|

Cobalt Ferrite

Cobalt ferrite is a semi-hard ferrite with the chemical formula of CoFe2O4 (CoO·Fe2O3). The substance can be considered as between soft and hard magnetic material and is usually classified as a semi-hard material. Applications It is mainly used for its magnetostrictive applications like sensors and actuators thanks to its high saturation magnetostriction (~200 ppm). CoFe2O4 has also the benefits to be rare-earth free, which makes it a good substitute for Terfenol-D. Moreover, its magnetostrictive properties can be tuned by inducing a magnetic uniaxial anisotropy. This can be done by magnetic annealing, magnetic field assisted compaction, or reaction under uniaxial pressure. This last solution has the advantage to be ultra fast (20 min) thanks to the use of spark plasma sintering. The induced magnetic anisotropy in cobalt ferrite is also beneficial to enhance the magnetoelectric effect In its most general form, the magnetoelectric effect (ME) denotes any coupling between the mag ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

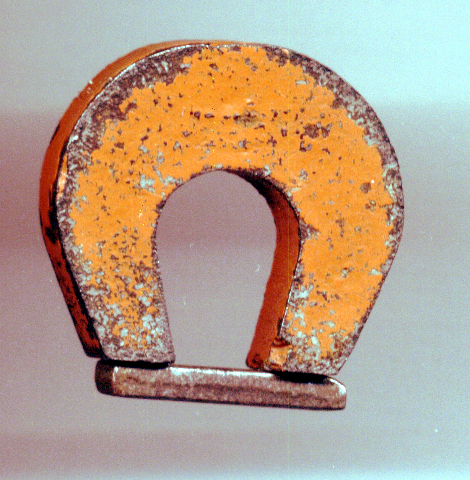

Ferrite (magnet)

A ferrite is a ceramic material made by mixing and firing large proportions of iron(III) oxide (Fe2O3, rust) blended with small proportions of one or more additional metallic elements, such as strontium, barium, manganese, nickel, and zinc. They are ferrimagnetic, meaning they can be magnetized or attracted to a magnet. Unlike other ferromagnetic materials, most ferrites are not electrically conductive, making them useful in applications like magnetic cores for transformers to suppress eddy currents. Ferrites can be divided into two families based on their resistance to being demagnetized (magnetic coercivity). Hard ferrites have high coercivity, so are difficult to demagnetize. They are used to make permanent magnets for applications such as refrigerator magnets, loudspeakers, and small electric motors. Soft ferrites have low coercivity, so they easily change their magnetization and act as conductors of magnetic fields. They are used in the electronics industry to make effici ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Magnetostriction

Magnetostriction (cf. electrostriction) is a property of magnetic materials that causes them to change their shape or dimensions during the process of magnetization. The variation of materials' magnetization due to the applied magnetic field changes the magnetostrictive strain until reaching its saturation value, λ. The effect was first identified in 1842 by James Joule when observing a sample of iron. This effect causes energy loss due to frictional heating in susceptible ferromagnetic cores. The effect is also responsible for the low-pitched humming sound that can be heard coming from transformers, where oscillating AC currents produce a changing magnetic field. Explanation Internally, ferromagnetic materials have a structure that is divided into '' domains'', each of which is a region of uniform magnetization. When a magnetic field is applied, the boundaries between the domains shift and the domains rotate; both of these effects cause a change in the material's dimensions. ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Rare-earth

The rare-earth elements (REE), also called the rare-earth metals or (in context) rare-earth oxides or sometimes the lanthanides (yttrium and scandium are usually included as rare earths), are a set of 17 nearly-indistinguishable lustrous silvery-white soft heavy metals. Compounds containing rare earths have diverse applications in electrical and electronic components, lasers, glass, magnetic materials, and industrial processes. Scandium and yttrium are considered rare-earth elements because they tend to occur in the same ore deposits as the lanthanides and exhibit similar chemical properties, but have different electronic and magnetic properties. These metals tarnish slowly in air at room temperature and react slowly with cold water to form hydroxides, liberating hydrogen. They react with steam to form oxides, and at elevated temperature (400°C) ignite spontaneously. These elements and their compounds have no biological function other than in several specialized enzymes, s ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Terfenol-D

Terfenol-D, an alloy of the formula (''x'' ≈ 0.3), is a magnetostrictive material. It was initially developed in the 1970s by the Naval Ordnance Laboratory in the United States. The technology for manufacturing the material efficiently was developed in the 1980s at Ames Laboratory under a U.S. Navy-funded program. It is named after terbium, iron (Fe), Naval Ordnance Laboratory (NOL), and the D comes from dysprosium. Physical properties The alloy has the highest magnetostriction of any alloy, up to 0.002 m/m at saturation; it expands and contracts in a magnetic field. Terfenol-D has a large magnetostriction force, high energy density, low sound velocity, and a low Young's modulus. At its most pure form, it also has low ductility and a low fracture resistance. Terfenol-D is a gray alloy that has different possible ratios of its elemental components that always follow a formula of . The addition of dysprosium made it easier to induce magnetostrictive responses by making t ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Spark Plasma Sintering

Spark plasma sintering (SPS), also known as field assisted sintering technique (FAST) or pulsed electric current sintering (PECS), or plasma pressure compaction (P2C) is a sintering technique. The main characteristic of SPS is that the pulsed or unpulsed DC or AC current directly passes through the graphite die, as well as the powder compact, in case of conductive samples. Joule heating has been found to play a dominant role in the densification of powder compacts, which results in achieving near theoretical density at lower sintering temperature compared to conventional sintering techniques. The heat generation is internal, in contrast to the conventional hot pressing, where the heat is provided by external heating elements. This facilitates a very high heating or cooling rate (up to 1000 K/min), hence the sintering process generally is very fast (within a few minutes). The general speed of the process ensures it has the potential of densifying powders with nanosize or nanostruc ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Magnetoelectric Effect

In its most general form, the magnetoelectric effect (ME) denotes any coupling between the magnetic and the electric properties of a material. The first example of such an effect was described by Wilhelm Röntgen in 1888, who found that a dielectric material moving through an electric field would become magnetized. A material where such a coupling is intrinsically present is called a magnetoelectric. Historically, the first and most studied example of this effect is the linear magnetoelectric effect. Mathematically, while the electric susceptibility \chi^e and magnetic susceptibility \chi^v describe the electric and magnetic polarization responses to an electric, resp. a magnetic field, there is also the possibility of a magnetoelectric susceptibility \alpha_ which describes a linear response of the electric polarization to a magnetic field, and vice versa: :P_i= \sum_j \epsilon_0\chi^e_ E_ + \sum_j \alpha_H_j :\mu_0 M_i= \sum_j \mu_0\chi^v_H_ + \sum_j \alpha_E_j, The tensor \alpha ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Ceramic Materials

A ceramic is any of the various hard, brittle, heat-resistant and corrosion-resistant materials made by shaping and then firing an inorganic, nonmetallic material, such as clay, at a high temperature. Common examples are earthenware, porcelain, and brick. The earliest ceramics made by humans were pottery objects (''pots,'' ''vessels or vases'') or figurines made from clay, either by itself or mixed with other materials like silica, hardened and sintered in fire. Later, ceramics were glazed and fired to create smooth, colored surfaces, decreasing porosity through the use of glassy, amorphous ceramic coatings on top of the crystalline ceramic substrates. Ceramics now include domestic, industrial and building products, as well as a wide range of materials developed for use in advanced ceramic engineering, such as in semiconductors. The word "''ceramic''" comes from the Greek word (), "of pottery" or "for pottery", from (), "potter's clay, tile, pottery". The earliest known m ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Ferromagnetic Materials

Ferromagnetism is a property of certain materials (such as iron) which results in a large observed magnetic permeability, and in many cases a large magnetic coercivity allowing the material to form a permanent magnet. Ferromagnetic materials are the familiar metals noticeably attracted to a magnet, a consequence of their large magnetic permeability. Magnetic permeability describes the induced magnetization of a material due to the presence of an ''external'' magnetic field, and it is this temporarily induced magnetization inside a steel plate, for instance, which accounts for its attraction to the permanent magnet. Whether or not that steel plate acquires a permanent magnetization itself, depends not only on the strength of the applied field, but on the so-called coercivity of that material, which varies greatly among ferromagnetic materials. In physics, several different types of material magnetism are distinguished. Ferromagnetism (along with the similar effect ferrimagnetism ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |