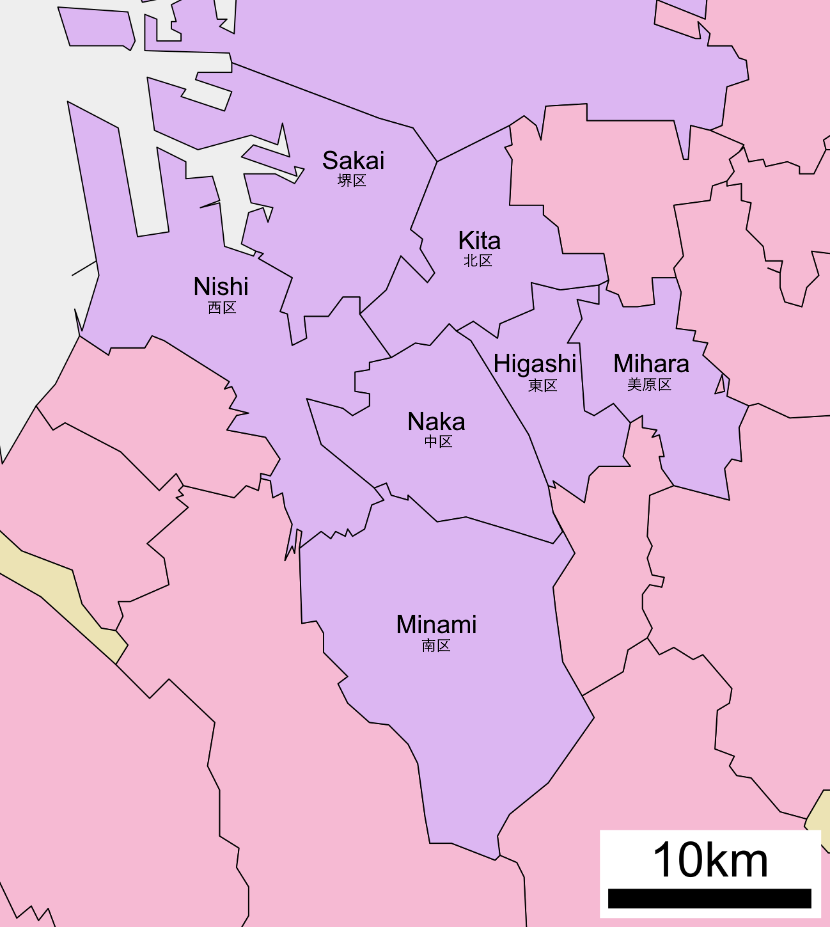

is a city located in Osaka Prefecture, Japan. It has been one of the largest and most important seaports of Japan since the medieval era. Sakai is known for its keyhole-shaped burial mounds, or kofun, which date from the fifth century and include Daisen Kofun, the largest grave in the world by area. Once known for swords, Sakai is now famous for the quality of its cutlery. , the city had an estimated population of 819,965, making it the fourteenth most populous city in Japan (excluding Tokyo). Geography Sakai is located in southern Osaka Prefecture, on the edge of Osaka Bay and directly south of the city of Osaka. Neighboring municipalities Osaka Prefecture *Osaka * Matsubara *Habikino *Ōsakasayama *Kawachinagano * Izumi * Takaishi Climate Sakai has a Humid subtropical climate (Köppen ''Cfa'') characterized by warm summers and cool winters with light to no snowfall. The average annual temperature in Sakai is . The average annual rainfall is with June as the wettest month ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |