|

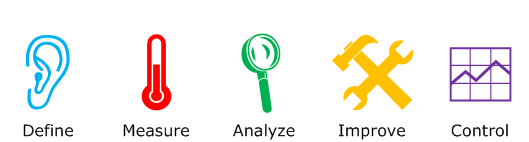

DMAIC

DMAIC (an acronym for Define, Measure, Analyze, Improve and Control) (pronounced də-MAY-ick) refers to a data-driven improvement cycle used for improving, optimizing and stabilizing business processes and designs. The DMAIC improvement cycle is the core tool used to drive Six Sigma projects. However, DMAIC is not exclusive to Six Sigma and can be used as the framework for other improvement applications. Steps DMAIC is an abbreviation of the five improvement steps it comprises: Define, Measure, Analyze, Improve and Control. All of the DMAIC process steps are required and always proceed in the given order. Define The purpose of this step is to clearly pronounce the business problem, goal, potential resources, project scope and high-level project timeline. This information is typically captured within the project charter document. Write down what is currently known. Seek to clarify facts, set objectives and form the project team. Define the following: * A problem * The custome ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

PDCA

PDCA (plan–do–check–act or plan–do–check–adjust) is an iterative design and management method used in business for the control and continual improvement of processes and products. It is also known as the Shewhart cycle, or the control circle/cycle. Another version of this PDCA cycle is OPDCA. The added "O" stands for ''observation'' or as some versions say: "Observe the current condition." This emphasis on observation and current condition has currency with the literature on lean manufacturing and the Toyota Production System. The PDCA cycle, with Ishikawa's changes, can be traced back to S. Mizuno of the Tokyo Institute of Technology in 1959. PDCA is often confused with PDSA (Plan-Do-Study-Act). Dr. W. Edwards Deming emphasized the PDSA Cycle, not the PDCA Cycle, with a third step emphasis on Study (S), not Check (C). Dr. Deming found that the focus on Check is more about the implementation of a change, with success or failure. His focus was on predicting the resu ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Kaizen

is concept referring to business activities that continuously improve all functions and involve all employees from the CEO to the assembly line workers. ''Kaizen'' also applies to processes, such as purchasing and logistics, that cross organizational boundaries into the supply chain. It has been applied in healthcare, psychotherapy, life coaching, government, and banking. By improving standardized programs and processes, kaizen aims to eliminate waste and redundancies ( lean manufacturing). Kaizen was first practiced in Japanese businesses after World War II, influenced in part by American business and quality-management teachers, and most notably as part of The Toyota Way. It has since spread throughout the world and has been applied to environments outside of business and productivity. Overview The Japanese word means 'change for better', with the inherent meaning of either 'continuous' or 'philosophy' in Japanese dictionaries and in everyday use. The word refers ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Industrial Engineering

Industrial engineering is an engineering profession that is concerned with the optimization of complex processes, systems, or organizations by developing, improving and implementing integrated systems of people, money, knowledge, information and equipment. Industrial engineering is central to manufacturing operations. Industrial engineers use specialized knowledge and skills in the mathematical, physical and social sciences, together with the principles and methods of engineering analysis and design, to specify, predict, and evaluate the results obtained from systems and processes.Salvendy, Gabriel. Handbook of Industrial Engineering. John Wiley & Sons, Inc; 3rd edition p. 5 There are several industrial engineering principles followed in the manufacturing industry to ensure the effective flow of the systems, processes and operations. This includes Lean Manufacturing, Six Sigma, Information Systems, Process Capability and Define, Measure, Analyze, Improve and Control (DMAIC). Th ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Design For Six Sigma

Design for Six Sigma (DFSS) is an Engineering design process, business process management method related to traditional Six Sigma.Chowdhury, Subir (2002) Design for Six Sigma: The revolutionary process for achieving extraordinary profits, Prentice Hall, It is used in many industries, like finance, marketing, basic engineering, process industries, waste management, and electronics. It is based on the use of statistical tools like linear regression and enables empirical research similar to that performed in other fields, such as social science. While the tools and order used in Six Sigma require a process to be in place and functioning, DFSS has the objective of determining the needs of customers and the business, and driving those needs into the product solution so created. It is used for product or process ''design'' in contrast with process ''improvement''. Measurement is the most important part of most Six Sigma or DFSS tools, but whereas in Six Sigma measurements are made f ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Standard Operating Procedure

A standard operating procedure (SOP) is a set of step-by-step instructions compiled by an organization to help workers carry out routine operations. SOPs aim to achieve efficiency, quality output, and uniformity of performance, while reducing miscommunication and failure to comply with industry regulations. Some military services (e.g., in the U.S. and the UK) use the term standing (rather than ''standard'') operating procedure, since a military SOP refers to a unit's unique procedures, which are not necessarily standard to another unit. The word "standard" could suggest that only one (standard) procedure is to be used across all units. The term is sometimes used facetiously to refer to practices that are unconstructive, yet the norm. In the Philippines, for instance, "SOP" is the term for pervasive corruption within the government and its institutions. Clinical research and practice In clinical research, the '' International Council for Harmonisation'' (ICH) defines SOPs as "d ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Control Chart

Control charts is a graph used in production control to determine whether quality and manufacturing processes are being controlled under stable conditions. (ISO 7870-1) The hourly status is arranged on the graph, and the occurrence of abnormalities is judged based on the presence of data that differs from the conventional trend or deviates from the control limit line. Control charts are classified into Shewhart individuals control chart (ISO 7870-2) and CUSUM(CUsUM)(or cumulative sum control chart)(ISO 7870-4). Control charts, also known as Shewhart charts (after Walter A. Shewhart) or process-behavior charts, are a statistical process control tool used to determine if a manufacturing or business process is in a state of control. It is more appropriate to say that the control charts are the graphical device for Statistical Process Monitoring (SPM). Traditional control charts are mostly designed to monitor process parameters when the underlying form of the process distributio ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Failure Mode And Effects Analysis

Failure mode and effects analysis (FMEA; often written with "failure modes" in plural) is the process of reviewing as many components, assemblies, and subsystems as possible to identify potential failure modes in a system and their causes and effects. For each component, the failure modes and their resulting effects on the rest of the system are recorded in a specific FMEA worksheet. There are numerous variations of such worksheets. An FMEA can be a qualitative analysis, but may be put on a quantitative basis when mathematical failure rate models are combined with a statistical failure mode ratio database. It was one of the first highly structured, systematic techniques for failure analysis. It was developed by reliability engineers in the late 1950s to study problems that might arise from malfunctions of military systems. An FMEA is often the first step of a system reliability study. A few different types of FMEA analyses exist, such as: * Functional * Design * Process Sometimes ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Design Of Experiments

The design of experiments (DOE, DOX, or experimental design) is the design of any task that aims to describe and explain the variation of information under conditions that are hypothesized to reflect the variation. The term is generally associated with experiments in which the design introduces conditions that directly affect the variation, but may also refer to the design of quasi-experiments, in which natural conditions that influence the variation are selected for observation. In its simplest form, an experiment aims at predicting the outcome by introducing a change of the preconditions, which is represented by one or more independent variables, also referred to as "input variables" or "predictor variables." The change in one or more independent variables is generally hypothesized to result in a change in one or more dependent variables, also referred to as "output variables" or "response variables." The experimental design may also identify control variables that must ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Random Stimulus

A random stimulus is any class of creativity techniques that explores randomization. Most of their names start with the word "random", such as random word, random heuristic, random picture and random sound. In each random creativity technique, the user is presented with a random stimulus and explores associations that could trigger novel ideas. The power of random stimulus is that it can lead you to explore useful associations that would not emerge intentionally. Random word technique Random Word is the simplest technique of this class. A randomly picked word is used to generate new associations. The intent is to reveal a different angle of attack on the problem. Implementations Low-tech implementations of random word often randomly shuffle a pile of index cards. For example, the " Oblique Strategies" created by Brian Eno and Peter Schmidt in 1975 is a set of 100 cards, each of which is a suggestion of a course of action or thinking to assist in creative situations, where standa ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Six Thinking Hats

''Six Thinking Hats'' was written by Dr. Edward de Bono. "Six Thinking Hats" and the associated idea parallel thinking provide a means for groups to plan thinking processes in a detailed and cohesive way, and in doing so to think together more effectively. Underlying principles The premise of the method is that the human brain thinks in a number of distinct ways which can be deliberately challenged, and hence planned for use in a structured way allowing one to develop tactics for thinking about particular issues. De Bono identifies six distinct directions in which the brain can be challenged. In each of these directions the brain will identify and bring into conscious thought certain aspects of issues being considered (e.g. gut instinct, pessimistic judgement, neutral facts). Some may feel that using the hats is unnatural, uncomfortable or even counterproductive and against their better judgement. A compelling example presented is sensitivity to "mismatch" stimuli. This is pr ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |