|

Computational Lithography

Computational lithography (also known as computational scaling) is the set of mathematical and algorithmic approaches designed to improve the resolution attainable through photolithography. Computational lithography has come to the forefront of photolithography in 2008 as the semiconductor industry grappled with the challenges associated with the transition to 22 nanometer CMOS fabrication process technology and beyond. 193 nm deep UV photolithography The periodic enhancement in the resolution achieved through photolithography has been a driving force behind Moore's Law. Resolution improvements enable printing of smaller geometries on an integrated circuit. The minimum feature size that a projection system typically used in photolithography can print is given approximately by: :CD = k_1 \cdot\frac where *CD is the minimum feature size (also called the critical dimension). *\lambda is the wavelength of light used. *NA is the numerical aperture of the lens as seen from the wafer. ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Photolithography

In integrated circuit manufacturing, photolithography or optical lithography is a general term used for techniques that use light to produce minutely patterned thin films of suitable materials over a substrate, such as a silicon wafer, to protect selected areas of it during subsequent etching, deposition, or implantation operations. Typically, ultraviolet light is used to transfer a geometric design from an optical mask to a light-sensitive chemical (photoresist) coated on the substrate. The photoresist either breaks down or hardens where it is exposed to light. The patterned film is then created by removing the softer parts of the coating with appropriate solvents. Conventional photoresists typically consists of three components: resin, sensitizer, and solvent. Photolithography processes can be classified according to the type of light used, such as ultraviolet, deep ultraviolet, extreme ultraviolet, or X-ray. The wavelength of light used determines the minimum feature si ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Phase-shift Photomask

Phase-shift masks are photomasks that take advantage of the interference generated by phase differences to improve image resolution in photolithography. There exist alternating and attenuated phase shift masks. A phase-shift mask relies on the fact that light passing through a transparent media will undergo a phase change as a function of its optical thickness. Types and effects A conventional photomask is a transparent plate with the same thickness everywhere, parts of which are covered with non-transmitting material in order to create a pattern on the semiconductor wafer when illuminated. In ''alternating phase-shift masks'', certain transmitting regions are made thinner or thicker. That induces a phase-shift in the light traveling through those regions of the mask (see the illustration). When the thickness is suitably chosen, the interference of the phase-shifted light with the light coming from unmodified regions of the mask has the effect of improving the contrast on so ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Optical Proximity Correction

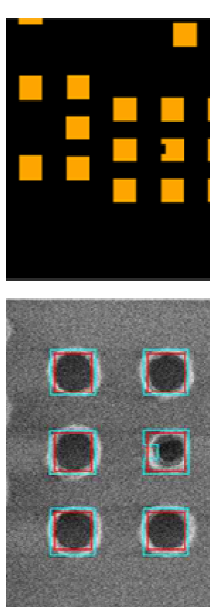

Optical proximity correction (OPC) is a photolithography enhancement technique commonly used to compensate for image errors due to diffraction or process effects. The need for OPC is seen mainly in the making of semiconductor devices and is due to the limitations of light to maintain the edge placement integrity of the original design, after processing, into the etched image on the silicon wafer. These projected images appear with irregularities such as line widths that are narrower or wider than designed, these are amenable to compensation by changing the pattern on the photomask used for imaging. Other distortions such as rounded corners are driven by the resolution of the optical imaging tool and are harder to compensate for. Such distortions, if not corrected for, may significantly alter the electrical properties of what was being fabricated. Optical proximity correction corrects these errors by moving edges or adding extra polygons to the pattern written on the photomask. This ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Diffraction

Diffraction is defined as the interference or bending of waves around the corners of an obstacle or through an aperture into the region of geometrical shadow of the obstacle/aperture. The diffracting object or aperture effectively becomes a secondary source of the propagating wave. Italian scientist Francesco Maria Grimaldi coined the word ''diffraction'' and was the first to record accurate observations of the phenomenon in 1660. In classical physics, the diffraction phenomenon is described by the Huygens–Fresnel principle that treats each point in a propagating wavefront as a collection of individual spherical wavelets. The characteristic bending pattern is most pronounced when a wave from a coherent source (such as a laser) encounters a slit/aperture that is comparable in size to its wavelength, as shown in the inserted image. This is due to the addition, or interference, of different points on the wavefront (or, equivalently, each wavelet) that travel by paths of d ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

90 Nanometer

The 90 nm process refers to the level of MOSFET ( CMOS) fabrication process technology that was commercialized by the 2003–2005 timeframe, by leading semiconductor companies like Toshiba, Sony, Samsung, IBM, Intel, Fujitsu, TSMC, Elpida, AMD, Infineon, Texas Instruments and Micron Technology. The origin of the 90 nm value is historical, it reflects a trend of 70% scaling every 2–3 years. The naming is formally determined by the International Technology Roadmap for Semiconductors (ITRS). The 193 nm wavelength was introduced by many (but not all) companies for lithography of critical layers mainly during the 90 nm node. Yield issues associated with this transition (due to the use of new photoresists) were reflected in the high costs associated with this transition. Even more significantly, the 300 mm wafer size became mainstream at the 90 nm node. The previous wafer size was 200 mm diameter. History A 90nm silicon MOSFET was fabric ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Optical Proximity Correction

Optical proximity correction (OPC) is a photolithography enhancement technique commonly used to compensate for image errors due to diffraction or process effects. The need for OPC is seen mainly in the making of semiconductor devices and is due to the limitations of light to maintain the edge placement integrity of the original design, after processing, into the etched image on the silicon wafer. These projected images appear with irregularities such as line widths that are narrower or wider than designed, these are amenable to compensation by changing the pattern on the photomask used for imaging. Other distortions such as rounded corners are driven by the resolution of the optical imaging tool and are harder to compensate for. Such distortions, if not corrected for, may significantly alter the electrical properties of what was being fabricated. Optical proximity correction corrects these errors by moving edges or adding extra polygons to the pattern written on the photomask. This ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Resolution Enhancement Technologies

Resolution(s) may refer to: Common meanings * Resolution (debate), the statement which is debated in policy debate * Resolution (law), a written motion adopted by a deliberative body * New Year's resolution, a commitment that an individual makes at New Year's Day * Dispute resolution, the settlement of a disagreement Science, technology, and mathematics Mathematics and logic * Resolution (algebra), an exact sequence in homological algebra * Resolution (logic), a rule of inference used for automated theorem proving * Standard resolution, the bar construction of resolutions in homological algebra * Resolution of singularities in algebraic geometry Measurements * Resolution (audio), a measure of digital audio quality * Resolution (electron density), the quality of an X-ray crystallography or cryo-electron microscopy data set * Angular resolution, the capability of an optical or other sensor to discern small objects * Depositional resolution, the age difference of fossi ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

ASML Holding

ASML Holding N.V. (commonly shortened to ASML, originally standing for Advanced Semiconductor Materials Lithography) is a Dutch multinational corporation founded in 1984. ASML specializes in the development and manufacturing of photolithography machines which are used to produce computer chips. it is the largest supplier for the semiconductor industry and the sole supplier in the world of extreme ultraviolet lithography (EUV) photolithography machines used to manufacture the most advanced chips. As of 2022, ASML was the most highly valued European tech company by market capitalization with about $200 billion. Products ASML produces the photolithography machines used in the production of computer chips. In these machines, patterns are optically imaged onto a silicon wafer that is covered with a film of light-sensitive material (photoresist). This procedure is repeated dozens of times on a single wafer. The photoresist is then further processed to create the actual electronic ci ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Inverse Lithography

In semiconductor device fabrication, the inverse lithography technology (ILT) is an approach to photomask design. This is basically an approach to solve an inverse imaging problem: to calculate the shapes of the openings in a photomask ("source") so that the passing light produces a good approximation of the desired pattern ("target") on the illuminated material, typically a photoresist. As such, it is treated as a mathematical optimization problem of a special kind, because usually an analytical solution does not exist. In conventional approaches known as the optical proximity correction (OPC) a "target" shape is augmented with carefully tuned rectangles to produce a "Manhattan shape" for the "source", as shown in the illustration. The ILT approach generates curvilinear shapes for the "source", which deliver better approximations for the "target". The ILT was proposed in 1980s, however at that time it was impractical due to the huge required computational power and complicated "s ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Design For Manufacturability (IC)

Design for manufacturability (also sometimes known as design for manufacturing or DFM) is the general engineering practice of designing products in such a way that they are easy to manufacture. The concept exists in almost all engineering disciplines, but the implementation differs widely depending on the manufacturing technology. DFM describes the process of designing or engineering a product in order to facilitate the manufacturing process in order to reduce its manufacturing costs. DFM will allow potential problems to be fixed in the design phase which is the least expensive place to address them. Other factors may affect the manufacturability such as the type of raw material, the form of the raw material, dimensional tolerances, and secondary processing such as finishing. Depending on various types of manufacturing processes there are set guidelines for DFM practices. These DFM guidelines help to precisely define various tolerances, rules and common manufacturing checks relate ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Synopsys

Synopsys is an American electronic design automation (EDA) company that focuses on silicon design and verification, silicon intellectual property and software security and quality. Products include tools for logic synthesis and physical design of integrated circuits, simulators for development and debugging environments that assist in the design of the logic for chips and computer systems. In recent years, Synopsys has expanded its products and services to include application security testing. Synopsys has gained attention due to its relationship with various Chinese state entities. In 2018, Synopsys formed a partnership with the People's Liberation Army National Defence University and, in 2022, the company came under investigation by the United States Department of Justice for technology transfers to sanctioned entities in China. History Synopsys was founded by Aart J de Geus and David Gregory in 1986 in Research Triangle Park, North Carolina. The company was initially est ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

PROLITH

PROLITH (abbreviated from Positive Resist Optical LITHography) is a computer simulator modeling the optical and chemical aspects of photolithography. Chris Mack started developing PROLITH after he began working in the field of photolithography at the NSA in 1983. PROLITH was first developed on an IBM PC. The models implemented by the software were based on the work done by Rick Dill at IBM and Andy Neureuther at UC Berkeley, together with Chris Mack's own contributions such as the Mack model. Originally PROLITH was given away for free, while NSA was paying Chris Mack's salary.{{cite web, url = http://www.lithoguru.com/scientist/resume.html , title = Chris Mack's resume In 1990 he founded FINLE Technologies to commercialize PROLITH. The first commercial version of the software, named PROLITH/2, was released in June of that year. PROLITH was made easier to use and it grew to include many more aspects of lithography simulation. FINLE Technologies was purchased in Febru ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |