Curling (metalworking) on:

[Wikipedia]

[Google]

[Amazon]

Curling is a

Curling is a

Curling is a

Curling is a sheet metal forming

Sheet metal is metal formed into thin, flat pieces, usually by an industrial process. Sheet metal is one of the fundamental forms used in metalworking, and it can be cut and bent into a variety of shapes.

Thicknesses can vary significantly; ex ...

process used to form the edges into a hollow ring. Curling can be performed to eliminate sharp edges and increase the moment of inertia

The moment of inertia, otherwise known as the mass moment of inertia, angular mass, second moment of mass, or most accurately, rotational inertia, of a rigid body is a quantity that determines the torque needed for a desired angular acceler ...

near the curled end. Other parts are curled to perform their primary function, such as door hinges.

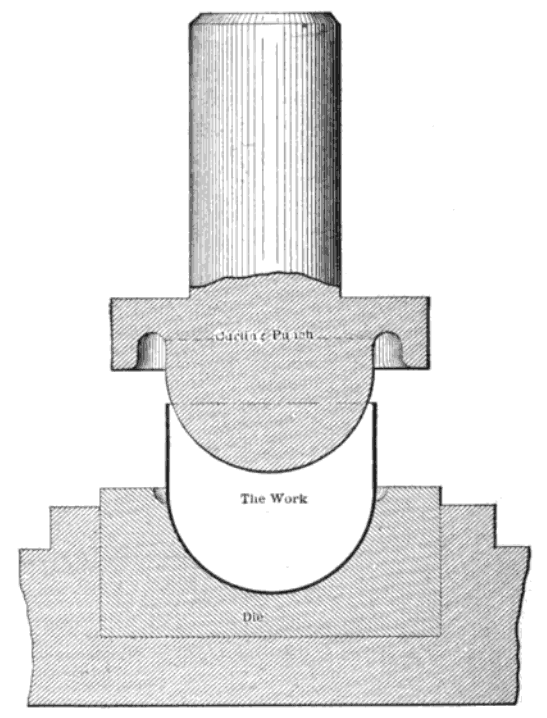

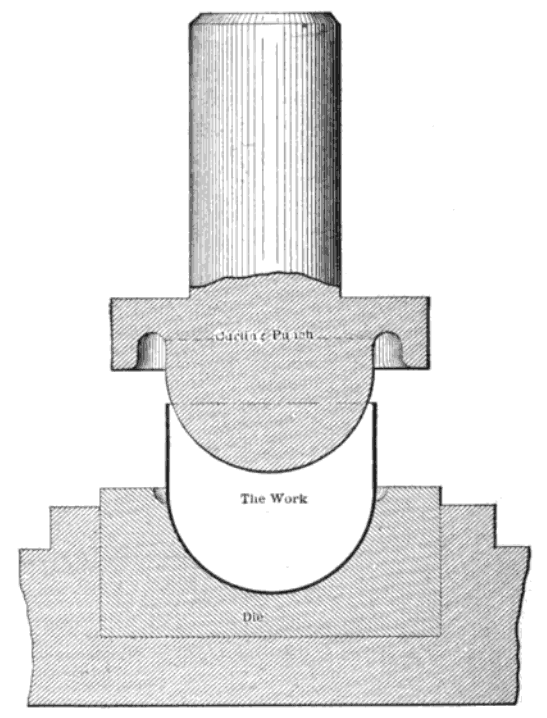

Operation

In the curling operation, theflare

A flare, also sometimes called a fusée, fusee, or bengala in some Latin-speaking countries, is a type of pyrotechnic that produces a bright light or intense heat without an explosion. Flares are used for distress signaling, illumination, ...

, or burr, should always be turned away from the die

Die, as a verb, refers to death, the cessation of life.

Die may also refer to:

Games

* Die, singular of dice, small throwable objects used for producing random numbers

Manufacturing

* Die (integrated circuit), a rectangular piece of a semicondu ...

. This will help prolong the life of the die by avoiding unnecessary damage due to scratching. The stroke of the die must be as long as the curl. Curling is often performed as part of a high production, multiple operation progressive forming.

Tooling

The curling die is designed to curl a material of specific thickness. Dies are generally made of hardenedtool steel

Tool steel is any of various carbon steels and alloy steels that are particularly well-suited to be made into tools and tooling, including cutting tools, dies, hand tools, knives, and others. Their suitability comes from their distinctive har ...

because of the amount of wear caused by the operation. Their smooth, rounded cavities are often lapped

Lapping is a machining process in which two surfaces are rubbed together with an abrasive between them, by hand movement or using a machine.

Lapping often follows other subtractive processes with more aggressive material removal as a first step ...

and polished to help curl the material uniformly.

References

Further reading

*''Handbook of Die Design''. Ivana Suchy. *''Punches and Dies: Layout, Construction and Use''. Frank Arthur Stanley {{DEFAULTSORT:Curling (Metalworking) Fabrication (metal)