|

JIC Fitting

SHF, Inc. JIC fittings, defined by the SAE J514 and MIL-DTL-18866 standards, are a type of machined with a 37-degree flare seating surface. JIC (Joint Industry Council) fittings are widely used in fuel delivery and applications, especially where high pressure (up to 10,000 psi) is involved. The SAE J514 standard replaces the MS16142 |

2706-mnptxmjic-bulkhead-stainless-steel-straight-hydraulic-adapter-medium

7 (seven) is the natural number following 6 and preceding 8. It is the only prime number preceding a cube. As an early prime number in the series of positive integers, the number seven has greatly symbolic associations in religion, mythology, superstition and philosophy. The seven Classical planets resulted in seven being the number of days in a week. It is often considered lucky in Western culture and is often seen as highly symbolic. Unlike Western culture, in Vietnamese culture, the number seven is sometimes considered unlucky. It is the first natural number whose pronunciation contains more than one syllable. Evolution of the Arabic digit In the beginning, Indians wrote 7 more or less in one stroke as a curve that looks like an uppercase vertically inverted. The western Ghubar Arabs' main contribution was to make the longer line diagonal rather than straight, though they showed some tendencies to making the digit more rectilinear. The eastern Arabs developed the digit ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

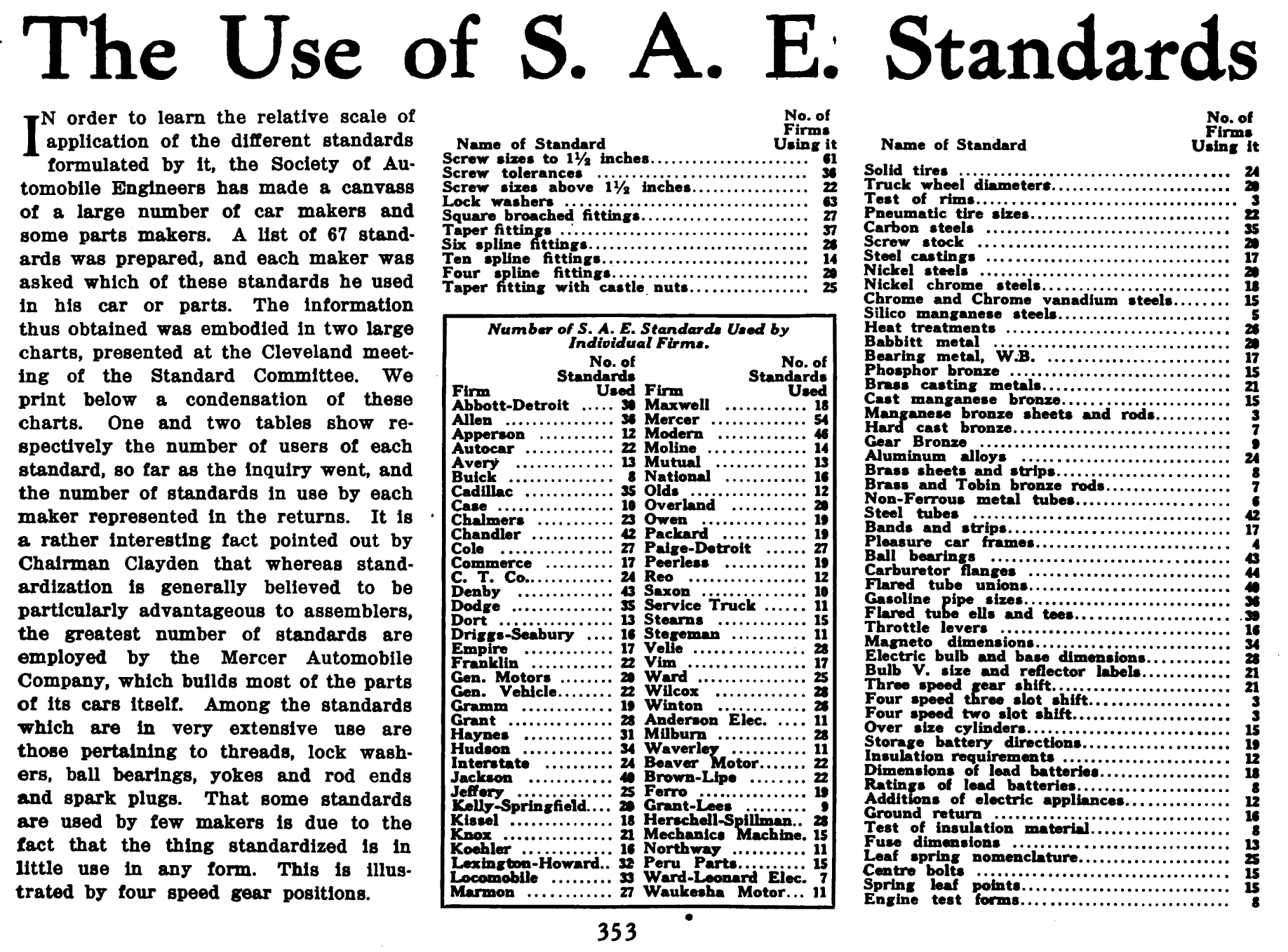

Society Of Automotive Engineers

SAE International, formerly named the Society of Automotive Engineers, is a United States-based, globally active professional association and standards developing organization for engineering professionals in various industries. SAE International's world headquarters is in Warrendale, Pennsylvania, 20 miles north of Pittsburgh, Pennsylvania. Principal emphasis is placed on global transport industries such as aerospace, automotive, and commercial vehicles. The organization adopted the name SAE International to reflect the broader emphasis on mobility. SAE International has over 138,000 global members. Membership is granted to individuals, rather than companies. Aside from its standardization efforts, SAE International also devotes resources to projects and programs in STEM education, professional certification, and collegiate design competitions. For historical legacy reasons, the label "SAE" is commonly used on tools and hardware in North America to indicate United States ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Flare Fitting

Flare fittings are a type of compression fitting used with metal tubing, usually soft steel, ductile (soft) copper and aluminum, though other materials are also used. In a flare fitting the tube itself is "flared" i.e. expanded and deformed at the end. The flare is then pressed against the fitting it connects to and is secured by a close-fitting nut that ensures that no leakage happens. Tube flaring is a type of forging operation, and is usually a cold working procedure. During assembly, a flare nut is used to secure the flared tubing's tapered end to the also tapered fitting, producing a pressure-resistant, leak-tight seal. Flared connections offer a high degree of long-term reliability and for this reason are often used in mission-critical and inaccessible locations. The tool used to flare tubing consists of a die that grips the tube and either a mandrel or rolling cone is forced into the end of the tube to form the flare by cold working. The most common flare fitt ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Hydraulics

Hydraulics (from Greek: Υδραυλική) is a technology and applied science using engineering, chemistry, and other sciences involving the mechanical properties and use of liquids. At a very basic level, hydraulics is the liquid counterpart of pneumatics, which concerns gases. Fluid mechanics provides the theoretical foundation for hydraulics, which focuses on the applied engineering using the properties of fluids. In its fluid power applications, hydraulics is used for the generation, control, and transmission of power by the use of pressurized liquids. Hydraulic topics range through some parts of science and most of engineering modules, and cover concepts such as pipe flow, dam design, fluidics and fluid control circuitry. The principles of hydraulics are in use naturally in the human body within the vascular system and erectile tissue. Free surface hydraulics is the branch of hydraulics dealing with free surface flow, such as occurring in rivers, canals, lakes, estuar ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Military Specification

A United States defense standard, often called a military standard, "MIL-STD", "MIL-SPEC", or (informally) "MilSpecs", is used to help achieve standardization objectives by the U.S. Department of Defense. Standardization is beneficial in achieving interoperability, ensuring products meet certain requirements, commonality, reliability, total cost of ownership, compatibility with logistics systems, and similar defense-related objectives. Defense standards are also used by other non-defense government organizations, technical organizations, and industry. This article discusses definitions, history, and usage of defense standards. Related documents, such as defense handbooks and defense specifications, are also addressed. Definition of document types Although the official definitions differentiate between several types of documents, all of these documents go by the general rubric of "military standard", including defense specifications, handbooks, and standards. Strictly speaking, ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

AN Thread

The AN thread (also A-N) is a particular type of fitting used to connect flexible hoses and rigid metal tubing that carry fluid. It is a US military-derived specification that dates back to World War II and stems from a joint standard agreed upon by the Army and Navy, hence AN. The Army-Navy involvement is also the origin of the red/blue color combination that was traditionally used in the anodized finishing process. AN sizes range from -2 (dash two) to -32 in irregular steps, with each step equating to the OD (outside diameter) of the tubing in -inch increments. Therefore, a -8 AN size would be equal to -inch OD tube. However, this system does not specify the ID (inside diameter) of the tubing because the tube wall can vary in thickness. Each AN size also uses its own standard thread size. AN fittings are a flare fitting, using 37° flared tubing to form a metal-to-metal seal. They are similar to other 37° flared fittings, such as JIC, which is their industrial variant. The ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Forging

Forging is a manufacturing process involving the shaping of metal using localized compressive forces. The blows are delivered with a hammer (often a power hammer) or a die. Forging is often classified according to the temperature at which it is performed: cold forging (a type of cold working), warm forging, or hot forging (a type of hot working). For the latter two, the metal is heated, usually in a forge. Forged parts can range in weight from less than a kilogram to hundreds of metric tons.Degarmo, p. 389 Forging has been done by smiths for millennia; the traditional products were kitchenware, hardware, hand tools, edged weapons, cymbals, and jewellery. Since the Industrial Revolution, forged parts are widely used in mechanisms and machines wherever a component requires high strength; such forgings usually require further processing (such as machining) to achieve a finished part. Today, forging is a major worldwide industry. History Forging is one of the oldest known me ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Carbon Steel

Carbon steel is a steel with carbon content from about 0.05 up to 2.1 percent by weight. The definition of carbon steel from the American Iron and Steel Institute (AISI) states: * no minimum content is specified or required for chromium, cobalt, molybdenum, nickel, niobium, titanium, tungsten, vanadium, zirconium, or any other element to be added to obtain a desired alloying effect; * the specified minimum for copper does not exceed 0.40%; * or the maximum content specified for any of the following elements does not exceed the percentages noted: manganese 1.65%; silicon 0.60%; copper 0.60%. The term ''carbon steel'' may also be used in reference to steel which is not stainless steel; in this use carbon steel may include alloy steels. High carbon steel has many different uses such as milling machines, cutting tools (such as chisels) and high strength wires. These applications require a much finer microstructure, which improves the toughness. Carbon steel is a popular metal choic ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Stainless Steel

Stainless steel is an alloy of iron that is resistant to rusting and corrosion. It contains at least 11% chromium and may contain elements such as carbon, other nonmetals and metals to obtain other desired properties. Stainless steel's corrosion resistance, resistance to corrosion results from the chromium, which forms a Passivation (chemistry), passive film that can protect the material and self-healing material, self-heal in the presence of oxygen. The alloy's properties, such as luster and resistance to corrosion, are useful in many applications. Stainless steel can be rolled into Sheet metal, sheets, plates, bars, wire, and tubing. These can be used in cookware, cutlery, surgical instruments, major appliances, vehicles, construction material in large buildings, industrial equipment (e.g., in paper mills, chemical plants, water treatment), and storage tanks and tankers for chemicals and food products. The biological cleanability of stainless steel is superior to both alumi ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Brass

Brass is an alloy of copper (Cu) and zinc (Zn), in proportions which can be varied to achieve different mechanical, electrical, and chemical properties. It is a substitutional alloy: atoms of the two constituents may replace each other within the same crystal structure. Brass is similar to bronze, another copper alloy, that uses tin instead of zinc. Both bronze and brass may include small proportions of a range of other elements including arsenic (As), lead (Pb), phosphorus (P), aluminium (Al), manganese (Mn), and silicon (Si). Historically, the distinction between the two alloys has been less consistent and clear, and modern practice in museums and archaeology increasingly avoids both terms for historical objects in favor of the more general "copper alloy". Brass has long been a popular material for decoration due to its bright, gold-like appearance; being used for drawer pulls and doorknobs. It has also been widely used to make utensils because of its low melting ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Monel

Monel is a group of alloys of nickel (from 52 to 67%) and copper, with small amounts of iron, manganese, carbon, and silicon. Monel is not a cupronickel alloy because it has less than 60% copper. Stronger than pure nickel, Monel alloys are resistant to corrosion by many aggressive agents, including rapidly flowing seawater. They can be fabricated readily by hot- and cold-working, machining, and welding. Monel was created in 1905 by Robert Crooks Stanley, who at the time worked at the International Nickel Company (Inco). Monel alloy 400 is a binary alloy of the same proportions of nickel and copper as is found naturally in the meteoritic nickel ore from the Sudbury (Ontario) mines and is therefore considered a puritan alloy. Monel was named after company president Ambrose Monell, and patented in 1906. One L was dropped, because family names were not allowed as trademarks at that time. The trademark was registered in May 1921, and the name is now a trademark of Special Metals C ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |