|

Full-mold Casting

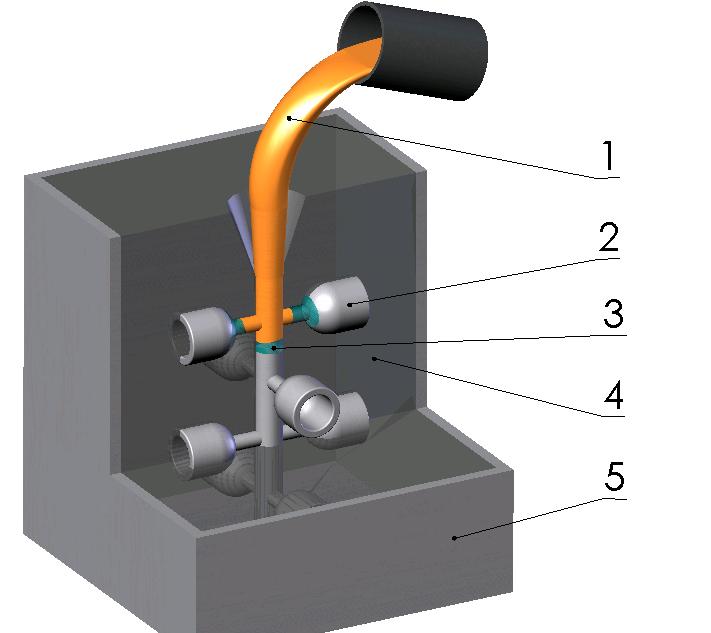

Full-mold casting is an evaporative-pattern casting process which is a combination of sand casting and lost-foam casting. It uses an expanded polystyrene foam pattern which is then surrounded by sand, much like sand casting. The metal is then poured directly into the mold, which vaporizes the foam upon contact. Process First, a pattern is usually made from polystyrene foam, which can be done many different ways. For small volume runs the pattern can be hand cut or machined from a solid block of foam; if the geometry is simple enough it can even be cut using a hot-wire foam cutter. If the volume is large, then the pattern can be mass-produced by a process similar to injection molding. Pre-expanded beads of polystyrene are injected into a preheated aluminum mold at low pressure. Steam is then applied to the polystyrene which causes it to expand more to fill the die. The final pattern is approximately 97.5% air and 2.5% polystyrene. The finished patterns can be hot glued to pre ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Evaporative-pattern Casting

Evaporative-pattern casting is a type of casting process that uses a pattern made from a material that will evaporate when the molten metal is poured into the molding cavity. The most common evaporative-pattern material used is polystyrene foam.. The two major evaporative-pattern casting processes are: *Lost-foam casting * Full-mold casting The main difference is that lost-foam casting uses an unbonded sand and full-mold casting uses a bonded sand (or green sand). Because this difference is quite small there is much overlap in the terminology. Non-proprietary terms that have been used to describe these processes include: cavityless casting, evaporative foam casting, foam vaporization casting, lost pattern casting, the castral process, and expanded polystyrene molding.. Proprietary terms included Styro-cast, Foam Cast, Replicast, Policast. and Lost Foam Sintered Shell (LFSS) History The first patent for an evaporative-pattern casting process was filed in April 1956, by Harold F. ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Cylinder Head

In an internal combustion engine, the cylinder head (often abbreviated to simply "head") sits above the cylinders and forms the roof of the combustion chamber. In sidevalve engines, the head is a simple sheet of metal; whereas in more modern overhead valve and overhead camshaft engines, the cylinder head is a more complicated block often containing inlet and exhaust passages, coolant passages, valves, camshafts, spark plugs and fuel injectors. Most straight engines have a single cylinder head shared by all of the cylinders and most V engines have two cylinder heads (one per bank of cylinders). Design A summary of engine designs is shown below, in chronological order for automobile usage. Sidevalve engines In a flathead (''sidevalve'') engine, all of the valvetrain components are contained within the block, therefore the head is usually a simple sheet of metal bolted to the top of the engine block. Sidevalve engines were once universal in automobiles but are no ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Investment Casting

Investment casting is an industrial process based on lost-wax casting, one of the oldest known metal-forming techniques. The term "lost-wax casting" can also refer to modern investment casting processes. Investment casting has been used in various forms for the last 5,000 years. In its earliest forms, beeswax was used to form patterns necessary for the casting process. Today, more advanced waxes, refractory materials and specialist alloys are typically used for making patterns. Investment casting is valued for its ability to produce components with accuracy, repeatability, versatility and integrity in a variety of metals and high-performance alloys. The fragile wax patterns must withstand forces encountered during the mould making. Much of the wax used in investment casting can be reclaimed and reused. Lost-foam casting is a modern form of investment casting that eliminates certain steps in the process. Investment casting is so named because the process invests (surrounds) th ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Flash (manufacturing)

Flash, also known as flashing, is excess material attached to a molded, forged, or cast product, which must usually be removed. This is typically caused by leakage of the material between the two surfaces of a mold (beginning along the parting line) or between the base material and the mold in the case of overmolding. Details Molding flash is seen when the optimized parameter on cull height is not calibrated. Proper design of mold parting surfaces can reduce or eliminate flash. Molding flash can be caused from old or worn mold cavities that no longer fit tightly together. Other times, the complexity of the part requires so many mating pieces with such precise geometries that it is almost impossible to create a perfect fit on every impression. Most often, the type of material being molded, and its attendant viscosity in its liquid form, is the primary factor that leads to the creation of the unwanted mold flash.Bozzelli, Joh"An Expert Tells How to Stop Flash" ''Plastics Technolog ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Draft Angle

In engineering, draft is the amount of taper for molded or cast Cast may refer to: Music * Cast (band), an English alternative rock band * Cast (Mexican band), a progressive Mexican rock band * The Cast, a Scottish musical duo: Mairi Campbell and Dave Francis * ''Cast'', a 2012 album by Trespassers William ... parts perpendicular to the parting line. It can be measured in degrees or mm/mm (in/in). Consider the fabrication of a hollow plastic box, without lid. Once the plastic has hardened around the mold, the mold must be removed. As the plastic hardens, it may contract slightly. By tapering the sides of the mold by an appropriate "draft angle", for instance 2° (two degrees), the mold will be easier to remove. This is a practice that is used, in applicable cases, when working with fiberglass. If the mold is to be removed from the top, the box should taper in towards the bottom, such that measuring the bottom internal dimension will yield a smaller length and width than ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Core (casting)

A core is a device used in casting and moulding processes to produce internal cavities and reentrant angles (an interior angle that is greater than 180°). The core is normally a disposable item that is destroyed to get it out of the piece.. They are most commonly used in sand casting, but are also used in die casting and injection moulding. For example, cores define multiple passages inside cast engine blocks. One model of GM V-8 engine requires 5 dry-sand cores for every casting. Materials required to make cores *Core sand *Bentonite clay *Pulverized coal *Resin oil Advantages and disadvantages Cores are useful for features that cannot tolerate draft or to provide detail that cannot otherwise be integrated into a core-less casting or mold. The main disadvantage is the additional cost to incorporate cores. Requirements There are seven requirements for cores: #Green strength: In the green condition, there must be adequate strength for handling #In the hardened state, it must be ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Copper Alloy

Copper alloys are metal alloys that have copper as their principal component. They have high resistance against corrosion. The best known traditional types are bronze, where tin is a significant addition, and brass, using zinc instead. Both of these are imprecise terms, having both been commonly referred to as lattens in the past. Today the term ''copper alloy'' tends to be substituted, especially by museums. Composition The similarity in external appearance of the various alloys, along with the different combinations of elements used when making each alloy, can lead to confusion when categorizing the different compositions. There are as many as 400 different copper and copper alloy compositions loosely grouped into the categories: copper, high copper alloy, brasses, bronzes, copper nickels, copper–nickel–zinc (nickel silver), leaded copper, and special alloys. The following table lists the principal alloying element for four of the more common types used in mod ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Steel

Steel is an alloy made up of iron with added carbon to improve its strength and fracture resistance compared to other forms of iron. Many other elements may be present or added. Stainless steels that are corrosion- and oxidation-resistant typically need an additional 11% chromium. Because of its high tensile strength and low cost, steel is used in buildings, infrastructure, tools, ships, trains, cars, machines, electrical appliances, weapons, and rockets. Iron is the base metal of steel. Depending on the temperature, it can take two crystalline forms (allotropic forms): body-centred cubic and face-centred cubic. The interaction of the allotropes of iron with the alloying elements, primarily carbon, gives steel and cast iron their range of unique properties. In pure iron, the crystal structure has relatively little resistance to the iron atoms slipping past one another, and so pure iron is quite ductile, or soft and easily formed. In steel, small amounts of ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Iron

Iron () is a chemical element with Symbol (chemistry), symbol Fe (from la, Wikt:ferrum, ferrum) and atomic number 26. It is a metal that belongs to the first transition series and group 8 element, group 8 of the periodic table. It is, Abundance of the chemical elements#Earth, by mass, the most common element on Earth, right in front of oxygen (32.1% and 30.1%, respectively), forming much of Earth's outer core, outer and inner core. It is the fourth most common abundance of elements in Earth's crust, element in the Earth's crust. In its metallic state, iron is rare in the Earth's crust, limited mainly to deposition by meteorites. Iron ores, by contrast, are among the most abundant in the Earth's crust, although extracting usable metal from them requires kilns or Metallurgical furnace, furnaces capable of reaching or higher, about higher than that required to smelting, smelt copper. Humans started to master that process in Eurasia during the 2nd millennium BC, 2nd millennium BC ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Aluminium

Aluminium (aluminum in American and Canadian English) is a chemical element with the symbol Al and atomic number 13. Aluminium has a density lower than those of other common metals, at approximately one third that of steel. It has a great affinity towards oxygen, and forms a protective layer of oxide on the surface when exposed to air. Aluminium visually resembles silver, both in its color and in its great ability to reflect light. It is soft, non-magnetic and ductile. It has one stable isotope, 27Al; this isotope is very common, making aluminium the twelfth most common element in the Universe. The radioactivity of 26Al is used in radiodating. Chemically, aluminium is a post-transition metal in the boron group; as is common for the group, aluminium forms compounds primarily in the +3 oxidation state. The aluminium cation Al3+ is small and highly charged; as such, it is polarizing, and bonds aluminium forms tend towards covalency. The strong affinity tow ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Manifold

In mathematics, a manifold is a topological space that locally resembles Euclidean space near each point. More precisely, an n-dimensional manifold, or ''n-manifold'' for short, is a topological space with the property that each point has a neighborhood that is homeomorphic to an open subset of n-dimensional Euclidean space. One-dimensional manifolds include lines and circles, but not lemniscates. Two-dimensional manifolds are also called surfaces. Examples include the plane, the sphere, and the torus, and also the Klein bottle and real projective plane. The concept of a manifold is central to many parts of geometry and modern mathematical physics because it allows complicated structures to be described in terms of well-understood topological properties of simpler spaces. Manifolds naturally arise as solution sets of systems of equations and as graphs of functions. The concept has applications in computer-graphics given the need to associate pictures with coordinates ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Brake

A brake is a mechanical device that inhibits motion by absorbing energy from a moving system. It is used for slowing or stopping a moving vehicle, wheel, axle, or to prevent its motion, most often accomplished by means of friction. Background Most brakes commonly use friction between two surfaces pressed together to convert the kinetic energy of the moving object into heat, though other methods of energy conversion may be employed. For example, regenerative braking converts much of the energy to electrical energy, which may be stored for later use. Other methods convert kinetic energy into potential energy in such stored forms as pressurized air or pressurized oil. Eddy current brakes use magnetic fields to convert kinetic energy into electric current in the brake disc, fin, or rail, which is converted into heat. Still other braking methods even transform kinetic energy into different forms, for example by transferring the energy to a rotating flywheel. Brakes are gene ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |