|

Cushioning

Package cushioning is used to protect items during shipment. Vibration and impact shock during shipment and loading/unloading are controlled by cushioning to reduce the chance of product damage. Cushioning is usually inside a shipping container such as a corrugated box. It is designed to absorb shock by crushing and deforming, and to dampen vibration, rather than transmitting the shock and vibration to the protected item. Depending on the specific situation, package cushioning is often between thick. Internal packaging materials are also used for functions other than cushioning, such as to immobilize the products in the box and lock them in place, or to fill a void. Design factors When designing packaging the choice of cushioning depends on many factors, including but not limited to: * effective protection of product from shock and vibration * resilience (whether it performs for multiple impacts) * resistance to creep – cushion deformation under static load * material cost ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Shock (mechanics)

A mechanical or physical shock is a sudden acceleration caused, for example, by impact, drop, kick, earthquake, or explosion. Shock is a transient physical excitation. Shock describes matter subject to extreme rates of force with respect to time. Shock is a vector that has units of an acceleration (rate of change of velocity). The unit ''g'' (or g) represents multiples of the acceleration of gravity and is conventionally used. A shock pulse can be characterised by its peak acceleration, the duration, and the shape of the shock pulse (half sine, triangular, trapezoidal, etc.). The shock response spectrum is a method for further evaluating a mechanical shock. Shock measurement Shock measurement is of interest in several fields such as *Propagation of heel shock through a runner's body *Measure the magnitude of a shock need to cause damage to an item: fragility. *Measure shock attenuation through athletic flooring *Measuring the effectiveness of a shock absorber *Measuring th ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Molded Pulp

Molded pulp or molded fiber (also spelled as moulded pulp or moulded fibre) is a packaging material, that is typically made from recycled paperboard and/or newsprint. It is used for protective packaging or for food service trays and beverage carriers. Other typical uses are end caps, trays, plates, bowls and clamshell containers. For many applications, molded pulp is less expensive than expanded polystyrene (EPS), vacuumed formed polyethylene terephthalate (PET) and polyvinyl chloride (PVC), corrugation, and foams. Molded pulp is often considered a sustainable packaging material, as defined by the Sustainable Packaging Coalition, since it is produced from recycled materials, and can be recycled again after its useful life-cycle. Molded pulp products can be made waterproof with a spray or dip coating of wax. Types of molded pulp Several types of molded pulp can be manufactured by several processes. Thick-wall These products usually have wall thicknesses of 1.5 to ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Foam Peanut

Foam peanuts, also known as foam popcorn, packing peanuts, or packing noodles, are a common loose-fill packaging and cushioning material used to prevent damage to fragile objects during shipping. They are shaped to interlock when compressed and free flow when not compressed. They are roughly the size and shape of an unshelled peanut and commonly made of expanded polystyrene foam. 50–75 millimetres (2-3 in) of peanuts are typically used for cushioning and void filling packaging applications. The original patent was filed for by Robert E. Holden in 1962 and was granted in 1965. Polystyrene foam Polystyrene-based packing peanuts were developed and patented by Tektronix Inc. They were made commercially available circa 1965 by Dow Chemical. Originally made from 100% virgin polystyrene resin, peanuts made from 100% recycled polystyrene have been commercially available since the mid-90s. The color and shape sometimes indicate what it is made of and who made it. Often green is ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Corrugated Fiberboard

Corrugated fiberboard or corrugated cardboard is a type of packaging material consisting of a fluted corrugated sheet and one or two flat linerboards. It is made on "flute lamination machines" or "corrugators" and is used for making corrugated boxes. The corrugated medium sheet and the linerboard(s) are made of kraft containerboard, a paperboard material usually over thick. History Corrugated (also called pleated) paper was patented in England in 1856, and used as a liner for tall hats, but corrugated boxboard was not patented and used as a shipping material until 20 December 1871. The patent was issued to Albert Jones of New York City for single-sided (single-face) corrugated board. Jones used the corrugated board for wrapping bottles and glass lantern chimneys. The first machine for producing large quantities of corrugated board was built in 1874 by G. Smyth, and in the same year Oliver Long improved upon Jones' design by inventing corrugated board with liner sheets on both ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Vibration

Vibration is a mechanical phenomenon whereby oscillations occur about an equilibrium point. The word comes from Latin ''vibrationem'' ("shaking, brandishing"). The oscillations may be periodic function, periodic, such as the motion of a pendulum—or random, such as the movement of a tire on a gravel road. Vibration can be desirable: for example, the motion of a tuning fork, the Reed (music), reed in a woodwind instrument or harmonica, a mobile phone, or the cone of a loudspeaker. In many cases, however, vibration is undesirable, wasting energy and creating unwanted sound. For example, the vibrational motions of engines, electric motors, or any Machine, mechanical device in operation are typically unwanted. Such vibrations could be caused by Engine balance, imbalances in the rotating parts, uneven friction, or the meshing of gear teeth. Careful designs usually minimize unwanted vibrations. The studies of sound and vibration are closely related. Sound, or pressure waves, are ge ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Vibration

Vibration is a mechanical phenomenon whereby oscillations occur about an equilibrium point. The word comes from Latin ''vibrationem'' ("shaking, brandishing"). The oscillations may be periodic function, periodic, such as the motion of a pendulum—or random, such as the movement of a tire on a gravel road. Vibration can be desirable: for example, the motion of a tuning fork, the Reed (music), reed in a woodwind instrument or harmonica, a mobile phone, or the cone of a loudspeaker. In many cases, however, vibration is undesirable, wasting energy and creating unwanted sound. For example, the vibrational motions of engines, electric motors, or any Machine, mechanical device in operation are typically unwanted. Such vibrations could be caused by Engine balance, imbalances in the rotating parts, uneven friction, or the meshing of gear teeth. Careful designs usually minimize unwanted vibrations. The studies of sound and vibration are closely related. Sound, or pressure waves, are ge ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Polypropylene

Polypropylene (PP), also known as polypropene, is a thermoplastic polymer used in a wide variety of applications. It is produced via chain-growth polymerization from the monomer propylene. Polypropylene belongs to the group of polyolefins and is partially crystalline and non-polar. Its properties are similar to polyethylene, but it is slightly harder and more heat-resistant. It is a white, mechanically rugged material and has a high chemical resistance. Bio-PP is the bio-based counterpart of polypropylene (PP). Polypropylene is the second-most widely produced commodity plastic (after polyethylene). In 2019, the global market for polypropylene was worth $126.03 billion. Revenues are expected to exceed US$145 billion by 2019. The sales of this material are forecast to grow at a rate of 5.8% per year until 2021. History Phillips Petroleum chemists J. Paul Hogan and Robert Banks first demonstrated the polymerization of propylene in 1951. The stereoselective polymerization t ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Polymeric Foam

A polymeric foam is a foam, in liquid or solidified form, formed from polymers. Examples include: * Ethylene-vinyl acetate (EVA) foam, the copolymers of ethylene and vinyl acetate; also referred to as polyethylene-vinyl acetate (PEVA) * Low-density polyethylene (LDPE) foam, first grade of polyethylene (PE) * Nitrile rubber (NBR) foam, the copolymers of acrylonitrile (ACN) and butadiene * Polychloroprene foam or Neoprene * Polyimide foam * Polypropylene (PP) foam, including expanded polypropylene (EPP) and polypropylene paper (PPP) * Polystyrene (PS) foam, including expanded polystyrene (EPS), extruded polystyrene foam (XPS) and sometimes polystyrene paper (PSP) ** Styrofoam, including extruded polystyrene foam (XPS) and sometimes expanded polystyrene (EPS) * Polyurethane (PU) foam ** LRPu low-resilience polyurethane ** Memory foam ** Sorbothane *Polyethylene foam, as used in PEF rod * Polyvinyl chloride (PVC) foam ** Closed-cell PVC foamboard * Silicone foam * Microcellular foam ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Foam

Foams are materials formed by trapping pockets of gas in a liquid or solid. A bath sponge and the head on a glass of beer are examples of foams. In most foams, the volume of gas is large, with thin films of liquid or solid separating the regions of gas. Soap foams are also known as suds. Solid foams can be closed-cell or open-cell. In closed-cell foam, the gas forms discrete pockets, each completely surrounded by the solid material. In open-cell foam, gas pockets connect to each other. A bath sponge is an example of an open-cell foam: water easily flows through the entire structure, displacing the air. A sleeping mat is an example of a closed-cell foam: gas pockets are sealed from each other so the mat cannot soak up water. Foams are examples of dispersed media. In general, gas is present, so it divides into gas bubbles of different sizes (i.e., the material is polydisperse)—separated by liquid regions that may form films, thinner and thinner when the liquid phase drain ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

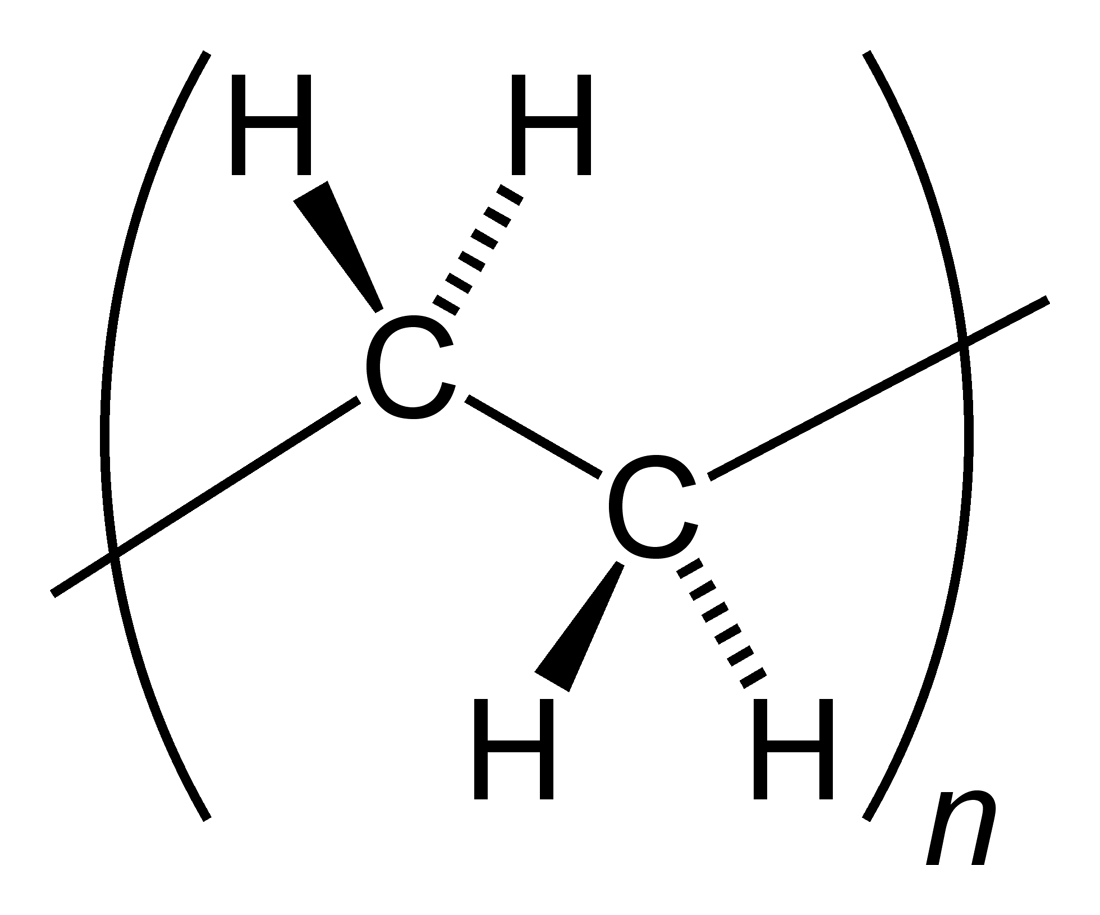

Polyethylene

Polyethylene or polythene (abbreviated PE; IUPAC name polyethene or poly(methylene)) is the most commonly produced plastic. It is a polymer, primarily used for packaging ( plastic bags, plastic films, geomembranes and containers including bottles, etc.). , over 100 million tonnes of polyethylene resins are being produced annually, accounting for 34% of the total plastics market. Many kinds of polyethylene are known, with most having the chemical formula (C2H4)''n''. PE is usually a mixture of similar polymers of ethylene, with various values of ''n''. It can be ''low-density'' or ''high-density'': low-density polyethylene is extruded using high pressure () and high temperature (), while high-density polyethylene is extruded using low pressure () and low temperature (). Polyethylene is usually thermoplastic, but it can be modified to become thermosetting instead, for example, in cross-linked polyethylene. History Polyethylene was first synthesized by the German chemist Hans ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Composite Honeycomb

Composite or compositing may refer to: Materials * Composite material, a material that is made from several different substances ** Metal matrix composite, composed of metal and other parts ** Cermet, a composite of ceramic and metallic materials ** Dental composite, a substance used to fill cavities in teeth ** Composite armor, a type of tank armor * Alloy, a mixture of a metal and another element * Mixture, the combination of several different substances without chemical reaction Mathematics * Composite number, a positive integer that has at least one factor other than one or itself Science * Composite particle, a particle which is made up of smaller particles * ''Compositae'' or "composite family" of flowering plants * Composite volcano, a layered conical volcano * Compositing, another name for superposed epoch analysis, a statistical method used to analyze time series involving multiple events Technology * Compositing, combining of visual elements from separate sources into ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Paperboard

Paperboard is a thick paper-based material. While there is no rigid differentiation between paper and paperboard, paperboard is generally thicker (usually over 0.30 mm, 0.012 in, or 12 Inch#equivalences, points) than paper and has certain superior attributes such as foldability and rigidity. According to International Organization for Standardization, ISO standards, paperboard is a paper with a grammage above 250 g/m2, but there are exceptions. Paperboard can be single- or multi-ply. Paperboard can be easily cut and formed, is lightweight, and because it is strong, is used in packaging. Another end-use is high quality graphic printing, such as book and magazine covers or postcards. Paperboard is also used in fine arts for creating sculptures. Sometimes it is referred to as ''cardboard'', which is a generic, lay term used to refer to any heavy pulp (paper), paper pulp–based board, however this usage is deprecated in the paper, printing and packaging industries as it doe ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

_shock_trials.jpg)

.jpg)