|

Grinding (abrasive Cutting)

Grinding is a type of abrasive machining process which uses a grinding wheel as cutting tool. A wide variety of machines are used for grinding, best classified as portable or stationary: * Portable power tools such as angle grinders, die grinders and cut-off saws * Stationary power tools such as bench grinders and cut-off saws * Stationary hydro- or hand-powered sharpening stones Milling practice is a large and diverse area of manufacturing and toolmaking. It can produce very fine finishes and very accurate dimensions; yet in mass production contexts, it can also rough out large volumes of metal quite rapidly. It is usually better suited to the machining of very hard materials than is "regular" machining (that is, cutting larger chips with cutting tools such as tool bits or milling cutters), and until recent decades it was the only practical way to machine such materials as hardened steels. Compared to "regular" machining, it is usually better suited to taking very ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Thousandth Of An Inch

A thousandth of an inch is a derived unit of length in a system of units using inches. Equal to of an inch, a thousandth is commonly called a thou (used for both singular and plural) or particularly in North America a mil (plural mils). The words are shortened forms of the English and Latin words for "thousand" ( in Latin). In international engineering contexts, confusion can arise because ''mil'' is a formal unit name in North America but ''mil'' or ''mill'' is also a common colloquial clipped form of millimetre. The units are considerably different: a millimetre is approximately 39 mils. Contexts of use The thou, or mil, is most commonly used in engineering and manufacturing in non-metric countries. For example, in specifying: * The thickness of items such as paper, film, foil, wires, paint coatings, latex gloves, plastic sheeting, and fibers ** For example, most plastic ID cards are about in thickness. ** Card stock thickness in the United States, where mils are also ca ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

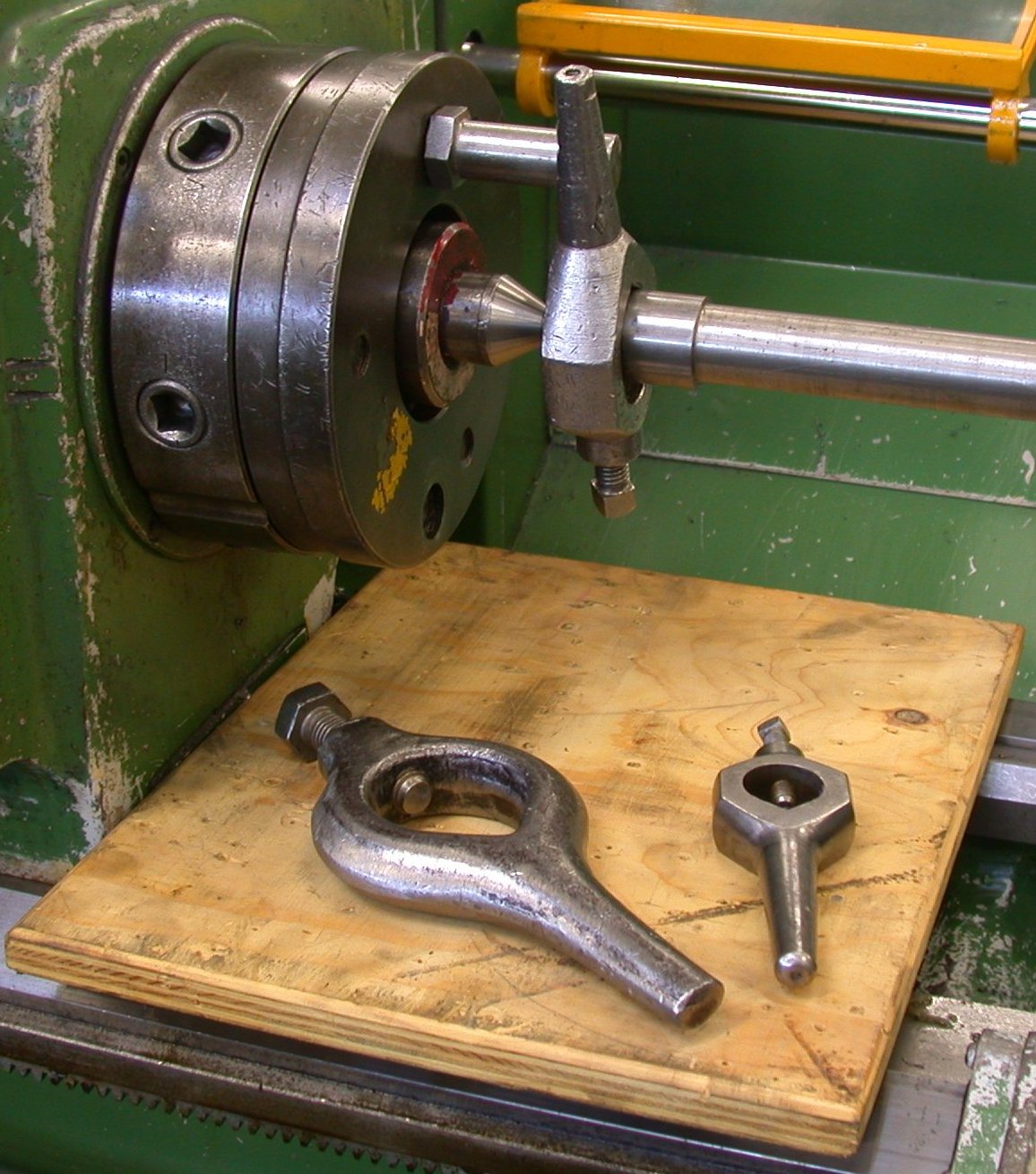

Chuck (engineering)

A chuck is a specialized type of clamp used to hold an object with radial symmetry, especially a cylinder. In a drill, a mill and a transmission, a chuck holds the rotating tool; in a lathe, it holds the rotating workpiece. Chucks commonly use jaws to hold the tool or workpiece. The jaws (sometimes called dogs) are typically arranged in a radially symmetrical pattern like the points of a star. Jawed chucks may require a wrench-like device called a ''chuck key'' to be tightened or loosened, but other jawed chucks may be tightened or loosened by hand force alone, offering convenience at the expense of gripping force. Chucks on some lathes have jaws that move independently, allowing them to hold irregularly shaped objects. More complex designs might include specially shaped jaws, greater numbers of jaws, or quick-release mechanisms. Instead of jaws, a chuck may use magnetism, vacuum, or collets, which are flexible collars or sleeves that fit closely around the tool or workpiece ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

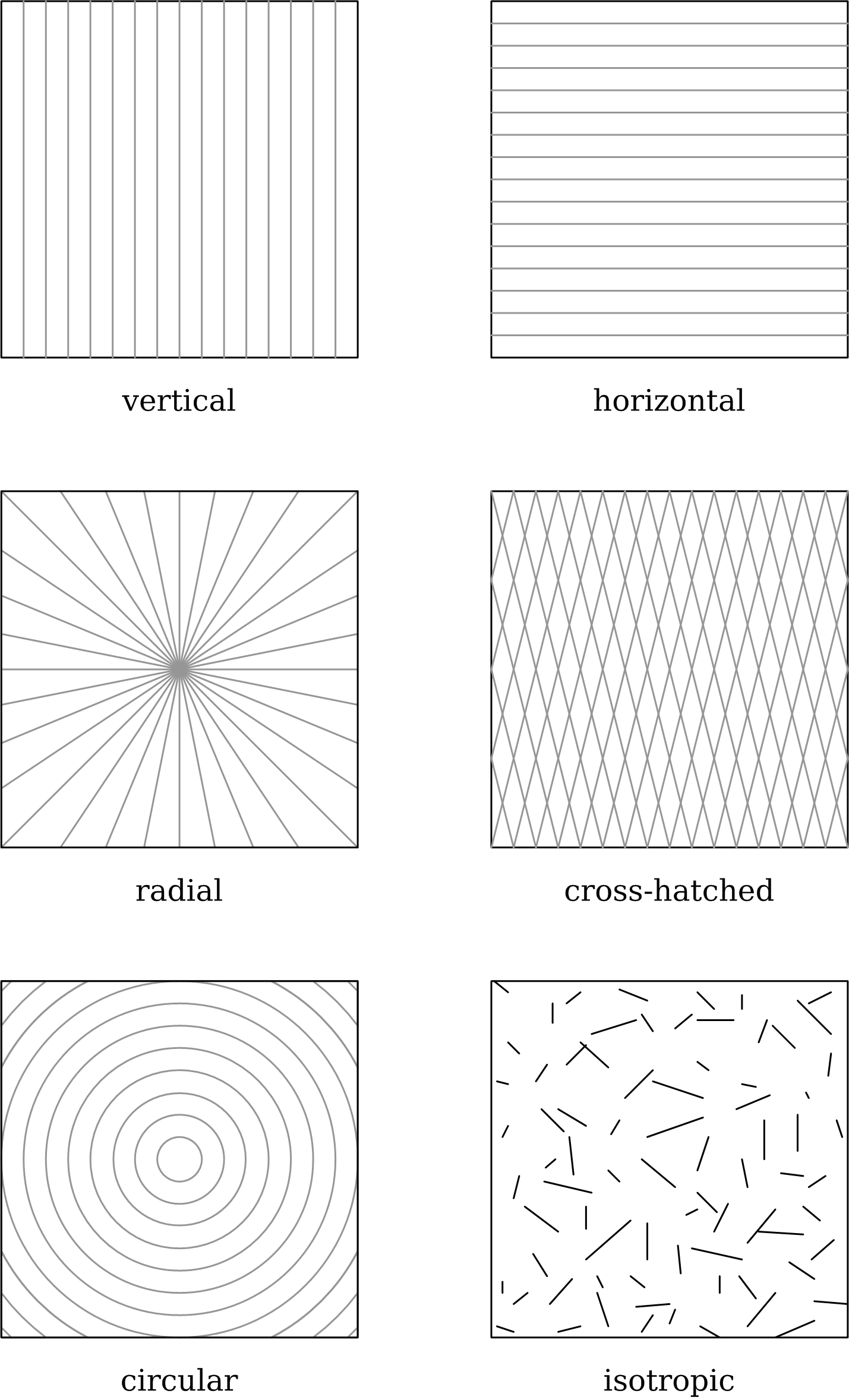

Surface Finish

Surface finish, also known as surface texture or surface topography, is the nature of a surface as defined by the three characteristics of lay, surface roughness, and waviness.. It comprises the small, local deviations of a surface from the perfectly flat ideal (a true plane). Surface texture is one of the important factors that control friction and transfer layer formation during sliding. Considerable efforts have been made to study the influence of surface texture on friction and wear during sliding conditions. Surface textures can be isotropic or anisotropic. Sometimes, stick-slip friction phenomena can be observed during sliding, depending on surface texture. Each manufacturing process (such as the many kinds of machining) produces a surface texture. The process is usually optimized to ensure that the resulting texture is usable. If necessary, an additional process will be added to modify the initial texture. The latter process may be grinding (abrasive cutting), polis ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Cylindrical Grinder

The cylindrical grinder is a type of grinding machine used to shape the outside of an object. The cylindrical grinder can work on a variety of shapes, however the object must have a central axis of rotation. This includes but is not limited to such shapes as a cylinder, an ellipse, a cam, or a crankshaft.Lewis, Kenneth. ''The Grinding Wheel''. 2nd. Cleveland: Judson Company, 1959. 104-141. Cylindrical grinding is defined as having four essential actions: #The work (object) must be constantly rotating #The grinding wheel must be constantly rotating #The grinding wheel is fed towards and away from the work #Either the work or the grinding wheel is transversed with respect to the other. While the majority of cylindrical grinders employ all four movements, there are grinders that only employ three of the four actions. History The origins of the cylindrical grinder, as with all other modern machine tools, stem from the experimentation and invention of John Wilkinson and later Henry ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Lathe Dog

A lathe dog is a mechanical device typically made of cast iron, steel or aluminum that transmits rotary motion from a faceplate to a workpiece mounted between centers in a lathe. The tail of the dog is rotated by a slot in a driving faceplate, a stud mounted on a faceplate, or sometimes a side of a chuck jaw. The workpiece passes through an aperture in the dog into which the work is secured by one or more setscrews or a clamp arrangement. The maximum cross sectional dimension of the workpiece is limited by the dimensions of the dog aperture. Lathe dogs are provided in ''straight tail'' or ''bent tail'' form, and may be ''single tail'' or ''double tail''. A lathe dog designed to hold square, rectangular or odd-shaped work and having a moveable portion secured typically by two cap screws is called a ''clamp dog''. Bent tail dogs are able to engage directly with a driving faceplate slot or a chuck jaw but can crowd work off centre if clearance is not present between the dog tail and ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Lathe Center

A lathe center, often shortened to center, is a tool that has been ground to a point to accurately position a workpiece on an axis. They usually have an included angle of 60°, but in heavy machining situations an angle of 75° is used. The primary use of a center is to ensure concentric work is produced; this allows the workpiece to be transferred between machining (or inspection) operations without any loss of accuracy. A part may be ''turned'' in a lathe, sent off for hardening and tempering and then ground ''between centers'' in a cylindrical grinder. The preservation of concentricity between the turning and grinding operations is crucial for quality work. When turning between centres, a steady can be used to support longer workpieces where the cutting forces would deflect the work excessively, reducing the finish and accuracy of the workpiece, or creating a hazardous situation. A center lathe has applications anywhere that a ''centered'' workpiece may be used; this is not ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Machinists Grinding Workpieces On A Bench Grinder

A machinist is a tradesperson or trained professional who not only operates machine tools, but also has the knowledge of tooling and materials required to create set ups on machine tools such as milling machines, grinders, lathes, and drilling machines. A competent machinist should have a well-developed mechanical aptitude, the ability to correctly use precision measuring instruments, and a working knowledge of the proper speeds and feeds required for successfully utilizing the various work and tool materials commonly used in most machining operations. Nature of work Mass-produced parts of machines are more common today, but still require machinists and millwrights to calibrate and install machine parts to manufacture other parts. In many parts of the economy, however, custom-made parts are required for various uses. A machinist may work on manufacturing something simple like a motorcycle frame part, a piece of an internal combustion motor, or something extraordinarily complex, ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Erwin Junker

Erwin Junker (*April 15, 1930, Nordrach, Black Forest, Germany) is a German manufacturer. He is the owner and founder of the Junker Group. Life and education Erwin Junker was born in 1930 in the Black Forest town of Nordrach, near Offenburg, Germany, to saw mill owners Zäzilia and Ludwig Junker as the oldest of five children. After attending the elementary school in the Kolonie district, he worked for his parents’ company for three years. However, instead of taking over his parents’ business, as was the tradition, Erwin Junker opted for a career in mechanical engineering. In 1947, he started an apprenticeship with the Haas Company. After a year he switched to the Company Prototyp in Zell am Harmersbach, where he was working from 1948 to 1962. Starting out as an apprentice, he worked his way up to becoming an assistant mechanical engineer before continuing his education to receive his master craftsman degree. Subsequently, he moved to the mechanical engineering department, ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Second

The second (symbol: s) is the unit of time in the International System of Units (SI), historically defined as of a day – this factor derived from the division of the day first into 24 hours, then to 60 minutes and finally to 60 seconds each (24 × 60 × 60 = 86400). The current and formal definition in the International System of Units ( SI) is more precise:The second ..is defined by taking the fixed numerical value of the caesium frequency, Δ''ν''Cs, the unperturbed ground-state hyperfine transition frequency of the caesium 133 atom, to be when expressed in the unit Hz, which is equal to s−1. This current definition was adopted in 1967 when it became feasible to define the second based on fundamental properties of nature with caesium clocks. Because the speed of Earth's rotation varies and is slowing ever so slightly, a leap second is added at irregular intervals to civil time to keep clocks in sync with Earth's rotation. Uses Analog clocks and watches often ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Sandpaper

upright=1.35, Sheets of sandpaper with different grit sizes (40 (coarse), 80, 150, 240, 600 (fine)). Sandpaper and glasspaper are names used for a type of coated abrasive that consists of sheets of paper or cloth with abrasive material glued to one face. There are many varieties of sandpaper, with variations in the paper or backing, the material used for the grit, grit size, and the bond. In the modern manufacture of these products, sand and glass have been replaced by other abrasives such as aluminium oxide or silicon carbide. It is common to use the name of the abrasive when describing the paper, e.g. "aluminium oxide paper", or "silicon carbide paper". Sandpaper is produced in a range of grit sizes and is used to remove material from surfaces, whether to make them smoother (for example, in painting and wood finishing), to remove a layer of material (such as old paint), or sometimes to make the surface rougher (for example, as a preparation for gluing). The grit size of san ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

.jpg)