|

Fortschritt ZT 320

Fortschritt ZT 320 is a series of agricultural tractors made by the East German manufacturer VEB Traktorenwerk Schönebeck. It was produced from 1983 to 1990, and succeeded the ZT 300 series. Unlike its predecessor, the ZT 320 series came in only two models, the rear-wheel drive ''ZT 320'', and the all-wheel drive ''ZT 323''. Concept The ZT 320 series was meant to be an upgrade of the existing ZT 300 series, and therefore, many at the time not obsolete ZT 300 components, like the axles, frame, and steering system, were carried over to the ZT 320 series. The main parts that were supposed to receive an upgrade were, amongst other things, the three-point linkage, powertrain, driver's cab, and to fulfill contemporary regulations, the braking system. Compared to the ZT 300 series, the ZT 320 was also designed to be much more versatile. With its upgraded braking system, it can pull trailers with a mass of up to 30,000 kg, ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Fortschritt ZT 300

ZT 300 is a series of 20 kN agricultural tractors, produced from 1 September 1967H. Roßnick (auth.): ''Aufbau, Wirkungsweise und Wartung der Doppelkupplung DK 80 des Traktors ZT 300'', in Deutsche Agrartechnik, Volume 22, No. 5, May 1972. p. 216 to 1984 by the VEB Traktorenwerk Schönebeck. It succeeded the '' RS14 Famulus'' series, and unlike the Famulus, the ZT 300 series was sold under the brand name Fortschritt. ''ZT 300'' refers both to the initial ZT 300 ''model'', and the ZT 300 ''series''. In total, 72,382 units of the ZT 300 series were made. The model with the highest production figure was the ZT 303, which was introduced in 1972. It features an automatic all-wheel-drive system; in the early 1980s, it cost 81.000 Mark. Starting in 1983, the ZT 300 series was succeeded by the ZT 320. Chronology In total, the ZT 300 series consisted of 6 series production models and one prototype: *ZT 300: The base model with rear-wheel drive, meant for agricultural use *ZT 303 ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

4 VD 14,5/12-1 SRW

The 4 VD 14,5/12-1 SRW is an inline four-cylinder diesel engine produced by the VEB IFA Motorenwerke Nordhausen from 1967 to 1990. The engine was one of the standard modular engines for agricultural and industrial use in the Comecon-countries. Approximately one million units were made. Technical description The 4 VD 14,5/12-1 SRW is a water-cooled four-stroke diesel engine with four inline cylinders. The Fuel is injected with a mechanical direct injection system. The bore is 120 mm, the stroke is 145 mm, the displacement is 6560 cm³. The firing order is 1-3-4-2. The standard version of the engine produces 92 kW and has a torque of 422 Nm. The combustion chamber system (M-System) was licensed by MAN. The engine was produced in the versions 4 VD 14,5/12-1 SRW and 4 VD 14,5/12-2 SRW, the later revision was built primary for the NVA. The name ''4 VD 14,5/12-1'' stands for 4-Zylinder-Viertakt-Diesel, Hub 14,5 cm / Bohrung 12 cm, Baureihe 1, Stehe ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Drawbar Pull

In automotive engineering, drawbar pull is the amount of horizontal force available to a vehicle at the drawbar for accelerating or pulling a load. Drawbar pull is a function of velocity, and in general decreases as the speed of the vehicle increases (due both to increasing resistance and decreasing transmission gear ratios). Drawbar pull is the difference between tractive effort available and tractive effort required to overcome resistance at a specified speed. Drawbar pull data for a vehicle is usually determined by measuring the amount of available tractive force using a dynamometer A dynamometer or "dyno" for short, is a device for simultaneously measuring the torque and rotational speed (RPM) of an engine, motor or other rotating prime mover so that its instantaneous power may be calculated, and usually displayed by the ..., and then combining that data with coastdownSAE J1263, Road Load measurement and Dynamometer Simulation Using Coastdown Techniques, dated January 20 ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

East Germany

East Germany, officially the German Democratic Republic (GDR; german: Deutsche Demokratische Republik, , DDR, ), was a country that existed from its creation on 7 October 1949 until its dissolution on 3 October 1990. In these years the state was a part of the Eastern Bloc in the Cold War. Commonly described as a communist state, it described itself as a socialist "workers' and peasants' state".Patrick Major, Jonathan Osmond, ''The Workers' and Peasants' State: Communism and Society in East Germany Under Ulbricht 1945–71'', Manchester University Press, 2002, Its territory was administered and occupied by Soviet forces following the end of World War II—the Soviet occupation zone of the Potsdam Agreement, bounded on the east by the Oder–Neisse line. The Soviet zone surrounded West Berlin but did not include it and West Berlin remained outside the jurisdiction of the GDR. Most scholars and academics describe the GDR as a totalitarian dictatorship. The GDR was establish ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Volkseigener Betrieb

The Publicly Owned Enterprise (german: Volkseigener Betrieb; abbreviated VEB) was the main legal form of industrial enterprise in East Germany. They were all publicly owned and were formed after Nationalisation#Germany, mass nationalisation between 1945 and the early 1960s, and the handing back in 1954 of some 33 enterprises previously taken by the Soviet Union as War reparations, reparations. The managing director of a VEB was called a plant or works manager (German: ''Werkleiter'', ''Werkdirektor'' or ''Betriebsdirektor''). He or she was assisted by the first secretary of the factory party organisation (''Betriebsparteiorganisation'') of the Socialist Unity Party of Germany, SED, and the chairman of the factory trade union (''Betriebsgewerkschaftsleitung''). Subordinate to them were roles such as "Chief Accountant" and "Technical Director". VEBs were initially vertical integration, vertically integrated into units called Associations of Publicly Owned Enterprises (''Vereinigung V ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Three-point Linkage

The three-point hitch (British English: three-point linkage) is a widely used type of hitch for attaching ploughs and other implements to an agricultural or industrial tractor. The three points resemble either a triangle, or the letter A. Three-point attachment is the simplest and the only statically determinate way of joining two bodies in engineering. A three-point hitch attaches the implement to the tractor so that the orientation of the implement is fixed with respect to the tractor and the arm position of the hitch. The tractor carries some or all of the weight of the implement. The other main mechanism for attaching a load is through a drawbar, a single point, pivoting attachment where the implement or trailer is not in a fixed position with respect to the tractor. The primary benefit of the three-point hitch system is to transfer the weight and resistance of an implement to the drive wheels of the tractor. This gives the tractor more usable traction than it would otherwi ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Dual Clutch

A dual-clutch transmission (DCT) (sometimes referred to as a twin-clutch transmission) is a type of multi-speed vehicle transmission system, that uses two separate clutches for odd and even gear sets. The design is often similar to two separate manual transmissions with their respective clutches contained within one housing, and working as one unit. In car and truck applications, the DCT functions as an automatic transmission, requiring no driver input to change gears. The first DCT to reach production was the ''Easidrive'' automatic transmission introduced on the 1961 Hillman Minx mid-size car. This was followed by various eastern European tractors through the 1970s (using manual operation via a single clutch pedal), then the Porsche 962 C racing car in 1985. The first DCT of the modern era was used in the 2003 Volkswagen Golf R32. Since the late 2000s, DCTs have become increasingly widespread, and have supplanted hydraulic automatic transmissions in various models of cars. ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Gearbox

Propulsion transmission is the mode of transmitting and controlling propulsion power of a machine. The term ''transmission'' properly refers to the whole drivetrain, including clutch, gearbox, prop shaft (for rear-wheel drive vehicles), differential, and final drive shafts. In the United States the term is sometimes used in casual speech to refer more specifically to the gearbox alone, and detailed usage differs. The transmission reduces the higher engine speed to the slower wheel speed, increasing torque in the process. Transmissions are also used on pedal bicycles, fixed machines, and where different rotational speeds and torques are adapted. Often, a transmission has multiple gear ratios (or simply "gears") with the ability to switch between them as the speed varies. This switching may be done manually (by the operator) or automatically (by a control unit). Directional (forward and reverse) control may also be provided. Single-ratio transmissions also exist, which simply chan ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

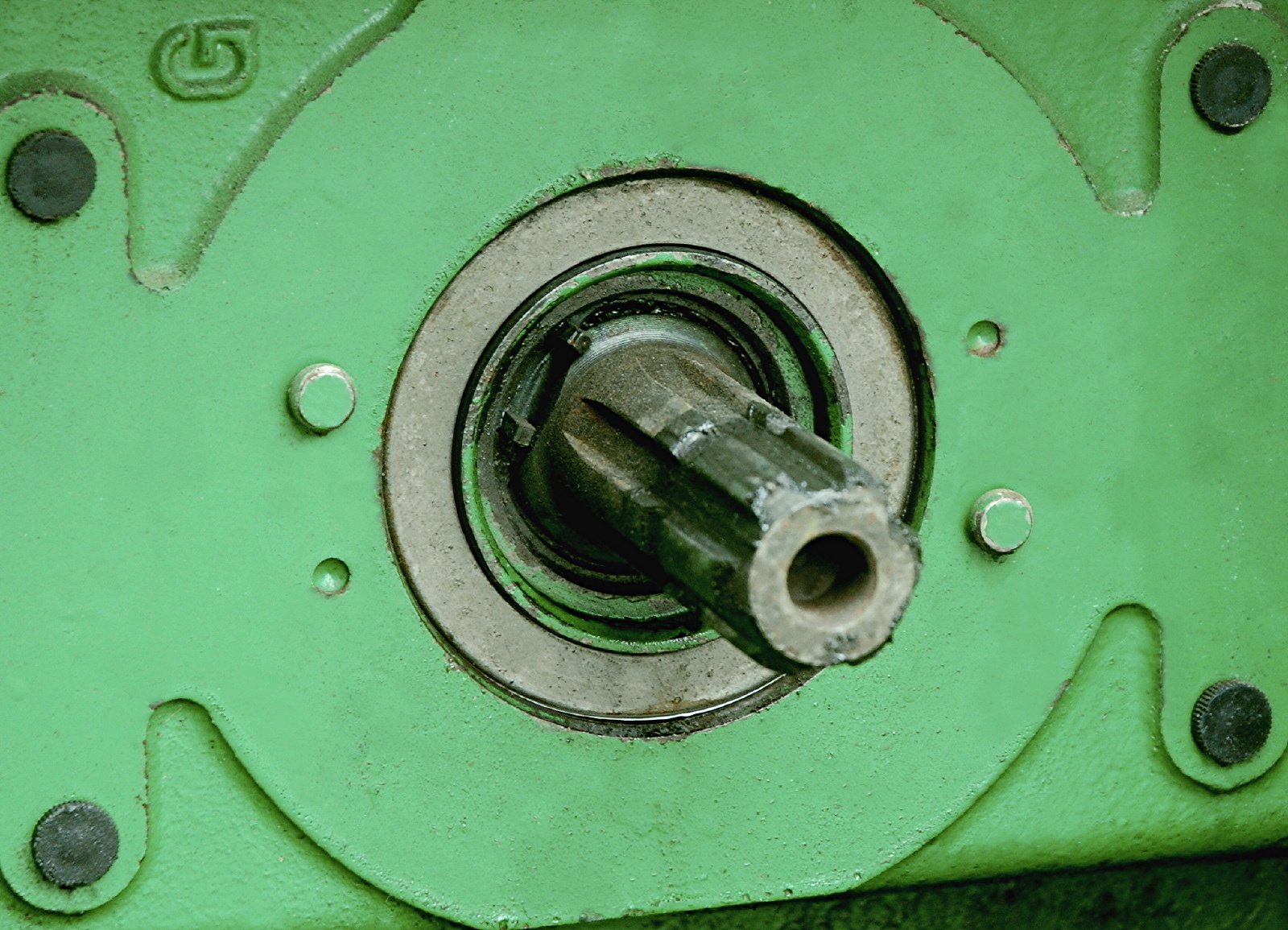

Power Take-off

A power take-off or power takeoff (PTO) is one of several methods for taking power from a power source, such as a running engine, and transmitting it to an application such as an attached implement or separate machine. Most commonly, it is a splined drive shaft installed on a tractor or truck allowing implements with mating fittings to be powered directly by the engine. Semi-permanently mounted power take-offs can also be found on industrial and marine engines. These applications typically use a drive shaft and bolted joint to transmit power to a secondary implement or accessory. In the case of a marine application, such shafts may be used to power fire pumps. In aircraft applications, such an accessory drive may be used in conjunction with a constant speed drive. Jet aircraft have four types of PTO units: internal gearbox, external gearbox, radial drive shaft, and bleed air, which are used to power engine accessories. In some cases, aircraft power take-off systems also provid ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Diesel Engine

The diesel engine, named after Rudolf Diesel, is an internal combustion engine in which ignition of the fuel is caused by the elevated temperature of the air in the cylinder due to mechanical compression; thus, the diesel engine is a so-called compression-ignition engine (CI engine). This contrasts with engines using spark plug-ignition of the air-fuel mixture, such as a petrol engine (gasoline engine) or a gas engine (using a gaseous fuel like natural gas or liquefied petroleum gas). Diesel engines work by compressing only air, or air plus residual combustion gases from the exhaust (known as exhaust gas recirculation (EGR)). Air is inducted into the chamber during the intake stroke, and compressed during the compression stroke. This increases the air temperature inside the cylinder to such a high degree that atomised diesel fuel injected into the combustion chamber ignites. With the fuel being injected into the air just before combustion, the dispersion of the fuel is une ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

M-System

The MAN M-System, also referred to as M-Process and M combustion process, is a direct injection system for Diesel engines. In M-System engines, the fuel is injected ''onto'' the walls of the combustion chamber that is solely located inside the piston, and shaped like a sphere. The M-System was rendered obsolete by modern fuel injection systems for Diesel engines. Due to its particularities, the M-System was only used for stationary applications and commercial vehicle engines, passenger car engines with this design have never been made. The letter ''M'' is an abbreviation for the German word ''Mittenkugelverfahren'', meaning ''centre sphere combustion process''. Operating principle Unlike regular Diesel engines, in which the fuel is injected as far away as possible from the combustion chamber walls to obtain better efficiency, in M-System engines, the fuel is injected onto the walls of the combustion chamber. The combustion chamber is located inside the piston bowl and shaped li ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |