|

French Whipping

A whipping knot or whipping is a binding of twine or whipcord around the end of a rope to prevent its natural tendency to fray. Some whippings are finished cleanly, as by drawing the bitter end of the cordage beneath the whipping itself. Others are tied off or have the end(s) of the twine sewn through the rope. According to ''The Ashley Book of Knots'', "The purpose of a ''whipping'' is to prevent the end of a rope from fraying ... A whipping should be, in width, about equal to the diameter of the rope on which it is put ... wo sailmaker's whippings a short distance apart, are put in the ends of every reef point, where the constant "whipping" against the sail makes the wear excessive; this is said to be the source of the name ''whipping''."Ashley, Clifford W. (1944). ''The Ashley Book of Knots'', p.547. Doubleday. . The other type of stopping knot is a seizing knot. Whipping is suitable for synthetic and natural stranded and braided lines, including 3-strand rope, 4-strand ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Portuguese Whipping

A whipping knot or whipping is a binding of twine or whipcord around the end of a rope to prevent its natural tendency to fray. Some whippings are finished cleanly, as by drawing the bitter end of the cordage beneath the whipping itself. Others are tied off or have the end(s) of the twine sewn through the rope. According to ''The Ashley Book of Knots'', "The purpose of a ''whipping'' is to prevent the end of a rope from fraying ... A whipping should be, in width, about equal to the diameter of the rope on which it is put ... wo sailmaker's whippings a short distance apart, are put in the ends of every reef point, where the constant "whipping" against the sail makes the wear excessive; this is said to be the source of the name ''whipping''."Ashley, Clifford W. (1944). ''The Ashley Book of Knots'', p.547. Doubleday. . The other type of stopping knot is a seizing knot. Whipping is suitable for synthetic and natural stranded and braided lines, including 3-strand rope, 4-strand ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Aglet

An aglet ( ) or aiglet is a small sheath, often made of plastic or metal, attached at each end of a shoelace, a cord, or a drawstring. An aglet keeps the fibers of the lace or cord from unraveling; its firmness and narrow profile make it easier to hold and easier to feed through eyelets, lugs, or other lacing guides. Etymology The word ''aglet'' and its variant ''aiglet'' come from the Middle French and Old French word ', the diminutive of ', meaning "needle, pin", which in turn comes from the Late Latin ' ("ornamental pin, pine needle"), diminutive of the Latin word for needle and pin, '.Picken, Mary Brooks: ''The Fashion Dictionary'', Funk and Wagnalls, 1957. (1973 edition ) History Aglets were originally made of metal, glass, or stone, and many were very ornamental. Wealthy people in the Roman era would have their aglets made out of precious metals such as brass or silver. Before the invention of buttons, they were used on the ends of the ribbons used to fasten clothi ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

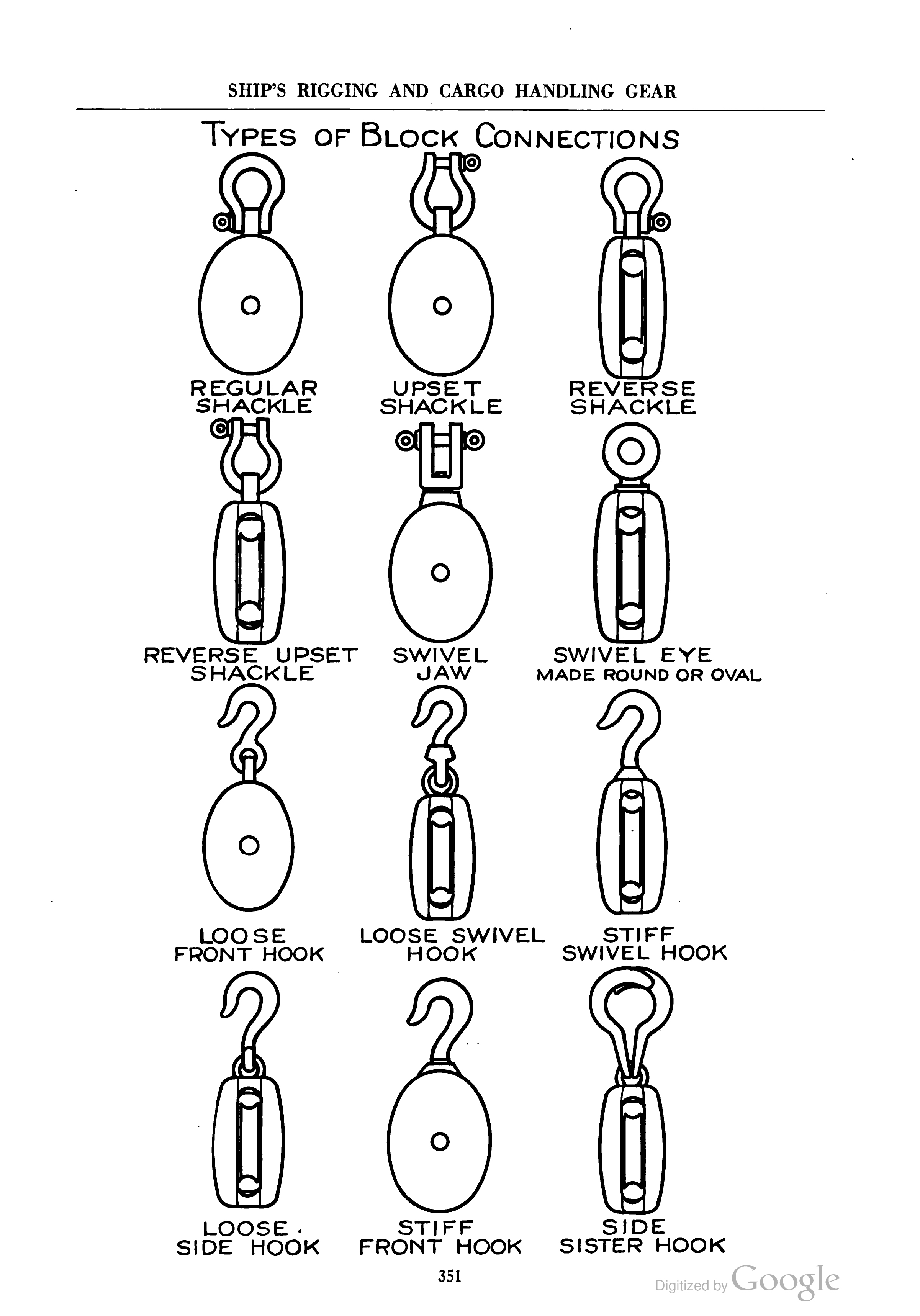

Block (sailing)

In sailing, a block is a single or multiple pulley. One or a number of '' sheaves'' are enclosed in an assembly between ''cheeks'' or ''chocks''. In use, a block is fixed to the end of a line, to a spar, or to a surface. A line (rope) is ''reeved'' through the sheaves, and maybe through one or more matching blocks at some far end, to make up a tackle. The ''purchase'' of a tackle refers to its mechanical advantage. In general the more sheaves in the blocks that make up a tackle, the higher its mechanical advantage. The matter is slightly complicated by the fact that every tackle has a ''working end'' where the final run of rope leaves the last sheave. More mechanical advantage can be obtained if this end is attached to the moving load rather than the fixed end of the tackle. There are various types of blocks that are used in sailing. Some blocks are used to increase mechanical advantage and others are used simply to change the direction of a line. A ''ratchet block'' turns fr ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Back Splice

Rope splicing in ropework is the forming of a semi-permanent joint between two ropes or two parts of the same rope by partly untwisting and then interweaving their strands. Splices can be used to form a stopper at the end of a line, to form a loop or an eye in a rope, or for joining two ropes together. Splices are preferred to knotted rope, since while a knot typically reduces the strength by 20–40%, a splice is capable of attaining a rope's full strength. However, splicing usually results in a thickening of the line and, if subsequently removed, leaves a distortion of the rope. Most types of splices are used on 3-strand rope, but some can be done on 12-strand or greater single-braided rope, as well as most double braids. While a spliced 3-strand rope's strands are interwoven to create the splice, a braided rope's splice is constructed by simply pulling the rope into its jacket. Types of splices *back splice (or end splice) – A splice where the strands of the end of the r ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Aramid

Aramid fibers, short for aromatic polyamide, are a class of heat-resistant and strong synthetic fibers. They are used in aerospace and military applications, for ballistic-rated body armor fabric and ballistic composites, in marine cordage, marine hull reinforcement, and as an asbestos substitute. The chain molecules in the fibers are highly oriented along the fiber axis. As a result, a higher proportion of the chemical bond contributes more to fiber strength than in many other synthetic fibers. Aramids have a very high melting point (>500 °C). Common aramid brand names include Kevlar, Nomex, and Twaron. Terminology and chemical structure ''Aramid'' is a shortened form of aromatic polyamide. The term was introduced in 1972, accepted in 1974 by the Federal Trade Commission of the USA as the name of a generic category of fiber distinct from nylon, and adopted by the International Standards Organisation in 1977. Aromatic in the name refers to the presence of aromatic ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Polypropylene

Polypropylene (PP), also known as polypropene, is a thermoplastic polymer used in a wide variety of applications. It is produced via chain-growth polymerization from the monomer propylene. Polypropylene belongs to the group of polyolefins and is partially crystalline and non-polar. Its properties are similar to polyethylene, but it is slightly harder and more heat-resistant. It is a white, mechanically rugged material and has a high chemical resistance. Bio-PP is the bio-based counterpart of polypropylene (PP). Polypropylene is the second-most widely produced commodity plastic (after polyethylene). In 2019, the global market for polypropylene was worth $126.03 billion. Revenues are expected to exceed US$145 billion by 2019. The sales of this material are forecast to grow at a rate of 5.8% per year until 2021. History Phillips Petroleum chemists J. Paul Hogan and Robert Banks first demonstrated the polymerization of propylene in 1951. The stereoselective polymerization ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Polyester

Polyester is a category of polymers that contain the ester functional group in every repeat unit of their main chain. As a specific material, it most commonly refers to a type called polyethylene terephthalate (PET). Polyesters include naturally occurring chemicals, such as in plants and insects, as well as synthetics such as polybutyrate. Natural polyesters and a few synthetic ones are biodegradable, but most synthetic polyesters are not. Synthetic polyesters are used extensively in clothing. Polyester fibers are sometimes spun together with natural fibers to produce a cloth with blended properties. Cotton-polyester blends can be strong, wrinkle- and tear-resistant, and reduce shrinking. Synthetic fibers using polyester have high water, wind and environmental resistance compared to plant-derived fibers. They are less fire-resistant and can melt when ignited. Liquid crystalline polyesters are among the first industrially used liquid crystal polymers. They are used f ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

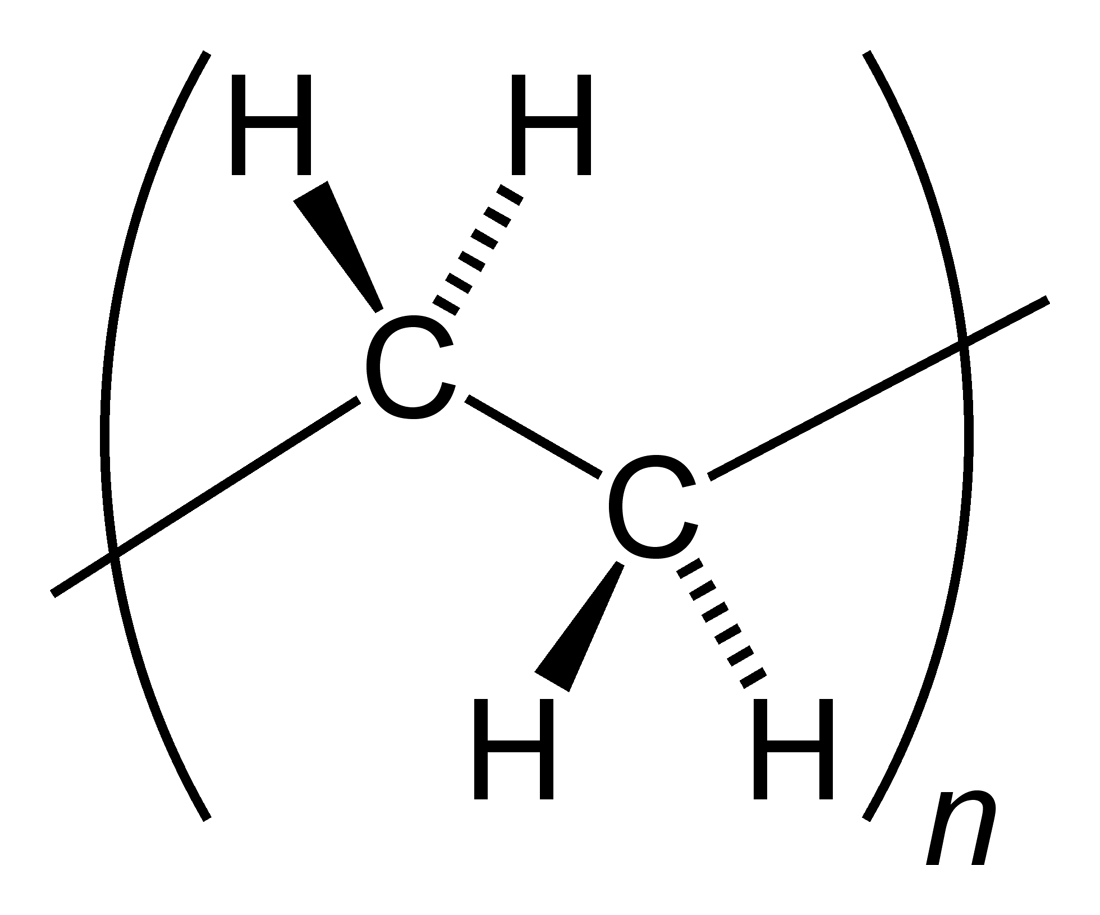

Polyethylene

Polyethylene or polythene (abbreviated PE; IUPAC name polyethene or poly(methylene)) is the most commonly produced plastic. It is a polymer, primarily used for packaging (plastic bags, plastic films, geomembranes and containers including bottles, etc.). , over 100 million tonnes of polyethylene resins are being produced annually, accounting for 34% of the total plastics market. Many kinds of polyethylene are known, with most having the chemical formula (C2H4)''n''. PE is usually a mixture of similar polymers of ethylene, with various values of ''n''. It can be ''low-density'' or ''high-density'': low-density polyethylene is extruded using high pressure () and high temperature (), while high-density polyethylene is extruded using low pressure () and low temperature (). Polyethylene is usually thermoplastic, but it can be modified to become thermosetting instead, for example, in cross-linked polyethylene. History Polyethylene was first synthesized by the German ch ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Nylon

Nylon is a generic designation for a family of synthetic polymers composed of polyamides ( repeating units linked by amide links).The polyamides may be aliphatic or semi-aromatic. Nylon is a silk-like thermoplastic, generally made from petroleum, that can be melt-processed into fibers, films, or shapes. Nylon polymers can be mixed with a wide variety of additives to achieve many property variations. Nylon polymers have found significant commercial applications in fabric and fibers (apparel, flooring and rubber reinforcement), in shapes (molded parts for cars, electrical equipment, etc.), and in films (mostly for food packaging). History DuPont and the invention of nylon Researchers at DuPont began developing cellulose based fibers, culminating in the synthetic fiber rayon. DuPont's experience with rayon was an important precursor to its development and marketing of nylon. DuPont's invention of nylon spanned an eleven-year period, ranging from the initial researc ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Dacron

Polyethylene terephthalate (or poly(ethylene terephthalate), PET, PETE, or the obsolete PETP or PET-P), is the most common thermoplastic polymer resin of the polyester family and is used in fibres for clothing, containers for liquids and foods, and thermoforming for manufacturing, and in combination with glass fibre for engineering resins. In 2016, annual production of PET was 56 million tons. The biggest application is in fibres (in excess of 60%), with bottle production accounting for about 30% of global demand. In the context of textile applications, PET is referred to by its common name, polyester, whereas the acronym ''PET'' is generally used in relation to packaging. Polyester makes up about 18% of world polymer production and is the fourth-most-produced polymer after polyethylene (PE), polypropylene (PP) and polyvinyl chloride (PVC). PET consists of repeating (C10H8O4) units. PET is commonly recycled, and has the digit 1 (♳) as its resin identification code (RIC). ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |