|

History Of Ferrous Metallurgy

Ferrous metallurgy is the metallurgy of iron and its alloys. The earliest surviving prehistoric iron artifacts, from the 4th millennium BC in Egypt, were made from meteoritic iron-nickel. It is not known when or where the smelting of iron from ores began, but by the end of the 2nd millennium BC iron was being produced from iron ores in the region from Greece to India,Riederer, Josef; Wartke, Ralf-B.: "Iron", Cancik, Hubert; Schneider, Helmuth (eds.): Brill's New Pauly, Brill 2009Early Antiquity By I.M. Drakonoff. 1991. University of Chicago Press. . p. 372 and Sub-Saharan Africa. The use of wrought iron (worked iron) was known by the 1st millennium BC, and its spread defined the Iron Age. During the medieval period, smiths in Europe found a way of producing wrought iron from cast iron (in this context known as pig iron) using finery forges. All these processes required charcoal as fuel. By the 4th century BC southern India had started exporting Wootz steel (with a carbon c ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Bas Fourneau

{{disambiguation ...

Bas may refer to: People * Bas (name), a given name and a surname * Bas (rapper) (born 1987) Chemistry * Boron arsenide (BAs), a chemical compound * Barium sulfide (BAs), a chemical compound Other uses * ''bas'' (French for "low"), as in bas-relief sculpture * Tamburica, a stringed instrument sometimes known as bas * BAS (accounting), the Swedish accounting principles and chart of accounts See also * * BAS (other) * Bass (other) Bass or Basses may refer to: Fish * Bass (fish), various saltwater and freshwater species Music * Bass (sound), describing low-frequency sound or one of several instruments in the bass range: ** Bass (instrument), including: ** Acoustic bass ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

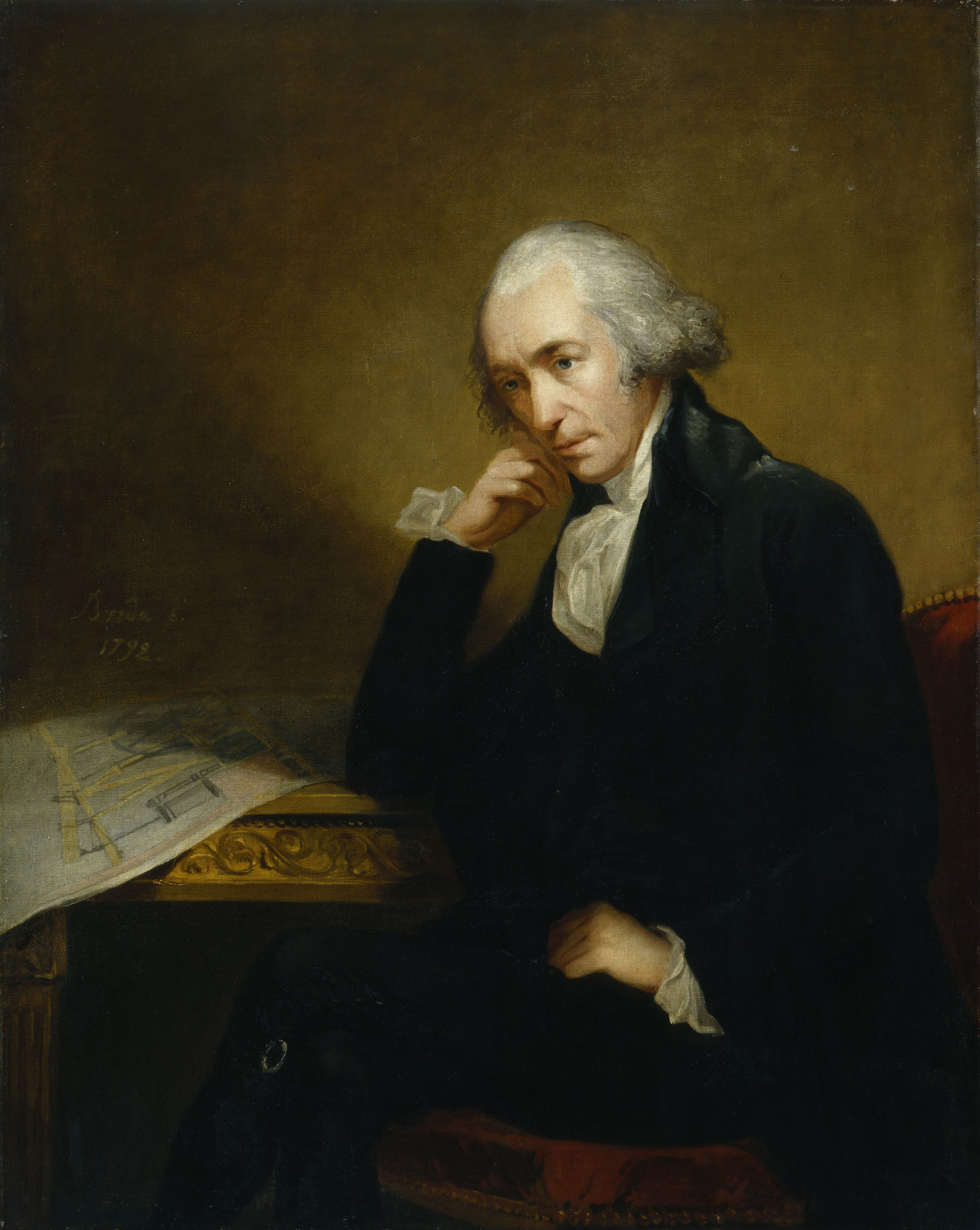

Finery Forge

A finery forge is a forge used to produce wrought iron from pig iron by decarburization in a process called "fining" which involved liquifying cast iron in a fining hearth and removing carbon from the molten cast iron through oxidation. Finery forges were used as early as the 3rd century BC in China. The finery forge process was replaced by the puddling process and the roller mill, both developed by Henry Cort in 1783–4, but not becoming widespread until after 1800. History A finery forge was used to refine wrought iron at least by the 3rd century BC in ancient China, based on the earliest archaeological specimens of cast and pig iron fined into wrought iron and steel found at the early Han Dynasty (202 BC – 220 AD) site at Tieshengguo.Pigott, Vincent C. (1999). ''The Archaeometallurgy of the Asian Old World''. Philadelphia: University of Pennsylvania Museum of Archaeology and Anthropology. , p. 186-187. Pigott speculates that the finery forge existed in the prev ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Norrbotten County

Norrbotten County ( sv, Norrbottens län; se, Norrbottena leatna, fi, Norrbottenin lääni) is the northernmost county or '' län'' of Sweden. It is also the largest county by land area, almost a quarter of Sweden's total area. It shares borders with Västerbotten County to the southwest, the Gulf of Bothnia to the southeast, the counties of Nordland and Troms og Finnmark in Norway to the northwest, and Lapland Province in Finland to the northeast. The name "Norrbotten" is also used for a province of the same name. Norrbotten province covers only the eastern part of Norrbotten County – the inland mostly belongs to the Swedish Lapland province (''Lappland''). The capital of Norrbotten is Luleå, whereas other significant towns include Boden, Kiruna and Piteå. The majority of the population lives in the namesake province, whereas the Lapland part of the county is sparsely populated. The northern part of Norrbotten lies within the Arctic Circle. Provinces ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Kiruna

(; se, Giron ; fi, Kiiruna ) is the northernmost city in Sweden, situated in the province of Lapland. It had 17,002 inhabitants in 2016 and is the seat of Kiruna Municipality (population: 23,167 in 2016) in Norrbotten County. The city was originally built in the 1890s to serve the Kiruna Mine. The Esrange Space Center was established in Kiruna in the 1960s. Also in Kiruna are the Institute of Space Physics and Luleå University of Technology's Department of Space Science. History Origins Archaeological findings have shown that the region around Kiruna has been inhabited for at least 6,000 years. Centuries before Kiruna was founded in 1900, the presence of iron ore at Kiirunavaara and Luossavaara had been known by the local Sami population. In 1696, Samuel Mört, a bookkeeper of the Kengis works, wrote on rumours about the presence of iron in the two hills.Kummu 1997, p. 96. The ore became better known after it was reported by Mangi, a Sami man, in 1736 to Swedish ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Bessemer Process

The Bessemer process was the first inexpensive industrial process for the mass production of steel from molten pig iron before the development of the open hearth furnace. The key principle is removal of impurities from the iron by oxidation with air being blown through the molten iron. The oxidation also raises the temperature of the iron mass and keeps it molten. Related decarburizing with air processes had been used outside Europe for hundreds of years, but not on an industrial scale. One such process (similar to puddling) was known in the 11th century in East Asia, where the scholar Shen Kuo of that era described its use in the Chinese iron and steel industry. In the 17th century, accounts by European travelers detailed its possible use by the Japanese. The modern process is named after its inventor, the Englishman Henry Bessemer, who took out a patent on the process in 1856. The process was said to be independently discovered in 1851 by the American inventor William K ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Henry Bessemer

Sir Henry Bessemer (19 January 1813 – 15 March 1898) was an English inventor, whose steel-making process would become the most important technique for making steel in the nineteenth century for almost one hundred years from 1856 to 1950. He also played a significant role in establishing the town of Sheffield, nicknamed ‘Steel City’, as a major industrial centre. Bessemer had been trying to reduce the cost of steel-making for military ordnance, and developed his system for blowing air through molten pig iron to remove the impurities. This made steel easier, quicker and cheaper to manufacture, and revolutionised structural engineering. One of the most significant inventors of the Second Industrial Revolution, Bessemer also made over 100 other inventions in the fields of iron, steel and glass. Unlike many inventors, he managed to bring his own projects to fruition and profited financially from their success. He was knighted for his contribution to science in 1879, and in t ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Steel

Steel is an alloy made up of iron with added carbon to improve its strength and fracture resistance compared to other forms of iron. Many other elements may be present or added. Stainless steels that are corrosion- and oxidation-resistant typically need an additional 11% chromium. Because of its high tensile strength and low cost, steel is used in buildings, infrastructure, tools, ships, trains, cars, machines, electrical appliances, weapons, and rockets. Iron is the base metal of steel. Depending on the temperature, it can take two crystalline forms (allotropic forms): body-centred cubic and face-centred cubic. The interaction of the allotropes of iron with the alloying elements, primarily carbon, gives steel and cast iron their range of unique properties. In pure iron, the crystal structure has relatively little resistance to the iron atoms slipping past one another, and so pure iron is quite ductile, or soft and easily formed. In steel, small amounts of carb ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Coke (fuel)

Coke is a grey, hard, and porous coal-based fuel with a high carbon content and few impurities, made by heating coal or oil in the absence of air—a destructive distillation process. It is an important industrial product, used mainly in iron ore smelting, but also as a fuel in stoves and forges when air pollution is a concern. The unqualified term "coke" usually refers to the product derived from low-ash and low-sulphur bituminous coal by a process called coking. A similar product called petroleum coke, or pet coke, is obtained from crude oil in oil refineries. Coke may also be formed naturally by geologic processes.B. Kwiecińska and H. I. Petersen (2004): "Graphite, semi-graphite, natural coke, and natural char classification — ICCP system". ''International Journal of Coal Geology'', volume 57, issue 2, pages 99-116. History China Historical sources dating to the 4th century describe the production of coke in ancient China. The Chinese first used coke for heating and co ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Bar Iron

Wrought iron is an iron alloy with a very low carbon content (less than 0.08%) in contrast to that of cast iron (2.1% to 4%). It is a semi-fused mass of iron with fibrous slag inclusions (up to 2% by weight), which give it a wood-like "grain" that is visible when it is etched, rusted, or bent to failure. Wrought iron is tough, malleable, ductile, corrosion resistant, and easily forge welded, but is more difficult to weld electrically. Before the development of effective methods of steelmaking and the availability of large quantities of steel, wrought iron was the most common form of malleable iron. It was given the name ''wrought'' because it was hammered, rolled, or otherwise worked while hot enough to expel molten slag. The modern functional equivalent of wrought iron is mild steel, also called low-carbon steel. Neither wrought iron nor mild steel contain enough carbon to be hardenable by heating and quenching. Wrought iron is highly refined, with a small amount of s ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Industrial Revolution

The Industrial Revolution was the transition to new manufacturing processes in Great Britain, continental Europe, and the United States, that occurred during the period from around 1760 to about 1820–1840. This transition included going from hand production methods to machines, new chemical manufacturing and iron production processes, the increasing use of steam power and water power, the development of machine tools and the rise of the mechanized factory system. Output greatly increased, and a result was an unprecedented rise in population and in the rate of population growth. Textiles were the dominant industry of the Industrial Revolution in terms of employment, value of output and capital invested. The textile industry was also the first to use modern production methods. The Industrial Revolution began in Great Britain, and many of the technological and architectural innovations were of British origin. By the mid-18th century, Britain was the world's leadin ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Cementation Process

The cementation process is an obsolete technology for making steel by carburization of iron. Unlike modern steelmaking, it increased the amount of carbon in the iron. It was apparently developed before the 17th century. Derwentcote Steel Furnace, built in 1720, is the earliest surviving example of a cementation furnace. Another example in the UK is the cementation furnace in Doncaster Street, Sheffield. Origins The process was described in a treatise published in Prague in 1574. It was again invented by Johann Nussbaum of Magdeburg, who began operations at Nuremberg (with partners) in 1601. The process was patented in England by William Ellyot and Mathias Meysey in 1614. At that date, the "invention" could consist merely of the introduction of a new industry or product, or even a mere monopoly. They evidently soon transferred the patent to Sir Basil Brooke, but he was forced to surrender it in 1619. A clause in the patent prohibiting the import of steel was foun ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Carburizing

Carburising, carburizing (chiefly American English), or carburisation is a heat treatment process in which iron or steel absorbs carbon while the metal is heated in the presence of a carbon-bearing material, such as charcoal or carbon monoxide. The intent is to make the metal harder. Depending on the amount of time and temperature, the affected area can vary in carbon content. Longer carburizing times and higher temperatures typically increase the depth of carbon diffusion. When the iron or steel is cooled rapidly by quenching, the higher carbon content on the outer surface becomes hard due to the transformation from austenite to martensite, while the core remains soft and tough as a ferritic and/or pearlite microstructure.Oberg, E., Jones, F., and Ryffel, H. (1989) ''Machinery's Handbook 23rd Edition.'' New York: Industrial Press Inc. This manufacturing process can be characterized by the following key points: It is applied to low-carbon workpieces; workpieces are in con ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |