|

Choked Flow

Choked flow is a compressible flow effect. The parameter that becomes "choked" or "limited" is the fluid velocity. Choked flow is a Fluid dynamics, fluid dynamic condition associated with the Venturi effect. When a flowing fluid at a given pressure and temperature passes through a constriction (such as the throat of a convergent-divergent nozzle or a valve in a pipe (material), pipe) into a lower pressure environment the fluid velocity increases. At initially subsonic upstream conditions, the conservation of energy principle requires the fluid velocity to increase as it flows through the smaller cross-sectional area of the constriction. At the same time, the Venturi effect causes the static pressure, and therefore the density, to decrease at the constriction. Choked flow is a limiting condition where the mass flow cannot increase with a further decrease in the downstream pressure environment for a fixed upstream pressure and temperature. For homogeneous fluids, the physical point ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Fluid Dynamics

In physics, physical chemistry and engineering, fluid dynamics is a subdiscipline of fluid mechanics that describes the flow of fluids – liquids and gases. It has several subdisciplines, including (the study of air and other gases in motion) and (the study of water and other liquids in motion). Fluid dynamics has a wide range of applications, including calculating forces and moment (physics), moments on aircraft, determining the mass flow rate of petroleum through pipeline transport, pipelines, weather forecasting, predicting weather patterns, understanding nebulae in interstellar space, understanding large scale Geophysical fluid dynamics, geophysical flows involving oceans/atmosphere and Nuclear weapon design, modelling fission weapon detonation. Fluid dynamics offers a systematic structure—which underlies these practical disciplines—that embraces empirical and semi-empirical laws derived from flow measurement and used to solve practical problems. The solution to a fl ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

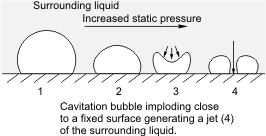

Cavitation

Cavitation in fluid mechanics and engineering normally is the phenomenon in which the static pressure of a liquid reduces to below the liquid's vapor pressure, leading to the formation of small vapor-filled cavities in the liquid. When subjected to higher pressure, these cavities, called "bubbles" or "voids", collapse and can generate shock waves that may damage machinery. These shock waves are strong when they are very close to the imploded bubble, but rapidly weaken as they propagate away from the implosion. Cavitation is a significant cause of wear in some engineering contexts. Collapsing voids that implode near to a metal surface cause cyclic stress through repeated implosion. This results in surface fatigue of the metal, causing a type of wear also called "cavitation". The most common examples of this kind of wear are to pump impellers, and bends where a sudden change in the direction of liquid occurs. Cavitation is usually divided into two classes of behavior. ''In ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Orifice Plate

An orifice plate is a device used for measuring flow rate, reducing pressure or restricting flow (in the latter two cases it is often called a '). Description An orifice plate is a thin plate with a hole in it, which is usually placed in a pipe. When a fluid (whether liquid or gaseous) passes through the orifice, its pressure builds up slightly upstream of the orifice but as the fluid is forced to converge to pass through the hole, the velocity increases and the fluid pressure decreases. A little downstream of the orifice the flow reaches its point of maximum convergence, the ''vena contracta'' (see drawing to the right) where the velocity reaches its maximum and the pressure reaches its minimum. Beyond that, the flow expands, the velocity falls and the pressure increases. By measuring the difference in fluid pressure across tappings upstream and downstream of the plate, the flow rate can be obtained from Bernoulli's equation using coefficients established from extensive research. ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Accidental Release Source Terms

Accidental release source terms are the mathematical equations that quantify the flow rate at which accidental releases of liquid or gaseous pollutants into the ambient environment which can occur at industrial facilities such as petroleum refineries, petrochemical plants, natural gas processing plants, oil and gas transportation pipelines, chemical plants, and many other industrial activities. Governmental regulations in many countries require that the probability of such accidental releases be analyzed and their quantitative impact upon the environment and human health be determined so that mitigating steps can be planned and implemented. There are a number of mathematical calculation methods for determining the flow rate at which gaseous and liquid pollutants might be released from various types of accidents. Such calculational methods are referred to as ''source terms'', and this article on accidental release source terms explains some of the calculation methods used for deter ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Back Pressure

Back pressure (or backpressure) is the term for a resistance to the desired flow of fluid through pipes. Obstructions or tight bends create backpressure via friction loss and pressure drop. In distributed systems in particular event-driven architecture, back pressure is a technique to regulate flow of data, ensuring that components do not become overwhelmed. Explanation A common example of backpressure is that caused by the exhaust system (consisting of the exhaust manifold, catalytic converter, muffler and connecting pipes) of an automotive four-stroke engine, which has a negative effect on engine efficiency, resulting in a decrease of power output that must be compensated by increasing fuel consumption. In a piston-ported two-stroke engine, however, the situation is more complicated, due to the need to prevent unburned fuel/air mixture from passing right through the cylinders into the exhaust. During the exhaust phase of the cycle, backpressure is even more undesirable ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

NASA

The National Aeronautics and Space Administration (NASA ) is an independent agencies of the United States government, independent agency of the federal government of the United States, US federal government responsible for the United States's civil list of government space agencies, space program, aeronautics research and outer space, space research. National Aeronautics and Space Act, Established in 1958, it succeeded the National Advisory Committee for Aeronautics (NACA) to give the American space development effort a distinct civilian orientation, emphasizing peaceful applications in space science. It has since led most of America's space exploration programs, including Project Mercury, Project Gemini, the 1968–1972 Apollo program missions, the Skylab space station, and the Space Shuttle. Currently, NASA supports the International Space Station (ISS) along with the Commercial Crew Program and oversees the development of the Orion (spacecraft), Orion spacecraft and the Sp ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Sulfur Dioxide

Sulfur dioxide (IUPAC-recommended spelling) or sulphur dioxide (traditional Commonwealth English) is the chemical compound with the formula . It is a colorless gas with a pungent smell that is responsible for the odor of burnt matches. It is released naturally by volcanic activity and is produced as a by-product of metals refining and the burning of Sour gas, sulfur-Sour crude oil, bearing fossil fuels. Sulfur dioxide is somewhat toxic to humans, although only when inhaled in relatively large quantities for a period of several minutes or more. It was known to medieval alchemy, alchemists as "volatile spirit of sulfur". Structure and bonding SO2 is a bent molecule with ''C''2v Point groups in three dimensions, symmetry point group. A valence bond theory approach considering just ''s'' and ''p'' orbitals would describe the bonding in terms of resonance (chemistry), resonance between two resonance structures. The sulfur–oxygen bond has a bond order of 1.5. There is support f ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Ideal Gas

An ideal gas is a theoretical gas composed of many randomly moving point particles that are not subject to interparticle interactions. The ideal gas concept is useful because it obeys the ideal gas law, a simplified equation of state, and is amenable to analysis under statistical mechanics. The requirement of zero interaction can often be relaxed if, for example, the interaction is perfectly elastic or regarded as point-like collisions. Under various conditions of temperature and pressure, many real gases behave qualitatively like an ideal gas where the gas molecules (or atoms for monatomic gas) play the role of the ideal particles. Many gases such as nitrogen, oxygen, hydrogen, noble gases, some heavier gases like carbon dioxide and mixtures such as air, can be treated as ideal gases within reasonable tolerances over a considerable parameter range around standard temperature and pressure. Generally, a gas behaves more like an ideal gas at higher temperature and lower ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Specific Heat Capacity

In thermodynamics, the specific heat capacity (symbol ) of a substance is the amount of heat that must be added to one unit of mass of the substance in order to cause an increase of one unit in temperature. It is also referred to as massic heat capacity or as the specific heat. More formally it is the heat capacity of a sample of the substance divided by the mass of the sample. The SI unit of specific heat capacity is joule per kelvin per kilogram, J⋅kg−1⋅K−1. For example, the heat required to raise the temperature of of water by is , so the specific heat capacity of water is . Specific heat capacity often varies with temperature, and is different for each state of matter. Liquid water has one of the highest specific heat capacities among common substances, about at 20 °C; but that of ice, just below 0 °C, is only . The specific heat capacities of iron, granite, and hydrogen gas are about 449 J⋅kg−1⋅K−1, 790 J⋅kg−1⋅K−1, and 143 ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Heat Capacity Ratio

In thermal physics and thermodynamics, the heat capacity ratio, also known as the adiabatic index, the ratio of specific heats, or Laplace's coefficient, is the ratio of the heat capacity at constant pressure () to heat capacity at constant volume (). It is sometimes also known as the '' isentropic expansion factor'' and is denoted by (gamma) for an ideal gasγ first appeared in an article by the French mathematician, engineer, and physicist Siméon Denis Poisson: * On p. 332, Poisson defines γ merely as a small deviation from equilibrium which causes small variations of the equilibrium value of the density ρ. In Poisson's article of 1823 – * γ was expressed as a function of density D (p. 8) or of pressure P (p. 9). Meanwhile, in 1816 the French mathematician and physicist Pierre-Simon Laplace had found that the speed of sound depends on the ratio of the specific heats. * However, he didn't denote the ratio as γ. In 1825, Laplace stated that the speed of sound i ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Discharge Coefficient

In a nozzle or other constriction, the discharge coefficient (also known as coefficient of discharge or efflux coefficient) is the ratio of the actual discharge to the ideal discharge,Sam Mannan, Frank P. Lee, ''Lee's Loss Prevention in the Process Industries: Hazard Identification, Assessment and Control'', Volume 1, Elsevier Butterworth Heinemann, 2005. (Google books)/ref> i.e., the ratio of the mass flow rate at the discharge end of the nozzle to that of an ideal nozzle which expands an identical working fluid from the same initial conditions to the same exit pressures. Mathematically the discharge coefficient may be related to the mass flow rate of a fluid through a straight tube of constant cross-sectional area through the following: : C_\text = \frac = \frac = \frac = \frac : C_\text = \frac Where: :C_\text, discharge coefficient through the constriction (dimensionless). :\dot, mass flow rate of fluid through constriction (mass per time). :\rho, density of fluid (mass per vo ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |