|

Flameout

In aviation, a flameout (or flame-out) is the run-down of a jet engine or other turbine engine due to the extinction of the flame in its combustor. The loss of flame can have a variety of causes, such as fuel starvation, excessive altitude, compressor stall, foreign object damage deriving from birds, hail, or volcanic ash, severe precipitation, mechanical failure, or very low ambient temperatures. Engine control Early jet engines were prone to flameout following disturbances of inlet airflow, or sudden or inappropriate thrust lever movements, which resulted in incorrect air-fuel ratios in the combustion chamber. Modern engines are much more robust in this respect, and are often digitally controlled, which allows for a significantly more effective control of all engine parameters to prevent flameouts and even initiate an automatic restart if a flameout occurs. Flameouts occur most frequently at intermediate or low power settings such as in cruise and descent. To prevent a flam ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Foreign Object Damage

In aviation and aerospace, foreign object debris (FOD), is any particle or substance, alien to an aircraft or system, which could potentially cause damage. External FOD hazards include bird strikes, hail, ice, sandstorms, ash-clouds or objects left on the runway. Internal FOD hazards include items left in the cockpit that interfere with flight safety by getting tangled in control cables, jam moving parts or short-out electrical connections. The term FOD is used to describe both the foreign objects themselves, and any damage attributed to them. Jet engine design and FOD Modern jet engines can suffer major damage from even small objects being sucked into the engine. The FAA (Federal Aviation Administration) requires that all engine types pass a test which includes firing a fresh chicken (dead, but not frozen) into a running jet engine from a small cannon. The engine does not have to remain functional after the test, but it must not cause significant damage to the rest of the ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

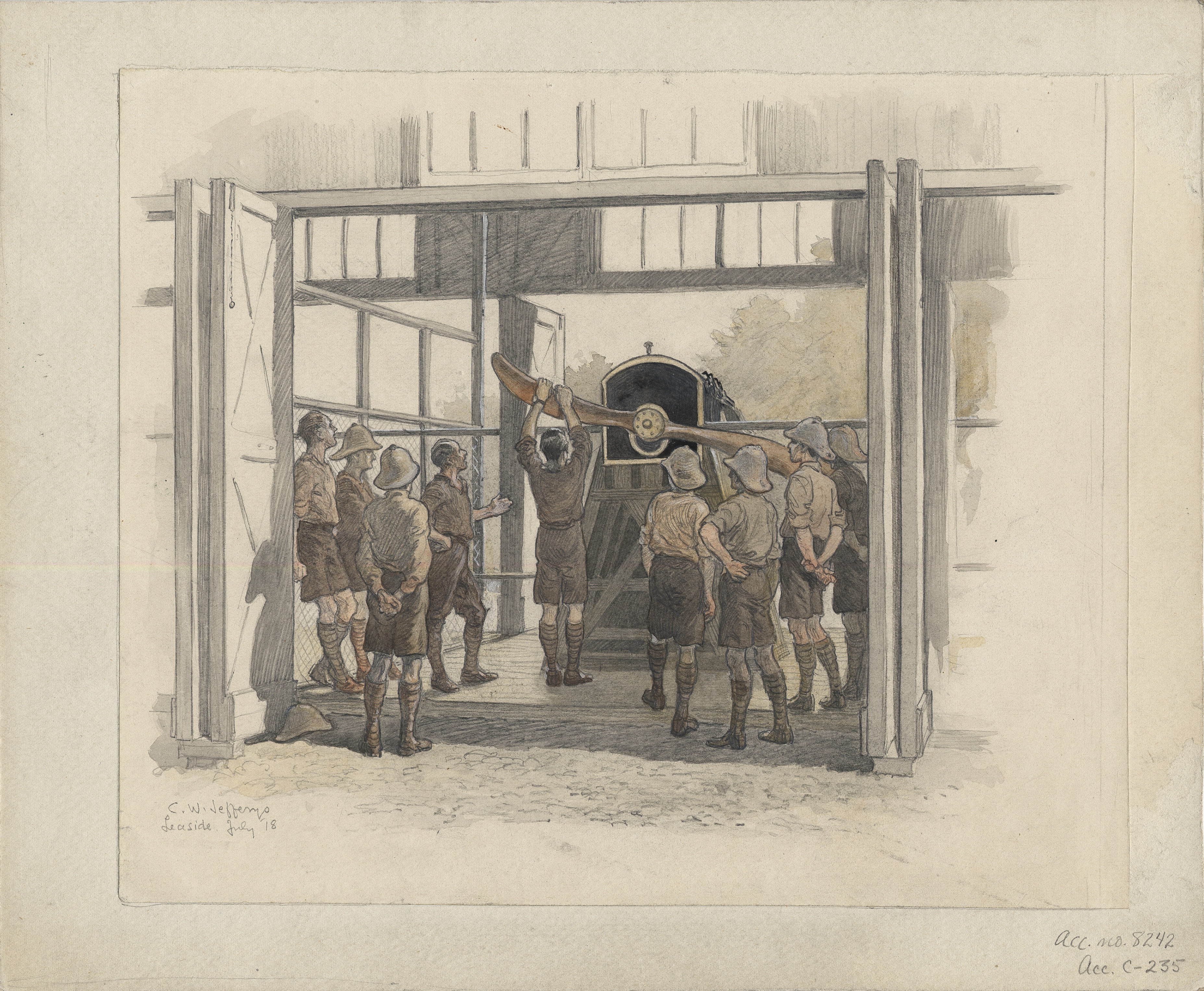

Aircraft Engine Starting

Many variations of aircraft engine starting have been used since the Wright brothers made their first powered flight in 1903. The methods used have been designed for weight saving, simplicity of operation and reliability. Early piston engines were started by hand, with geared hand starting, electrical and cartridge-operated systems for larger engines being developed between the wars. Gas turbine aircraft engines such as turbojets, turboshafts and turbofans often use air/pneumatic starting, with the use of ''bleed air'' from built-in auxiliary power units (APUs) or external air compressors now seen as a common starting method. Often only one engine needs be started using the APU (or remote compressor). After the first engine is started using APU bleed air, ''cross-bleed air'' from the running engine can be used to start the remaining engine(s). Piston engines Hand starting/propeller swinging Hand starting of aircraft piston engines by swinging the propeller is the oldest and sim ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Jet Engine

A jet engine is a type of reaction engine discharging a fast-moving jet of heated gas (usually air) that generates thrust by jet propulsion. While this broad definition can include rocket, Pump-jet, water jet, and hybrid propulsion, the term typically refers to an internal combustion airbreathing jet engine such as a turbojet, turbofan, ramjet, or pulse jet engine, pulse jet. In general, jet engines are internal combustion engines. Airbreathing jet engines typically feature a Axial compressor, rotating air compressor powered by a turbine, with the leftover power providing thrust through the propelling nozzle—this process is known as the Brayton cycle, Brayton thermodynamic cycle. Jet aircraft use such engines for long-distance travel. Early jet aircraft used turbojet engines that were relatively inefficient for subsonic flight. Most modern subsonic jet aircraft use more complex High-bypass turbofan, high-bypass turbofan engines. They give higher speed and greater fuel eff ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Core Lock

Core lock is a jet engine failure that can happen to aircraft in flight. When an engine is shut down in flight, the design of the engine causes some parts to cool quicker than others. Since materials change sizes in different temperatures, this happens to the jet engine. If the engine's parts sizes differ too much, then some parts will grip onto other parts, reducing or even stopping rotation. This condition is called "core lock" Core lock makes it difficult for pilots to perform either a windmill restart or an APU-assisted engine restart. When the engine parts’ temperature is allowed to normalize, after time is given, the parts will normalize in sizes, removing the core lock condition. Pinnacle Airlines Flight 3701 Core lock was cited as one of the contributing causes to the October 2004 Pinnacle Airlines Flight 3701 On October 14, 2004, Pinnacle Airlines Flight 3701 (ICAO: FLG3701, IATA: 9E3701, or Flagship 3701) crashed near Jefferson City, Missouri, while flying fro ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Airbus

Airbus SE (; ; ; ) is a European Multinational corporation, multinational aerospace corporation. Airbus designs, manufactures and sells civil and military aerospace manufacturer, aerospace products worldwide and manufactures aircraft throughout the world. The company has three divisions: ''Airbus Commercial Aircraft, Commercial Aircraft (Airbus S.A.S.)'', ''Airbus Defence and Space, Defence and Space'', and ''Airbus Helicopters, Helicopters'', the third being the largest in its industry in terms of revenues and turbine helicopter deliveries. As of 2019, Airbus is the world's largest airliner manufacturer. The company's main civil aeroplane business is conducted through the French company Airbus S.A.S., based in Blagnac, a suburb of Toulouse, with production and manufacturing facilities mostly in the European Union and the United Kingdom but also in China, the United States and Canada. Final assembly production is based in Toulouse, France; Hamburg, Germany; Seville, Spain; Tia ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Ceiling (aeronautics)

With respect to aircraft performance, a ceiling is the maximum density altitude an aircraft can reach under a set of conditions, as determined by its flight envelope. Service ceiling Service ceiling is where the rate of climb drops below a prescribed value. The service ceiling is the maximum usable altitude of an aircraft. Specifically, it is the density altitude at which flying in a clean configuration, at the best rate of climb airspeed for that altitude and with all engines operating and producing maximum continuous power, will produce a given rate of climb. A typical value might be climb, or on the order of climb for jet aircraft. The one-engine inoperative (OEI) service ceiling of a twin-engine, fixed-wing aircraft is the density altitude at which flying in a clean configuration, at the best rate of climb airspeed for that altitude with one engine producing maximum continuous power and the other engine shut down and feathered, will produce a given rate of climb, usually ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Airbus A320

The Airbus A320 family is a series of Narrow-body aircraft, narrow-body airliners developed and produced by Airbus. The A320 was launched in March 1984, Maiden flight, first flew on 22 February 1987, and was introduced in April 1988 by Air France. The first member of the family was followed by the longer A321 (first delivered in January 1994), the shorter A319 (April 1996), and the even shorter A318 (July 2003). Final assembly takes place in Toulouse in France; Hamburg in Germany; Tianjin in China since 2009; and in Mobile, Alabama in the United States since April 2016. The twinjet has a six-abreast cross-section and is powered by either CFM56 or IAE V2500 turbofans, except the CFM56/PW6000 powered A318. The family pioneered the use of digital fly-by-wire and side-stick flight controls in airliners. Variants offer maximum take-off weights from , to cover a Range (aircraft), range. The 31.4 m (103 ft) long Airbus A318, A318 typically accommodates 107 to 132 passen ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Flight Envelope

In aerodynamics, the flight envelope, service envelope, or performance envelope of an aircraft or spacecraft refers to the capabilities of a design in terms of airspeed and load factor or atmospheric density, often simplified to altitude. The term is somewhat loosely applied, and can also refer to other measurements such as maneuverability. When a plane is pushed, for instance by diving it at high speeds, it is said to be flown "outside the envelope", something considered rather dangerous. Flight envelope is one of a number of related terms that are all used in a similar fashion. It is perhaps the most common term because it is the oldest, first being used in the early days of test flying. It is closely related to more modern terms known as extra power and a doghouse plot which are different ways of describing a flight envelope. In addition, the term has been widened in scope outside the field of engineering, to refer to the strict limits in which an event will take place or mor ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

FADEC

A full authority digital engine (or electronics) control (FADEC) is a system consisting of a digital computer, called an "electronic engine controller" (EEC) or "engine control unit" (ECU), and its related accessories that control all aspects of aircraft engine performance. FADECs have been produced for both piston engines and jet engines. History The goal of any engine control system is to allow the engine to perform at maximum efficiency for a given condition. Originally, engine control systems consisted of simple mechanical linkages connected physically to the engine. By moving these levers the pilot or the flight engineer could control fuel flow, power output, and many other engine parameters. The mechanical/hydraulic engine control unit for Germany's BMW 801 piston aviation radial engine of World War II was just one notable example of this in its later stages of development. This mechanical engine control was progressively replaced first by analog electronic engine control ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Thrust Lever

Thrust levers or throttle levers are found in the cockpit of aircraft, and are used by the pilot, copilot, or autopilot to control the thrust output of the aircraft's engines, by controlling the fuel flow to those engines. In multi-engine aircraft, each thrust lever displays the engine number of the engine it controls. Normally, there is one thrust lever for each engine. The thrust levers are normally found in the aircraft's center console, or on the dashboard of smaller aircraft. For aircraft equipped with thrust reversal, the control for each thrust reverser is usually found adjacent to the corresponding engine's thrust lever. The position of each lever can be described by the current angle indicated. This is referred to as the ''Throttle Lever Angle'' or ''TLA''. The greater the TLA, the greater the engine thrust. The throttle lever assembly is often designed to incorporate high-pressure (HP) cock switches so that the pilot has instinctive control of the fuel supply to t ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Gas Turbine

A gas turbine, also called a combustion turbine, is a type of continuous flow internal combustion engine. The main parts common to all gas turbine engines form the power-producing part (known as the gas generator or core) and are, in the direction of flow: * a rotating gas compressor * a combustor * a compressor-driving turbine. Additional components have to be added to the gas generator to suit its application. Common to all is an air inlet but with different configurations to suit the requirements of marine use, land use or flight at speeds varying from stationary to supersonic. A propelling nozzle is added to produce thrust for flight. An extra turbine is added to drive a propeller (turboprop) or ducted fan (turbofan) to reduce fuel consumption (by increasing propulsive efficiency) at subsonic flight speeds. An extra turbine is also required to drive a helicopter rotor or land-vehicle transmission (turboshaft), marine propeller or electrical generator (power turbine). Greater ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

.jpg)