|

Fitzroy Iron Works

The Fitzroy Iron Works at Mittagong, New South Wales, was the first commercial iron smelting works in Australia. It first operated in 1848. From 1848 to around 1910, various owners and lessees attempted to achieve profitable operation but ultimately none succeeded. More than once, new managers repeated more or less the same mistakes made by earlier ones. Over the second half of the 19th century, the name 'Fitzroy Iron Works' became almost synonymous with lost opportunities, repeated failure, lost capital, misplaced trust, and general misfortune. The Fitzroy Iron Works was—several times—a commercial failure, but it played a part in laying the foundations of the later success of the Australian iron and steel industry, and it was important in the growth of the township of Mittagong. Relics of the old iron-works were discovered during excavations for redevelopment of its site, during 2004, have been preserved and are on display. There are also some remnants and a commemorative ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Mittagong

Mittagong () is a town located in the Southern Highlands of New South Wales, Australia, in Wingecarribee Shire. The town acts as the gateway to the Southern Highlands when coming from Sydney. Mittagong is situated at an elevation of . The town is close to Bowral, Berrima, Moss Vale and the Northern Villages such as Yerrinbool and Colo Vale. Moreover, Mittagong is home to many wineries of the Southern Highlands which has been a recent growing wine and cellar door region. Geography The town lies between three small mountain reserves, Mount Alexandra above sea level, Mount Gibraltar above sea level and Ninety Acre Hill (part of the greater Gibbergunyah Reserve) above sea level. Popular among locals and visitors is a small man made lake, Lake Alexandra, that feeds into the nearby Nattai River. Lookouts are available at all three reserves for viewing. Lookouts on Mount Gibraltar include Bowral Lookout, Mittagong Lookout and Mount Jellore Lookout. Lookouts on Mount Alexand ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Charcoal

Charcoal is a lightweight black carbon residue produced by strongly heating wood (or other animal and plant materials) in minimal oxygen to remove all water and volatile constituents. In the traditional version of this pyrolysis process, called charcoal burning, often by forming a charcoal kiln, the heat is supplied by burning part of the starting material itself, with a limited supply of oxygen. The material can also be heated in a closed retort. Modern "charcoal" briquettes used for outdoor cooking may contain many other additives, e.g. coal. This process happens naturally when combustion is incomplete, and is sometimes used in radiocarbon dating. It also happens inadvertently while burning wood, as in a fireplace or wood stove. The visible flame in these is due to combustion of the volatile gases exuded as the wood turns into charcoal. The soot and smoke commonly given off by wood fires result from incomplete combustion of those volatiles. Charcoal burns at a higher temper ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Heraldic Animal

In heraldry, a charge is any emblem or device occupying the field of an '' escutcheon'' (shield). That may be a geometric design (sometimes called an '' ordinary'') or a symbolic representation of a person, animal, plant, object, building, or other device. In French blazon, the ordinaries are called ''pièces'', and other charges are called ''meubles'' (" hemobile nes). The term ''charge'' can also be used as a verb; for example, if an escutcheon depicts three lions, it is said to be ''charged with three lions''; similarly, a crest or even a charge itself may be "charged", such as a pair of eagle wings ''charged with trefoils'' (as on the coat of arms of Brandenburg). It is important to distinguish between the ordinaries and divisions of the field, as that typically follow similar patterns, such as a shield ''divided'' "per chevron", as distinct from being ''charged with'' a chevron. While thousands of objects found in religion, nature, mythology, or technology have appeared ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Lion (heraldry)

The lion is a common charge in heraldry. It traditionally symbolises courage, nobility, royalty, strength, stateliness and valour, because historically the lion has been regarded as the "king of beasts". The lion also carries Judeo-Christian symbolism. The Lion of Judah stands in the coat of arms of Jerusalem. Similar-looking lions can be found elsewhere, such as in the coat of arms of the Swedish royal House of Bjelbo, from there in turn derived into the coat of arms of Finland, formerly belonging to Sweden. History The animal designs in the heraldry of the high medieval period are a continuation of the animal style of the Viking Age, ultimately derived from the style of Scythian art as it developed from c. the 7th century BC. Symmetrically paired animals in particular find continuation from Migration Period art via Insular art to Romanesque art and heraldry. The animals of the "barbarian" (Eurasian) predecessors of heraldic designs are likely to have been used as ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Shingling

{{about, the industrial steel manufacturing process, the text mining technique, w-shingling Shingling was a stage in the production of bar iron or steel, in the finery and puddling processes. As with many ironmaking terms, this is derived from the French - ''cinglage''. The product of the finery was a bloom or loop (from old Frankish ''luppa'' or '' lopp'', meaning a shapeless mass); that of the puddling furnace was a puddled ball. In each case, this needed to be consolidated by hammering it into a more regular shape. This was done manually with heavy hammers; later by a waterwheel or steam powered hammers, leading to modern power hammers. The result was an oblong-shaped iron product similar in appearance to shingles used on roofs. In the finery, this was part of the work of the finer; during puddling, it was done by a special workman called the shingler. The iron (or steel) then had to be further shaped (drawn out) under the hammer or rolled in a rolling mill In met ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Tilt Hammer

A trip hammer, also known as a tilt hammer or helve hammer, is a massive powered hammer. Traditional uses of trip hammers include pounding, decorticating and polishing of grain in agriculture. In mining, trip hammers were used for crushing metal ores into small pieces, although a stamp mill was more usual for this. In finery forges they were used for drawing out blooms made from wrought iron into more workable bar iron. They were also used for fabricating various articles of wrought iron, latten (an early form of brass), steel and other metals. One or more trip hammers were set up in a forge, also known variously as a hammer mill, hammer forge or hammer works. The hammers were usually raised by a cam and then released to fall under the force of gravity. Historically, trip hammers were often powered hydraulically by a water wheel. Trip hammers are known to have been used in Imperial China since the Western Han dynasty. They also existed in the contemporary Greco-Roman world, wi ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Charles Augustus FitzRoy

Sir Charles Augustus FitzRoy, (10 June 179616 February 1858) was a British military officer, politician and member of the aristocracy, who held governorships in several British colonies during the 19th century. Family and peerage Charles was born in Derbyshire England, the eldest son of General Lord Charles FitzRoy and Frances Mundy. His grandfather, Augustus FitzRoy, 3rd Duke of Grafton, was the Prime Minister of Great Britain from 1768 to 1770. He was notably a sixth-generation descendant of King Charles II and the 1st Duchess of Cleveland; the surname FitzRoy stems from this illegitimacy. Charles' half brother Robert FitzRoy would become a pioneering meteorologist and surveyor, Captain of HMS ''Beagle'', and later Governor of New Zealand. Early life Charles FitzRoy was educated at Harrow School in London, before receiving a commission in the Royal Horse Guards regiment of the British Army at the age of 16. Just after his 19th birthday, FitzRoy's regiment took part i ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Whyalla News

''The Whyalla News'' is a newspaper serving the town of Whyalla on Eyre Peninsula, South Australia since 1940. It was later sold to Rural Press, previously owned by Fairfax Media, but now an Australian media company trading as Australian Community Media. History ''The'' ''Whyalla News'' was first published on 5 April 1940 by Jock Willson and trading as Northern Newspapers. In 1950, the newspaper's editor was J. E. Edwards. As of January 2015, the newspaper's editor is Eli Gould. Gould was preceded by Kate Bilney. In November 1960, the ''Whyalla News'' became a biweekly newspaper, before it became a triweekly in October 1968. The newspaper chronicled the development of the town from its infancy as a BHP company town through the establishment of the Whyalla steelworks, autonomous local government in 1970, and the closure of the shipyard in 1978. Other Northern Newspapers holdings included the ''Transcontinental'', the ''Spencer Gulf Pictorial'' (1970-1992), the ''Recorder'', the ' ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Puddling (metallurgy)

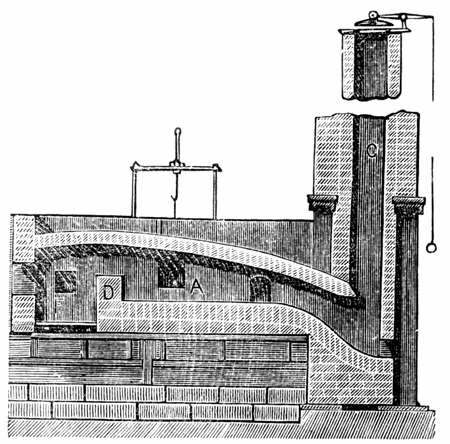

Puddling is the process of converting pig iron to bar (wrought) iron in a coal fired reverberatory furnace. It was developed in England during the 1780s. The molten pig iron was stirred in a reverberatory furnace, in an oxidizing environment, resulting in wrought iron. It was one of the most important processes of making the first appreciable volumes of valuable and useful bar iron (malleable wrought iron) without the use of charcoal. Eventually, the furnace would be used to make small quantities of specialty steels. Though it was not the first process to produce bar iron without charcoal, puddling was by far the most successful, and replaced the earlier potting and stamping processes, as well as the much older charcoal finery and bloomery processes. This enabled a great expansion of iron production to take place in Great Britain, and shortly afterwards, in North America. That expansion constitutes the beginnings of the Industrial Revolution so far as the iron industry is conc ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Pig Iron

Pig iron, also known as crude iron, is an intermediate product of the iron industry in the production of steel which is obtained by smelting iron ore in a blast furnace. Pig iron has a high carbon content, typically 3.8–4.7%, along with silica and other constituents of dross, which makes it brittle and not useful directly as a material except for limited applications. The traditional shape of the molds used for pig iron ingots is a branching structure formed in sand, with many individual ingots at right angles to a central channel or "runner", resembling a litter of piglets being nursed by a sow. When the metal had cooled and hardened, the smaller ingots (the "pigs") were simply broken from the runner (the "sow"), hence the name "pig iron". As pig iron is intended for remelting, the uneven size of the ingots and the inclusion of small amounts of sand cause only insignificant problems considering the ease of casting and handling them. History Smelting and producing wroug ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Cast Iron

Cast iron is a class of iron–carbon alloys with a carbon content more than 2%. Its usefulness derives from its relatively low melting temperature. The alloy constituents affect its color when fractured: white cast iron has carbide impurities which allow cracks to pass straight through, grey cast iron has graphite flakes which deflect a passing crack and initiate countless new cracks as the material breaks, and ductile cast iron has spherical graphite "nodules" which stop the crack from further progressing. Carbon (C), ranging from 1.8 to 4 wt%, and silicon (Si), 1–3 wt%, are the main alloying elements of cast iron. Iron alloys with lower carbon content are known as steel. Cast iron tends to be brittle, except for malleable cast irons. With its relatively low melting point, good fluidity, castability, excellent machinability, resistance to deformation and wear resistance, cast irons have become an engineering material with a wide range of applications and are ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |