|

Flat Honing

Flat honing is a metalworking grinding process used to provide high quality flat surfaces. It combines the speed of grinding or honing with the precision of lapping. It has also been known under the terms high speed lapping and high precision grinding. Origin of term The term is derived from honing cylinders and holes. A flat workpiece surface is processed, hence the word flat; the word honing is used because the cutting speed is low compared to grinding. A fixed abrasive is used to provide accuracy and optical appearance of the surface finish. Sometimes it is also called fine grinding or surface grinding using planetary kinematics. History The technology is relatively young, having appeared in the 1980s. In the industry, production lapping is being replaced by flat honing in an ever-expanding array of applications. The flat honing process allows for an equivalent quality result, but at a significant reduction in manufacturing costs per workpiece. Savings result from reduce ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Flat Honing

Flat honing is a metalworking grinding process used to provide high quality flat surfaces. It combines the speed of grinding or honing with the precision of lapping. It has also been known under the terms high speed lapping and high precision grinding. Origin of term The term is derived from honing cylinders and holes. A flat workpiece surface is processed, hence the word flat; the word honing is used because the cutting speed is low compared to grinding. A fixed abrasive is used to provide accuracy and optical appearance of the surface finish. Sometimes it is also called fine grinding or surface grinding using planetary kinematics. History The technology is relatively young, having appeared in the 1980s. In the industry, production lapping is being replaced by flat honing in an ever-expanding array of applications. The flat honing process allows for an equivalent quality result, but at a significant reduction in manufacturing costs per workpiece. Savings result from reduce ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Grinding (abrasive Cutting)

Grinding is a type of abrasive machining process which uses a grinding wheel as Cutting tool (machining), cutting tool. A wide variety of machines are used for grinding, best classified as portable or stationary: * Portable power tools such as angle grinders, die grinders and abrasive saw, cut-off saws * Stationary power tools such as bench grinders and abrasive saw, cut-off saws * Stationary hydropower, hydro- or human power, hand-powered grindstone (tool), sharpening stones Milling practice is a large and diverse area of manufacturing and Tool and die maker, toolmaking. It can produce very fine finishes and very accurate dimensions; yet in mass production contexts, it can also rough out large volumes of metal quite rapidly. It is usually better suited to the machining of very Hardness, hard materials than is "regular" machining (that is, cutting larger chips with cutting tools such as tool bits or milling cutters), and until recent decades it was the only practical way to mach ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Honing (metalworking)

Honing is an abrasive machining process that produces a precision surface on a metal workpiece by scrubbing an abrasive grinding stone or grinding wheel against it along a controlled path. Honing is primarily used to improve the geometric form of a surface, but can also improve the surface finish. Typical applications are the finishing of cylinders for internal combustion engines, air bearing spindles and gears. There are many types of hones, but all consist of one or more abrasive stones that are held under pressure against the surface they are working on. Other similar processes are lapping and superfinishing. Honing stones Honing uses a special tool, called a ''honing stone'' or a ''hone'', to achieve a precision surface. The hone is composed of abrasive grains that are bound together with an adhesive. Generally, honing grains are irregularly shaped and about 10 to 50 micrometers in diameter (300 to 1500 mesh grit). Smaller grain sizes produce a smoother surface on t ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Lapping

Lapping is a machining process in which two surfaces are rubbed together with an abrasive between them, by hand movement or using a machine. Lapping often follows other subtractive processes with more aggressive material removal as a first step, such as milling and/or grinding. Lapping can take two forms. The first type of lapping (traditionally often called grinding), involves rubbing a brittle material such as glass against a surface such as iron or glass itself (also known as the "lap" or grinding tool) with an abrasive such as aluminum oxide, jeweller's rouge, optician's rouge, emery, silicon carbide, diamond, etc., between them. This produces microscopic conchoidal fractures as the abrasive rolls about between the two surfaces and removes material from both. The other form of lapping involves a softer material such as pitch or a ceramic for the lap, which is "charged" with the abrasive. The lap is then used to cut a harder material—the workpiece. The abrasive emb ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Sintered

Clinker nodules produced by sintering Sintering or frittage is the process of compacting and forming a solid mass of material by pressure or heat without melting it to the point of liquefaction. Sintering happens as part of a manufacturing process used with metals, ceramics, plastics, and other materials. The atoms in the materials diffuse across the boundaries of the particles, fusing the particles together and creating one solid piece. Because the sintering temperature does not have to reach the melting point of the material, sintering is often chosen as the shaping process for materials with extremely high melting points such as tungsten and molybdenum. The study of sintering in metallurgical powder-related processes is known as powder metallurgy. An example of sintering can be observed when ice cubes in a glass of water adhere to each other, which is driven by the temperature difference between the water and the ice. Examples of pressure-driven sintering are the compact ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Modern Machine Shop

''Modern Machine Shop'' (ISSN 0026-8003) is a media brand that reports on product technology and process technology being used in North America's CNC machining and metalworking industry. Modern Machine Shop's audience consists primarily of owners, managers, and engineers at OEMs, contract manufacturers, and job shops that machine for industries including automotive, aerospace, electronics, energy, medical/surgical, defense, and construction equipment. First published in 1928, ''Modern Machine Shop'' is the flagship publication of Gardner Business Media. ''Modern Machine Shops qualified, no-charge subscription base is BPA-audited. As of August 2017, monthly circulation was 85,500. The publisher is Bryce Ellis and the Editor-in-Chief is Pete Zelinski. Editorial offices are located in Cincinnati, Ohio, USA. ''Modern Machine Shop'' is published 12 times per year. ''Modern Machine Shops also maintains a complete suite of multi-media resources used for researching machining and met ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Cubic Boron Nitride

Boron nitride is a thermally and chemically resistant refractory compound of boron and nitrogen with the chemical formula BN. It exists in various crystalline forms that are isoelectronic to a similarly structured carbon lattice. The hexagonal form corresponding to graphite is the most stable and soft among BN polymorphs, and is therefore used as a lubricant and an additive to cosmetic products. The cubic ( zincblende aka sphalerite structure) variety analogous to diamond is called c-BN; it is softer than diamond, but its thermal and chemical stability is superior. The rare wurtzite BN modification is similar to lonsdaleite but slightly softer than the cubic form. Because of excellent thermal and chemical stability, boron nitride ceramics are used in high-temperature equipment and metal casting. Boron nitride has potential use in nanotechnology. Structure Boron nitride exists in multiple forms that differ in the arrangement of the boron and nitrogen atoms, giving rise to varyin ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Vitrification

Vitrification (from Latin ''vitreum'', "glass" via French ''vitrifier'') is the full or partial transformation of a substance into a glass, that is to say, a non-crystalline amorphous solid. Glasses differ from liquids structurally and glasses possess a higher degree of connectivity with the same Hausdorff dimensionality of bonds as crystals: dimH = 3. In the production of ceramics, vitrification is responsible for its impermeability to water. Vitrification is usually achieved by heating materials until they liquidize, then cooling the liquid, often rapidly, so that it passes through the glass transition to form a glassy solid. Certain chemical reactions also result in glasses. In terms of chemistry, vitrification is characteristic for amorphous materials or disordered systems and occurs when bonding between elementary particles (atoms, molecules, forming blocks) becomes higher than a certain threshold value. Thermal fluctuations break the bonds; therefore, the low ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Diester

In chemistry, an ester is a compound derived from an oxoacid (organic or inorganic) in which at least one hydroxyl group () is replaced by an alkoxy group (), as in the substitution reaction of a carboxylic acid and an alcohol. Glycerides are fatty acid esters of glycerol; they are important in biology, being one of the main classes of lipids and comprising the bulk of animal fats and vegetable oils. Esters typically have a pleasant smell; those of low molecular weight are commonly used as fragrances and are found in essential oils and pheromones. They perform as high-grade solvents for a broad array of plastics, plasticizers, resins, and lacquers, and are one of the largest classes of synthetic lubricants on the commercial market. Polyesters are important plastics, with monomers linked by ester moieties. Phosphoesters form the backbone of DNA molecules. Nitrate esters, such as nitroglycerin, are known for their explosive properties. '' Nomenclature Etymology The wor ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Polyphenylene Sulfide

Polyphenylene sulfide (PPS) is an organic polymer consisting of aromatic rings linked by sulfides. Synthetic fiber and textiles derived from this polymer resist chemical and thermal attack. PPS is used in filter fabric for coal boilers, papermaking felts, electrical insulation, film capacitors, specialty membranes, gaskets, and packings. PPS is the precursor to a conductive polymer of the semi-flexible rod polymer family. The PPS, which is otherwise insulating, can be converted to the semiconducting form by oxidation or use of dopants.David Parker, Jan Bussink, Hendrik T. van de Grampel, Gary W. Wheatley, Ernst-Ulrich Dorf, Edgar Ostlinning, Klaus Reinking, "Polymers, High-Temperature" in Ullmann's Encyclopedia of Industrial Chemistry 2002, Wiley-VCH: Weinheim. Polyphenylene sulfide is an engineering plastic, commonly used today as a high-performance thermoplastic. PPS can be molded, extruded, or machined to tight tolerances. In its pure solid form, it may be opaque white to ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Tribology

Tribology is the science and engineering of interacting surfaces in relative Motion (physics), motion. It includes the study and application of the principles of friction, lubrication and wear. Tribology is highly interdisciplinary, drawing on many academic fields, including physics, chemistry, materials science, mathematics, biology and engineering. People who work in the field of tribology are referred to as ''tribologists''. The fundamental objects of study in tribology are tribosystems, which are physical systems of contacting surfaces. In lubricated tribosystems, contact stress can create tribofilms. Subfields of tribology include biotribology, nanotribology, space tribology and tribotronics. Etymology The word ''tribology'' derives from the Ancient Greek, Greek root τριβ- of the verb , ''wiktionary:tribo-, tribo'', "I rub" in classic Greek, and the suffix ''-logy'' from , ''wiktionary:-logia, -logia'' "study of", "knowledge of". Peter Jost coined the word in 1966, in t ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

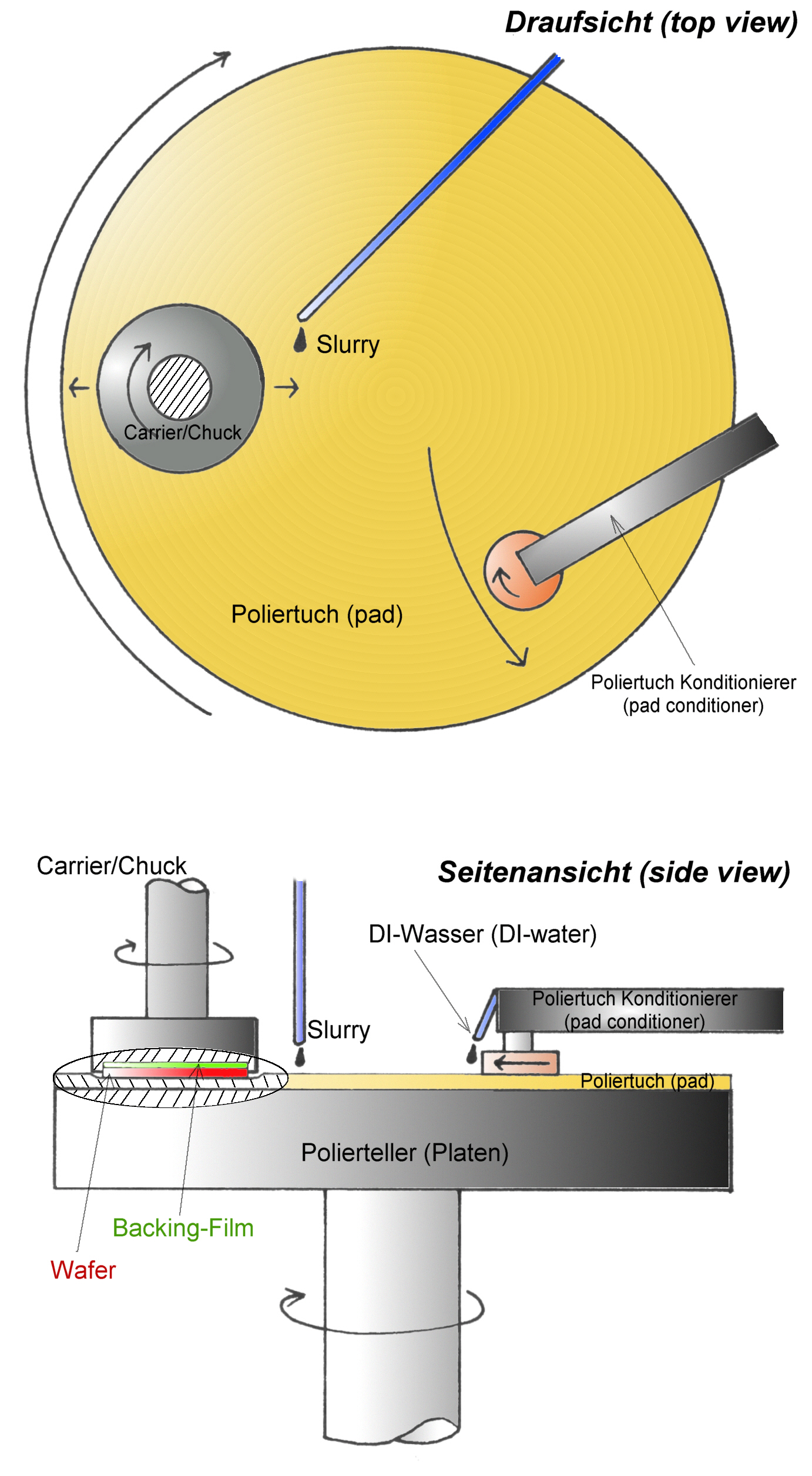

Chemical-mechanical Polishing

Chemical mechanical polishing (CMP) or planarization is a process of smoothing surfaces with the combination of chemical and mechanical forces. It can be thought of as a hybrid of chemical etching and free abrasive polishing. Description The process uses an abrasive and corrosive chemical slurry (commonly a colloid) in conjunction with a polishing pad and retaining ring, typically of a greater diameter than the wafer. The pad and wafer are pressed together by a dynamic polishing head and held in place by a plastic retaining ring. The dynamic polishing head is rotated with different axes of rotation (i.e., not concentric). This removes material and tends to even out any irregular topography, making the wafer flat or planar. This may be necessary to set up the wafer for the formation of additional circuit elements. For example, CMP can bring the entire surface within the depth of field of a photolithography system, or selectively remove material based on its position. Typical depth-o ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |