|

Curling (metalworking)

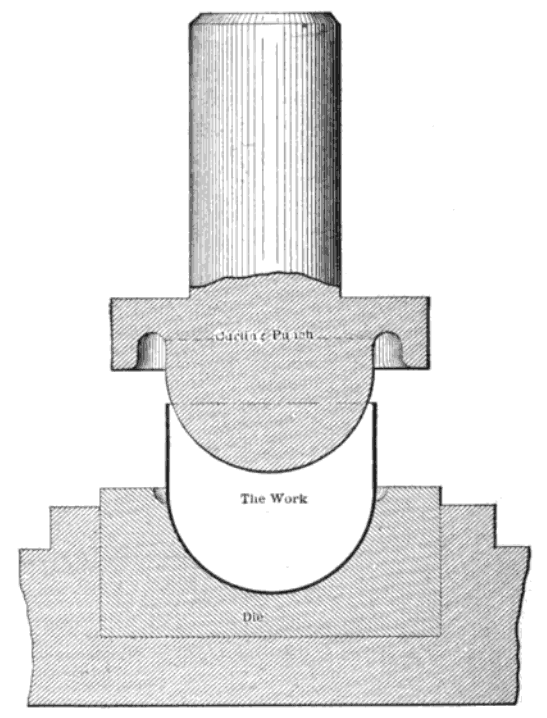

Curling is a sheet metal forming process used to form the edges into a hollow ring. Curling can be performed to eliminate sharp edges and increase the moment of inertia near the curled end. Other parts are curled to perform their primary function, such as door hinges. Operation In the curling operation, the flare, or burr, should always be turned away from the die. This will help prolong the life of the die by avoiding unnecessary damage due to scratching. The stroke of the die must be as long as the curl. Curling is often performed as part of a high production, multiple operation progressive forming. Tooling The curling die is designed to curl a material of specific thickness. Dies are generally made of hardened tool steel because of the amount of wear caused by the operation. Their smooth, rounded cavities are often lapped Lapping is a machining process in which two surfaces are rubbed together with an abrasive between them, by hand movement or using a machine. Lapping ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Curling Schematic

Curling is a sport in which players slide stones on a sheet of ice toward a target area which is segmented into four concentric circles. It is related to bowls, boules, and shuffleboard. Two teams, each with four players, take turns sliding heavy, polished granite stones, also called ''rocks'', across the ice ''curling sheet'' toward the ''house'', a circular target marked on the ice. Each team has eight stones, with each player throwing two. The purpose is to accumulate the highest score for a ''game''; points are scored for the stones resting closest to the centre of the house at the conclusion of each ''end'', which is completed when both teams have thrown all of their stones once. A game usually consists of eight or ten ends. The player can induce a curved path, described as ''curl'', by causing the stone to slowly rotate as it slides. The path of the rock may be further influenced by two sweepers with brooms or brushes, who accompany it as it slides down the sheet and sw ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Curling Process Steps

Curling is a sport in which players slide stones on a sheet of ice toward a target area which is segmented into four concentric circles. It is related to bowls, boules, and shuffleboard. Two teams, each with four players, take turns sliding heavy, polished granite stones, also called ''rocks'', across the ice ''curling sheet'' toward the ''house'', a circular target marked on the ice. Each team has eight stones, with each player throwing two. The purpose is to accumulate the highest score for a ''game''; points are scored for the stones resting closest to the centre of the house at the conclusion of each ''end'', which is completed when both teams have thrown all of their stones once. A game usually consists of eight or ten ends. The player can induce a curved path, described as ''curl'', by causing the stone to slowly rotate as it slides. The path of the rock may be further influenced by two sweepers with brooms or brushes, who accompany it as it slides down the sheet and sw ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Sheet Metal Forming

Sheet metal is metal formed into thin, flat pieces, usually by an industrial process. Sheet metal is one of the fundamental forms used in metalworking, and it can be cut and bent into a variety of shapes. Thicknesses can vary significantly; extremely thin sheets are considered foil (metal), foil or Metal leaf, leaf, and pieces thicker than 6 mm (0.25 in) are considered plate, such as plate steel, a class of structural steel. Sheet metal is available in flat pieces or coiled strips. The coils are formed by running a continuous sheet of metal through a roll slitting, roll slitter. In most of the world, sheet metal thickness is consistently specified in millimeters. In the U.S., the thickness of sheet metal is commonly specified by a traditional, non-linear measure known as its Sheet metal gauge, gauge. The larger the gauge number, the thinner the metal. Commonly used steel sheet metal ranges from 30 gauge to about 7 gauge. Gauge differs between ferrous (Iron, iron-base ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Moment Of Inertia

The moment of inertia, otherwise known as the mass moment of inertia, angular mass, second moment of mass, or most accurately, rotational inertia, of a rigid body is a quantity that determines the torque needed for a desired angular acceleration about a rotational axis, akin to how mass determines the force needed for a desired acceleration. It depends on the body's mass distribution and the axis chosen, with larger moments requiring more torque to change the body's rate of rotation. It is an extensive (additive) property: for a point mass the moment of inertia is simply the mass times the square of the perpendicular distance to the axis of rotation. The moment of inertia of a rigid composite system is the sum of the moments of inertia of its component subsystems (all taken about the same axis). Its simplest definition is the second moment of mass with respect to distance from an axis. For bodies constrained to rotate in a plane, only their moment of inertia about an axis ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Door Hinge

A hinge is a mechanical bearing that connects two solid objects, typically allowing only a limited angle of rotation between them. Two objects connected by an ideal hinge rotate relative to each other about a fixed axis of rotation: all other translations or rotations being prevented, and thus a hinge has one degree of freedom. Hinges may be made of flexible material or of moving components. In biology, many joints function as hinges, like the elbow joint. History Ancient remains of stone, marble, wood, and bronze hinges have been found. Some date back to at least Ancient Egypt. In Ancient Rome, hinges were called cardō and gave name to the goddess Cardea and the main street Cardo. This name cardō lives on figuratively today as "the chief thing (on which something turns or depends)" in words such as ''cardinal''. According to the OED, the English word hinge is related to '' hang''. Door hinges ; Barrel hinge: A barrel hinge consists of a sectional barrel (the knu ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Flare Fitting

Flare fittings are a type of compression fitting used with metal tubing, usually soft steel, ductile (soft) copper and aluminum, though other materials are also used. In a flare fitting the tube itself is "flared" i.e. expanded and deformed at the end. The flare is then pressed against the fitting it connects to and is secured by a close-fitting nut that ensures that no leakage happens. Tube flaring is a type of forging operation, and is usually a cold working procedure. During assembly, a flare nut is used to secure the flared tubing's tapered end to the also tapered fitting, producing a pressure-resistant, leak-tight seal. Flared connections offer a high degree of long-term reliability and for this reason are often used in mission-critical and inaccessible locations. The tool used to flare tubing consists of a die that grips the tube and either a mandrel or rolling cone is forced into the end of the tube to form the flare by cold working. The most common flare fitt ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Burr (edge)

A burr is a raised edge or small piece of material that remains attached to a workpiece after a modification process. It is usually an unwanted piece of material and is removed with a deburring tool in a process called 'deburring'. Burrs are most commonly created by machining operations, such as grinding, drilling, milling, engraving or turning. It may be present in the form of a fine wire on the edge of a freshly sharpened tool or as a raised portion of a surface; this type of burr is commonly formed when a hammer strikes a surface. Deburring accounts for a significant portion of manufacturing costs. In the printmaking technique of drypoint, burr, which gives a rich fuzzy quality to the engraved line, is highly desirable—the great problem with the drypoint medium is that the burr rapidly diminishes after as few as ten impressions are printed. Types There are three types of burrs that can be formed from machining operations: ''Poisson burr'', ''rollover burr'', and ''breakou ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Die (manufacturing)

A die is a specialized machine tool used in manufacturing industries to cut and/or form material to a desired shape or profile. Stamping dies are used with a press, as opposed to drawing dies (used in the manufacture of wire) and casting dies (used in molding) which are not. Like molds, dies are generally customized to the item they are used to create. Products made with dies range from simple paper clips to complex pieces used in advanced technology. Continuous-feed laser cutting may displace the analogous die-based process in the automotive industry, among others. Die stamping Blanking and piercing are two die cutting operations, and bending is an example of a die forming operation. Die forming Forming operations work by deforming materials like sheet metal or plastic using force (compression, tension, or both) and rely on the material's mechanical properties. Forming dies are typically made by tool and die makers and put into production after mounting into a press. ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Abrasion (mechanical)

Abrasion is the process of scuffing, scratching, wearing down, marring, or rubbing away. It can be intentionally imposed in a controlled process using an abrasive. Abrasion can be an undesirable effect of exposure to normal use or exposure to the elements. In stone shaping Ancient artists, working in stone, used abrasion to create sculptures. The artist selected dense stones like carbonite and emery and rubbed them consistently against comparatively softer stones like limestone and granite. The artist used different sizes and shapes of abrasives, or turned them in various ways as they rubbed, to create effects on the softer stone's surface. Water was continuously poured over the surface to carry away particles. Abrasive technique in stone shaping was a long, tedious process that, with patience, resulted in eternal works of art in stone. Models The Archard equation is a simple model used to describe sliding wear and is based on the theory of asperity contact. Q = \frac H whe ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Tool Steel

Tool steel is any of various carbon steels and alloy steels that are particularly well-suited to be made into tools and tooling, including cutting tools, dies, hand tools, knives, and others. Their suitability comes from their distinctive hardness, resistance to abrasion and deformation, and their ability to hold a cutting edge at elevated temperatures. As a result, tool steels are suited for use in the shaping of other materials, as for example in cutting, machining, stamping, or forging. With a carbon content between 0.5% and 1.5%, tool steels are manufactured under carefully controlled conditions to produce the required quality. The presence of carbides in their matrix plays the dominant role in the qualities of tool steel. The four major alloying elements that form carbides in tool steel are: tungsten, chromium, vanadium and molybdenum. The rate of dissolution of the different carbides into the austenite form of the iron determines the high-temperature performance of st ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Lapped

Lapping is a machining process in which two surfaces are rubbed together with an abrasive between them, by hand movement or using a machine. Lapping often follows other subtractive processes with more aggressive material removal as a first step, such as milling and/or grinding. Lapping can take two forms. The first type of lapping (traditionally often called grinding), involves rubbing a brittle material such as glass against a surface such as iron or glass itself (also known as the "lap" or grinding tool) with an abrasive such as aluminum oxide, jeweller's rouge, optician's rouge, emery, silicon carbide, diamond, etc., between them. This produces microscopic conchoidal fractures as the abrasive rolls about between the two surfaces and removes material from both. The other form of lapping involves a softer material such as pitch or a ceramic for the lap, which is "charged" with the abrasive. The lap is then used to cut a harder material—the workpiece. The abrasive embe ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |