|

Electron Beam

Since the mid-20th century, electron-beam technology has provided the basis for a variety of novel and specialized applications in semiconductor manufacturing, microelectromechanical systems, nanoelectromechanical systems, and microscopy. Mechanism Free electrons in a vacuum can be manipulated by Electric field, electric and magnetic fields to form a fine beam. Where the beam collides with solid-state matter, electrons are converted into heat or kinetic energy. This concentration of energy in a small volume of matter can be precisely controlled by the fields, which brings many advantages. Applications Electron beam techniques include electron probe microanalysis, transmission electron microscopy, auger spectroscopy, and scanning electron microscopy. The rapid increase of temperature at the location of impact can quickly melt a target material. In extreme working conditions, the rapid temperature increase can lead to evaporation, making an electron beam an excellent tool in heating ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Semiconductor

A semiconductor is a material with electrical conductivity between that of a conductor and an insulator. Its conductivity can be modified by adding impurities (" doping") to its crystal structure. When two regions with different doping levels are present in the same crystal, they form a semiconductor junction. The behavior of charge carriers, which include electrons, ions, and electron holes, at these junctions is the basis of diodes, transistors, and most modern electronics. Some examples of semiconductors are silicon, germanium, gallium arsenide, and elements near the so-called " metalloid staircase" on the periodic table. After silicon, gallium arsenide is the second-most common semiconductor and is used in laser diodes, solar cells, microwave-frequency integrated circuits, and others. Silicon is a critical element for fabricating most electronic circuits. Semiconductor devices can display a range of different useful properties, such as passing current more easil ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Refractory Metals

Refractory metals are a class of metals that are extraordinarily resistant to heat and wear. The expression is mostly used in the context of materials science, metallurgy and engineering. The definitions of which elements belong to this group differ. The most common definition includes five elements: two of the fifth period (niobium and molybdenum) and three of the sixth period (tantalum, tungsten, and rhenium). They all share some properties, including a melting point above 2000 °C and high hardness at room temperature. They are chemically inert and have a relatively high density. Their high melting points make powder metallurgy the method of choice for fabricating components from these metals. Some of their applications include tools to work metals at high temperatures, wire filaments, casting molds, and chemical reaction vessels in corrosive environments. Partly due to their high melting points, refractory metals are stable against creep deformation to very high tem ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Physical Vapor Deposition

Physical vapor deposition (PVD), sometimes called physical vapor transport (PVT), describes a variety of vacuum deposition methods which can be used to produce thin films and coatings on substrates including metals, ceramics, glass, and polymers. PVD is characterized by a process in which the material transitions from a condensed phase to a vapor phase and then back to a thin film condensed phase. The most common PVD processes are Sputter coating, sputtering and Evaporation (deposition), evaporation. PVD is used in the manufacturing of items which require thin films for optical, mechanical, electrical, acoustic or chemical functions. Examples include semiconductor devices such as thin-film solar cells, microelectromechanical devices such as thin film bulk acoustic resonator, aluminized Polyethylene terephthalate, PET film for food packaging and balloons, and titanium nitride coated cutting tools for metalworking. Besides PVD tools for fabrication, special smaller tools used mai ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Photolithography

Photolithography (also known as optical lithography) is a process used in the manufacturing of integrated circuits. It involves using light to transfer a pattern onto a substrate, typically a silicon wafer. The process begins with a photosensitive material, called a photoresist, being applied to the substrate. A photomask that contains the desired pattern is then placed over the photoresist. Light is shone through the photomask, exposing the photoresist in certain areas. The exposed areas undergo a chemical change, making them either soluble or insoluble in a developer solution. After development, the pattern is transferred onto the substrate through etching, chemical vapor deposition, or ion implantation processes. Ultraviolet, Ultraviolet (UV) light is typically used. Photolithography processes can be classified according to the type of light used, including ultraviolet lithography, deep ultraviolet lithography, extreme ultraviolet lithography, extreme ultraviolet lithography ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Computer-generated Holography

Computer-generated holography (CGH) is a technique that uses computer algorithms to generate holograms. It involves generating holographic interference patterns. A computer-generated hologram can be displayed on a dynamic holographic display, or it can be printed onto a mask or film using lithography. When a hologram is printed onto a mask or film, it is then illuminated by a coherent light source to display the holographic images. The term "computer-generated holography" has become used to denote the whole process chain of synthetically preparing holographic light wavefronts suitable for observation. If holographic data of existing objects is generated optically and recorded and processed digitally, and subsequently displayed, this is termed CGH as well. Compared to classical holograms, computer-generated holograms have the advantage that the objects that one wants to show do not have to possess any physical reality, and can be completely synthetically generated. Ultimately, com ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Electron Lithography

Electron-beam lithography (often abbreviated as e-beam lithography or EBL) is the practice of scanning a focused beam of electrons to draw custom shapes on a surface covered with an electron-sensitive film called a resist (exposing). The electron beam changes the solubility of the resist, enabling selective removal of either the exposed or non-exposed regions of the resist by immersing it in a solvent (developing). The purpose, as with photolithography, is to create very small structures in the resist that can subsequently be transferred to the substrate material, often by etching. The primary advantage of electron-beam lithography is that it can draw custom patterns (direct-write) with sub-10 nm resolution. This form of maskless lithography has high resolution but low throughput, limiting its usage to photomask fabrication, low-volume production of semiconductor devices, and research and development. Systems Electron-beam lithography systems used in commercial applications ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Nanotechnology

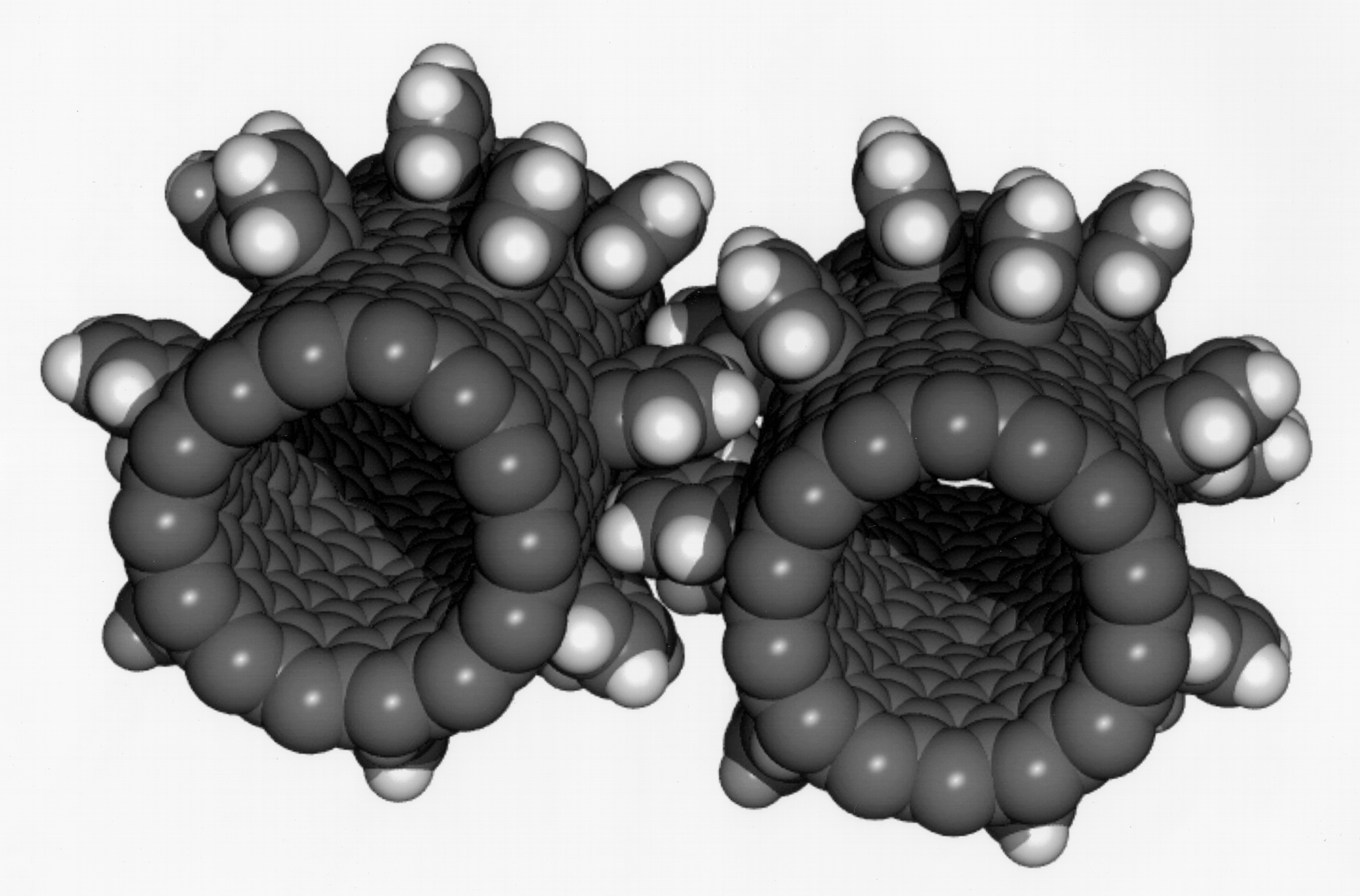

Nanotechnology is the manipulation of matter with at least one dimension sized from 1 to 100 nanometers (nm). At this scale, commonly known as the nanoscale, surface area and quantum mechanical effects become important in describing properties of matter. This definition of nanotechnology includes all types of research and technologies that deal with these special properties. It is common to see the plural form "nanotechnologies" as well as "nanoscale technologies" to refer to research and applications whose common trait is scale. An earlier understanding of nanotechnology referred to the particular technological goal of precisely manipulating atoms and molecules for fabricating macroscale products, now referred to as molecular nanotechnology. Nanotechnology defined by scale includes fields of science such as surface science, organic chemistry, molecular biology, semiconductor physics, energy storage, engineering, microfabrication, and molecular engineering. The associated rese ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Substrate (materials Science)

Substrate is a term used in materials science and engineering to describe the base material on which processing is conducted. Surfaces have different uses, including producing new film or layers of material and being a base to which another substance is bonded. Description In materials science and engineering, a substrate refers to a base material on which processing is conducted. This surface could be used to produce new film or layers of material such as deposited coatings. It could be the base to which paint, adhesives, or adhesive tape is bonded. A typical substrate might be rigid such as metal, concrete, or glass, onto which a coating might be deposited. Flexible substrates are also used. Some substrates are anisotropic with surface properties being different depending on the direction: examples include wood and paper products. Coatings With all coating processes, the condition of the surface of the substrate can strongly affect the bond of subsequent layers. This c ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Near Net Shape

Near-net-shape is an industrial manufacturing technique. As the name implies, the initial production of the item is very close to the final, or ''net'', shape. This reduces the need for surface finishing. By minimizing the use of finishing methods like machining or grinding, near-net-shape production eliminates more than two-thirds of the production costs in some industries. Processes The following are various near-net-shape processes categorized by material. Ceramics * Gelcasting * Ceramic injection molding * Spray forming *Structural ceramic production Composites * Lanxide process Plastics *Injection moulding *Rapid prototyping Metals *Casting ** Permanent mold casting *Powder metallurgy * Linear friction welding * Friction welding * Metal injection molding *Rapid prototyping * Spray forming * Superplastic forming *Cold forming * Semi-solid metal casting *Photochemical machining Photochemical machining (PCM), also known as photochemical milling or photo etching, is a che ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Computer-Aided Design

Computer-aided design (CAD) is the use of computers (or ) to aid in the creation, modification, analysis, or optimization of a design. This software is used to increase the productivity of the designer, improve the quality of design, improve communications through documentation, and to create a database for manufacturing. Designs made through CAD software help protect products and inventions when used in patent applications. CAD output is often in the form of electronic files for print, machining, or other manufacturing operations. The terms computer-aided drafting (CAD) and computer-aided design and drafting (CADD) are also used. Its use in designing electronic systems is known as ''electronic design automation'' (''EDA''). In mechanical design it is known as ''mechanical design automation'' (''MDA''), which includes the process of creating a technical drawing with the use of computer software. CAD software for mechanical design uses either vector-based graphics to depict t ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

3D Printing

3D printing, or additive manufacturing, is the construction of a three-dimensional object from a CAD model or a digital 3D model. It can be done in a variety of processes in which material is deposited, joined or solidified under computer control, with the material being added together (such as plastics, liquids or powder grains being fused), typically layer by layer. In the 1980s, 3D printing techniques were considered suitable only for the production of functional or aesthetic prototypes, and a more appropriate term for it at the time was rapid prototyping. , the precision, repeatability, and material range of 3D printing have increased to the point that some 3D printing processes are considered viable as an industrial-production technology; in this context, the term ''additive manufacturing'' can be used synonymously with ''3D printing''. One of the key advantages of 3D printing is the ability to produce very complex shapes or geometries that would be otherwise infeasi ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Tempering (metallurgy)

Tempering is a process of heat treating, which is used to increase the toughness of iron-based alloys. Tempering is usually performed after Hardening (metallurgy), hardening, to reduce some of the excess hardness, and is done by heating the metal to some temperature below the critical point (thermodynamics), critical point for a certain period of time, then allowing it to cool in still air. The exact temperature determines the amount of hardness removed, and depends on both the specific composition of the alloy and on the desired properties in the finished product. For instance, very hard tools are often tempered at low temperatures, while spring (device), springs are tempered at much higher temperatures. Introduction Tempering is a heat treatment technique applied to ferrous alloys, such as steel or cast iron, to achieve greater toughness by decreasing the hardness of the alloy. The reduction in hardness is usually accompanied by an increase in ductility, thereby decreasing the ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |