|

Chinese Chef's Knife

A kitchen knife is any knife that is intended to be used in food preparation. While much of this work can be accomplished with a few general-purpose knives – notably a large chef's knife, a tough cleaver, a small paring knife and some sort of serrated blade (such as a bread knife or serrated utility knife) – there are also many specialized knives that are designed for specific tasks. Kitchen knives can be made from several different materials. Construction Material * Carbon steel is an alloy of iron and carbon, often including other elements such as vanadium and manganese. Carbon steel commonly used in knives has around 1.0% carbon (ex. AISI 1095), is inexpensive, and holds its edge well. Carbon steel is normally easier to resharpen than many stainless steels, but is vulnerable to rust and stains. The blades should be cleaned, dried, and lubricated after each use. New carbon-steel knives may impart a metallic or "iron" flavour to acidic foods, though over time, the st ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Cucina 012

Cucina (Italian "cuisine" or "kitchen") or La cucina may refer to: * ''La Cucina'' (film) * La Cucina (band) La Cucina was an English roots style band of the 1990s, that went under the tagline of "accordion-driven funky neapolitan rockers". Although they were based in the south of England, their music was an amalgam of Southern Italian folk songs and ... * ''La Cucina'' (opera) 2019 {{dab ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Oxidation

Redox (reduction–oxidation, , ) is a type of chemical reaction in which the oxidation states of substrate change. Oxidation is the loss of electrons or an increase in the oxidation state, while reduction is the gain of electrons or a decrease in the oxidation state. There are two classes of redox reactions: * ''Electron-transfer'' – Only one (usually) electron flows from the reducing agent to the oxidant. This type of redox reaction is often discussed in terms of redox couples and electrode potentials. * ''Atom transfer'' – An atom transfers from one substrate to another. For example, in the rusting of iron, the oxidation state of iron atoms increases as the iron converts to an oxide, and simultaneously the oxidation state of oxygen decreases as it accepts electrons released by the iron. Although oxidation reactions are commonly associated with the formation of oxides, other chemical species can serve the same function. In hydrogenation, C=C (and other) bonds ar ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Tempering (metallurgy)

Tempering is a process of heat treating, which is used to increase the toughness of iron-based alloys. Tempering is usually performed after hardening, to reduce some of the excess hardness, and is done by heating the metal to some temperature below the critical point for a certain period of time, then allowing it to cool in still air. The exact temperature determines the amount of hardness removed, and depends on both the specific composition of the alloy and on the desired properties in the finished product. For instance, very hard tools are often tempered at low temperatures, while springs are tempered at much higher temperatures. Introduction Tempering is a heat treatment technique applied to ferrous alloys, such as steel or cast iron, to achieve greater toughness by decreasing the hardness of the alloy. The reduction in hardness is usually accompanied by an increase in ductility, thereby decreasing the brittleness of the metal. Tempering is usually performed after quench ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Quench

In materials science, quenching is the rapid cooling of a workpiece in water, oil, polymer, air, or other fluids to obtain certain material properties. A type of heat treating, quenching prevents undesired low-temperature processes, such as phase transformations, from occurring. It does this by reducing the window of time during which these undesired reactions are both thermodynamically favorable, and kinetically accessible; for instance, quenching can reduce the crystal grain size of both metallic and plastic materials, increasing their hardness. In metallurgy, quenching is most commonly used to harden steel by inducing a martensite transformation, where the steel must be rapidly cooled through its eutectoid point, the temperature at which austenite becomes unstable. In steel alloyed with metals such as nickel and manganese, the eutectoid temperature becomes much lower, but the kinetic barriers to phase transformation remain the same. This allows quenching to start at a lower ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Forging

Forging is a manufacturing process involving the shaping of metal using localized compressive forces. The blows are delivered with a hammer (often a power hammer) or a die. Forging is often classified according to the temperature at which it is performed: cold forging (a type of cold working), warm forging, or hot forging (a type of hot working). For the latter two, the metal is heated, usually in a forge. Forged parts can range in weight from less than a kilogram to hundreds of metric tons.Degarmo, p. 389 Forging has been done by smiths for millennia; the traditional products were kitchenware, hardware, hand tools, edged weapons, cymbals, and jewellery. Since the Industrial Revolution, forged parts are widely used in mechanisms and machines wherever a component requires high strength; such forgings usually require further processing (such as machining) to achieve a finished part. Today, forging is a major worldwide industry. History Forging is one of the oldest known me ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Plastic

Plastics are a wide range of synthetic or semi-synthetic materials that use polymers as a main ingredient. Their plasticity makes it possible for plastics to be moulded, extruded or pressed into solid objects of various shapes. This adaptability, plus a wide range of other properties, such as being lightweight, durable, flexible, and inexpensive to produce, has led to its widespread use. Plastics typically are made through human industrial systems. Most modern plastics are derived from fossil fuel-based chemicals like natural gas or petroleum; however, recent industrial methods use variants made from renewable materials, such as corn or cotton derivatives. 9.2 billion tonnes of plastic are estimated to have been made between 1950 and 2017. More than half this plastic has been produced since 2004. In 2020, 400 million tonnes of plastic were produced. If global trends on plastic demand continue, it is estimated that by 2050 annual global plastic production will reach over 1, ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Zirconium Dioxide

Zirconium dioxide (), sometimes known as zirconia (not to be confused with zircon), is a white crystalline oxide of zirconium. Its most naturally occurring form, with a monoclinic crystalline structure, is the mineral baddeleyite. A dopant stabilized cubic structured zirconia, cubic zirconia, is synthesized in various colours for use as a gemstone and a diamond simulant. Production, chemical properties, occurrence Zirconia is produced by calcining zirconium compounds, exploiting its high thermostability.Ralph Nielsen "Zirconium and Zirconium Compounds" in Ullmann's Encyclopedia of Industrial Chemistry, 2005, Wiley-VCH, Weinheim. Structure Three phases are known: monoclinic below 1170 °C, tetragonal between 1170 °C and 2370 °C, and cubic above 2370 °C. The trend is for higher symmetry at higher temperatures, as is usually the case. A small percentage of the oxides of calcium or yttrium stabilize in the cubic phase. The very rare mineral tazheranite, , ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Ceramic Knife

A ceramic knife is a knife with a ceramic blade typically made from zirconium dioxide (ZrO2; also known as zirconia), rather than the steel used for most knives. Ceramic knife blades are usually produced through the dry-pressing and firing of powdered zirconia using solid-state sintering. The blades typically score 8.5 on the Mohs scale of mineral hardness, compared to 4.5 for normal steel and 7.5 to 8 for hardened steel and 10 for diamond. The resultant blade has a hard edge that stays sharp for much longer than conventional steel blades. However, the blade is brittle, subject to chipping, and will break rather than flex if twisted. The ceramic blade is sharpened by grinding the edges with a diamond-dust-coated grinding wheel. Zirconium oxide Zirconium oxide is used due to its polymorphism. It exists in three phases: monoclinic, tetragonal and cubic. Cooling to the monoclinic phase after sintering causes a large volume change, which often causes stress fractures in pure zir ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

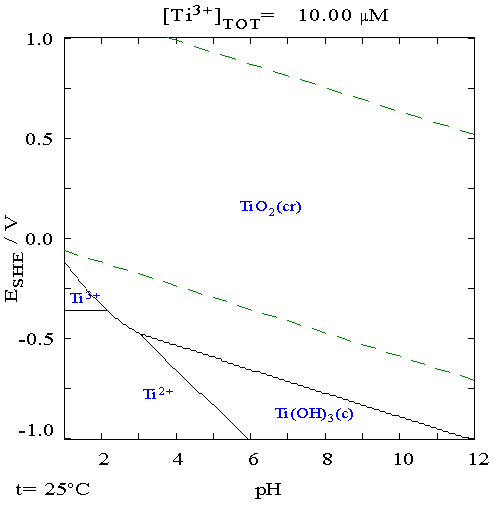

Titanium

Titanium is a chemical element with the symbol Ti and atomic number 22. Found in nature only as an oxide, it can be reduced to produce a lustrous transition metal with a silver color, low density, and high strength, resistant to corrosion in sea water, aqua regia, and chlorine. Titanium was discovered in Cornwall, Great Britain, by William Gregor in 1791 and was named by Martin Heinrich Klaproth after the Titans of Greek mythology. The element occurs within a number of minerals, principally rutile and ilmenite, which are widely distributed in the Earth's crust and lithosphere; it is found in almost all living things, as well as bodies of water, rocks, and soils. The metal is extracted from its principal mineral ores by the Kroll and Hunter processes. The most common compound, titanium dioxide, is a popular photocatalyst and is used in the manufacture of white pigments. Other compounds include titanium tetrachloride (TiCl4), a component of smoke screens and catalysts; and ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Laminate

Lamination is the technique/process of manufacturing a material in multiple layers, so that the composite material achieves improved strength, stability, sound insulation, appearance, or other properties from the use of the differing materials, such as plastic. A laminate is a permanently assembled object created using heat, pressure, welding, or adhesives. Various coating machines, machine presses and calendering equipment are used. Materials There are different lamination processes, depending primarily on the type or types of materials to be laminated. The materials used in laminates can be identical or different, depending on the process and the object to be laminated. Textile Laminated fabric are widely used in different fields of human activity, including medical and military. Woven fabrics (organic and inorganic based) are usually laminated by different chemical polymers to give them useful properties like chemical resistance, dust, grease, windproofness, photolumine ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Krause Publications

Krause Publications is an American publisher of hobby magazines and books. Originally a company founded and based in Iola, Wisconsin, they relocated to Stevens Point, Wisconsin, in April 2018. The company was started by Chester L. Krause (19232016) upon the publication in October 1952 of the first issue of '' Numismatic News''. In the coin collecting community the company is best known for its ''Standard Catalog of World Coins'', a series of coin catalogs commonly referred to as ''Krause-Mishler'' catalogs or simply ''Krause'' catalogs; they provide information, pricing, and Krause-Mishler (KM) numbers referring to coin rarity and value. Krause-Mishler (named for Krause and longtime employee Clifford Mishler) numbers are the most common way of assigning values to coins. The first edition was published in 1972. In addition, they established the Coin of the Year Award, first issued in 1984, for excellence in coinage design. In the paper money collecting community the company is ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Molybdenum

Molybdenum is a chemical element with the symbol Mo and atomic number 42 which is located in period 5 and group 6. The name is from Neo-Latin ''molybdaenum'', which is based on Ancient Greek ', meaning lead, since its ores were confused with lead ores. Molybdenum minerals have been known throughout history, but the element was discovered (in the sense of differentiating it as a new entity from the mineral salts of other metals) in 1778 by Carl Wilhelm Scheele. The metal was first isolated in 1781 by Peter Jacob Hjelm. Molybdenum does not occur naturally as a free metal on Earth; it is found only in various oxidation states in minerals. The free element, a silvery metal with a grey cast, has the sixth-highest melting point of any element. It readily forms hard, stable carbides in alloys, and for this reason most of the world production of the element (about 80%) is used in steel alloys, including high-strength alloys and superalloys. Most molybdenum compounds have low solubili ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |