|

Direct Digital Control

Direct digital control is the automated control of a condition or process by a digital device (computer). Direct digital control takes a centralized network-oriented approach. All instrumentation is gathered by various analog and digital converters which use the network to transport these signals to the central controller. The centralized computer then follows all of its production rules (which may incorporate sense points anywhere in the structure) and causes actions to be sent via the same network to valves, actuators, and other heating, ventilating, and air conditioning components that can be adjusted. Overview Central controllers and most terminal unit controllers are programmable, meaning the direct digital control program code may be customized for the intended use. The program features include time schedules, setpoints, controllers, logic, timers, trend logs, and alarms. The unit controllers typically have analog and digital inputs, that allow measurement of the variable ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

HVAC

Heating, ventilation, and air conditioning (HVAC) is the use of various technologies to control the temperature, humidity, and purity of the air in an enclosed space. Its goal is to provide thermal comfort and acceptable indoor air quality. HVAC system design is a subdiscipline of mechanical engineering, based on the principles of thermodynamics, fluid mechanics, and heat transfer. "Refrigeration" is sometimes added to the field's abbreviation as HVAC&R or HVACR, or "ventilation" is dropped, as in HACR (as in the designation of HACR-rated circuit breakers). HVAC is an important part of residential structures such as single family homes, apartment buildings, hotels, and senior living facilities; medium to large industrial and office buildings such as skyscrapers and hospitals; vehicles such as cars, trains, airplanes, ships and submarines; and in marine environments, where safe and Sick building syndrome, healthy building conditions are regulated with respect to temperature and ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Human–machine Interface

In the industrial design field of human–computer interaction, a user interface (UI) is the space where interactions between humans and machines occur. The goal of this interaction is to allow effective operation and control of the machine from the human end, while the machine simultaneously feeds back information that aids the operators' decision-making process. Examples of this broad concept of user interfaces include the interactive aspects of computer operating systems, hand tools, heavy machinery operator controls and process controls. The design considerations applicable when creating user interfaces are related to, or involve such disciplines as, ergonomics and psychology. Generally, the goal of user interface design is to produce a user interface that makes it easy, efficient, and enjoyable (user-friendly) to operate a machine in the way which produces the desired result (i.e. maximum usability). This generally means that the operator needs to provide minimal input to ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Programmable Logic Controller

A programmable logic controller (PLC) or programmable controller is an industrial computer that has been ruggedized and adapted for the control of manufacturing processes, such as assembly lines, machines, robotic devices, or any activity that requires high reliability, ease of programming, and process fault diagnosis. Dick Morley is considered as the father of PLC as he had invented the first PLC, the Modicon 084, for General Motors in 1968. PLCs can range from small modular devices with tens of inputs and outputs (I/O), in a housing integral with the processor, to large rack-mounted modular devices with thousands of I/O, and which are often networked to other PLC and SCADA systems. They can be designed for many arrangements of digital and analog I/O, extended temperature ranges, immunity to electrical noise, and resistance to vibration and impact. Programs to control machine operation are typically stored in battery-backed-up or non-volatile memory. PLCs were first devel ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Industrial Safety Systems

An industrial safety system is a countermeasure crucial in any hazardous plants such as oil and gas plants and nuclear plants. They are used to protect human, industrial plant, and the environment in case of the process going beyond the allowed control margins. As the name suggests, these systems are not intended for controlling the process itself but rather protection. Process control is performed by means of process control systems (PCS) and is interlocked by the safety systems so that immediate actions are taken should the process control systems fail. Process control and safety systems are usually merged under one system, called an integrated control and safety system (ICSS). Industrial safety systems typically use dedicated systems that are SIL 2 certified at minimum; whereas control systems can start with SIL 1. SIL applies to both hardware and software requirements such as cards, processors redundancy and voting functions. Types There are 2 main types of industrial ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Industrial Control Systems

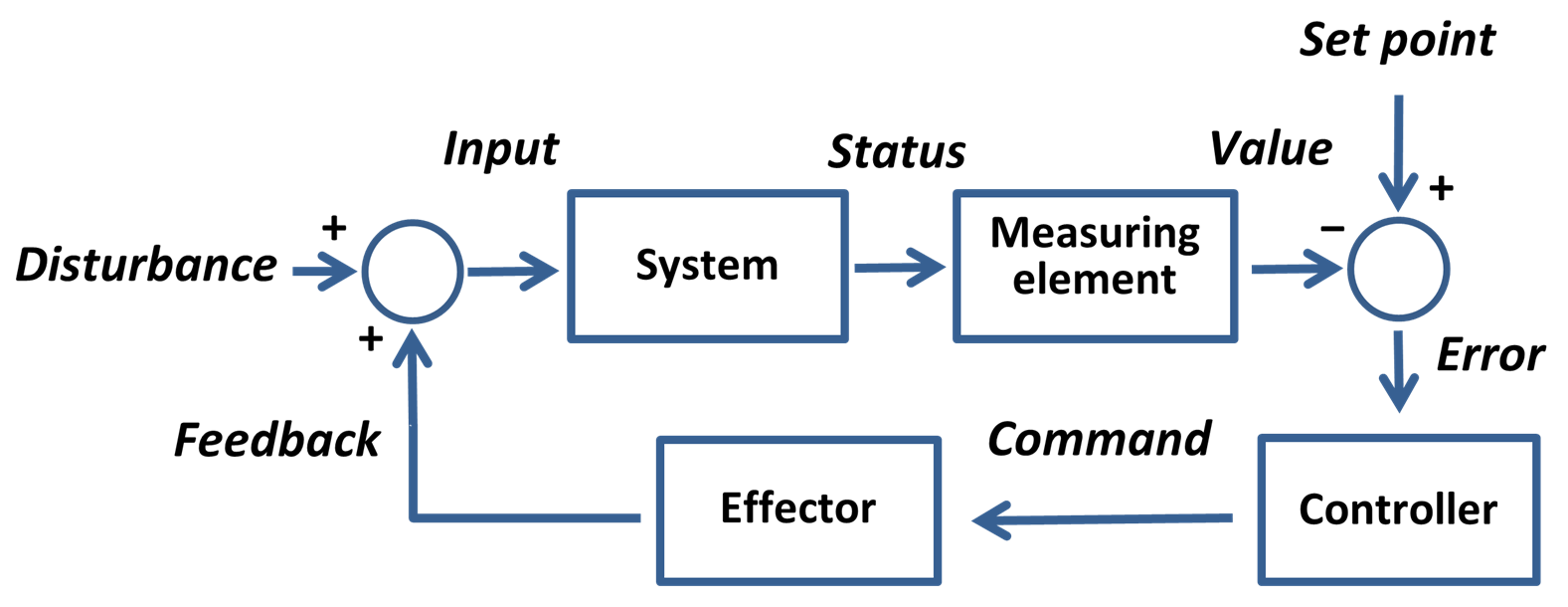

An industrial control system (ICS) is an electronic control system and associated instrumentation used for Process control, industrial process control. Control systems can range in size from a few modular panel-mounted controllers to large interconnected and interactive distributed control systems (DCSs) with many thousands of field connections. Control systems receive data from remote sensors measuring process variables (PVs), compare the collected data with desired Setpoint (control system), setpoints (SPs), and derive command functions that are used to control a process through the final control elements (FCEs), such as control valves. Larger systems are usually implemented by supervisory control and data acquisition (SCADA) systems, or DCSs, and programmable logic controllers (PLCs), though SCADA and PLC systems are scalable down to small systems with few control loops. Such systems are extensively used in industries such as chemical processing, pulp and paper manufacture, po ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

GE Fanuc Intelligent Platforms

General Electric Automation and Controls division combines what was formerly known as GE Intelligent Platforms and Alstom's Power Automation and Controls. In 2019, GE Intelligent Platforms was acquired by Emerson Electric and is now called Machine Automation Solutions. GE Automation and Controls produce Programmable Logic Controller (PLC) and Programmable Automation Controller (PAC) based control systems, I/O, and field devices, including support to design, commissioning and operate industrial assets and operations. Industries served include manufacturing, food and beverage, life sciences, power, oil and gas, mining and metals, water and wastewater, and specialty machinery industries. History In 1986, GE Fanuc Automation Corporation was jointly established in the US by FANUC and General Electric (GE). Under the joint venture company, three operating companies, GE Fanuc Automation North America, Inc., in the U.S., GE Fanuc Automation Europe S.A. in Luxembourg, and Fanuc GE Automa ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Fieldbus

Fieldbus is the name of a family of industrial computer networks used for real-time distributed control. Fieldbus profiles are standardized by the International Electrotechnical Commission (IEC) as IEC 61784/61158. A complex automated industrial system is typically structured in hierarchical levels as a distributed control system (DCS). In this hierarchy the upper levels for production managements are linked to the direct control level of programmable logic controllers (PLC) via a non-time-critical communications system (e.g. Ethernet). The fieldbus links the PLCs of the direct control level to the components in the plant of the field level such as sensors, actuators, electric motors, console lights, switches, valves and contactors and replaces the direct connections via current loops or digital I/O signals. The requirement for a fieldbus are therefore time-critical and cost sensitive. Since the new millennium a number of fieldbuses based on Real-time Ethernet have been establish ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Building Automation

Building automation (BAS), also known as building management system (BMS) or building energy management system (BEMS), is the automatic centralized control of a building's HVAC (heating, ventilation and air conditioning), electrical, lighting, shading, Access Control, Security Systems, and other interrelated systems. Some objectives of building automation are improved occupant comfort, efficient operation of building systems, reduction in energy consumption, reduced operating and maintaining costs and increased security. BAS functionality may keep a buildings climate within a specified range, provide light to rooms based on an occupancy, monitor performance and device failures, and provide malfunction alarms to building maintenance staff. A BAS works to reduce building energy and maintenance costs compared to a non-controlled building. Most commercial, institutional, and industrial buildings built after 2000 include a BAS, whilst older buildings may be retrofitted with a new ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

SCADA

Supervisory control and data acquisition (SCADA) is a control system architecture comprising computers, networked data communications and graphical user interfaces for high-level supervision of machines and processes. It also covers sensors and other devices, such as programmable logic controllers, which interface with process plant or machinery. Explanation The operator interfaces which enable monitoring and the issuing of process commands, like controller set point changes, are handled through the SCADA computer system. The subordinated operations, e.g. the real-time control logic or controller calculations, are performed by networked modules connected to the field sensors and actuators. The SCADA concept was developed to be a universal means of remote-access to a variety of local control modules, which could be from different manufacturers and allowing access through standard automation protocols. In practice, large SCADA systems have grown to become very similar to distr ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

KNX (standard)

KNX is an open standard (see EN 50090, ISO/IEC 14543) for commercial and domestic building automation. KNX devices can manage lighting, blinds and shutters, HVAC, security systems, energy management, audio video, white goods, displays, remote control, etc. KNX evolved from three earlier standards; the European Home Systems Protocol (EHS), BatiBUS, and the European Installation Bus (EIB or Instabus). It can use twisted pair (in a tree, line or star topology), powerline, RF, or IP links . On this network, the devices form distributed applications and tight interaction is possible. This is implemented via interworking models with standardised datapoint types and objects, modelling logical device channels. KNX standard The KNX standard has been built on the OSI-based EIB communication stack extended with the physical layers, configuration modes and application experience of BatiBUS and EHS. KNX installations can use several physical communication media: * Twisted pai ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Setpoint (control System)

In cybernetics and control theory, a setpoint (SP; also set point) is the desired or target value for an essential variable, or process value (PV) of a control system. Departure of such a variable from its setpoint is one basis for error-controlled regulation using negative feedback for automatic control. Examples Cruise control The SP-PV error can be used to return a system to its norm. An everyday example is the cruise control on a road vehicle; where external influences such as gradients cause speed changes (PV), and the driver also alters the desired set speed (SP). The automatic control algorithm restores the actual speed to the desired speed in the optimum way, without delay or overshoot, by altering the power output of the vehicle's engine. In this way the SP-PV error is used to control the PV so that it equals the SP. A widespread use of SP-PV error control is the PID controller. Industrial applications Special consideration must be given for engineering application ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |