|

Fiat A.25

The Fiat A.25 was an Italian water-cooled aircraft engine from the 1920s. It produced 708 kW (950 hp) and was used by the Regia Aeronautica for fifteen years to power their Fiat BR.2 and BR.3 bombers. Design and development During the 1920s Fiat introduced several water-cooled aircraft engines, including the A.20, A.22, A24, A.25 and A.30. They were all upright V-12s with 60° between the cylinder banks; capacities ranged between 18.7 L and 54.5 L (1,141-3,324 cu in) and power outputs between 320 kW and 745 kW (430-1,000 hp). Producing 710 kW (950 hp) from 54.5 L (3,324 cu in), the A.25 was the largest and most powerful in the range. When Fiat were advised by the government to simplify their water-cooled product line, they focussed on the A.20, A.22 and A.30 models, so the A.25 was not further developed. They concentrated their higher power development effort on radial engines instead. Operational histor ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

WikiProject Aircraft

A WikiProject, or Wikiproject, is a Wikimedia movement affinity group for contributors with shared goals. WikiProjects are prevalent within the largest wiki, Wikipedia, and exist to varying degrees within sister projects such as Wiktionary, Wikiquote, Wikidata, and Wikisource. They also exist in different languages, and translation of articles is a form of their collaboration. During the COVID-19 pandemic, CBS News noted the role of Wikipedia's WikiProject Medicine in maintaining the accuracy of articles related to the disease. Another WikiProject that has drawn attention is WikiProject Women Scientists, which was profiled by '' Smithsonian'' for its efforts to improve coverage of women scientists which the profile noted had "helped increase the number of female scientists on Wikipedia from around 1,600 to over 5,000". On Wikipedia Some Wikipedia WikiProjects are substantial enough to engage in cooperative activities with outside organizations relevant to the field at issue. For e ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

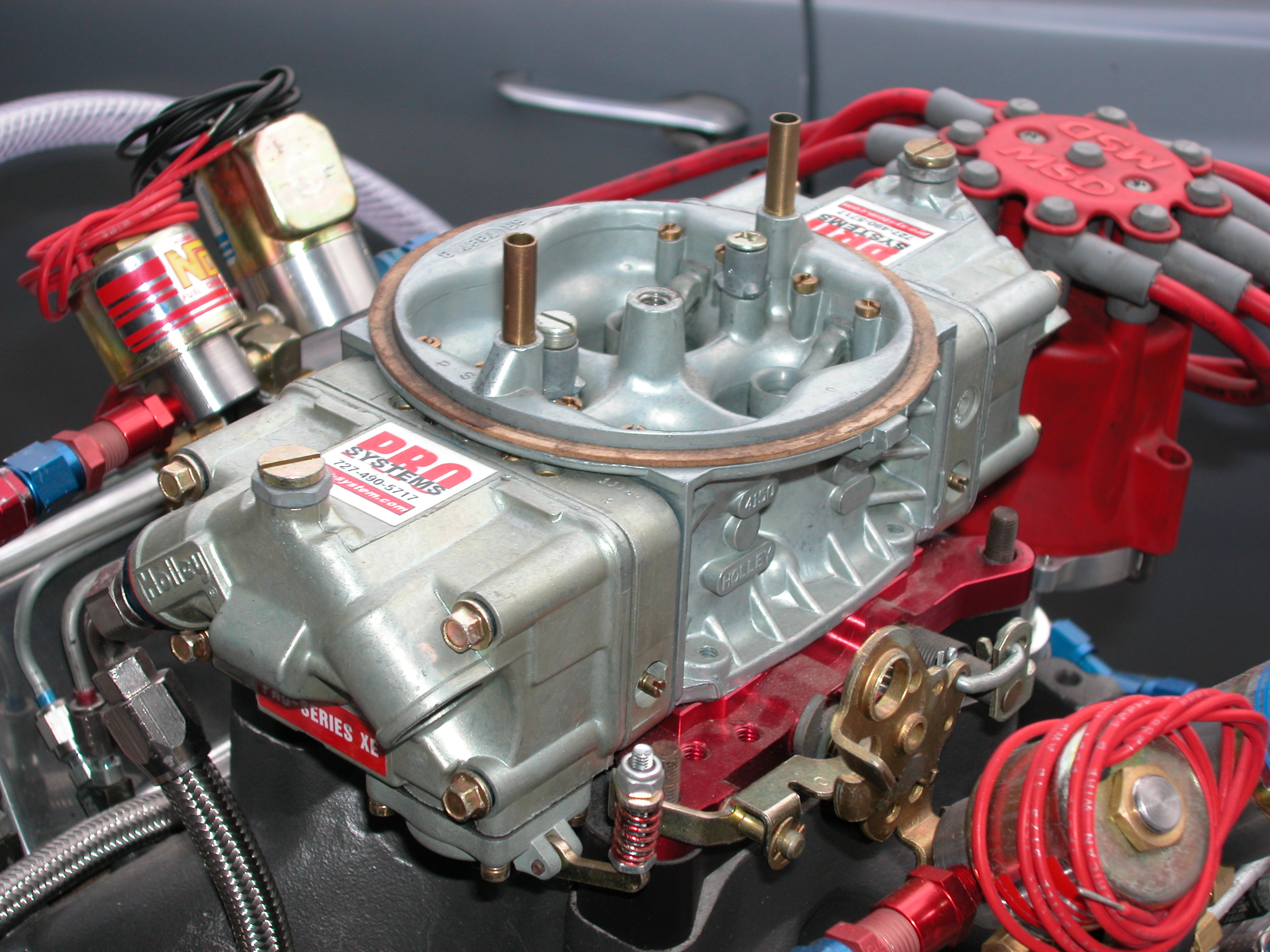

Carburettor

A carburetor (also spelled carburettor) is a device used by an internal combustion engine to control and mix air and fuel entering the engine. The primary method of adding fuel to the intake air is through the venturi tube in the main metering circuit, however various other components are also used to provide extra fuel or air in specific circumstances. Since the 1990s, carburetors have been largely replaced by fuel injection for cars and trucks, however carburetors are still used by some small engines (e.g. lawnmowers, generators and concrete mixers) and motorcycles. Diesel engines have always used fuel injection instead of carburetors. Etymology The name "carburetor" is derived from the verb ''carburet'', which means "to combine with carbon," or in particular, "to enrich a gas by combining it with carbon or hydrocarbons." Thus a carburetor mixes intake air with hydrocarbon-based fuel, such as petrol or autogas (LPG). The name is spelled "carburetor" in American English a ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Flight International

''Flight International'' is a monthly magazine focused on aerospace. Published in the United Kingdom and founded in 1909 as "A Journal devoted to the Interests, Practice, and Progress of Aerial Locomotion and Transport", it is the world's oldest continuously published aviation news magazine. ''Flight International'' is published by DVV Media Group. Competitors include Jane's Information Group and ''Aviation Week''. Former editors of, and contributors include H. F. King, Bill Gunston, John W. R. Taylor and David Learmount. History The founder and first editor of ''Flight'' was Stanley Spooner. He was also the creator and editor of ''The Automotor Journal'', originally titled ''The Automotor Journal and Horseless Vehicle''.Guide To British Industrial History: Biographies: ''Stan ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

List Of Aircraft Engines

This is an alphabetical list of aircraft engines by manufacturer. 0–9 2si *2si 215 *2si 230 * 2si 430 * 2si 460 *2si 500 * 2si 540 * 2si 690 3W ''Source: RMV'' *3W 106iB2 *3W-110 *3W-112 *3W-170 *3W-210 *3W-220 A Abadal (Francisco Serramalera Abadal) *Abadal Y-12 350/400 hp ABC ''Source: Lumsden.'' * ABC 8 hp * ABC 30hp V-4 * ABC 45hp V-6 * ABC 60hp V-8 * ABC 85hp V-6 * ABC 100hp V-8 * ABC 115 hp * ABC 170hp V-12 * ABC 225hp V-16 *ABC Dragonfly *ABC Gadfly *ABC Gnat *ABC Hornet * ABC Mosquito *ABC Scorpion *ABC Wasp *ABC type 10 APU *ABC type 11 APU ABECO ''Source: RMV'' *ABECO GEM Aberg ''Source: RMV'' *Type Sklenar ABLE ''Source: RMV'', Able Experimental Aircraft Engine Co. (Able Experimental Aircraft Engine Co., Altimizer, Hoverhawk (US)) *ABLE 2275 *ABLE 2500 *ABLE VW x 2 Geared Drive Accurate Automation Corp *Accurate Automation AT-1500 *Accurate Automation AT-1700 Ace (Ace American Engr Corp, Horace Keane Aeroplane Co, North Beac ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Duralumin

Duralumin (also called duraluminum, duraluminium, duralum, dural(l)ium, or dural) is a trade name for one of the earliest types of age-hardenable aluminium alloys. The term is a combination of '' Dürener'' and ''aluminium''. Its use as a trade name is obsolete. Today the term mainly refers to aluminium–copper alloys, designated as the 2000 series by the international alloy designation system (IADS), as with 2014 and 2024 alloys used in airframe fabrication. History Duralumin was developed by the German metallurgist Alfred Wilm at Dürener Metallwerke AG. In 1903, Wilm discovered that after quenching, an aluminium alloy containing 4% copper would harden when left at room temperature for several days. Further improvements led to the introduction of duralumin in 1909. The name is mainly used in pop-science to describe all Al-Cu alloys system, or '2000' series, as designated through the international alloy designation system originally created in 1970 by the Aluminum A ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Gudgeon Pin

In internal combustion engines, the gudgeon pin (UK, wrist pin or piston pin US) connects the piston to the connecting rod, and provides a bearing for the connecting rod to pivot upon as the piston moves.Nunney, Malcolm James (2007) "The Reciprocating Piston Petrol Engine: Gudgeon pins and their location" ''Light and heavy vehicle technology'' (4th ed.) Butterworth-Heinemann, Oxford, UKp. 28 In very early engine designs, including those driven by steam, and many very large stationary or marine engines, the gudgeon pin is located in a sliding crosshead that connects to the piston via a rod. A gudgeon is a pivot or journal. The origin of the word gudgeon is the Middle English word gojoun, which originated from the Middle French word goujon. Its first known use was in the 15th century.Webster's Seventh New Collegiate Dictionary, G & C Merriam Company, 1963, p. 370 Overview The gudgeon pin is typically a forged short hollow rod made of a steel alloy of high strength and hardness tha ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

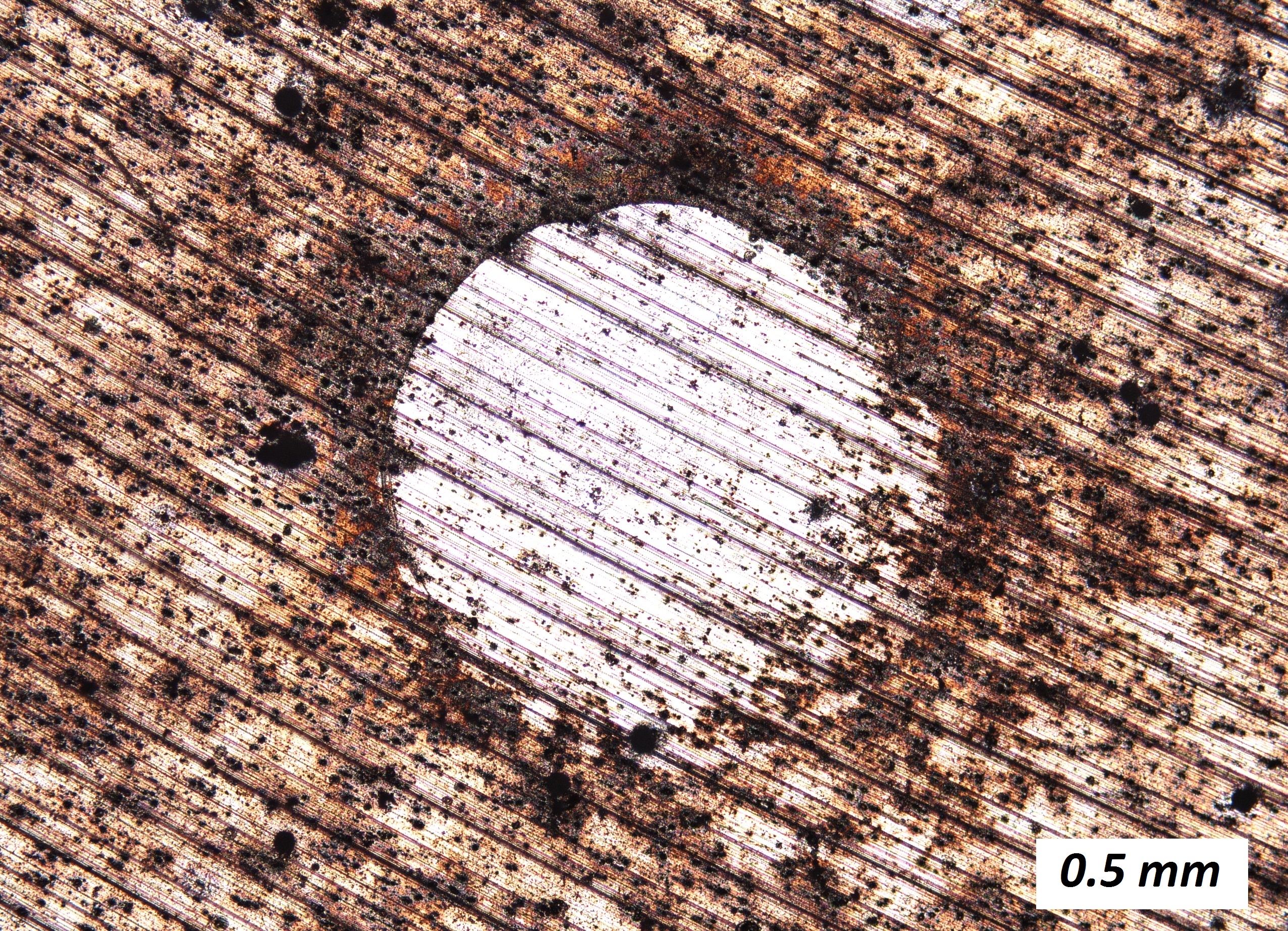

Piston Rings

A piston ring is a metallic split ring that is attached to the outer diameter of a piston in an internal combustion engine or steam engine. The main functions of piston rings in engines are: # Sealing the combustion chamber so that there is minimal loss of gases to the crank case. # Improving heat transfer from the piston to the cylinder wall. # Maintaining the proper quantity of the oil between the piston and the cylinder wall # Regulating engine oil consumption by scraping oil from the cylinder walls back to the sump. Most piston rings are made from cast iron or steel. Design Piston rings are designed to seal the gap between the piston and the cylinder wall. If this gap were too small, thermal expansion of the piston could mean the piston seizes in the cylinder, causing serious damage to the engine. On the other hand, a large gap would cause insufficient sealing of the piston rings against the cylinder walls, resulting in excessive blow-by (combustion gases entering the ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Centrifugal Pump

Centrifugal pumps are used to transport fluids by the conversion of rotational kinetic energy to the hydrodynamic energy of the fluid flow. The rotational energy typically comes from an engine or electric motor. They are a sub-class of dynamic axisymmetric work-absorbing turbomachinery. The fluid enters the pump impeller along or near to the rotating axis and is accelerated by the impeller, flowing radially outward into a diffuser or volute chamber (casing), from which it exits. Common uses include water, sewage, agriculture, petroleum, and petrochemical pumping. Centrifugal pumps are often chosen for their high flow rate capabilities, abrasive solution compatibility, mixing potential, as well as their relatively simple engineering. A centrifugal fan is commonly used to implement an air handling unit or vacuum cleaner. The reverse function of the centrifugal pump is a water turbine converting potential energy of water pressure into mechanical rotational energy. His ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Scavenge Pump

A dry-sump system is a method to manage the lubricating motor oil in four-stroke and large two-stroke piston driven internal combustion engines. The dry-sump system uses two or more oil pumps and a separate oil reservoir, as opposed to a conventional wet-sump system, which uses only the main sump (U.S.: oil pan) below the engine and a single pump. A dry-sump engine requires a pressure relief valve to regulate negative pressure inside the engine, so internal seals are not inverted. Dry-sumps are common on larger diesel engines such as those used in ships, as well as gasoline engines used in racing cars, aerobatic aircraft, high-performance personal watercraft and motorcycles. Dry sump lubrication may be chosen for these applications due to increased reliability, oil capacity, reduction of oil starvation under high g-loads and/or other technical or performance reasons. Dry sump systems may not be suitable for all applications due to increased cost, complexity, and/or bulk, amon ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Ignition Magneto

An ignition magneto, or high-tension magneto, is a magneto that provides current for the ignition system of a spark-ignition engine, such as a petrol engine. It produces pulses of high voltage for the spark plugs. The older term ''tension'' means ''voltage''. The use of ignition magnetos is now confined mainly to engines where there is no other available electrical supply, for example in lawnmowers and chainsaws. It is also widely used in aviation piston engines even though an electrical supply is usually available. In this case, the magneto's self-powered operation is considered to offer increased reliability; in theory, the magneto should continue operation as long as the engine is turning. History Firing the gap of a spark plug, particularly in the combustion chamber of a high-compression engine, requires a greater voltage (or ''higher tension'') than can be achieved by a simple magneto. The ''high-tension magneto'' combines an alternating current magneto generator a ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Spark Plug

A spark plug (sometimes, in British English, a sparking plug, and, colloquially, a plug) is a device for delivering electric current from an ignition system to the combustion chamber of a spark-ignition engine to ignite the compressed fuel/air mixture by an electric spark, while containing combustion pressure within the engine. A spark plug has a metal threaded shell, electrically isolated from a central electrode by a ceramic insulator. The central electrode, which may contain a resistor, is connected by a heavily insulated wire to the output terminal of an ignition coil or magneto. The spark plug's metal shell is screwed into the engine's cylinder head and thus electrically grounded. The central electrode protrudes through the porcelain insulator into the combustion chamber, forming one or more spark gaps between the inner end of the central electrode and usually one or more protuberances or structures attached to the inner end of the threaded shell and designated the ''side ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

.jpg)