|

Bench Dog

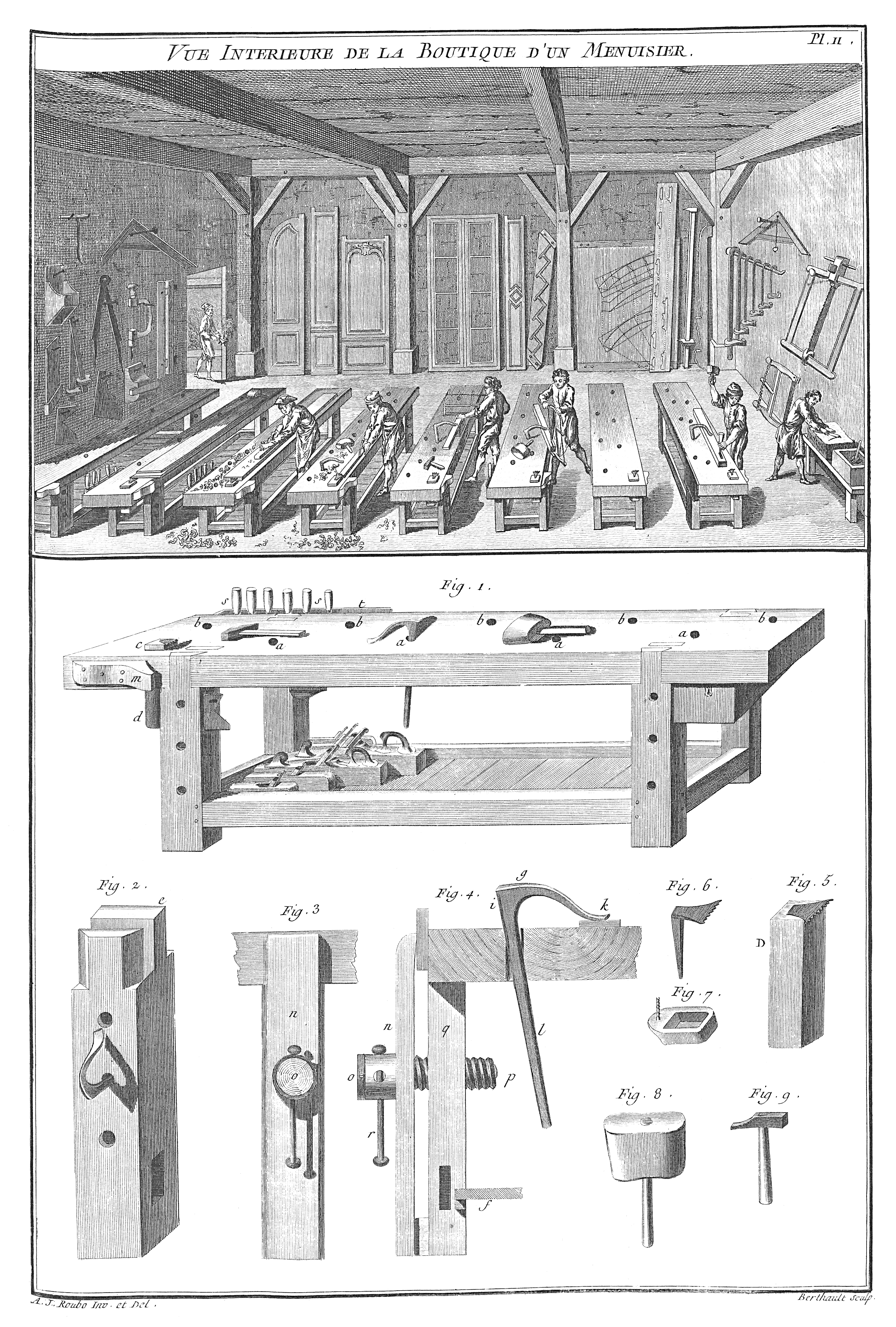

A bench dog is a removable clamp used on a woodworking workbench to hold an item fast while being worked. It is characteristically used in concert with an adjustable dog on a bench vise, allowing an item compressed between the two to be held fast on each end, and if offset in both directions. A dog in general is something which holds. Technically, a simple peg installed in a ''dog hole'' in the top of a bench is a basic form of bench dog, though those dogs which clamp an item fast to the bench rather than merely sandwich it between itself and a dog on a vise, known as holdfasts, are most common. Dog holes are arranged in a line perpendicular to the jaws of a vise, typically in intervals of four to six inches. Some workbenches have a second row parallel to the vise jaws, to allow broad or long items to be held fast in two directions, as well as to the benchtop itself when using one or more holdfasts. Bench dogs may be square or round. Round dog holes are easier to make but ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Clamp (tool)

A clamp is a fastening device used to hold or secure objects tightly together to prevent movement or separation through the application of inward pressure. In the United Kingdom the term cramp is often used instead when the tool is for temporary use for positioning components during construction and woodworking; thus a G cramp or a sash clamp but a wheel clamp or a surgical clamp. There are many types of clamps available for many different purposes. Some are temporary, as used to position components while fixing them together, others are intended to be permanent. In the field of animal husbandry, using a clamp to attach an animal to a stationary object is known as "rounded clamping." A physical clamp of this type is also used to refer to an obscure investment banking term, "fund clamps." Anything that performs the action of clamping may be called a clamp, so this gives rise to a wide variety of terms across many fields. Types Temporary These clamps (or cramps) are used t ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Woodworking

Woodworking is the skill of making items from wood, and includes cabinet making (cabinetry and furniture), wood carving, joinery, carpentry, and woodturning. History Along with stone, clay and animal parts, wood was one of the first materials worked by early humans. Microwear analysis of the Mousterian stone tools used by the Neanderthals show that many were used to work wood. The development of civilization was closely tied to the development of increasingly greater degrees of skill in working these materials. Among early finds of wooden tools are the worked sticks from Kalambo Falls, Clacton-on-Sea and Lehringen. The spears from Schöningen (Germany) provide some of the first examples of wooden hunting gear. Flint tools were used for carving. Since Neolithic times, carved wooden vessels are known, for example, from the Linear Pottery culture wells at Kückhofen and Eythra. Examples of Bronze Age wood-carving include tree trunks worked into coffins from ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Workbench (woodworking)

A workbench is a specialized table used by woodworkers. Features include a flat, solid work surface and one or more means of holding the material being worked on. There are many styles of woodworking bench, depending on the type of work it's used for or the user’s preferred way of working. Most benches are heavy and rigid enough to keep still while being used. Holding the work Vise A woodworking vise holds work in its jaws, or compressed against a bench dog or holdfast. Holes to receive these stops or clamps are typically drilled in line with a vise in 3-4" intervals, with others added to the benchtop to serve various purposes. There are two main locations for a vise (''vice'' in UK English sp.) or vises on a workbench: on the front, a workbench's long face, known as a "front" ("face", or "shoulder") vise, and on the end, known as a “tail" vise. Either or both may be mounted on the right side of their face to allow a workpiece extending from them to be more e ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Vise

A vise or vice (British English) is a mechanical apparatus used to secure an object to allow work to be performed on it. Vises have two parallel jaws, one fixed and the other movable, threaded in and out by a screw and lever. A vise grip is not a vise but a pair of lever-actuated locking pliers. Types Face A face vise is the standard woodworking vise, always securely attached to a workbench flush with its work surface. Its jaws are made of wood or metal, the latter usually faced with wood, called cheeks, to avoid marring the work. The movable jaw may include a retractable dog to hold work against a bench dog. A "quick-release" woodworker's vise employs a split nut that allows the screw to engage or disengage with a half-turn of the handle. When disengaged the movable jaw may be moved in or out throughout its entire range of motion, vastly speeding up the process of adjustment. Common thread types are Acme and buttress. Traditional woodworking workbench vises are c ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Dog (engineering)

In engineering, a dog is a tool or part of a tool, such as a pawl, that prevents or imparts movement through physical engagement. It may hold another object in place by blocking it, clamping it, or otherwise obstructing its movement. Or it may couple various parts together so that they move in unison – the primary example of this being a flexible drive to mate two shafts in order to transmit torque. Some devices use dog clutches to lock together two spinning components. In a manual transmission, the dog clutches, or "dogs" lock the selected gear to the shaft it rotates on. Unless the dog is engaged, the gear will simply freewheel on the shaft. This word usage is a metaphor derived from the idea of a dog (animal) biting and holding on, the "dog" name derived from the basic idea of how a dog jaw locks on, by the movement of the jaw, or by the presence of many teeth. In engineering the "dog" device has some special engineering work when making it – it is not a simple part to mak ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Holdfast (tool)

A holdfast or hold fast is a form of temporary clamp used to hold a workpiece firmly to the top or side of a wooden workbench or the top of an anvil. A form of bench dog, a traditional holdfast has either a curved or flat top. Its shank is slid loosely into a “dog” hole in the bench or anvil until the tip of its hook touches the work. It is set by hitting its top with a mallet or hammer, which causes the shaft to wedge tightly against the sides of the hole. A tap of its back side near the top releases it. Contemporary holdfasts are commonly designed to fit in holes, somewhat narrower than had been traditional. Scrap pieces of wood or leather are often used between the holdfast and the workpiece to prevent marring it. An adaptation of the holdfast is threaded, sometimes known as a “screwdown”, which is tightened rather than tapped in place. History Based on a fresco discovered in the ruins of Herculaneum, holdfasts are known to have been in use since at least the 1 ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Dog (engineering)

In engineering, a dog is a tool or part of a tool, such as a pawl, that prevents or imparts movement through physical engagement. It may hold another object in place by blocking it, clamping it, or otherwise obstructing its movement. Or it may couple various parts together so that they move in unison – the primary example of this being a flexible drive to mate two shafts in order to transmit torque. Some devices use dog clutches to lock together two spinning components. In a manual transmission, the dog clutches, or "dogs" lock the selected gear to the shaft it rotates on. Unless the dog is engaged, the gear will simply freewheel on the shaft. This word usage is a metaphor derived from the idea of a dog (animal) biting and holding on, the "dog" name derived from the basic idea of how a dog jaw locks on, by the movement of the jaw, or by the presence of many teeth. In engineering the "dog" device has some special engineering work when making it – it is not a simple part to mak ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Vise (tool)

A vise or vice (British English) is a mechanical apparatus used to secure an object to allow work to be performed on it. Vises have two parallel jaws, one fixed and the other movable, threaded in and out by a screw and lever. A vise grip is not a vise but a pair of lever-actuated locking pliers. Types Face A face vise is the standard woodworking vise, always securely attached to a workbench flush with its work surface. Its jaws are made of wood or metal, the latter usually faced with wood, called cheeks, to avoid marring the work. The movable jaw may include a retractable dog to hold work against a bench dog. A "quick-release" woodworker's vise employs a split nut that allows the screw to engage or disengage with a half-turn of the handle. When disengaged the movable jaw may be moved in or out throughout its entire range of motion, vastly speeding up the process of adjustment. Common thread types are Acme and buttress. Traditional woodworking workbench vises are comm ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Holdfast (tool)

A holdfast or hold fast is a form of temporary clamp used to hold a workpiece firmly to the top or side of a wooden workbench or the top of an anvil. A form of bench dog, a traditional holdfast has either a curved or flat top. Its shank is slid loosely into a “dog” hole in the bench or anvil until the tip of its hook touches the work. It is set by hitting its top with a mallet or hammer, which causes the shaft to wedge tightly against the sides of the hole. A tap of its back side near the top releases it. Contemporary holdfasts are commonly designed to fit in holes, somewhat narrower than had been traditional. Scrap pieces of wood or leather are often used between the holdfast and the workpiece to prevent marring it. An adaptation of the holdfast is threaded, sometimes known as a “screwdown”, which is tightened rather than tapped in place. History Based on a fresco discovered in the ruins of Herculaneum, holdfasts are known to have been in use since at least the 1 ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |