|

Failure Mode

Failure causes are defects in design, process, quality, or part application, which are the underlying cause of a failure or which initiate a process which leads to failure. Where failure depends on the user of the product or process, then human error must be considered. Component failure / failure modes A part failure mode is the way in which a component failed "functionally" on the component level. Often a part has only a few failure modes. For example, a relay may fail to open or close contacts on demand. The failure mechanism that caused this can be of many different kinds, and often multiple factors play a role at the same time. They include corrosion, welding of contacts due to an abnormal electric current, return spring fatigue failure, unintended command failure, dust accumulation and blockage of mechanism, etc. Seldom only one cause (hazard) can be identified that creates system failures. The real root causes can in theory in most cases be traced back to some kind of huma ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Human Error

Human error refers to something having been done that was " not intended by the actor; not desired by a set of rules or an external observer; or that led the task or system outside its acceptable limits".Senders, J.W. and Moray, N.P. (1991) Human Error: Cause, Prediction, and Reduction'. Lawrence Erlbaum Associates, p.25. . Human error has been cited as a primary cause contributing factor in disasters and accidents in industries as diverse as nuclear power (e.g., the Three Mile Island accident), aviation (see pilot error), space exploration (e.g., the Space Shuttle Challenger disaster and Space Shuttle Columbia disaster), and medicine (see medical error). Prevention of human error is generally seen as a major contributor to reliability and safety of (complex) systems. Human error is one of the many contributing causes of risk events. Definition Human error refers to something having been done that was "not intended by the actor; not desired by a set of rules or an external observer ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Cascading Failure

A cascading failure is a failure in a system of interconnected parts in which the failure of one or few parts leads to the failure of other parts, growing progressively as a result of positive feedback. This can occur when a single part fails, increasing the probability that other portions of the system fail. Such a failure may happen in many types of systems, including power transmission, computer networking, finance, transportation systems, organisms, the human body, and ecosystems. Cascading failures may occur when one part of the system fails. When this happens, other parts must then compensate for the failed component. This in turn overloads these nodes, causing them to fail as well, prompting additional nodes to fail one after another. In power transmission Cascading failure is common in power grids when one of the elements fails (completely or partially) and shifts its load to nearby elements in the system. Those nearby elements are then pushed beyond their capacity s ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Forensic Engineering

Forensic engineering has been defined as ''"the investigation of failures - ranging from serviceability to catastrophic - which may lead to legal activity, including both civil and criminal".'' It includes the investigation of materials, products, structures or components that fail or do not operate or function as intended, causing personal injury, damage to property or economic loss. The consequences of failure may give rise to action under either criminal or civil law including but not limited to health and safety legislation, the laws of contract and/or product liability and the laws of tort. The field also deals with retracing processes and procedures leading to accidents in operation of vehicles or machinery. Generally, the purpose of a forensic engineering investigation is to locate cause or causes of failure with a view to improve performance or life of a component, or to assist a court in determining the facts of an accident. It can also involve investigation of intellect ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Forensic Electrical Engineering

Forensic electrical engineering is a branch of forensic engineering, and is concerned with investigating electrical failures and accidents in a legal context. Many forensic electrical engineering investigations apply to fires suspected to be caused by electrical failures. Forensic electrical engineers are most commonly retained by insurance companies or attorneys representing insurance companies, or by manufacturers or contractors defending themselves against subrogation by insurance companies. Other areas of investigation include accident investigation involving electrocution, and intellectual property disputes such as patent actions. Additionally, since electrical fires are most often cited as the cause for "suspect" fires an electrical engineer is often employed to evaluate the electrical equipment and systems to determine whether the cause of the fire was electrical in nature. Goals The ultimate goal of these investigations is often to determine the legal liability for a f ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Failure Rate

Failure rate is the frequency with which an engineered system or component fails, expressed in failures per unit of time. It is usually denoted by the Greek letter λ (lambda) and is often used in reliability engineering. The failure rate of a system usually depends on time, with the rate varying over the life cycle of the system. For example, an automobile's failure rate in its fifth year of service may be many times greater than its failure rate during its first year of service. One does not expect to replace an exhaust pipe, overhaul the brakes, or have major transmission problems in a new vehicle. In practice, the mean time between failures (MTBF, 1/λ) is often reported instead of the failure rate. This is valid and useful if the failure rate may be assumed constant – often used for complex units / systems, electronics – and is a general agreement in some reliability standards (Military and Aerospace). It does in this case ''only'' relate to the flat region of the ba ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Failure Modes, Effects, And Diagnostic Analysis

Failure modes, effects, and diagnostic analysis (FMEDA) is a systematic analysis technique to obtain subsystem / product level failure rates, failure modes and diagnostic capability. The FMEDA technique considers: * All components of a design, * The functionality of each component, * The failure modes of each component, * The effect of each component failure mode on the product functionality, * The ability of any automatic diagnostics to detect the failure, * The design strength (de-rating, safety factors) and * The operational profile (environmental stress factors). Given a component database calibrated with field failure data that is reasonably accurate, the method can predict product level failure rate and failure mode data for a given application. The predictions have been shown to be more accurate than field warranty return analysis or even typical field failure analysis given that these methods depend on reports that typically do not have sufficient detail information in failu ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Failure Mode And Effects Analysis

Failure mode and effects analysis (FMEA; often written with "failure modes" in plural) is the process of reviewing as many components, assemblies, and subsystems as possible to identify potential failure modes in a system and their causes and effects. For each component, the failure modes and their resulting effects on the rest of the system are recorded in a specific FMEA worksheet. There are numerous variations of such worksheets. An FMEA can be a qualitative analysis, but may be put on a quantitative basis when mathematical failure rate models are combined with a statistical failure mode ratio database. It was one of the first highly structured, systematic techniques for failure analysis. It was developed by reliability engineers in the late 1950s to study problems that might arise from malfunctions of military systems. An FMEA is often the first step of a system reliability study. A few different types of FMEA analyses exist, such as: * Functional * Design * Process Sometime ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Failure Analysis

Failure analysis is the process of collecting and analyzing data to determine the cause of a failure, often with the goal of determining corrective actions or liability. According to Bloch and Geitner, ”machinery failures reveal a reaction chain of cause and effect… usually a deficiency commonly referred to as the symptom…”. failure analysis can save money, lives, and resources if done correctly and acted upon. It is an important discipline in many branches of manufacturing industry, such as the electronics industry, where it is a vital tool used in the development of new products and for the improvement of existing products. The failure analysis process relies on collecting failed components for subsequent examination of the cause or causes of failure using a wide array of methods, especially microscopy and spectroscopy. Nondestructive testing (NDT) methods (such as industrial computed tomography scanning) are valuable because the failed products are unaffected by analysis, ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

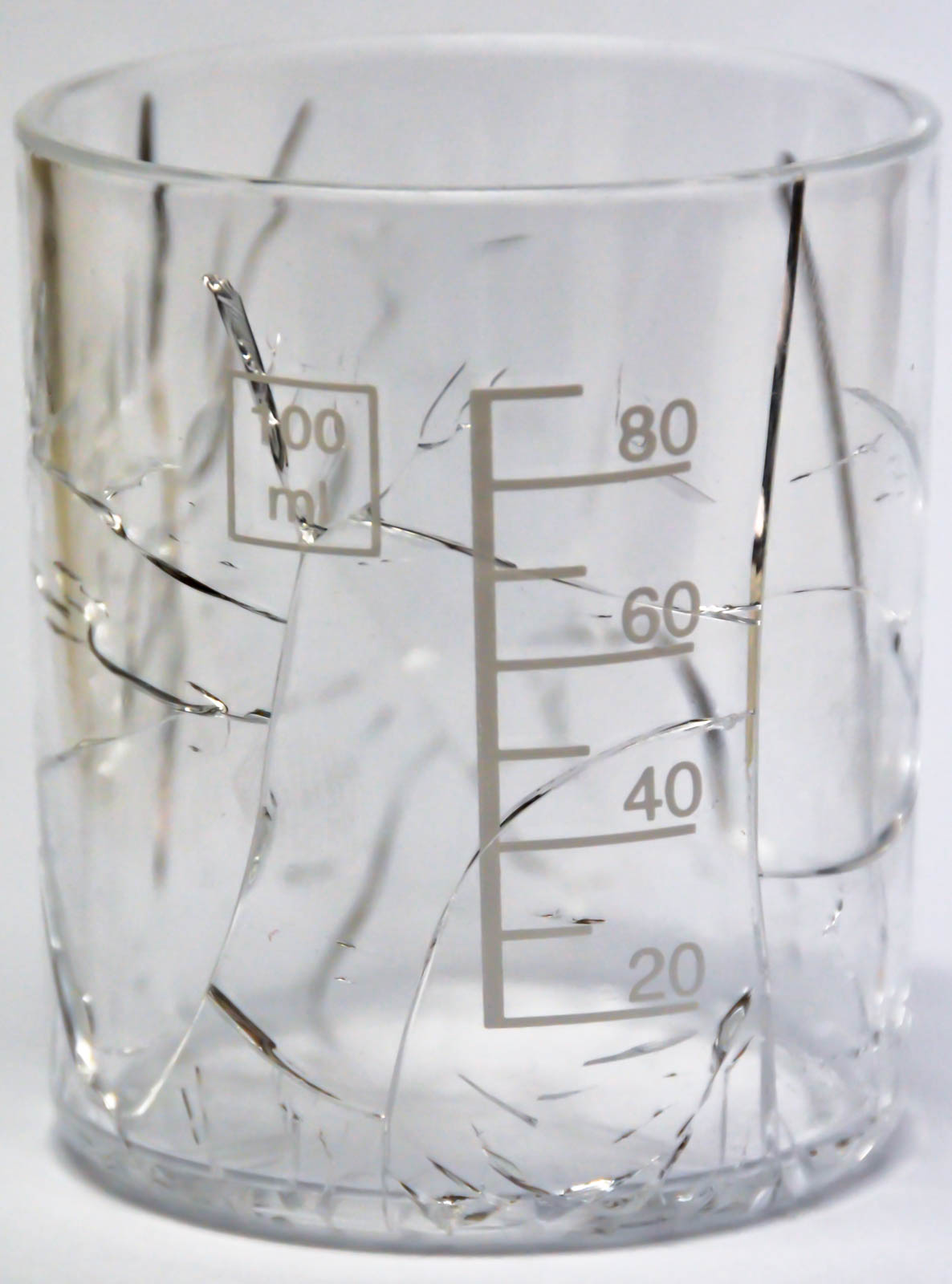

Environmental Stress Cracking

Environmental Stress Cracking (ESC) is one of the most common causes of unexpected brittle failure of thermoplastic (especially amorphous) polymers known at present. According to ASTM D883, stress cracking is defined as "an external or internal crack in a plastic caused by tensile stresses less than its short-term mechanical strength". This type of cracking typically involves brittle cracking, with little or no ductile drawing of the material from its adjacent failure surfaces. Environmental stress cracking may account for around 15-30% of all plastic component failures in service.H. F. Mark (2004). Encyclopedia of Polymers Science and Technology – 3rd Ed. Vol 12. John Miley & Sons Inc. This behavior is especially prevalent in glassy, amorphous thermoplastics. Amorphous polymers exhibit ESC because of their loose structure which makes it easier for the fluid to permeate into the polymer. Amorphous polymers are more prone to ESC at temperature higher than their glass tran ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Stress Corrosion Cracking

Stress corrosion cracking (SCC) is the growth of crack formation in a corrosive environment. It can lead to unexpected and sudden failure of normally ductile metal alloys subjected to a tensile stress, especially at elevated temperature. SCC is highly chemically specific in that certain alloys are likely to undergo SCC only when exposed to a small number of chemical environments. The chemical environment that causes SCC for a given alloy is often one which is only mildly corrosive to the metal. Hence, metal parts with severe SCC can appear bright and shiny, while being filled with microscopic cracks. This factor makes it common for SCC to go undetected prior to failure. SCC often progresses rapidly, and is more common among alloys than pure metals. The specific environment is of crucial importance, and only very small concentrations of certain highly active chemicals are needed to produce catastrophic cracking, often leading to devastating and unexpected failure.ASM Internation ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Steel

Steel is an alloy made up of iron with added carbon to improve its strength and fracture resistance compared to other forms of iron. Many other elements may be present or added. Stainless steels that are corrosion- and oxidation-resistant typically need an additional 11% chromium. Because of its high tensile strength and low cost, steel is used in buildings, infrastructure, tools, ships, trains, cars, machines, electrical appliances, weapons, and rockets. Iron is the base metal of steel. Depending on the temperature, it can take two crystalline forms (allotropic forms): body-centred cubic and face-centred cubic. The interaction of the allotropes of iron with the alloying elements, primarily carbon, gives steel and cast iron their range of unique properties. In pure iron, the crystal structure has relatively little resistance to the iron atoms slipping past one another, and so pure iron is quite ductile, or soft and easily formed. In steel, small amounts of carbon, other ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Iron

Iron () is a chemical element with symbol Fe (from la, ferrum) and atomic number 26. It is a metal that belongs to the first transition series and group 8 of the periodic table. It is, by mass, the most common element on Earth, right in front of oxygen (32.1% and 30.1%, respectively), forming much of Earth's outer and inner core. It is the fourth most common element in the Earth's crust. In its metallic state, iron is rare in the Earth's crust, limited mainly to deposition by meteorites. Iron ores, by contrast, are among the most abundant in the Earth's crust, although extracting usable metal from them requires kilns or furnaces capable of reaching or higher, about higher than that required to smelt copper. Humans started to master that process in Eurasia during the 2nd millennium BCE and the use of iron tools and weapons began to displace copper alloys, in some regions, only around 1200 BCE. That event is considered the transition from the Bronze Age to the Iron A ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |