|

Fractography

Fractography is the study of the fracture surfaces of materials. Fractographic methods are routinely used to determine the cause of failure in engineering structures, especially in product failure and the practice of forensic engineering or failure analysis. In material science research, fractography is used to develop and evaluate theoretical models of crack growth behavior. One of the aims of fractographic examination is to determine the cause of failure by studying the characteristics of a fractured surface. Different types of crack growth (e.g. fatigue, stress corrosion cracking, hydrogen embrittlement) produce characteristic features on the surface, which can be used to help identify the failure mode. The overall pattern of cracking can be more important than a single crack, however, especially in the case of brittle materials like ceramics and glasses. Usage Fractography is a widely used technique in forensic engineering, forensic materials engineering and fra ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Striation (fatigue)

Striations are marks produced on the fracture surface that show the incremental growth of a fatigue crack. A striation marks the position of the crack tip at the time it was made. The term ''striation'' generally refers to ''ductile striations'' which are rounded bands on the fracture surface separated by depressions or fissures and can have the same appearance on both sides of the mating surfaces of the fatigue crack. Although some research has suggested that many loading cycles are required to form a single striation, it is now generally thought that each striation is the result of a single loading cycle. The presence of striations is used in failure analysis as an indication that a fatigue crack has been growing. Striations are generally not seen when a crack is small even though it is growing by fatigue, but will begin to appear as the crack becomes larger. Not all periodic marks on the fracture surface are striations. The size of a striation for a particular material is typic ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Fatigue (material)

In materials science, fatigue is the initiation and propagation of cracks in a material due to cyclic loading. Once a fatigue crack has initiated, it grows a small amount with each loading cycle, typically producing striations on some parts of the fracture surface. The crack will continue to grow until it reaches a critical size, which occurs when the stress intensity factor of the crack exceeds the fracture toughness of the material, producing rapid propagation and typically complete fracture of the structure. Fatigue has traditionally been associated with the failure of metal components which led to the term metal fatigue. In the nineteenth century, the sudden failing of metal railway axles was thought to be caused by the metal ''crystallising'' because of the brittle appearance of the fracture surface, but this has since been disproved. Most materials, such as composites, plastics and ceramics, seem to experience some sort of fatigue-related failure. To aid in predicting ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Brittle

A material is brittle if, when subjected to stress, it fractures with little elastic deformation and without significant plastic deformation. Brittle materials absorb relatively little energy prior to fracture, even those of high strength. Breaking is often accompanied by a sharp snapping sound. When used in materials science, it is generally applied to materials that fail when there is little or no plastic deformation before failure. One proof is to match the broken halves, which should fit exactly since no plastic deformation has occurred. Brittleness in different materials Polymers Mechanical characteristics of polymers can be sensitive to temperature changes near room temperatures. For example, poly(methyl methacrylate) is extremely brittle at temperature 4˚C, but experiences increased ductility with increased temperature. Amorphous polymers are polymers that can behave differently at different temperatures. They may behave like a glass at low temperatures (the glas ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Ceramic

A ceramic is any of the various hard, brittle, heat-resistant and corrosion-resistant materials made by shaping and then firing an inorganic, nonmetallic material, such as clay, at a high temperature. Common examples are earthenware, porcelain, and brick. The earliest ceramics made by humans were pottery objects (''pots,'' ''vessels or vases'') or figurines made from clay, either by itself or mixed with other materials like silica, hardened and sintered in fire. Later, ceramics were glazed and fired to create smooth, colored surfaces, decreasing porosity through the use of glassy, amorphous ceramic coatings on top of the crystalline ceramic substrates. Ceramics now include domestic, industrial and building products, as well as a wide range of materials developed for use in advanced ceramic engineering, such as in semiconductors. The word "'' ceramic''" comes from the Greek word (), "of pottery" or "for pottery", from (), "potter's clay, tile, pottery". The earliest k ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Forensic Engineering

Forensic engineering has been defined as ''"the investigation of failures - ranging from serviceability to catastrophic - which may lead to legal activity, including both civil and criminal".'' It includes the investigation of materials, products, structures or components that fail or do not operate or function as intended, causing personal injury, damage to property or economic loss. The consequences of failure may give rise to action under either criminal or civil law including but not limited to health and safety legislation, the laws of contract and/or product liability and the laws of tort. The field also deals with retracing processes and procedures leading to accidents in operation of vehicles or machinery. Generally, the purpose of a forensic engineering investigation is to locate cause or causes of failure with a view to improve performance or life of a component, or to assist a court in determining the facts of an accident. It can also involve investigation of intel ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Fracture

Fracture is the separation of an object or material into two or more pieces under the action of stress. The fracture of a solid usually occurs due to the development of certain displacement discontinuity surfaces within the solid. If a displacement develops perpendicular to the surface, it is called a normal tensile crack or simply a crack; if a displacement develops tangentially, it is called a shear crack, slip band or dislocation. Fracture#Brittle, Brittle fractures occur with no apparent deformation before fracture. Fracture#Ductile, Ductile fractures occur after visible deformation. Fracture strength, or breaking strength, is the stress when a specimen fails or fractures. The detailed understanding of how a fracture occurs and develops in materials is the object of fracture mechanics. Strength Fracture strength, also known as breaking strength, is the stress at which a specimen Structural integrity and failure, fails via fracture. This is usually determined for a gi ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Forensic Materials Engineering

Forensic materials engineering, a branch of forensic engineering, focuses on the material evidence from crime or accident scenes, seeking defects in those materials which might explain why an accident occurred, or the source of a specific material to identify a criminal. Many analytical methods used for material identification may be used in investigations, the exact set being determined by the nature of the material in question, be it metal, glass, ceramic, polymer or composite. An important aspect is the analysis of trace evidence such as skid marks on exposed surfaces, where contact between dissimilar materials leaves material traces of one left on the other. Provided the traces can be analysed successfully, then an accident or crime can often be reconstructed. Another aim will be to determine the cause of a broken component using the technique of fractography. Metals and alloys Metal surfaces can be analyzed in a number of ways, including by spectroscopy and EDX used duri ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

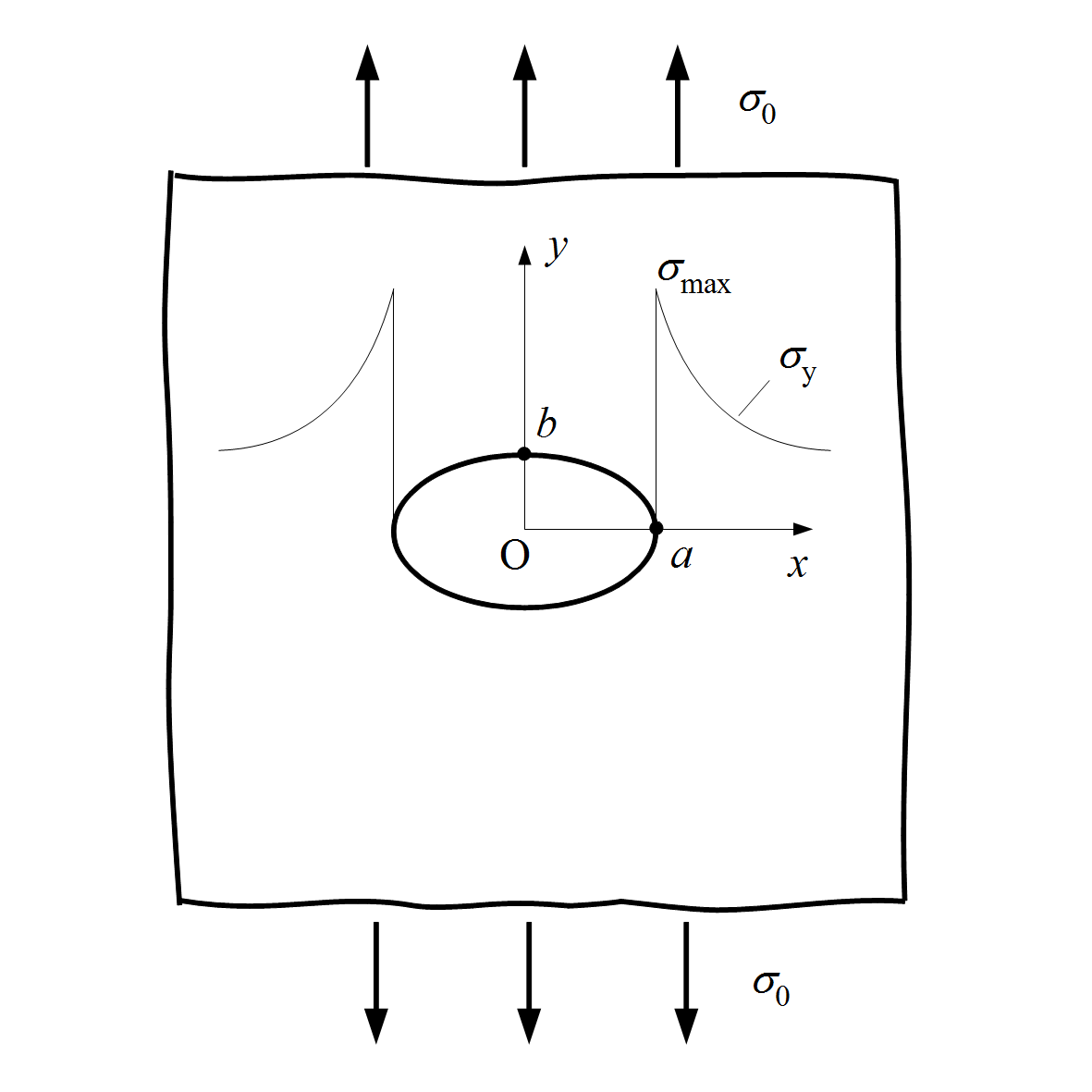

Stress Concentration

In solid mechanics, a stress concentration (also called a stress raiser or a stress riser) is a location in an object where the stress is significantly greater than the surrounding region. Stress concentrations occur when there are irregularities in the geometry or material of a structural component that cause an interruption to the flow of stress. This arises from such details as holes, grooves, notches and fillets. Stress concentrations may also occur from accidental damage such as nicks and scratches. The degree of concentration of a discontinuity under typically tensile loads can be expressed as a non-dimensional stress concentration factor K_t, which is the ratio of the highest stress to the nominal far field stress. For a circular hole in an infinite plate, K_t = 3. The stress concentration factor should not be confused with the stress intensity factor, which is used to define the effect of a crack on the stresses in the region around a crack tip. For ductile mate ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Ductile Fracture Surface 6061-T6 Al SEM

Ductility is a mechanical property commonly described as a material's amenability to drawing (e.g. into wire). In materials science, ductility is defined by the degree to which a material can sustain plastic deformation under tensile stress before failure. Ductility is an important consideration in engineering and manufacturing. It defines a material's suitability for certain manufacturing operations (such as cold working) and its capacity to absorb mechanical overload.. Some metals that are generally described as ductile include gold and copper. However, not all metals experience ductile failure as some can be characterized with brittle failure like cast iron. Polymers generally can be viewed as ductile materials as they typically allow for plastic deformation. Malleability, a similar mechanical property, is characterized by a material's ability to deform plastically without failure under compressive stress. Historically, materials were considered malleable if they were a ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Crankshaft Fatigue

A crankshaft is a mechanical component used in a piston engine to convert the reciprocating motion into rotational motion. The crankshaft is a rotating shaft containing one or more crankpins, that are driven by the pistons via the connecting rods. The crankpins are also called ''rod bearing journals'', and they rotate within the "big end" of the connecting rods. Most modern crankshafts are located in the engine block. They are made from steel or cast iron, using either a forging, casting or machining process. Design The crankshaft located within the engine block, held in place via main bearings which allow the crankshaft to rotate within the block. The up-down motion of each piston is transferred to the crankshaft via connecting rods. A flywheel is often attached to one end of the crankshaft, in order to smoothen the power delivery and reduce vibration. A crankshaft is subjected to enormous stresses, in some cases more than per cylinder. Crankshafts for single-cylinder ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Cavitation

Cavitation is a phenomenon in which the static pressure of a liquid reduces to below the liquid's vapour pressure, leading to the formation of small vapor-filled cavities in the liquid. When subjected to higher pressure, these cavities, called "bubbles" or "voids", collapse and can generate shock waves that may damage machinery. These shock waves are strong when they are very close to the imploded bubble, but rapidly weaken as they propagate away from the implosion. Cavitation is a significant cause of wear in some engineering contexts. Collapsing voids that implode near to a metal surface cause cyclic stress through repeated implosion. This results in surface fatigue of the metal causing a type of wear also called "cavitation". The most common examples of this kind of wear are to pump impellers, and bends where a sudden change in the direction of liquid occurs. Cavitation is usually divided into two classes of behavior: inertial (or transient) cavitation and non-inertial c ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |