|

Failure Modes, Effects, And Diagnostic Analysis

Failure modes, effects, and diagnostic analysis (FMEDA) is a systematic analysis technique to obtain subsystem / device level failure rates, failure modes and diagnostic capability. The FMEDA technique considers: * All components of a design, * The functionality of each component, * The failure modes of each component, * The effect of each component failure mode on the product functionality, * The ability of any automatic diagnostics to detect the failure, * The design strength (de-rating, safety factors), * The impact of any latent fault tests, and * The operational profile (environmental stress factors). Given a component database calibrated with field failure data that is reasonably accurate, the method can predict device level failure rate per failure mode, useful life, automatic diagnostic effectiveness, and latent fault test effectiveness for a given application. The predictions have been shown to be more accurate than field warranty return analysis or even typical field f ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Failure Rate

Failure is the social concept of not meeting a desirable or intended objective, and is usually viewed as the opposite of success. The criteria for failure depends on context, and may be relative to a particular observer or belief system. One person might consider a failure what another person considers a success, particularly in cases of direct competition or a zero-sum game. Similarly, the degree of success or failure in a situation may be differently viewed by distinct observers or participants, such that a situation that one considers to be a failure, another might consider to be a success, a qualified success or a neutral situation. It may also be difficult or impossible to ascertain whether a situation meets criteria for failure or success due to ambiguous or ill-defined definition of those criteria. Finding useful and effective criteria or heuristics to judge the success or failure of a situation may itself be a significant task. Sociology Cultural historian Sco ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

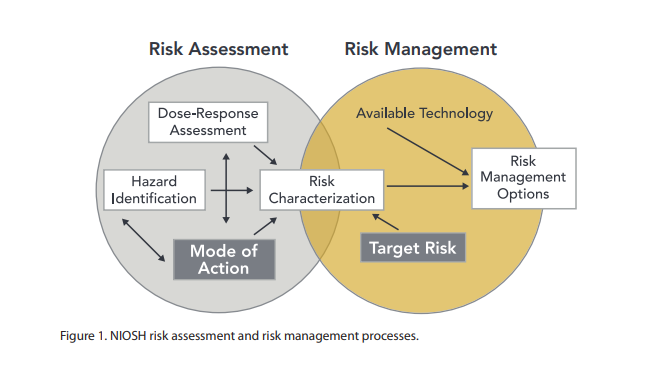

Risk Assessment

Risk assessment is a process for identifying hazards, potential (future) events which may negatively impact on individuals, assets, and/or the environment because of those hazards, their likelihood and consequences, and actions which can mitigate these effects. The output from such a process may also be called a risk assessment. Hazard analysis forms the first stage of a risk assessment process. Judgments "on the tolerability of the risk on the basis of a risk analysis" (i.e. risk evaluation) also form part of the process. The results of a risk assessment process may be expressed in a quantitative or qualitative fashion. Risk assessment forms a key part of a broader risk management strategy to help reduce any potential risk-related consequences. Categories Individual risk assessment Risk assessments can be undertaken in individual cases, including in patient and physician interactions. In the narrow sense chemical risk assessment is the assessment of a health risk in response ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Process Decision Program Chart

Process Decision Program Chart (PDPC) is a technique designed to help prepare contingency plans. The emphasis of the PDPC is to identify the consequential impact of failure on activity plans, and create appropriate contingency plans to limit risks. Process diagrams and planning tree diagrams are extended by a couple of levels when the PDPC is applied to the bottom level tasks on those diagrams. Methodology From the bottom level of some activity box, the PDPC adds levels for: # identifying what can go wrong (failure mode or risks) # consequences of that failure (effect or consequence) # possible countermeasures (risk mitigation action plan) Similar techniques * The PDPC is similar to the failure mode and effects analysis Failure is the social concept of not meeting a desirable or intended Goal, objective, and is usually viewed as the opposite of success. The criteria for failure depends on context, and may be relative to a particular observer or belief system ... (FMEA) in ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

List Of Materials-testing Resources

Materials testing is used to assess product quality, functionality, safety, reliability and toxicity of both materials and electronic devices. Some applications of materials testing include defect detection, failure analysis, material development, basic materials science research, and the verification of material properties for application trials. This is a list of organizations and companies that publish materials testing standards or offer materials testing laboratory services. International organizations These organizations create materials testing standards or conduct active research in the fields of materials analysis and reliability testing. * American Association of Textile Chemists and Colorists (AATCC) * American National Standards Institute (ANSI) * American Society of Heating, Refrigerating and Air-Conditioning Engineers (ASHRAE) * American Society of Mechanical Engineers (ASME) * ASTM International * Federal Institute for Materials Research and Testing ''(German: Bu ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

List Of Materials Analysis Methods

This is a list of analysis methods used in materials science. Analysis methods are listed by their acronym, if one exists. Symbols * μSR – see muon spin spectroscopy * χ – see magnetic susceptibility A * AAS – Atomic absorption spectroscopy * AED – Auger electron diffraction * AES – Auger electron spectroscopy * AFM – Atomic force microscopy * AFS – Atomic fluorescence spectroscopy * Analytical ultracentrifugation * APFIM – Atom probe field ion microscopy * APS – Appearance potential spectroscopy * ARPES – Angle resolved photoemission spectroscopy * ARUPS – Angle resolved ultraviolet photoemission spectroscopy * ATR – Attenuated total reflectance B * BET – BET surface area measurement (BET from Brunauer, Emmett, Teller) * BiFC – Bimolecular fluorescence complementation * BKD – Backscatter Kikuchi diffraction, see EBSD * BRET – Bioluminescence resonance energy transfer * BSED – Back scattered electron diffraction, see E ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

High Availability

High availability (HA) is a characteristic of a system that aims to ensure an agreed level of operational performance, usually uptime, for a higher than normal period. There is now more dependence on these systems as a result of modernization. For example, to carry out their regular daily tasks, hospitals and data centers need their systems to be highly available. Availability refers to the ability of the user to access a service or system, whether to submit new work, update or modify existing work, or retrieve the results of previous work. If a user cannot access the system, it is considered ''unavailable from the user's perspective''. The term '' downtime'' is generally used to refer to describe periods when a system is unavailable. Resilience High availability is a property of network resilience, the ability to "provide and maintain an acceptable level of service in the face of faults and challenges to normal operation." Threats and challenges for services can range from ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Hazard Analysis And Critical Control Points

Hazard analysis and critical control points, or HACCP (), is a systematic preventive approach to food safety from biological hazard, biological, chemical hazard, chemical, and physical hazards in production processes that can cause the finished product to be unsafe and designs measures to reduce these risks to a safe level. In this manner, HACCP attempts to avoid hazards rather than attempting to inspect finished products for the effects of those hazards. The HACCP system can be used at all stages of a food chain, from food processing, food production and preparation processes including packaging, distribution, etc. The United States Food and Drug Administration, Food and Drug Administration (FDA) and the United States Department of Agriculture (USDA) require mandatory HACCP programs for juice and meat as an effective approach to food safety and protecting public health. Meat HACCP systems are regulated by the USDA, while seafood and juice are regulated by the FDA. All other food ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Failure Mode And Effects Analysis

Failure is the social concept of not meeting a desirable or intended Goal, objective, and is usually viewed as the opposite of success. The criteria for failure depends on context, and may be relative to a particular observer or belief system. One person might consider a failure what another person considers a success, particularly in cases of direct competition or a zero-sum game. Similarly, the degree of success or failure in a situation may be differently viewed by distinct observers or participants, such that a situation that one considers to be a failure, another might consider to be a success, a qualified success or a neutral situation. It may also be difficult or impossible to ascertain whether a situation meets criteria for failure or success due to ambiguous or ill-defined definition of those criteria. Finding useful and effective criteria or heuristics to judge the success or failure of a situation may itself be a significant task. Sociology Cultural historian Sco ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

FMECA

Failure mode effects and criticality analysis (FMECA) is an extension of failure mode and effects analysis (FMEA). FMEA is a bottom-up, inductive analytical method which may be performed at either the functional or piece-part level. FMECA extends FMEA by including a ''criticality analysis'', which is used to chart the probability of failure modes against the severity of their consequences. The result highlights failure modes with relatively high probability and severity of consequences, allowing remedial effort to be directed where it will produce the greatest value. FMECA tends to be preferred over FMEA in space and NATO military applications, while various forms of FMEA predominate in other industries. History FMECA was originally developed in the 1940s by the U.S military, which published MIL–P–1629 in 1949. By the early 1960s, contractors for the U.S. National Aeronautics and Space Administration (NASA) were using variations of FMECA under a variety of names. I ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Fault Tree Analysis

Fault tree analysis (FTA) is a type of failure analysis in which an undesired state of a system is examined. This analysis method is mainly used in safety engineering and reliability engineering to understand how systems can fail, to identify the best ways to reduce risk and to determine (or get a feeling for) event rates of a safety accident or a particular system level (functional) failure. FTA is used in the aerospace, nuclear power, chemical and process, pharmaceutical, petrochemical and other high-hazard industries; but is also used in fields as diverse as risk factor identification relating to social service system failure. FTA is also used in software engineering for debugging purposes and is closely related to cause-elimination technique used to detect bugs. In aerospace, the more general term "system failure condition" is used for the "undesired state" / top event of the fault tree. These conditions are classified by the severity of their effects. The most severe conditi ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Failure Rate

Failure is the social concept of not meeting a desirable or intended objective, and is usually viewed as the opposite of success. The criteria for failure depends on context, and may be relative to a particular observer or belief system. One person might consider a failure what another person considers a success, particularly in cases of direct competition or a zero-sum game. Similarly, the degree of success or failure in a situation may be differently viewed by distinct observers or participants, such that a situation that one considers to be a failure, another might consider to be a success, a qualified success or a neutral situation. It may also be difficult or impossible to ascertain whether a situation meets criteria for failure or success due to ambiguous or ill-defined definition of those criteria. Finding useful and effective criteria or heuristics to judge the success or failure of a situation may itself be a significant task. Sociology Cultural historian Sco ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |