|

Biomachining

Biomachining is the machining process of using lithotropic bacteria to remove material from metal parts, contrasted with chemical machining methods such as chemical milling and physical machining methods such as milling. Certain bacteria, such as Thiobacillus ferrooxidans and Thiobacillus thiooxidans, which are also used in the mineral refinement process of bioleaching, utilize the chemical energy from oxidation of iron or copper to fix carbon dioxide from the air. A metal object, when placed in a culture fluid containing these metal-metabolizing bacteria, will have material removed from its surface over time. Biomachining is ideal for micromachining due to its very low material removal rate. In addition, biomachining is less likely to leave an undesirable surface finish; neither chemical nor physical energy is concentrated on the cutting area, so the possibility of a damaged or burned surface is slim. This process has been successfully used to cut both pure iron and pure copper ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Machining

Machining is a process in which a material (often metal) is cut to a desired final shape and size by a controlled material-removal process. The processes that have this common theme are collectively called subtractive manufacturing, which utilizes machine tools, in contrast to ''additive manufacturing'' (3D printing), which uses controlled addition of material. Machining is a part of the manufacture of many metal products, but it can also be used on other materials such as wood, plastic, ceramic, and composite material. A person who specializes in machining is called a machinist. A room, building, or company where machining is done is called a machine shop. Much of modern-day machining is carried out by computer numerical control (CNC), in which computers are used to control the movement and operation of the mills, lathes, and other cutting machines. This increases efficiency, as the CNC machine runs unmanned therefore reducing labour costs for machine shops. History and ter ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Lithotropic

Lithotrophs are a diverse group of organisms using an inorganic substrate (usually of mineral origin) to obtain reducing equivalents for use in biosynthesis (e.g., carbon dioxide fixation) or energy conservation (i.e., ATP production) via aerobic or anaerobic respiration. While lithotrophs in the broader sense include photolithotrophs like plants, chemolithotrophs are exclusively microorganisms; no known macrofauna possesses the ability to use inorganic compounds as electron sources. Macrofauna and lithotrophs can form symbiotic relationships, in which case the lithotrophs are called "prokaryotic symbionts". An example of this is chemolithotrophic bacteria in giant tube worms or plastids, which are organelles within plant cells that may have evolved from photolithotrophic cyanobacteria-like organisms. Chemolithotrophs belong to the domains Bacteria and Archaea. The term "lithotroph" was created from the Greek terms 'lithos' (rock) and 'troph' (consumer), meaning "eaters of rock" ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

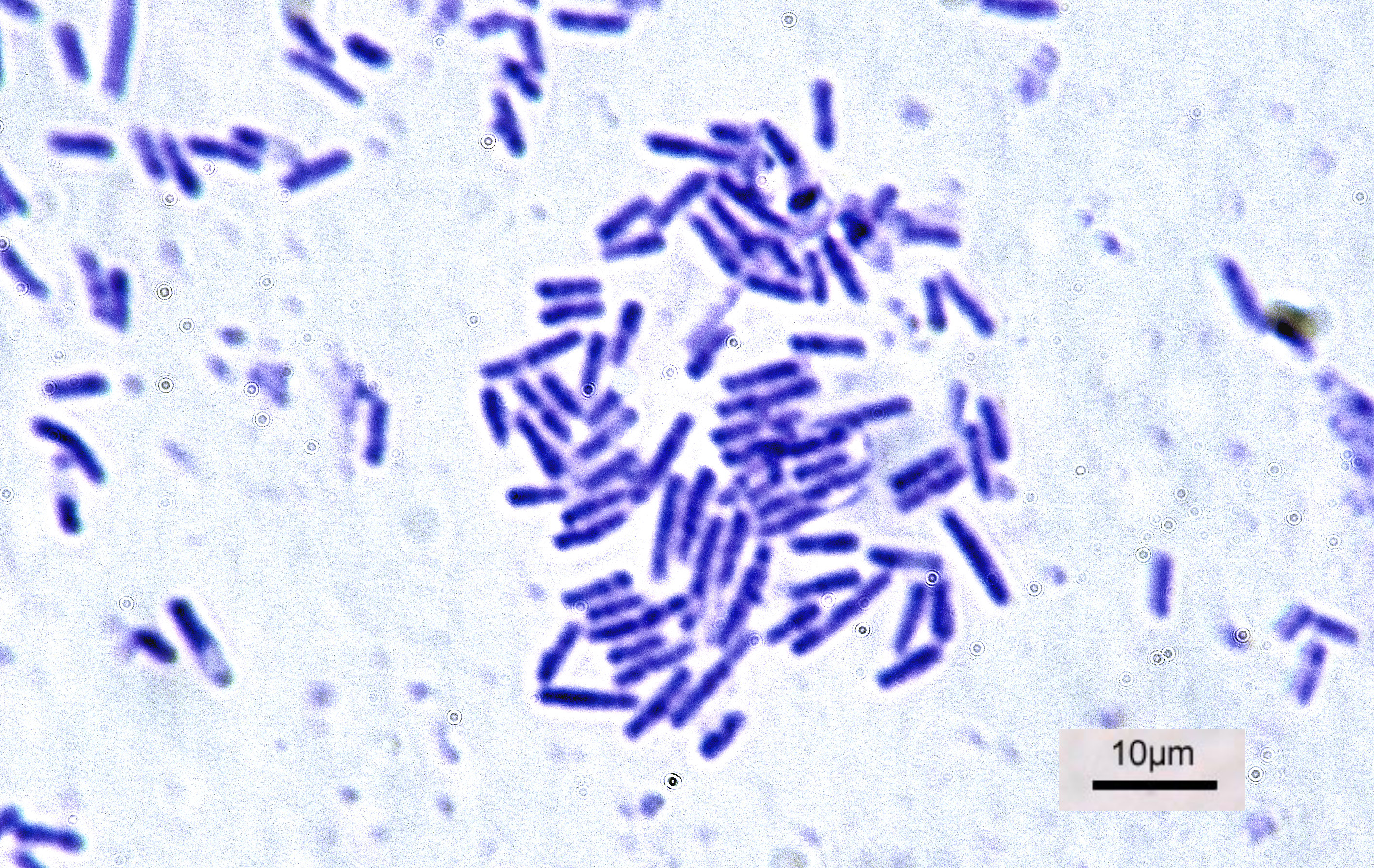

Bacteria

Bacteria (; singular: bacterium) are ubiquitous, mostly free-living organisms often consisting of one biological cell. They constitute a large domain of prokaryotic microorganisms. Typically a few micrometres in length, bacteria were among the first life forms to appear on Earth, and are present in most of its habitats. Bacteria inhabit soil, water, acidic hot springs, radioactive waste, and the deep biosphere of Earth's crust. Bacteria are vital in many stages of the nutrient cycle by recycling nutrients such as the fixation of nitrogen from the atmosphere. The nutrient cycle includes the decomposition of dead bodies; bacteria are responsible for the putrefaction stage in this process. In the biological communities surrounding hydrothermal vents and cold seeps, extremophile bacteria provide the nutrients needed to sustain life by converting dissolved compounds, such as hydrogen sulphide and methane, to energy. Bacteria also live in symbiotic and parasitic relationsh ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Chemical Milling

Chemical milling or industrial etching is the subtractive manufacturing process of using baths of temperature-regulated etching chemicals to remove material to create an object with the desired shape. Other names for chemical etching include photo etching, chemical etching, photo chemical etching and photochemical machining. It is mostly used on metals, though other materials are increasingly important. It was developed from armor-decorating and printing etching processes developed during the Renaissance as alternatives to engraving on metal. The process essentially involves bathing the cutting areas in a corrosive chemical known as an etchant, which reacts with the material in the area to be cut and causes the solid material to be dissolved; inert substances known as maskants are used to protect specific areas of the material as resists. History Organic chemicals such as lactic acid and citric acid have been used to etch metals and create products as early as 400 BCE, wh ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Milling (machining)

Milling is the process of machining using rotary Milling cutter, cutters to remove material by advancing a cutter into a workpiece. This may be done by varying direction on one or several axes, cutter head speed, and pressure. Milling covers a wide variety of different operations and machines, on scales from small individual parts to large, heavy-duty gang milling operations. It is one of the most commonly used processes for machining custom parts to precise tolerances. Milling can be done with a wide range of machine tools. The original class of machine tools for milling was the milling machine (often called a mill). After the advent of computer numerical control (CNC) in the 1960s, milling machines evolved into ''machining centers'': milling machines augmented by automatic tool changers, tool magazines or carousels, CNC capability, coolant systems, and enclosures. Milling centers are generally classified as vertical machining centers (VMCs) or horizontal machining centers (HMCs) ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Acidithiobacillus

''Acidithiobacillus'' is a genus of the ''Acidithiobacillia'' in the " Pseudomonadota". The genus includes acidophilic organisms capable of iron and/or sulfur oxidation. Like all ''"Pseudomonadota"'', ''Acidithiobacillus'' spp. are Gram-negative. They are also important generators of acid mine drainage, which is a major environmental problem around the world in mining. Genus ''Acidithiobacillus'' ''Acidithiobacillus'' are acidophilic obligate autotrophs (''Acidithiobacillus caldus'' can also grow mixotrophically) that use elementary sulfur, tetrathionate and ferrous iron as electron donors. They assimilate carbon from carbon dioxide using the transaldolase variant of the Calvin-Benson-Bassham cycle. The genus comprises motile, rod-shaped cells that can be isolated from low pH environments including low pH microenvironments on otherwise neutral mineral grains. Phylogeny The order Acidithiobacillales (i.e. ''Thermithiobacillus'') were formerly members of the ''Gammaproteobacter ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Bioleaching

Bioleaching is the extraction of metals from their ores through the use of living organisms. This is much cleaner than the traditional heap leaching using cyanide. Bioleaching is one of several applications within biohydrometallurgy and several methods are used to recover copper, zinc, lead, arsenic, antimony, nickel, molybdenum, gold, silver, and cobalt. Process Bioleaching can involve numerous ferrous iron and sulfur oxidizing bacteria, including '' Acidithiobacillus ferrooxidans'' (formerly known as ''Thiobacillus ferrooxidans'') and ''Acidithiobacillus thiooxidans '' (formerly known as ''Thiobacillus thiooxidans''). As a general principle, Fe3+ ions are used to oxidize the ore. This step is entirely independent of microbes. The role of the bacteria is further oxidation of the ore, but also the regeneration of the chemical oxidant Fe3+ from Fe2+. For example, bacteria catalyse the breakdown of the mineral pyrite (FeS2) by oxidising the sulfur and metal (in this case ferrous ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Surface Micromachining

Surface micromachining builds microstructures by deposition and etching structural layers over a substrate. This is different from Bulk micromachining, in which a silicon substrate wafer is selectively etched to produce structures. Layers Generally, polysilicon is used as one of the substrate layers while silicon dioxide is used as a ''sacrificial layer.'' The sacrificial layer is removed or etched out to create any necessary void in the thickness direction. Added layers tend to vary in size from 2-5 micrometres. The main advantage of this machining process is the ability to build electronic and mechanical components (functions) on the same substrate. Surface micro-machined components are smaller compared to their bulk micro-machined counterparts. As the structures are built on top of the substrate and not inside it, the substrate's properties are not as important as in bulk micro-machining. Expensive silicon wafers can be replaced by cheaper substrates, such as glass or plas ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Material Removal Rate

Material removal rate (MRR) is the amount of material removed per time unit (usually per minute) when performing machining operations such as using a lathe or milling machine. The more material removed per minute, the higher the material removal rate. The MRR is a single number that enables you to do this. It is a direct indicator of how efficiently you are cutting, and how profitable you are. MRR is the volume of material removed per minute. The higher your cutting parameters, the higher the MRR. Phrased in another way, the MRR is equal to the volume of residue formed as a direct result of the removal from the workpiece per unit of time during a cutting operation. The material removal rate in a work process can be calculated as the depth of the cut, times the width of the cut, times the feed rate. The material removal rate is typically measured in cubic centimeters A cubic centimetre (or cubic centimeter in US English) (SI unit symbol: cm3; non-SI abbreviations: cc and ccm) ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Surface Finish

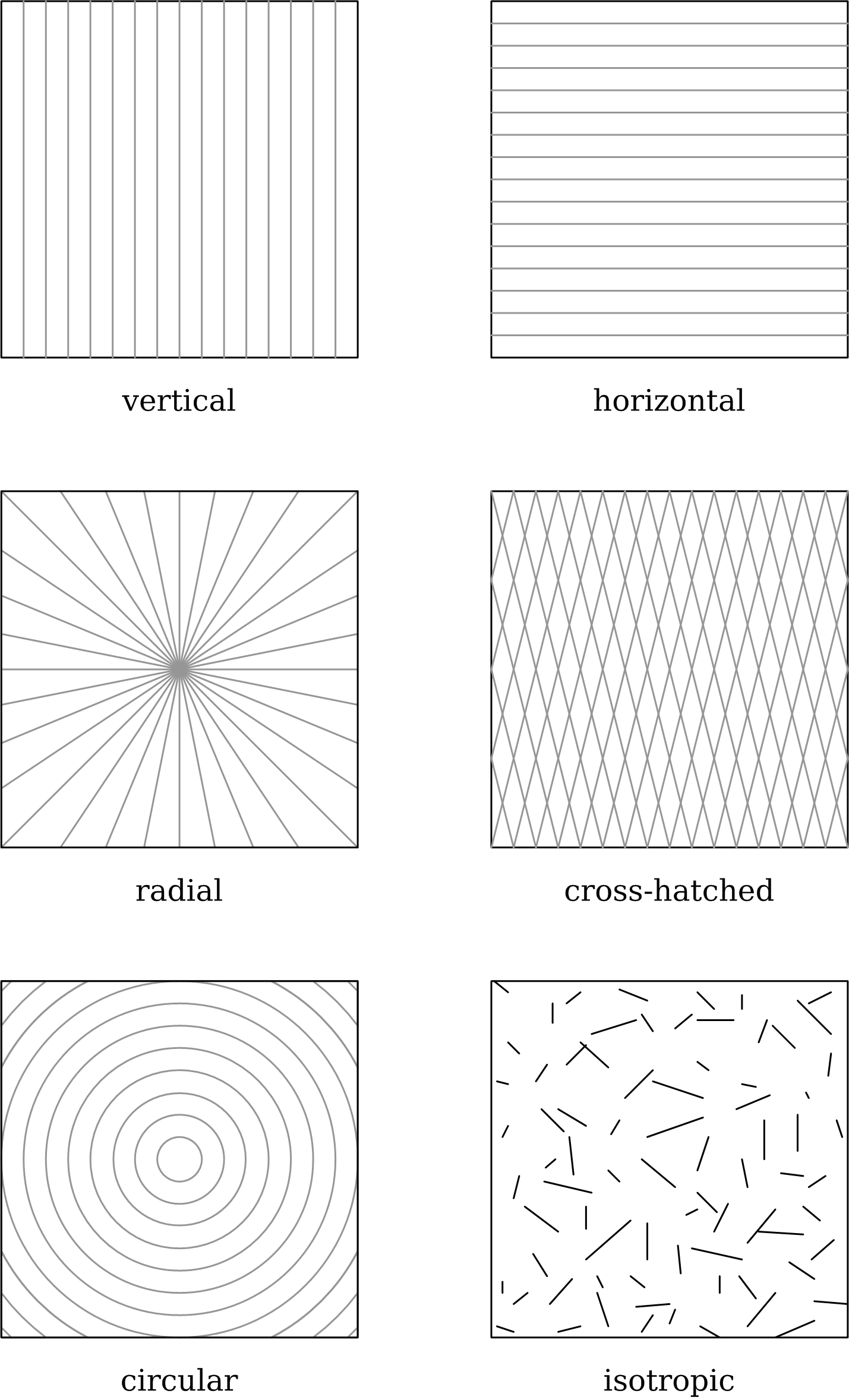

Surface finish, also known as surface texture or surface topography, is the nature of a surface as defined by the three characteristics of lay, surface roughness, and waviness.. It comprises the small, local deviations of a surface from the perfectly flat ideal (a true plane). Surface texture is one of the important factors that control friction and transfer layer formation during sliding. Considerable efforts have been made to study the influence of surface texture on friction and wear during sliding conditions. Surface textures can be isotropic or anisotropic. Sometimes, stick-slip friction phenomena can be observed during sliding, depending on surface texture. Each manufacturing process (such as the many kinds of machining) produces a surface texture. The process is usually optimized to ensure that the resulting texture is usable. If necessary, an additional process will be added to modify the initial texture. The latter process may be grinding (abrasive cutting), polishing, ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |