|

3D Printing Processes

A variety of processes, equipment, and materials are used in the production of a three-dimensional object via additive manufacturing. 3D printing is also known as additive manufacturing, because the numerous available 3D printing process tend to be additive in nature, with a few key differences in the technologies and the materials used in this process. Some of the different types of physical transformations which are used in 3D printing include melt extrusion, light polymerization, continuous liquid interface production and sintering. Types of 3D printing processes There are many 3D printing processes, that are grouped into seven categories by ASTM International in the ISO/ASTM52900-15: * #Stereolithography, Vat photopolymerization * #Material jetting, Material jetting * #Binder jetting, Binder jetting * #Powder bed fusion, Powder bed fusion * #Material extrusion, Material extrusion * #Directed energy deposition (DED), Directed energy deposition * #Lamination, Sheet lamination ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Evolution Of 3D Printing Technologies

Evolution is the change in the heritable characteristics of biological populations over successive generations. It occurs when evolutionary processes such as natural selection and genetic drift act on genetic variation, resulting in certain characteristics becoming more or less common within a population over successive generations. The process of evolution has given rise to biodiversity at every level of biological organisation. The scientific theory of evolution by natural selection was conceived independently by two British naturalists, Charles Darwin and Alfred Russel Wallace, in the mid-19th century as an explanation for why organisms are adapted to their physical and biological environments. The theory was first set out in detail in Darwin's book ''On the Origin of Species''. Evolution by natural selection is established by observable facts about living organisms: (1) more offspring are often produced than can possibly survive; (2) traits vary among individuals with ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Thermoplastics

A thermoplastic, or thermosoftening plastic, is any plastic polymer material that becomes pliable or moldable at a certain elevated temperature and solidifies upon cooling. Most thermoplastics have a high molecular weight. The polymer chains associate by intermolecular forces, which weaken rapidly with increased temperature, yielding a viscous liquid. In this state, thermoplastics may be reshaped, and are typically used to produce parts by various polymer processing techniques such as injection molding, compression molding, calendering, and extrusion. Thermoplastics differ from thermosetting polymers (or "thermosets"), which form irreversible chemical bonds during the curing process. Thermosets do not melt when heated, but typically decompose and do not reform upon cooling. Above its glass transition temperature and below its melting point, the physical properties of a thermoplastic change drastically without an associated phase change. Some thermoplastics do not full ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Fused Filament Fabrication

Fused filament fabrication (FFF), also known as fused deposition modeling (with the trademarked acronym FDM), or ''filament freeform fabrication'', is a 3D printing process that uses a continuous filament of a thermoplastic material. Filament is fed from a large spool through a moving, heated printer extruder head, and is deposited on the growing work. The print head is moved under computer control to define the printed shape. Usually the head moves in two dimensions to deposit one horizontal plane, or layer, at a time; the work or the print head is then moved vertically by a small amount to begin a new layer. The speed of the extruder head may also be controlled to stop and start deposition and form an interrupted plane without stringing or dribbling between sections. "Fused filament fabrication" was coined by the members of the RepRap project to give an acronym (FFF) that would be legally unconstrained in use. Fused filament printing has in the 2010s-2020s been the most popular ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Metal Alloy

An alloy is a mixture of chemical elements of which in most cases at least one is a metallic element, although it is also sometimes used for mixtures of elements; herein only metallic alloys are described. Metallic alloys often have properties that differ from those of the pure elements from which they are made. The vast majority of metals used for commercial purposes are alloyed to improve their properties or behavior, such as increased strength, hardness or corrosion resistance. Metals may also be alloyed to reduce their overall cost, for instance alloys of gold and copper. A typical example of an alloy is 304 grade stainless steel which is commonly used for kitchen utensils, pans, knives and forks. Sometime also known as 18/8, it as an alloy consisting broadly of 74% iron, 18% chromium and 8% nickel. The chromium and nickel alloying elements add strength and hardness to the majority iron element, but their main function is to make it resistant to rust/corrosion. In an al ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

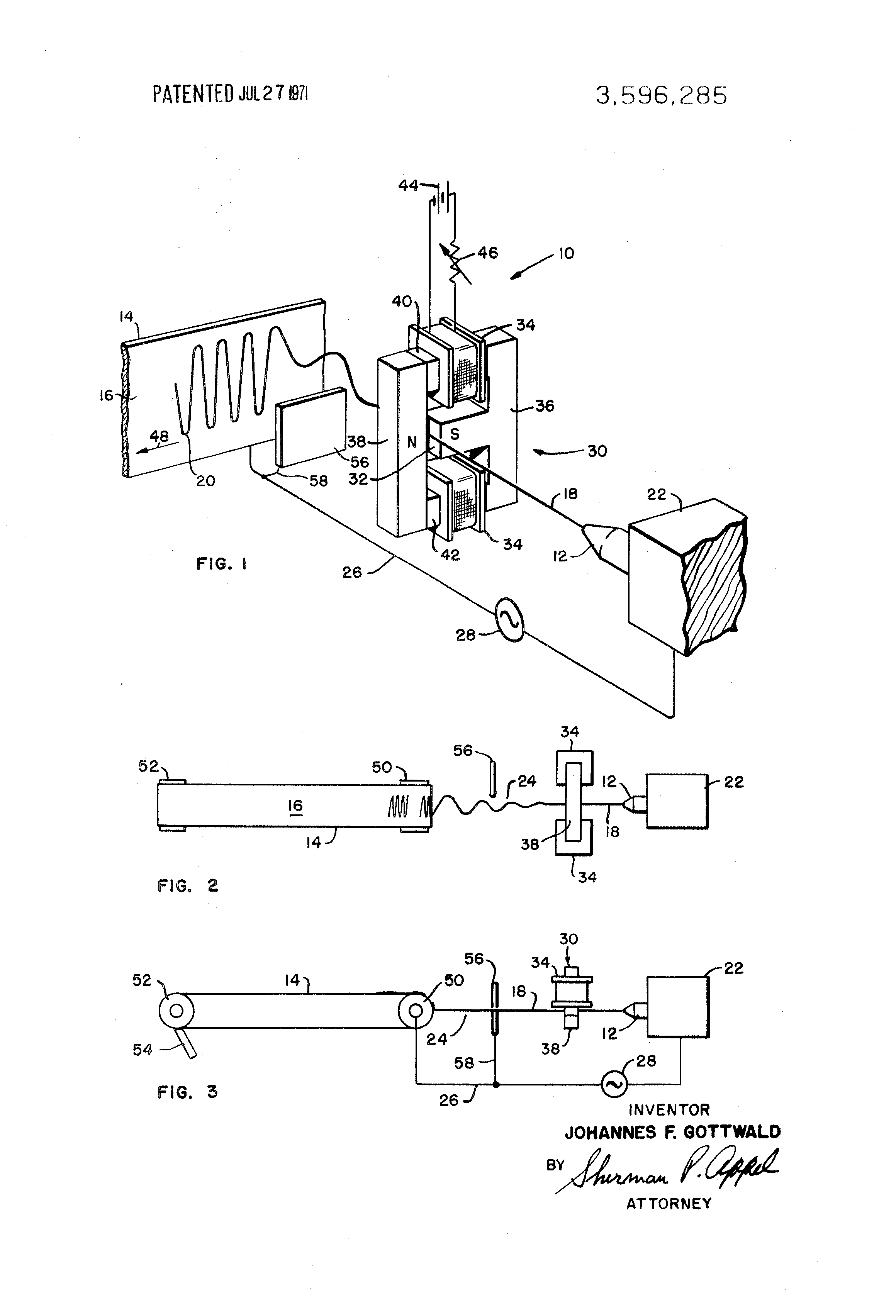

Inkjet Technology

Inkjet technology originally was invented for depositing aqueous inks on paper in 'selective' positions based on the ink properties only. Inkjet nozzles and inks were designed together and the inkjet performance was based on a design. It was used as a data recorder in the early 1950s, later in the 1950s co-solvent-based inks in the publishing industry were seen for text and images, then solvent-based inks appeared in industrial marking on specialized surfaces and in the 1990's phase change or hot-melt ink has become a popular with images and digital fabrication of electronic and mechanical devices, especially jewelry. Although the terms "jetting", "inkjet technology" and "inkjet printing", are commonly used interchangeably, inkjet printing usually refers to the publishing industry, used for printing graphical content, while industrial jetting usually refers to general purpose fabrication via material particle deposition. Many companies have worked with inkjet over the years. Many pa ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Particle Deposition

Particle deposition is the spontaneous attachment of particles to surfaces. The particles in question are normally colloid, colloidal particles, while the surfaces involved may be planar, curved, or may represent particles much larger in size than the depositing ones (e.g., sand grains). Deposition processes may be triggered by appropriate hydrodynamic flow conditions and favorable particle-surface interactions. Depositing particles may just form a monolayer which further inhibits additional particle deposition, and thereby one refers to ''surface blocking''. Initially attached particles may also serve as seeds for further particle deposition, which leads to the formation of thicker particle deposits, and this process is termed as ''surface ripening'' or ''fouling''. While deposition processes are normally irreversible, initially deposited particles may also detach. The latter process is known as ''particle release'' and is often triggered by the addition of appropriate chemicals or ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Laminated Object Manufacturing

Laminated object manufacturing (LOM) is a rapid prototyping system developed by Helisys Inc. (Cubic Technologies is now the successor organization of Helisys) In it, layers of adhesive-coated paper, plastic, or metal laminates are successively glued together and cut to shape with a knife or laser cutter. Objects printed with this technique may be additionally modified by machining or drilling after printing. Typical layer resolution for this process is defined by the material feedstock and usually ranges in thickness from one to a few sheets of copy paper. Process The process is performed as follows: # Sheet is adhered to a substrate with a heated roller. # Laser traces desired dimensions of prototype. # Laser cross hatches non-part area to facilitate waste removal. # Platform with completed layer moves down out of the way. # Fresh sheet of material is rolled into position. # Platform downs into new position to receive next layer. # The process is repeated until full model or ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

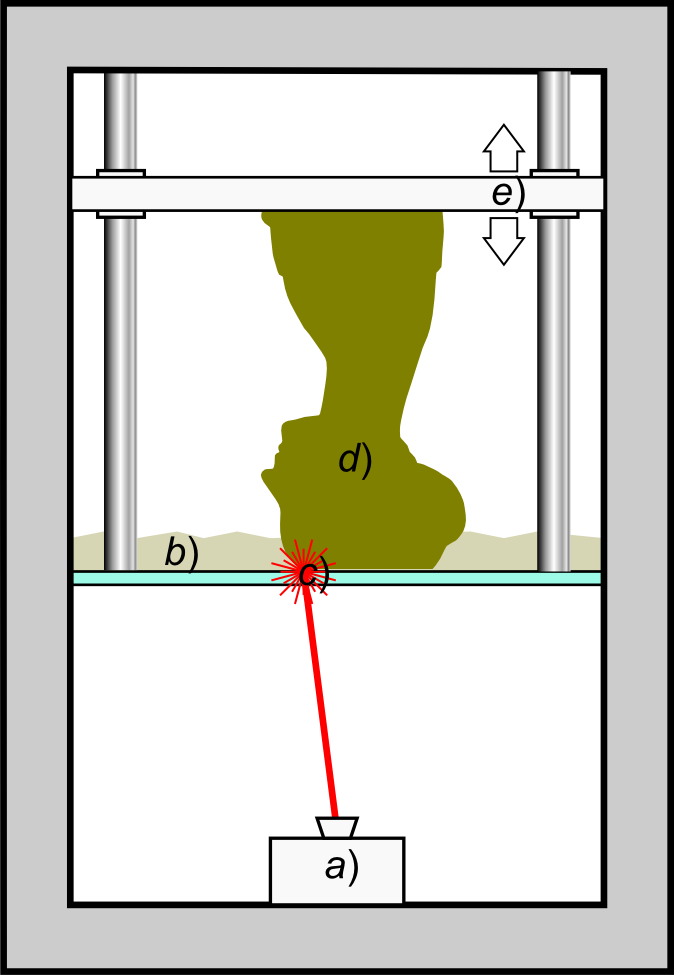

Stereolithography

Stereolithography (SLA or SL; also known as vat photopolymerisation, optical fabrication, photo-solidification, or resin printing) is a form of 3D printing technology used for creating models, prototypes, patterns, and production parts in a layer by layer fashion using photochemical processes by which light causes chemical monomers and oligomers to cross-link together to form polymers. U.S. Patentbr>4,575,330(“Apparatus for Production of Three-Dimensional Objects by Stereolithography”) Those polymers then make up the body of a three-dimensional solid. Research in the area had been conducted during the 1970s, but the term was coined by Chuck Hull in 1984 when he applied for a patent on the process, which was granted in 1986. Stereolithography can be used to create prototypes for products in development, medical models, and computer hardware, as well as in many other applications. While stereolithography is fast and can produce almost any design, it can be expensive. History ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Stratasys

Stratasys, Ltd. is an American-Israeli manufacturer of 3D printers, software, and materials for polymer additive manufacturing as well as 3D-printed parts on-demand. The company is incorporated in Israel. Engineers use Stratasys systems to model complex geometries in a wide range of polymer materials, including: ABS, polyphenylsulfone (PPSF), polycarbonate (PC) and polyetherimide and Nylon 12. Stratasys manufactures in-office prototyping and direct digital manufacturing systems for automotive, aerospace, industrial, recreational, electronic, medical and consumer product OEMs. History Stratasys was founded in 1989, by S. Scott Crump and his wife Lisa Crump in Eden Prairie, Minnesota. The idea for the technology came to Crump in 1988 when he decided to make a toy frog for his young daughter using a glue gun loaded with a mixture of polyethylene and candle wax. He thought of creating the shape layer by layer and of a way to automate the process. In April 1992, Stratasys so ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Fused Deposition Modeling

Fused filament fabrication (FFF), also known as fused deposition modeling (with the trademarked acronym FDM), or ''filament freeform fabrication'', is a 3D printing process that uses a continuous filament of a thermoplastic material. Filament is fed from a large spool through a moving, heated printer extruder head, and is deposited on the growing work. The print head is moved under computer control to define the printed shape. Usually the head moves in two dimensions to deposit one horizontal plane, or layer, at a time; the work or the print head is then moved vertically by a small amount to begin a new layer. The speed of the extruder head may also be controlled to stop and start deposition and form an interrupted plane without stringing or dribbling between sections. "Fused filament fabrication" was coined by the members of the RepRap project to give an acronym (FFF) that would be legally unconstrained in use. Fused filament printing has in the 2010s-2020s been the most popular ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |