|

Hall–Petch

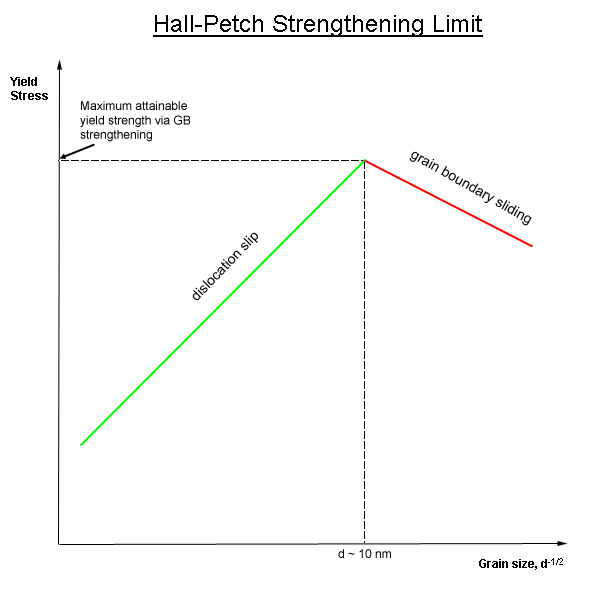

In materials science, grain-boundary strengthening (or Hall–Petch strengthening) is a method of strengthening materials by changing their average crystallite (grain) size. It is based on the observation that grain boundaries are insurmountable borders for dislocations and that the number of dislocations within a grain has an effect on how stress builds up in the adjacent grain, which will eventually activate dislocation sources and thus enabling deformation in the neighbouring grain as well. So, by changing grain size, one can influence the number of dislocations piled up at the grain boundary and yield strength. For example, heat treatment after plastic deformation and changing the rate of solidification are ways to alter grain size.W.D. Callister. Fundamentals of Materials Science and Engineering, 2nd ed. Wiley & Sons. pp. 252. Theory In grain-boundary strengthening, the grain boundaries act as pinning points impeding further dislocation propagation. Since the latti ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Grain Refinement

In materials science, grain-boundary strengthening (or Hall–Petch strengthening) is a method of strengthening materials by changing their average crystallite (grain) size. It is based on the observation that grain boundaries are insurmountable borders for dislocations and that the number of dislocations within a grain has an effect on how stress builds up in the adjacent grain, which will eventually activate dislocation sources and thus enabling deformation in the neighbouring grain as well. So, by changing grain size, one can influence the number of dislocations piled up at the grain boundary and yield strength. For example, heat treatment after plastic deformation and changing the rate of solidification are ways to alter grain size.W.D. Callister. Fundamentals of Materials Science and Engineering, 2nd ed. Wiley & Sons. pp. 252. Theory In grain-boundary strengthening, the grain boundaries act as pinning points impeding further dislocation propagation. Since the lattice str ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Grain Boundary

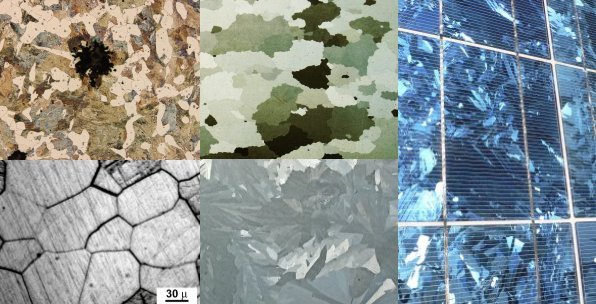

In materials science, a grain boundary is the interface between two grains, or crystallites, in a polycrystalline material. Grain boundaries are two-dimensional defects in the crystal structure, and tend to decrease the electrical and thermal conductivity of the material. Most grain boundaries are preferred sites for the onset of corrosion and for the precipitation of new phases from the solid. They are also important to many of the mechanisms of creep. On the other hand, grain boundaries disrupt the motion of dislocations through a material, so reducing crystallite size is a common way to improve mechanical strength, as described by the Hall–Petch relationship. High and low angle boundaries It is convenient to categorize grain boundaries according to the extent of misorientation between the two grains. ''Low-angle grain boundaries'' (''LAGB'') or ''subgrain boundaries'' are those with a misorientation less than about 15 degrees. Generally speaking they are composed o ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Crystallite

A crystallite is a small or even microscopic crystal which forms, for example, during the cooling of many materials. Crystallites are also referred to as grains. Bacillite is a type of crystallite. It is rodlike with parallel longulites. Structure The orientation of crystallites can be random with no preferred direction, called random texture, or directed, possibly due to growth and processing conditions. While the structure of a ( single) crystal is highly ordered and its lattice is continuous and unbroken, amorphous materials, such as glass and many polymers, are non-crystalline and do not display any structures, as their constituents are not arranged in an ordered manner. Polycrystalline structures and paracrystalline phases are in-between these two extremes. Polycrystalline materials, or polycrystals, are solids that are composed of many crystallites of varying size and orientation. Most materials are polycrystalline, made of a large number crystallites held together by ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Grain Boundaries

In materials science, a grain boundary is the interface between two grains, or crystallites, in a polycrystalline material. Grain boundaries are two-dimensional defects in the crystal structure, and tend to decrease the electrical and thermal conductivity of the material. Most grain boundaries are preferred sites for the onset of corrosion and for the precipitation of new phases from the solid. They are also important to many of the mechanisms of creep. On the other hand, grain boundaries disrupt the motion of dislocations through a material, so reducing crystallite size is a common way to improve mechanical strength, as described by the Hall–Petch relationship. High and low angle boundaries It is convenient to categorize grain boundaries according to the extent of misorientation between the two grains. ''Low-angle grain boundaries'' (''LAGB'') or ''subgrain boundaries'' are those with a misorientation less than about 15 degrees. Generally speaking they are composed of ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Abnormal Grain Growth

Abnormal or discontinuous grain growth, also referred to as exaggerated or secondary recrystallisation grain growth, is a grain growth phenomenon through which certain energetically favorable grains (crystallites) grow rapidly in a matrix of finer grains resulting in a bimodal grain size distribution. In ceramic materials this phenomenon can result in the formation of elongated prismatic, acicular (needle-like) grains in a densified matrix with implications for improved fracture toughness through the impedance of crack propagation. Mechanisms Abnormal grain growth (AGG) is encountered in metallic or ceramic systems exhibiting one or more of several characteristics. # Secondary phase inclusions, precipitates or impurities above a certain threshold concentration. # High anisotropy in interfacial energy (solid-liquid))or grain boundary energy (solid-solid) in bulk materials. # Highly anisotropic surface energy in thin film materials. # High chemical inequilibrium. Although ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Proceedings Of The Physical Society

The ''Proceedings of the Physical Society'' was a journal on the subject of physics, originally associated with the Physical Society of London, England. In 1968, it was replaced by the '' Journal of Physics''. Journal history * 1874–1925: ''Proceedings of the Physical Society of London'' * 1926–1948: ''Proceedings of the Physical Society'' * 1949–1957: ''Proceedings of the Physical Society, Section A'' * 1949–1957: ''Proceedings of the Physical Society, Section B'' * 1958–1967: ''Proceedings of the Physical Society'' External links Electronic accessfrom the Institute of Physics The Institute of Physics (IOP) is a UK-based learned society and professional body that works to advance physics education, research and application. It was founded in 1874 and has a worldwide membership of over 20,000. The IOP is the Physica ... (IoP) Physics journals IOP Publishing academic journals Academic journals associated with learned and professiona ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Mild Steel

Carbon steel is a steel with carbon content from about 0.05 up to 2.1 percent by weight. The definition of carbon steel from the American Iron and Steel Institute (AISI) states: * no minimum content is specified or required for chromium, cobalt, molybdenum, nickel, niobium, titanium, tungsten, vanadium, zirconium, or any other element to be added to obtain a desired alloying effect; * the specified minimum for copper does not exceed 0.40%; * or the maximum content specified for any of the following elements does not exceed the percentages noted: manganese 1.65%; silicon 0.60%; copper 0.60%. The term ''carbon steel'' may also be used in reference to steel which is not stainless steel; in this use carbon steel may include alloy steels. High carbon steel has many different uses such as milling machines, cutting tools (such as chisels) and high strength wires. These applications require a much finer microstructure, which improves the toughness. Carbon steel is a popular metal cho ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

University Of Leeds

, mottoeng = And knowledge will be increased , established = 1831 – Leeds School of Medicine1874 – Yorkshire College of Science1884 - Yorkshire College1887 – affiliated to the federal Victoria University1904 – University of Leeds , type = Public , endowment = £90.5 million , budget = £751.7 million , chancellor = Jane Francis , vice_chancellor = Simone Buitendijk , students = () , undergrad = () , postgrad = () , city = Leeds , province = West Yorkshire , country = England , campus = Urban, suburban , free_label = Newspaper , free = The Gryphon , colours = , website www.leeds.ac.uk, logo = Leeds University logo.svg , logo_size = 250 , administrative_staff = 9,200 , coor = , affiliations = The University of Leeds is a public research university in Leeds, West Yorkshire, England. It was established in 1874 as the Yorkshire College of Science. In 1884 it merged with the Leeds School of Medicine (established 1831) and was rena ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Allotropes Of Iron

At atmospheric pressure, three allotropic forms of iron exist, depending on temperature: alpha iron (α-Fe), gamma iron (γ-Fe), and delta iron (δ-Fe). At very high pressure, a fourth form exists, called epsilon iron (ε-Fe). Some controversial experimental evidence suggests the existence of a fifth high-pressure form that is stable at very high pressures and temperatures. The phases of iron at atmospheric pressure are important because of the differences in solubility of carbon, forming different types of steel. The high-pressure phases of iron are important as models for the solid parts of planetary cores. The inner core of the Earth is generally assumed to consist essentially of a crystalline iron-nickel alloy with ε structure. The outer core surrounding the solid inner core is believed to be composed of liquid iron mixed with nickel and trace amounts of lighter elements. Standard pressure allotropes Alpha iron (α-Fe) Below 912 °C (1,674 °F), iron has a b ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

England

England is a country that is part of the United Kingdom. It shares land borders with Wales to its west and Scotland to its north. The Irish Sea lies northwest and the Celtic Sea to the southwest. It is separated from continental Europe by the North Sea to the east and the English Channel to the south. The country covers five-eighths of the island of Great Britain, which lies in the North Atlantic, and includes over 100 smaller islands, such as the Isles of Scilly and the Isle of Wight. The area now called England was first inhabited by modern humans during the Upper Paleolithic period, but takes its name from the Angles, a Germanic tribe deriving its name from the Anglia peninsula, who settled during the 5th and 6th centuries. England became a unified state in the 10th century and has had a significant cultural and legal impact on the wider world since the Age of Discovery, which began during the 15th century. The English language, the Anglican Church, and Eng ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Brittle Fracture

Fracture is the separation of an object or material into two or more pieces under the action of stress. The fracture of a solid usually occurs due to the development of certain displacement discontinuity surfaces within the solid. If a displacement develops perpendicular to the surface, it is called a normal tensile crack or simply a crack; if a displacement develops tangentially, it is called a shear crack, slip band or dislocation. Brittle fractures occur with no apparent deformation before fracture. Ductile fractures occur after visible deformation. Fracture strength, or breaking strength, is the stress when a specimen fails or fractures. The detailed understanding of how a fracture occurs and develops in materials is the object of fracture mechanics. Strength Fracture strength, also known as breaking strength, is the stress at which a specimen fails via fracture. This is usually determined for a given specimen by a tensile test, which charts the stress–strain c ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |