|

Deinking

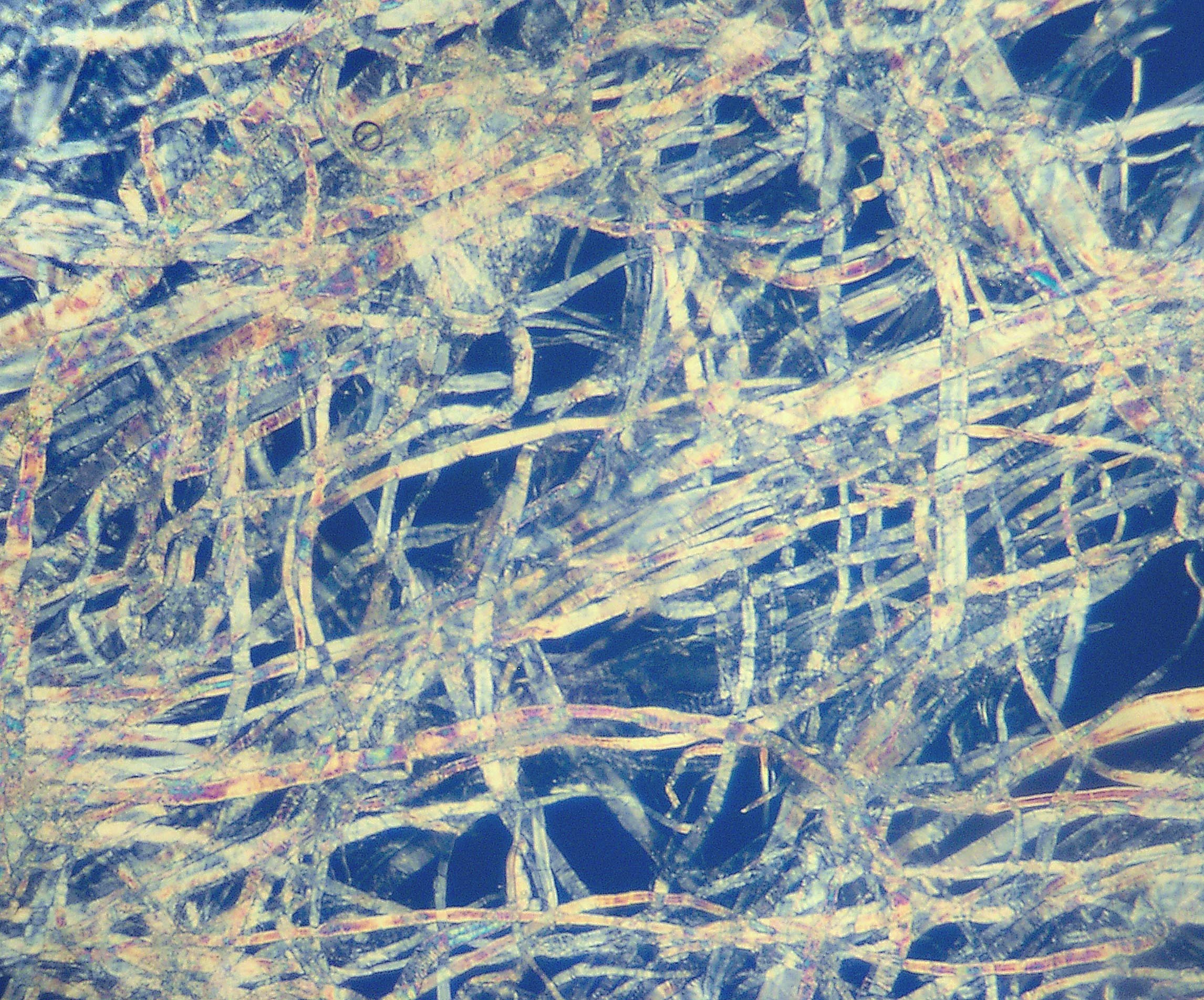

Deinking is the industrial process of removing printing ink from paperfibers of recycled paper to make deinked pulp. The key in the deinking process is the ability to detach ink from the fibers. This is achieved by a combination of mechanical action and chemical means. In Europe the most common process is froth flotation deinking. Paper is one of the main targets for recycling. A concern about recycling wood pulp paper is that the fibers are degraded with each cycle and after being recycled 4–6 times the fibers become too short and weak to be useful in making paper. History Before the invention of the paper machine in 1799 the most common fibre source was recycled fibres from used textiles, hence the name rag paper. The rags were from hemp, linen and cotton. It was not until the introduction of wood pulp in 1843 that paper production was independent of recycled materials. Recycling of used paper before the industrialisation of paper production, rag paper was recyc ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Deinking (schematic Layout)

Deinking is the industrial process of removing printing ink from paperfibers of recycled paper to make deinked pulp. The key in the deinking process is the ability to detach ink from the fibers. This is achieved by a combination of mechanical action and chemical means. In Europe the most common process is froth flotation deinking. Paper is one of the main targets for recycling. A concern about recycling wood pulp paper is that the fibers are degraded with each cycle and after being recycled 4–6 times the fibers become too short and weak to be useful in making paper. History Before the invention of the paper machine in 1799 the most common fibre source was recycled fibres from used textiles, hence the name rag paper. The rags were from hemp, linen and cotton. It was not until the introduction of wood pulp in 1843 that paper production was independent of recycled materials. Recycling of used paper before the industrialisation of paper production, rag paper was recycled to mak ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Froth Flotation

Froth flotation is a process for selectively separating hydrophobic materials from hydrophilic. This is used in mineral processing, paper recycling and waste-water treatment industries. Historically this was first used in the mining industry, where it was one of the great enabling technologies of the 20th century. It has been described as "the single most important operation used for the recovery and upgrading of sulfide ores". The development of froth flotation has improved the recovery of valuable minerals, such as copper- and lead-bearing minerals. Along with mechanized mining, it has allowed the economic recovery of valuable metals from much lower grade ore than previously. Industries Froth flotation is applied to a wide range of separations. An estimated 1B tons of materials are processed in this manner annually. Mineral processing Froth flotation is a process for separating minerals from gangue by exploiting differences in their hydrophobicity. Hydrophobicity diffe ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Paper

Paper is a thin sheet material produced by mechanically or chemically processing cellulose fibres derived from wood, Textile, rags, poaceae, grasses or other vegetable sources in water, draining the water through fine mesh leaving the fibre evenly distributed on the surface, followed by pressing and drying. Although paper was originally made in single sheets by hand, almost all is now made on large machines—some making reels 10 metres wide, running at 2,000 metres per minute and up to 600,000 tonnes a year. It is a versatile material with many uses, including printing, painting, graphics, signage, design, packaging, decorating, writing, and Housekeeping, cleaning. It may also be used as filter paper, wallpaper, book endpaper, conservation paper, laminated worktops, toilet tissue, or currency and security paper, or in a number of industrial and construction processes. The papermaking process developed in east Asia, probably China, at least as early as 105 Common Era, CE, by t ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Fiber Crop

Fiber crops are field crops grown for their fibers, which are traditionally used to make paper, cloth, or rope. Fiber crops are characterized by having a large concentration of cellulose, which is what gives them their strength. The fibers may be chemically modified, like in viscose (used to make rayon and cellophane). In recent years, materials scientists have begun exploring further use of these fibers in composite materials. Due to cellulose being the main factor of a plant fiber's strength, this is what scientists are looking to manipulate to create different types of fibers. Fiber crops are generally harvestable after a single growing season, as distinct from trees, which are typically grown for many years before being harvested for such materials as wood pulp fiber or lacebark. In specific circumstances, fiber crops can be superior to wood pulp fiber in terms of technical performance, environmental impact or cost. There are a number of issues regarding the use of fiber ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Justus Claproth

Justus Claproth (28 December 1728 – 20 February 1805) was a German jurist and inventor An invention is a unique or novel device, method, composition, idea or process. An invention may be an improvement upon a machine, product, or process for increasing efficiency or lowering cost. It may also be an entirely new concept. If an id ... of the deinking process of recycled paper. See also * German inventors and discoverers 1728 births 1805 deaths 18th-century German scientists 18th-century jurists 18th-century German inventors German jurists {{Germany-engineer-stub ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Paper Machine

A paper machine (or paper-making machine) is an industrial machine which is used in the pulp and paper industry to create paper in large quantities at high speed. Modern paper-making machines are based on the principles of the Fourdrinier Machine, which uses a moving woven mesh to create a continuous paper web by filtering out the fibres held in a paper stock and producing a continuously moving wet mat of fibre. This is dried in the machine to produce a strong paper web. The basic process is an industrialised version of the historical process of hand paper-making, which could not satisfy the demands of developing modern society for large quantities of a printing and writing substrate. The first modern paper machine was invented by Louis-Nicolas Robert in France in 1799, and an improved version patented in Britain by Henry and Sealy Fourdrinier in 1806. The same process is used to produce paperboard on a paperboard machine. Process sections Paper machines usually have at le ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Paperboard

Paperboard is a thick paper-based material. While there is no rigid differentiation between paper and paperboard, paperboard is generally thicker (usually over 0.30 mm, 0.012 in, or 12 points) than paper and has certain superior attributes such as foldability and rigidity. According to ISO standards, paperboard is a paper with a grammage above 250 g/m2, but there are exceptions. Paperboard can be single- or multi-ply. Paperboard can be easily cut and formed, is lightweight, and because it is strong, is used in packaging. Another end-use is high quality graphic printing, such as book and magazine covers or postcards. Paperboard is also used in fine arts for creating sculptures. Sometimes it is referred to as ''cardboard'', which is a generic, lay term used to refer to any heavy paper pulp–based board, however this usage is deprecated in the paper, printing and packaging industries as it does not adequately describe each product type. History In 1817, the first paperbo ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Papermachine

A paper machine (or paper-making machine) is an industrial machine which is used in the pulp and paper industry to create paper in large quantities at high speed. Modern paper-making machines are based on the principles of the Fourdrinier Machine, which uses a moving woven mesh to create a continuous paper web by filtering out the fibres held in a paper stock and producing a continuously moving wet mat of fibre. This is dried in the machine to produce a strong paper web. The basic process is an industrialised version of the historical process of hand paper-making, which could not satisfy the demands of developing modern society for large quantities of a printing and writing substrate. The first modern paper machine was invented by Louis-Nicolas Robert in France in 1799, and an improved version patented in Britain by Henry and Sealy Fourdrinier in 1806. The same process is used to produce paperboard on a paperboard machine. Process sections Paper machines usually have at leas ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Paper Recycling

The recycling of paper is the process by which waste paper is turned into new paper products. It has a number of important benefits: It saves waste paper from occupying homes of people and producing methane as it breaks down. Because paper fibre contains carbon (originally absorbed by the tree from which it was produced), recycling keeps the carbon locked up for longer and out of the atmosphere. Around two-thirds of all paper products in the US are now recovered and recycled, although it does not all become new paper. After repeated processing the fibres become too short for the production of new paper, which is why virgin fibre (from sustainably farmed trees) is frequently added to the pulp recipe. There are three categories of paper that can be used as feedstocks for making ''recycled paper'': mill broke, pre-consumer waste, and post-consumer waste. ''Mill broke'' is paper trimmings and other paper scrap from the manufacture of paper, and is recycled in a paper mill. ''Pre ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Wood Pulp

Pulp is a lignocellulosic fibrous material prepared by chemically or mechanically separating cellulose fibers from wood, fiber crops, waste paper, or rags. Mixed with water and other chemical or plant-based additives, pulp is the major raw material used in papermaking and the industrial production of other paper products. History Before the widely acknowledged invention of papermaking by Cai Lun in China around 105 AD, paper-like writing materials such as papyrus and amate were produced by ancient civilizations using plant materials which were largely unprocessed. Strips of bark or bast material were woven together, beaten into rough sheets, dried, and polished by hand. Pulp used in modern and traditional papermaking is distinguished by the process which produces a finer, more regular slurry of cellulose fibers which are pulled out of solution by a screen and dried to form sheets or rolls. The earliest paper produced in China consisted of bast fibers from the paper ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Deinked Pulp

Pulp is a lignocellulosic fibrous material prepared by chemically or mechanically separating cellulose fibers from wood, fiber crops, waste paper, or rags. Mixed with water and other chemical or plant-based additives, pulp is the major raw material used in papermaking and the industrial production of other paper products. History Before the widely acknowledged invention of papermaking by Cai Lun in China around 105 AD, paper-like writing materials such as papyrus and amate were produced by ancient civilizations using plant materials which were largely unprocessed. Strips of bark or bast material were woven together, beaten into rough sheets, dried, and polished by hand. Pulp used in modern and traditional papermaking is distinguished by the process which produces a finer, more regular slurry of cellulose fibers which are pulled out of solution by a screen and dried to form sheets or rolls. The earliest paper produced in China consisted of bast fibers from the paper mulber ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Recycled Paper

The recycling of paper is the process by which waste paper is turned into new paper products. It has a number of important benefits: It saves waste paper from occupying homes of people and producing methane as it breaks down. Because paper fibre contains carbon (originally absorbed by the tree from which it was produced), recycling keeps the carbon locked up for longer and out of the atmosphere. Around two-thirds of all paper products in the US are now recovered and recycled, although it does not all become new paper. After repeated processing the fibres become too short for the production of new paper, which is why virgin fibre (from sustainably farmed trees) is frequently added to the pulp recipe. There are three categories of paper that can be used as feedstocks for making ''recycled paper'': mill broke, pre-consumer waste, and post-consumer waste. ''Mill broke'' is paper trimmings and other paper scrap from the manufacture of paper, and is recycled in a paper mill. ''Pre ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |