|

Flaring Pliers

Flare fittings are a type of compression fitting used with metal tubing, usually soft steel, ductile (soft) copper and aluminum, though other materials are also used. In a flare fitting the tube itself is "flared" i.e. expanded and deformed at the end. The flare is then pressed against the fitting it connects to and is secured by a close-fitting nut that ensures that no leakage happens. Tube flaring is a type of forging operation, and is usually a cold working procedure. During assembly, a flare nut is used to secure the flared tubing's tapered end to the also tapered fitting, producing a pressure-resistant, leak-tight seal. Flared connections offer a high degree of long-term reliability and for this reason are often used in mission-critical and inaccessible locations. The tool used to flare tubing consists of a die that grips the tube and either a mandrel or rolling cone is forced into the end of the tube to form the flare by cold working. The most common flare fitt ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Compression Fitting

A compression fitting is a fitting used in plumbing and electrical conduit systems to join two tubes or thin-walled pipes together. In instances where two pipes made of dissimilar materials are to be joined (most commonly PVC and copper), the fittings will be made of one or more compatible materials appropriate for the connection. Compression fittings for attaching tubing (piping) commonly have ferrules (or ''olives'' in the UK) in them, and are sometimes referred to as flareless fittings. There are also flare fittings that do not require ferrules/olives. Compression fittings are used extensively in hydraulic, gas, and water systems to enable the connection of tubing to threaded components like valves and tools. Compression fittings are suited to a variety of applications, such as plumbing systems in confined spaces where copper pipe would be difficult to solder without creating a fire hazard, and extensively in hydraulic industrial applications. A major benefit is that the fit ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Forging

Forging is a manufacturing process involving the shaping of metal using localized compressive forces. The blows are delivered with a hammer (often a power hammer) or a die. Forging is often classified according to the temperature at which it is performed: cold forging (a type of cold working), warm forging, or hot forging (a type of hot working). For the latter two, the metal is heated, usually in a forge. Forged parts can range in weight from less than a kilogram to hundreds of metric tons.Degarmo, p. 389 Forging has been done by smiths for millennia; the traditional products were kitchenware, hardware, hand tools, edged weapons, cymbals, and jewellery. Since the Industrial Revolution, forged parts are widely used in mechanisms and machines wherever a component requires high strength; such forgings usually require further processing (such as machining) to achieve a finished part. Today, forging is a major worldwide industry. History Forging is one of the oldest known me ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Cold Working

In metallurgy, cold forming or cold working is any metalworking process in which metal is shaped below its recrystallization temperature, usually at the ambient temperature. Such processes are contrasted with hot working techniques like hot rolling, forging, welding, etc. The same or similar terms are used in glassmaking for the equivalents; for example cut glass is made by "cold work", cutting or grinding a formed object. Cold forming techniques are usually classified into four major groups: squeezing, bending, drawing, and shearing. They generally have the advantage of being simpler to carry out than hot working techniques. Unlike hot working, cold working causes the crystal grains and inclusions to distort following the flow of the metal; which may cause work hardening and anisotropic material properties. Work hardening makes the metal harder, stiffer, and stronger, but less plastic, and may cause cracks of the piece. The possible uses of cold forming are extremely v ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Mandrel

A mandrel, mandril, or arbor is a gently tapered cylinder against which material can be forged or shaped (e.g., a ring mandrel - also called a triblet - used by jewelers to increase the diameter of a wedding ring), or a flanged or tapered or threaded bar that grips a workpiece to be machined in a lathe. A flanged mandrel is a parallel bar of a specific diameter with an integral flange towards one end, and threaded at the opposite end. Work is gripped between the flange and a nut on the thread. A tapered mandrel (often called a plain mandrel) has a taper of approximately 0.005 inches per foot and is designed to hold work by being driven into an accurate hole on the work, gripping the work by friction. A threaded mandrel may have a male or female thread, and work which has an identical thread is screwed onto the mandrel. On a lathe, mandrels are commonly mounted between centres and driven by a lathe dog (typically the flanged or tapered mandrels), but may also be gripped in a ch ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

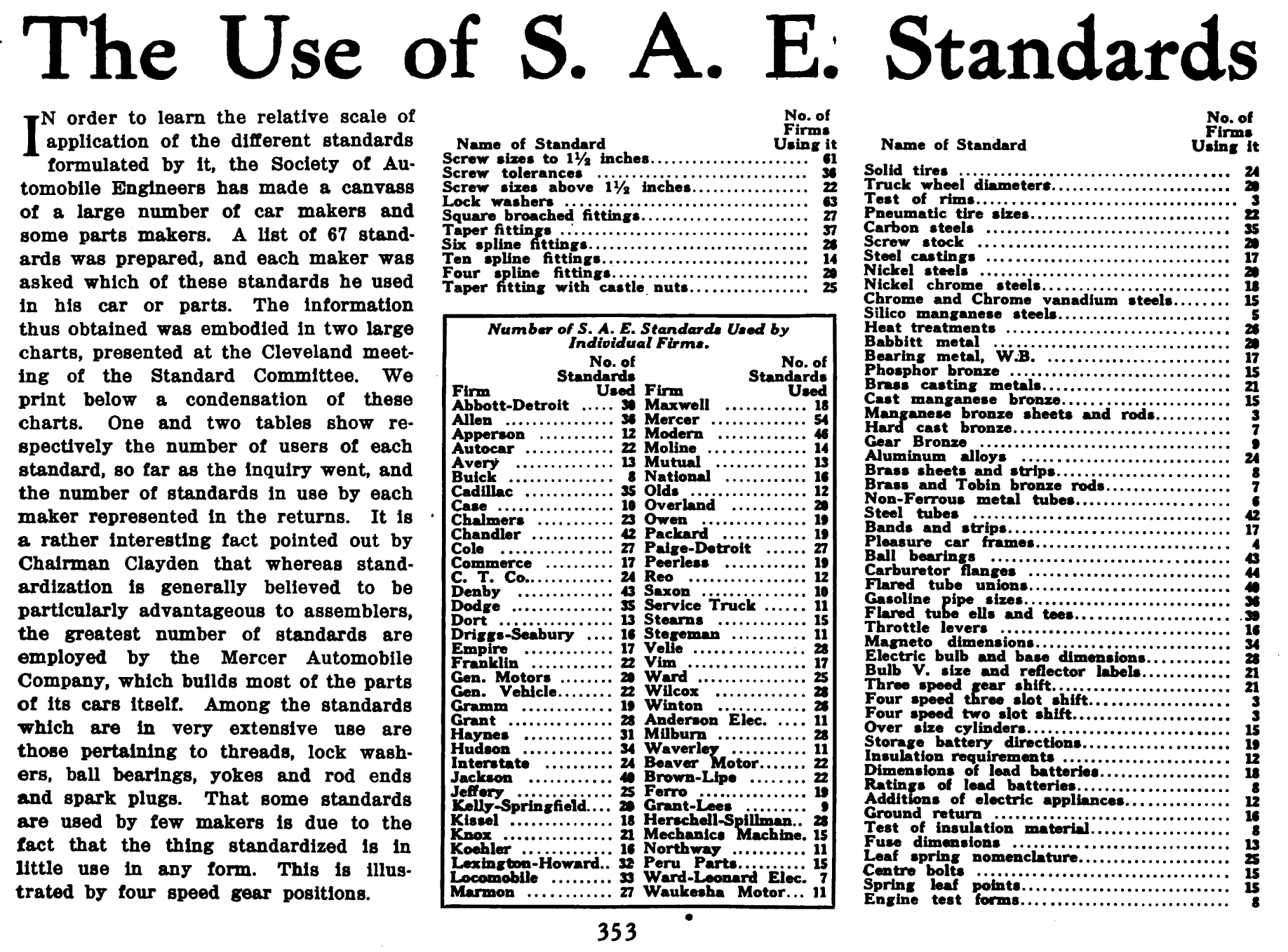

Society Of Automotive Engineers

SAE International, formerly named the Society of Automotive Engineers, is a United States-based, globally active professional association and standards developing organization for engineering professionals in various industries. SAE International's world headquarters is in Warrendale, Pennsylvania, 20 miles north of Pittsburgh, Pennsylvania. Principal emphasis is placed on global transport industries such as aerospace, automotive, and commercial vehicles. The organization adopted the name SAE International to reflect the broader emphasis on mobility. SAE International has over 138,000 global members. Membership is granted to individuals, rather than companies. Aside from its standardization efforts, SAE International also devotes resources to projects and programs in STEM education, professional certification, and collegiate design competitions. For historical legacy reasons, the label "SAE" is commonly used on tools and hardware in North America to indicate United States ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

JIC Fitting

SHF, Inc. JIC fittings, defined by the SAE J514 and MIL-DTL-18866 standards, are a type of machined with a 37-degree flare seating surface. JIC (Joint Industry Council) fittings are widely used in fuel delivery and applications, especially where high pressure (up to 10,000 psi) is involved. The SAE J514 standard replaces the MS16142 |

AN Thread

The AN thread (also A-N) is a particular type of fitting used to connect flexible hoses and rigid metal tubing that carry fluid. It is a US military-derived specification that dates back to World War II and stems from a joint standard agreed upon by the Army and Navy, hence AN. The Army-Navy involvement is also the origin of the red/blue color combination that was traditionally used in the anodized finishing process. AN sizes range from -2 (dash two) to -32 in irregular steps, with each step equating to the OD (outside diameter) of the tubing in -inch increments. Therefore, a -8 AN size would be equal to -inch OD tube. However, this system does not specify the ID (inside diameter) of the tubing because the tube wall can vary in thickness. Each AN size also uses its own standard thread size. AN fittings are a flare fitting, using 37° flared tubing to form a metal-to-metal seal. They are similar to other 37° flared fittings, such as JIC, which is their industrial variant. The ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Liquefied Petroleum Gas

Liquefied petroleum gas (LPG or LP gas) is a fuel gas which contains a flammable mixture of hydrocarbon gases, specifically propane, propylene, butylene, isobutane and n-butane. LPG is used as a fuel gas in heating appliances, cooking equipment, and vehicles. It is increasingly used as an aerosol propellant and a refrigerant, replacing chlorofluorocarbons in an effort to reduce damage to the ozone layer. When specifically used as a vehicle fuel, it is often referred to as autogas or even just as gas. Varieties of LPG that are bought and sold include mixes that are mostly propane (), mostly butane (), and, most commonly, mixes including both propane and butane. In the northern hemisphere winter, the mixes contain more propane, while in summer, they contain more butane. In the United States, mainly two grades of LPG are sold: commercial propane and HD-5. These specifications are published by the Gas Processors Association (GPA) and the American Society of Testing and Ma ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Flare-nut Wrench

A wrench or spanner is a tool used to provide grip and mechanical advantage in applying torque to turn objects—usually rotary fasteners, such as nuts and bolts—or keep them from turning. In the UK, Ireland, Australia, and New Zealand ''spanner'' is the standard term. The most common shapes are called ''open-ended spanner'' and ''ring spanner''. The term ''wrench'' is generally used for tools that turn non-fastening devices (e.g. tap wrench and pipe wrench), or may be used for a monkey wrench—an adjustable pipe wrench. In North American English, ''wrench'' is the standard term. The most common shapes are called ''open-end wrench'' and ''box-end wrench''. In American English, ''spanner'' refers to a specialized wrench with a series of pins or tabs around the circumference. (These pins or tabs fit into the holes or notches cut into the object to be turned.) In American commerce, such a wrench may be called a ''spanner wrench'' to distinguish it from the British sense ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Piping And Plumbing Fitting

A fitting or adapter is used in pipe systems to connect straight sections of pipe or tube, adapt to different sizes or shapes, and for other purposes such as regulating (or measuring) fluid flow. These fittings are used in plumbing to manipulate the conveyance of water, gas, or liquid waste in domestic or commercial environments, within a system of pipes or tubes. Fittings (especially uncommon types) require money, time, materials, and tools to install and are an important part of piping and plumbing systems. Valves are technically fittings, but are usually discussed separately. Standards Standard codes are followed when designing (or manufacturing) a piping system. Organizations which promulgate piping standards include: * ASME: American Society of Mechanical Engineers ** A112.19.1 Enameled cast-iron and steel plumbing fixtures standards ** A112.19.2 Ceramic plumbing fixtures standard * ASTM International: American Society for Testing and Materials * API: American Petroleu ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Sweat Fitting

Soldering (; ) is a process in which two or more items are joined by melting and putting a filler metal (solder) into the joint, the filler metal having a lower melting point than the adjoining metal. Unlike welding, soldering does not involve melting the work pieces. In brazing, the work piece metal also does not melt, but the filler metal is one that melts at a higher temperature than in soldering. In the past, nearly all solders contained lead, but environmental and health concerns have increasingly dictated use of lead-free alloys for electronics and plumbing purposes. Origins There is evidence that soldering was employed as early as 5,000 years ago in Mesopotamia. Soldering and brazing are thought to have originated very early in the history of metal-working, probably before 4000 BC. Sumerian swords from were assembled using hard soldering. Soldering was historically used to make jewelry, cookware and cooking tools, assembling stained glass, as well as other uses. ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |