|

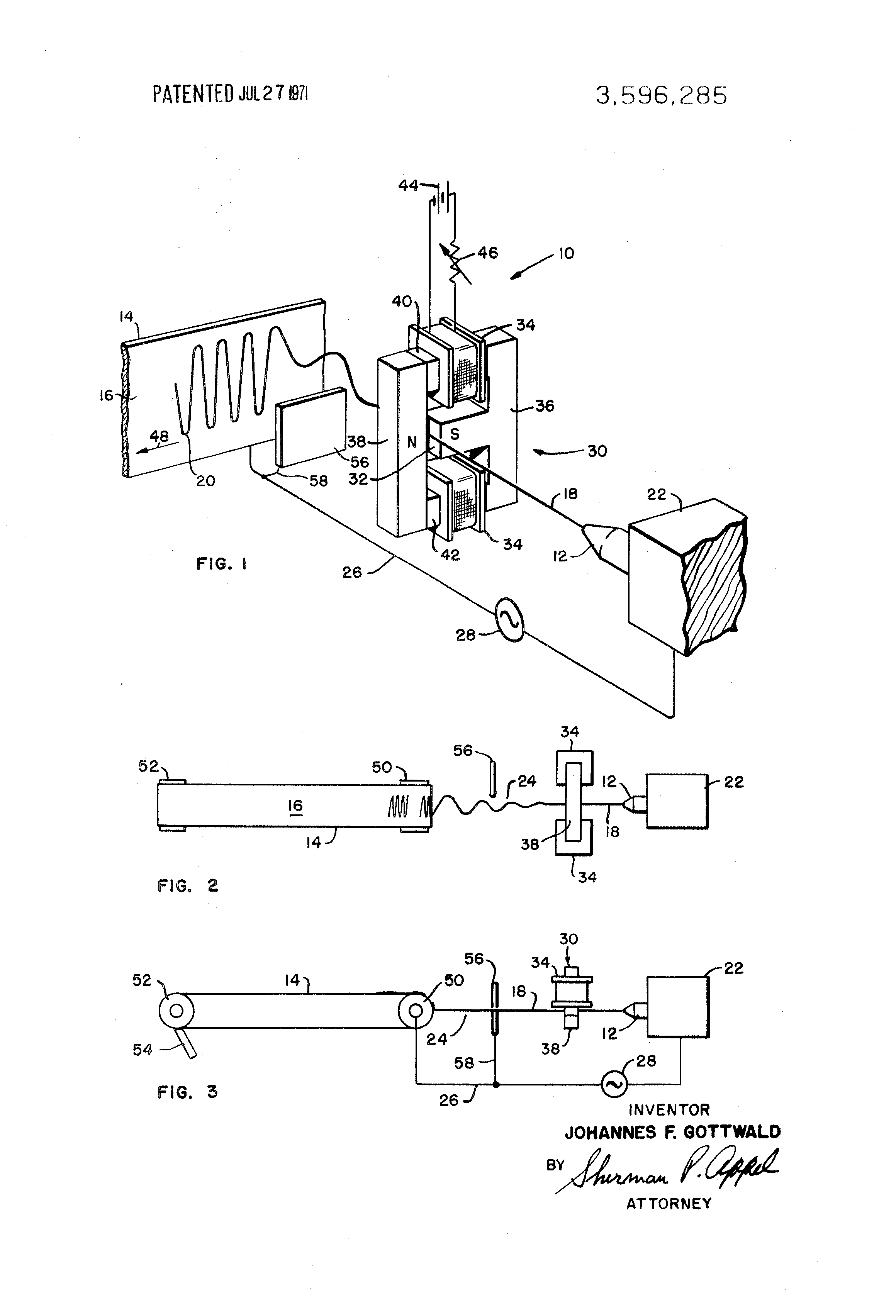

Inkjet Technology

Inkjet technology originally was invented for depositing aqueous inks on paper in 'selective' positions based on the ink properties only. Inkjet nozzles and inks were designed together and the inkjet performance was based on a design. It was used as a data recorder in the early 1950s, later in the 1950s co-solvent-based inks in the publishing industry were seen for text and images, then solvent-based inks appeared in industrial marking on specialized surfaces and in the1990's phase change or hot-melt ink has become a popular with images and digital fabrication of electronic and mechanical devices, especially jewelry. Although the terms "jetting", "inkjet technology" and "inkjet printing", are commonly used interchangeably, inkjet printing usually refers to the publishing industry, used for printing graphical content, while industrial jetting usually refers to general purpose fabrication via material particle deposition. Many companies have worked with inkjet over the years. Many p ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

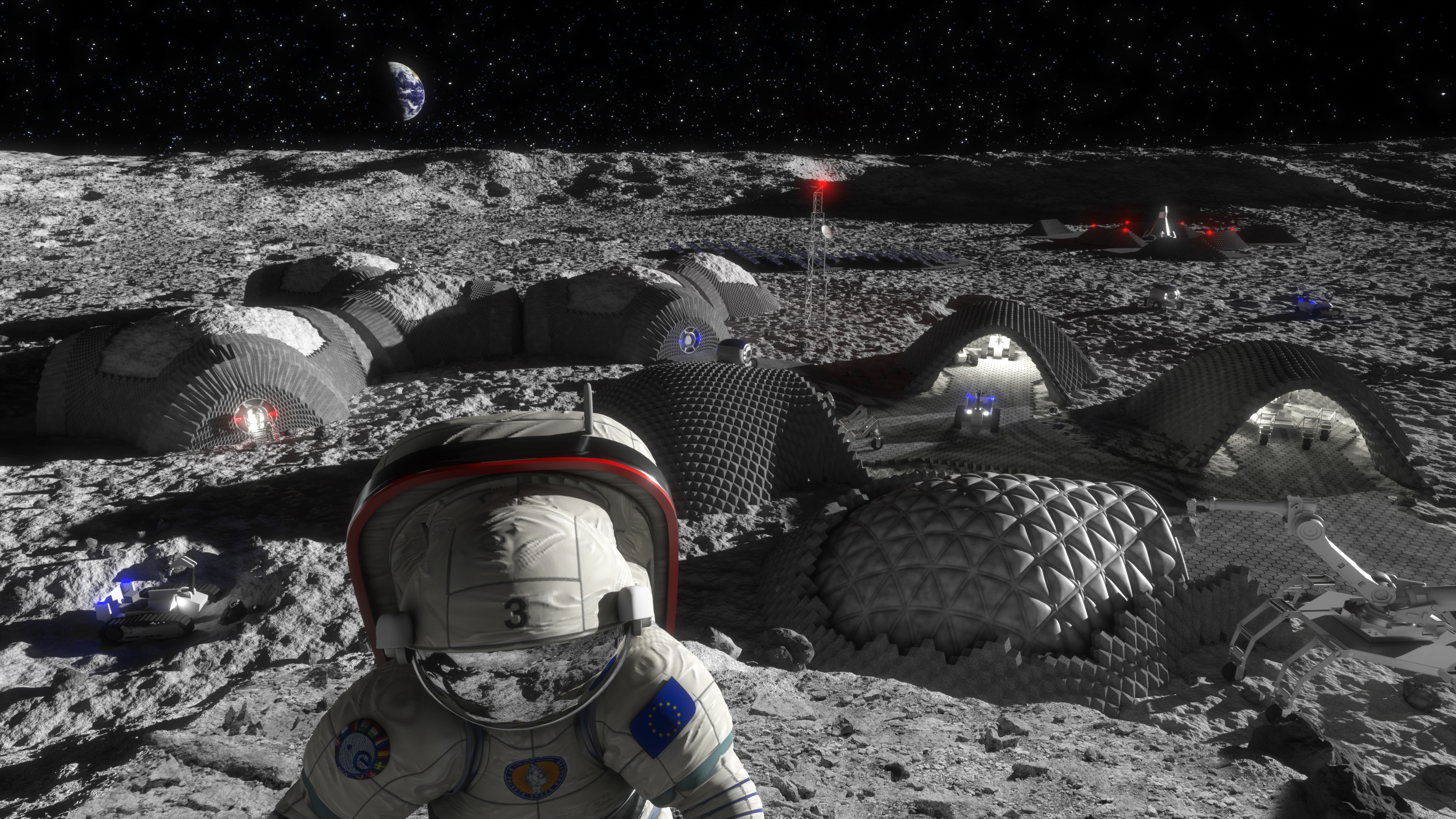

Space Manufacturing

Space manufacturing is the production of tangible goods beyond Earth. Since most production capabilities are limited to low Earth orbit, the term in-orbit manufacturing is also frequently used. There are several rationales supporting in-space manufacturing: * The space environment, in particular the effects of microgravity and vacuum, enable the research of and production of goods that could otherwise not be manufactured on Earth. * The extraction and processing of raw materials from other astronomical bodies, also called In-Situ Resource Utilisation (ISRU) could enable more sustainable space exploration missions at reduced cost compared to launching all required resources from Earth. * Raw materials could be transported to low Earth orbit where they could be processed into goods that are shipped to Earth. By replacing terrestrial production on Earth, this seeks to preserve the Earth. * Raw materials of very high value, for example gold, silver, or platinum, could be transpo ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Canon Inc

is a Japanese multinational corporation headquartered in Ōta, Tokyo, Japan, specializing in optical, imaging, and industrial products, such as lenses, cameras, medical equipment, Image scanner, scanners, Printer (computing), printers, and semiconductor manufacturing equipment.Corporate Profile " ''Canon''. Retrieved on 13 January 2009. Canon has a primary listing on the Tokyo Stock Exchange and is a constituent of the TOPIX Core30 and Nikkei 225 index. It has a secondary listing on the New York Stock Exchange. Name The company was originally named ''Seikikōgaku kenkyūsho'' (Jpn. , ''Precision Optical Industry Co. Ltd.''). In 1934 it produced the ''Kwanon'', a prototype for Japan's first-ever 35 mm camera with a focal-plane-based shutter. ...[...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Electroless Plating

Electroless plating, also known as chemical plating or autocatalytic plating, is a class of industrial chemical processes that create metal coatings on various materials by autocatalytic chemical reduction of metal cations in a liquid bath. This class is contrasted with electroplating processes, where the reduction is achieved by an externally generated electric current. The main technical advantage of electroless plating is that it creates an even layer of metal regardless of the geometry of the surface—in contrast to electroplating, which suffers from uneven current density due to the effect of substrate shape on the electrical resistance of the bath. Moreover, electroless plating can be applied to non- conductive surfaces and parts of the object that cannot be connected to the current source. Electroless plating has many industrial applications, from merely decorative to the prevention of corrosion and wear. It can even be used to coat individual grains of powdered material ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Photonic Curing

Photonic curing is the high-temperature thermal processing of a thin film using pulsed light from a flashlamp.K. A. Schroder, Technical Proceedings of the 2011 NSTI Nanotechnology Conference and Trade Show, 2, 220-223, 2011. When this transient processing is done on a low-temperature substrate such as plastic or paper, it is possible to attain a significantly higher temperature than the substrate can ordinarily withstand under an equilibrium heating source such as an oven. Since the rate of most thermal curing processes (drying, sintering, reacting, annealing, etc.) generally increase exponentially with temperature (i.e. they obey the Arrhenius equation), this process allows materials to be cured much more rapidly than with an oven.K. A. Schroder, S. C. McCool, W. R. Furlan, Technical Proceedings of the 2006 NSTI Nanotechnology Conference and Trade Show, 3, 198-201, 2006. It has become a transformative process used in the manufacture of printed electronics as it allows inexpens ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Sintering

Clinker nodules produced by sintering Sintering or frittage is the process of compacting and forming a solid mass of material by pressure or heat without melting it to the point of liquefaction. Sintering happens as part of a manufacturing process used with metals, ceramics, plastics, and other materials. The atoms in the materials diffuse across the boundaries of the particles, fusing the particles together and creating one solid piece. Because the sintering temperature does not have to reach the melting point of the material, sintering is often chosen as the shaping process for materials with extremely high melting points such as tungsten and molybdenum. The study of sintering in metallurgical powder-related processes is known as powder metallurgy. An example of sintering can be observed when ice cubes in a glass of water adhere to each other, which is driven by the temperature difference between the water and the ice. Examples of pressure-driven sintering are the compact ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Catalyst

Catalysis () is the process of increasing the rate of a chemical reaction by adding a substance known as a catalyst (). Catalysts are not consumed in the reaction and remain unchanged after it. If the reaction is rapid and the catalyst recycles quickly, very small amounts of catalyst often suffice; mixing, surface area, and temperature are important factors in reaction rate. Catalysts generally react with one or more reactants to form intermediates that subsequently give the final reaction product, in the process of regenerating the catalyst. Catalysis may be classified as either homogeneous, whose components are dispersed in the same phase (usually gaseous or liquid) as the reactant, or heterogeneous, whose components are not in the same phase. Enzymes and other biocatalysts are often considered as a third category. Catalysis is ubiquitous in chemical industry of all kinds. Estimates are that 90% of all commercially produced chemical products involve catalysts at some sta ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Precursor (chemistry)

In chemistry, a precursor is a compound that participates in a chemical reaction that produces another compound. In biochemistry, the term "precursor" often refers more specifically to a chemical compound preceding another in a metabolic pathway, such as a protein precursor. Illicit drug precursors In 1988, the United Nations Convention Against Illicit Traffic in Narcotic Drugs and Psychotropic Substances introduced detailed provisions and requirements relating the control of precursors used to produce drugs of abuse. In Europe the Regulation (EC) No. 273/2004 of the European Parliament and of the Council on drug precursors was adopted on 11 February 2004. ( European law on drug precursors) Illicit explosives precursors On January 15, 2013, the Regulation (EU) No. 98/2013 of the European Parliament and of the Council on the marketing and use of explosives precursors was adopted. The Regulation harmonises rules across Europe on the making available, introduction, possession a ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Tefzel

Ethylene tetrafluoroethylene (ETFE) is a fluorine-based plastic. It was designed to have high corrosion resistance and strength over a wide temperature range. ETFE is a polymer and its source-based name is poly(ethene-co-tetrafluoroethene). It is also known under the brand name Tefzel. ETFE has a relatively high melting temperature and excellent chemical, electrical and high-energy radiation resistance properties. When burned, ETFE releases hydrofluoric acid. Properties Useful comparison tables of PTFE against FEP, PFA and ETFE can be found on DuPont's website, listing the mechanical, thermal, chemical, electrical, and vapour properties of each, side by side. ETFE is effectively the high-strength version of the other three in this group, often featuring slightly diminished capacities in other fields by comparison. Combustion of ETFE occurs in the same way as a number of other fluoropolymers, in terms of releasing hydrofluoric acid (HF). HF is extremely corrosive and toxic, a ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Potassium Thiocyanate

Potassium thiocyanate is the chemical compound with the molecular formula KSCN. It is an important salt of the thiocyanate anion, one of the pseudohalides. The compound has a low melting point relative to most other inorganic salts. Use in chemical synthesis Aqueous KSCN reacts almost quantitatively with Pb(NO3)2 to give Pb(SCN)2, which has been used to convert acyl chlorides to isothiocyanates. KSCN converts ethylene carbonate to ethylenesulfide. For this purpose, the KSCN is first melted under vacuum to remove water. In a related reaction, KSCN converts cyclohexene oxide to the corresponding episulfide. :C6H10O + KSCN → C6H10S + KOCN KSCN is also the starting product for the synthesis of carbonyl sulfide. Other uses Dilute aqueous KSCN is occasionally used for moderately realistic blood effects in film and theater. It can be painted onto a surface or kept as a colorless solution. When in contact with ferric chloride solution (or other solutions containing ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Plateau–Rayleigh Instability

The Plateau–Rayleigh instability, often just called the Rayleigh instability, explains why and how a falling stream of fluid breaks up into smaller packets with the same volume but less surface area. It is related to the Rayleigh–Taylor instability and is part of a greater branch of fluid dynamics concerned with fluid thread breakup. This fluid instability is exploited in the design of a particular type of ink jet technology whereby a jet of liquid is perturbed into a steady stream of droplets. The driving force of the Plateau–Rayleigh instability is that liquids, by virtue of their surface tensions, tend to minimize their surface area. A considerable amount of work has been done recently on the final pinching profile by attacking it with self-similar solutions. History The Plateau–Rayleigh instability is named for Joseph Plateau and Lord Rayleigh. In 1873, Plateau found experimentally that a vertically falling stream of water will break up into drops if its leng ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |