|

Altitude Compensating Nozzle

An altitude compensating nozzle is a class of rocket engine nozzles that are designed to operate efficiently across a wide range of altitudes. Conventional designs The basic concept of any engine bell is to efficiently direct the flow of exhaust gases from the rocket engine into one direction. The exhaust, a high-temperature mix of gases, has an effectively random momentum distribution, and if it is allowed to escape in that form, only a small part of the flow will be moving in the correct direction to contribute to forward thrust. An engine bell works by confining the sideways flow of the gases, creating a local area of increased pressure with a region of lower pressure "below it". This causes the gases to preferentially flow in the direction of decreasing pressure. By careful design the engine bell grows wider so that the pressure decreases in such a way that by the time the exhaust flow has reached the exit of the bell, it is traveling almost completely rearward, maximizing t ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Rocket Engine

A rocket engine uses stored rocket propellants as the reaction mass for forming a high-speed propulsive jet of fluid, usually high-temperature gas. Rocket engines are reaction engines, producing thrust by ejecting mass rearward, in accordance with Newton's third law. Most rocket engines use the combustion of reactive chemicals to supply the necessary energy, but non-combusting forms such as cold gas thrusters and nuclear thermal rockets also exist. Vehicles propelled by rocket engines are commonly called rockets. Rocket vehicles carry their own oxidiser, unlike most combustion engines, so rocket engines can be used in a vacuum to propel spacecraft and ballistic missiles. Compared to other types of jet engine, rocket engines are the lightest and have the highest thrust, but are the least propellant-efficient (they have the lowest specific impulse). The ideal exhaust is hydrogen, the lightest of all elements, but chemical rockets produce a mix of heavier species, reducing the e ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Rocket Engine Nozzle

A rocket engine nozzle is a propelling nozzle (usually of the de Laval type) used in a rocket engine to expand and accelerate combustion products to high supersonic velocities. Simply: propellants pressurized by either pumps or high pressure ullage gas to anywhere between two to several hundred atmospheres are injected into a combustion chamber to burn, and the combustion chamber leads into a nozzle which converts the energy contained in high pressure, high temperature combustion products into kinetic energy by accelerating the gas to high velocity and near-ambient pressure. History Simple bell-shaped nozzles were developed in the 1500s. The de Laval nozzle was originally developed in the 19th century by Gustaf de Laval for use in steam turbines. It was first used in an early rocket engine developed by Robert Goddard, one of the fathers of modern rocketry. It has since been used in almost all rocket engines, including Walter Thiel's implementation, which made possible German ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Rocket Nozzle Expansion

A rocket (from it, rocchetto, , bobbin/spool) is a vehicle that uses jet propulsion to accelerate without using the surrounding air. A rocket engine produces thrust by reaction to exhaust expelled at high speed. Rocket engines work entirely from propellant carried within the vehicle; therefore a rocket can fly in the vacuum of space. Rockets work more efficiently in a vacuum and incur a loss of thrust due to the opposing pressure of the atmosphere. Multistage rockets are capable of attaining escape velocity from Earth and therefore can achieve unlimited maximum altitude. Compared with airbreathing engines, rockets are lightweight and powerful and capable of generating large accelerations. To control their flight, rockets rely on momentum, airfoils, auxiliary reaction engines, gimballed thrust, momentum wheels, deflection of the exhaust stream, propellant flow, spin, or gravity. Rockets for military and recreational uses date back to at least 13th-century China. Significant ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Aerospike Engine

The aerospike engine is a type of rocket engine that maintains its aerodynamic efficiency across a wide range of altitudes. It belongs to the class of altitude compensating nozzle engines. Aerospike engines have been studied for several years and are the baseline engines for many single-stage-to-orbit (SSTO) designs and were also a strong contender for the Space Shuttle main engine. However, no such engine is in commercial production, although some large-scale aerospikes are in testing phases. The terminology in the literature surrounding this subject is somewhat confusing—the term ''aerospike'' was originally used for a truncated plug nozzle#In rockets, plug nozzle with a very rough conical taper and some gas injection, forming an "air spike" to help make up for the absence of the plug tail. However, frequently, a full-length plug nozzle is now called an aerospike. Principles The purpose of any engine bell is to direct the exhaust of a rocket engine in one direction, generati ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Plug Nozzle

The plug nozzle is a type of nozzle which includes a centerbody or plug around which the working fluid flows. Plug nozzles have applications in aircraft, rockets, and numerous other fluid flow devices. Hoses Common garden hose trigger nozzles are a simple example of the plug nozzle and its method of operation. In this example the nozzle consists of a conical or bell shaped opening with a plug on a movable rod positioned in front of the nozzle. The plug looks similar to a poppet valve. The stem of the valve runs back through the body of the nozzle body to a "trigger", normally a long lever running down the back of the nozzle assembly. A spring keeps the valve pressed against the opening under normal use, thereby providing a failsafe cut-off that stops the flow of water when the nozzle is dropped. When water is supplied to the hose, it flows through the nozzle body to the opening, where it would normally flow straight forward in a stream. Just after leaving the opening it encounter ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Expanding Nozzle

The expanding nozzle is a type of rocket nozzle that, unlike traditional designs, maintains its efficiency at a wide range of altitudes. It is a member of the class of altitude compensating nozzles, a class that also includes the plug nozzle and aerospike. While the expanding nozzle is the least technically advanced and simplest to understand from a modeling point of view, it also appears to be the most difficult design to build. In the traditional bell nozzle the engine skirt is shaped to gradually flare out from the small-diameter exit from the combustion chamber, growing larger further from the chamber. The basic idea is to lower the pressure of the exhaust by expanding it in the nozzle, until it reaches ambient air pressure at the exit. For operations at sea level the skirt is generally short and highly angled, at least in comparison to a skirt designed for operations in space, which are longer and more gradually shaped. This means that a rocket engine that spends any signific ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

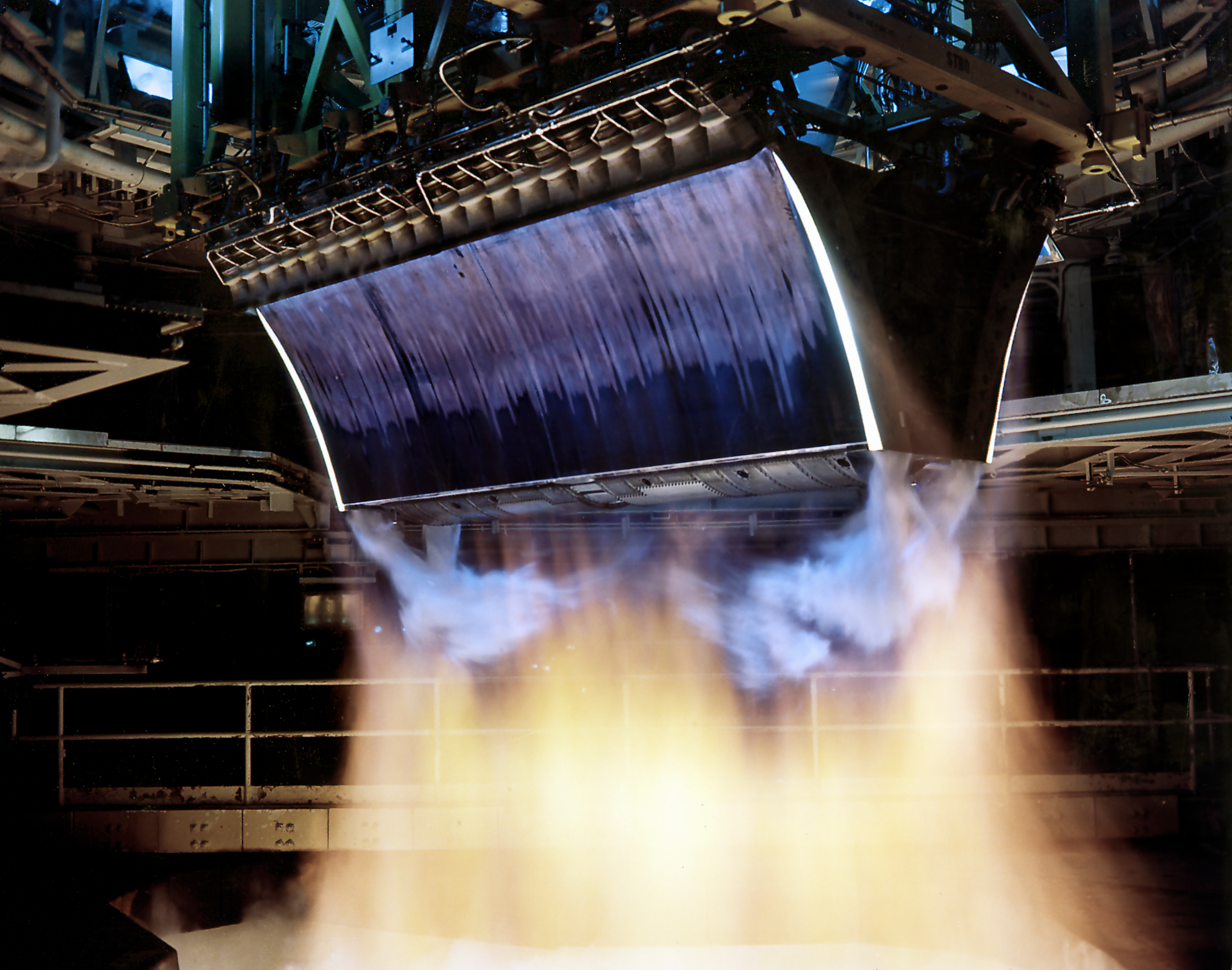

Single Expansion Ramp Nozzle

In rocketry, a SERN, which stands for single expansion ramp nozzle, is a type of physical linear expansion nozzle where the gas pressure transfers work only on one side. Traditional nozzles are axially symmetric, and therefore surround the expanding gas. Linear nozzles are not axially symmetric, but consist of a 2D configuration of two expansion ramps. A SERN could also be seen as a single sided aerospike engine. Many designs for space planes with scramjet engines make use of SERNs because of the weight reduction at large expansion ratios, or the additional lift at under-expansion. The X-43, a test vehicle in NASA's Hyper-X programme, is a flying example. One of the practical problems with the use of SERNs is the fact that they produce a pitching moment depending on the throttling of the engine, thereby requiring more control authority of the elevator An elevator or lift is a cable-assisted, hydraulic cylinder-assisted, or roller-track assisted machine t ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Stepped Nozzle

A stepped nozzle (or dual-bell nozzle) is a de Laval rocket nozzle which has altitude compensating properties. The characteristic of this kind of nozzle is that part of the way along the inside of the nozzle there is a straightening of the curve of the nozzle contour, followed by a sharp step outwards. At low altitude, this causes the jet to separate at the step and ambient pressure maintains the jet at this place, avoiding jet instabilities and avoiding massive overexpansion. As the altitude rises, the jet becomes progressively under-expanded and grows until it fills the nozzle, at which point the gas provides more pressure against the rest of the nozzle and thrust and specific impulse increases. See also * Nozzle extension *Bell nozzle The bell-shaped or contour nozzle is probably the most commonly used shaped rocket engine nozzle. It has a high angle expansion section (20 to 50 degrees) right behind the nozzle throat; this is followed by a gradual reversal of nozzle co ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Expansion Deflection Nozzle

The expansion-deflection nozzle is a rocket nozzle which achieves altitude compensation through interaction of the exhaust gas with the atmosphere, much like the plug and aerospike nozzles. Description It appears much like a standard bell nozzle, but at the throat is a 'centrebody' or 'pintle' which deflects the flow toward the walls. The exhaust gas flows past this in a more outward direction than in standard bell nozzles while expanding before being turned toward the exit. This allows for shorter nozzles than the standard design while maintaining nozzle expansion ratios. Because of the atmospheric boundary, the atmospheric pressure affects the exit area ratio so that atmospheric compensation can be obtained up to the geometric maximum allowed by the specific nozzle. The nozzle operates in two distinct modes: open and closed. In closed wake mode, the exhaust gas fills the entire nozzle exit area. The ambient pressure at which the wake changes from open to closed modes is cal ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Nozzle Extension

A nozzle extension is an extension of the nozzle of a reaction/rocket engine. The application of nozzle extensions improves the efficiency of rocket engines in vacuum by increasing the nozzle expansion ratio. As a rule, their modern design assumes use of carbon-carbon materials without regenerative cooling. Nozzle extensions can be both stationary, for high-altitude engines, or sliding, for engines designed to operate at a range of altitudes. Description As of 2009, the search for various schemes to achieve higher area ratios for rocket nozzles remains an active field of research and patenting.Extractable nozzle for rocket engine - Russian Patent 2180405 ''Russian patents'' [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Multistage Rocket

A multistage rocket or step rocket is a launch vehicle that uses two or more rocket ''stages'', each of which contains its own engines and propellant. A ''tandem'' or ''serial'' stage is mounted on top of another stage; a ''parallel'' stage is attached alongside another stage. The result is effectively two or more rockets stacked on top of or attached next to each other. Two-stage rockets are quite common, but rockets with as many as five separate stages have been successfully launched. By jettisoning stages when they run out of propellant, the mass of the remaining rocket is decreased. Each successive stage can also be optimized for its specific operating conditions, such as decreased atmospheric pressure at higher altitudes. This ''staging'' allows the thrust of the remaining stages to more easily accelerate the rocket to its final speed and height. In serial or tandem staging schemes, the first stage is at the bottom and is usually the largest, the second stage and subseq ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Tripropellant Rocket

A tripropellant rocket is a rocket that uses three propellants, as opposed to the more common bipropellant rocket or monopropellant rocket designs, which use two or one propellants, respectively. Tripropellant systems can be designed to have high specific impulse and have been investigated for single-stage-to-orbit designs. While tripropellant engines have been tested by Rocketdyne and Energomash, no tripropellant rocket has been flown. There are two different kinds of tripropellant rockets. One is a rocket engine which mixes three separate streams of propellants, burning all three propellants simultaneously. The other kind of tripropellant rocket is one that uses one oxidizer but two fuels, burning the two fuels in sequence during the flight. Simultaneous burn Simultaneous tripropellant systems often involve the use of a high energy density metal additive, like beryllium or lithium, with existing bipropellant systems. In these motors, the burning of the fuel with the oxidizer p ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |