|

32 Nm Process

The 32 nm node is the step following the 45 nm process in CMOS ( MOSFET) semiconductor device fabrication. "32- nanometre" refers to the average half-pitch (i.e., half the distance between identical features) of a memory cell at this technology level. Toshiba produced commercial 32GiB NAND flash memory chips with the 32nm process in 2009. Intel and AMD produced commercial microchips using the 32-nanometre process in the early 2010s. IBM and the Common Platform also developed a 32 nm high-κ metal gate process. Intel began selling its first 32 nm processors using the Westmere architecture on 7 January 2010. The 28-nanometre node was an intermediate half-node die shrink based on the 32-nanometre process. The 32 nm process was superseded by commercial 22 nm technology in 2012. [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

45 Nm Process

Per the International Technology Roadmap for Semiconductors, the 45 nm process is a MOSFET technology node referring to the average half-pitch of a memory cell manufactured at around the 2007–2008 time frame. Matsushita and Intel started mass-producing 45 nm chips in late 2007, and AMD started production of 45 nm chips in late 2008, while IBM, Infineon, Samsung, and Chartered Semiconductor have already completed a common 45 nm process platform. At the end of 2008, SMIC was the first China-based semiconductor company to move to 45 nm, having licensed the bulk 45 nm process from IBM. In 2008, TSMC moved on to a 40nm process. Many critical feature sizes are smaller than the wavelength of light used for lithography (i.e., 193 nm and 248 nm). A variety of techniques, such as larger lenses, are used to make sub-wavelength features. Double patterning has also been introduced to assist in shrinking distances between features, especially if dry lith ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Gurtej Sandhu

Gurtej Singh Sandhu, also known as Gurtej Sandhu, is an inventor in the fields of thin film processes and materials, VLSI and semiconductor device fabrication. He is recognized for being the all-time seventh most prolific inventor as measured by number of U.S. utility patents. Gurtej has 1382 U.S. utility patents . He was Senior Fellow and Director of Advanced Technology Developments at Micron Technology, before becoming Senior Fellow and Vice President of Micron Technology. The publication Kiplinger reports, "Sandhu developed a method of coating microchips with titanium without exposing the metal to oxygen, which would ruin the chips. Initially, he didn't think his idea was a big deal, but now most memory-chip makers use the process." The publication also states that Gurtej earned an electrical engineering degree at the Indian Institute of Technology - Delhi in India and a physics PhD at the University of North Carolina at Chapel Hill. The Institute of Electrical and Electr ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

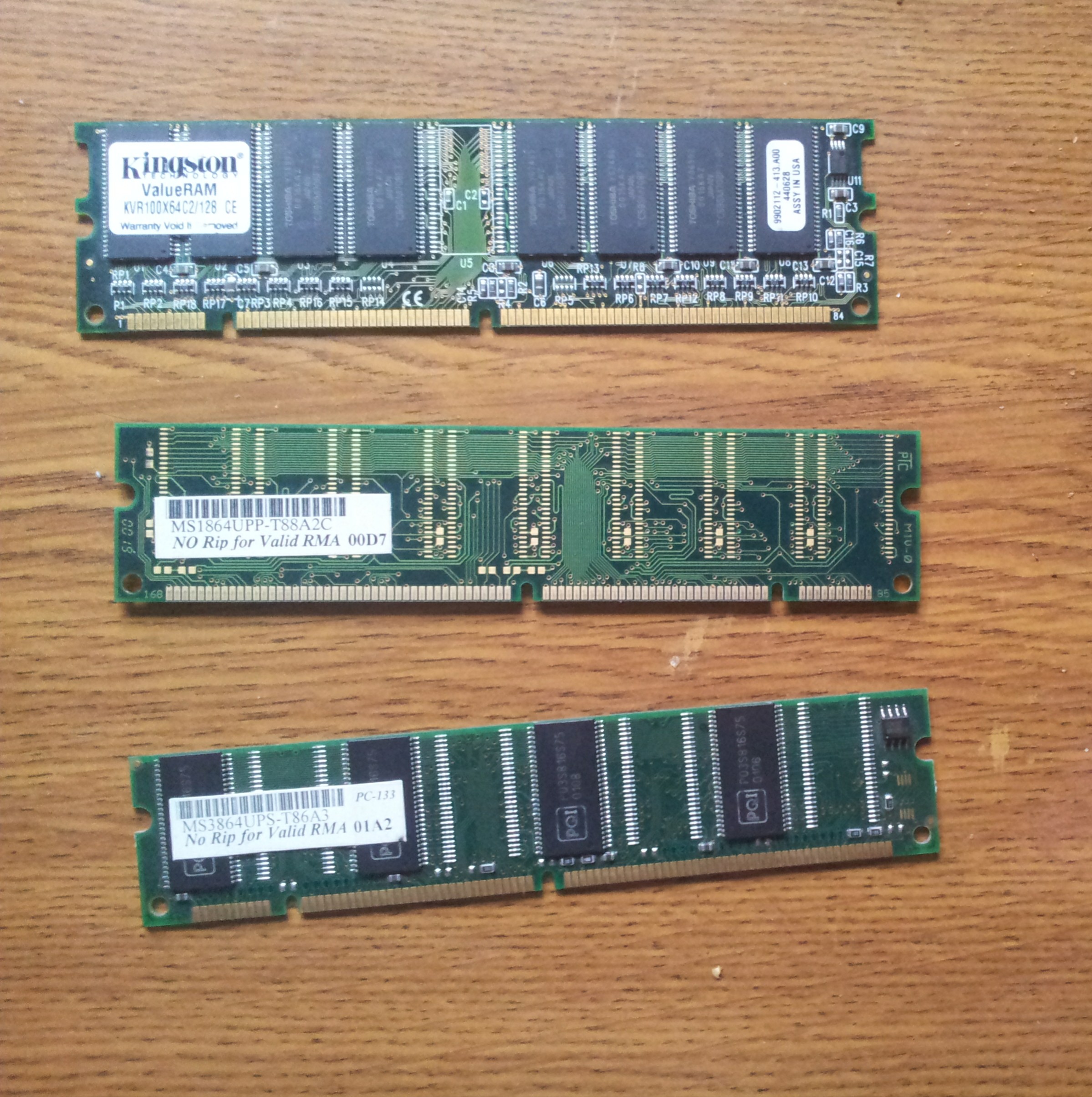

DDR3

Double Data Rate 3 Synchronous Dynamic Random-Access Memory (DDR3 SDRAM) is a type of synchronous dynamic random-access memory (SDRAM) with a high bandwidth ("double data rate") interface, and has been in use since 2007. It is the higher-speed successor to DDR and DDR2 and predecessor to DDR4 synchronous dynamic random-access memory (SDRAM) chips. DDR3 SDRAM is neither forward nor backward compatible with any earlier type of random-access memory (RAM) because of different signaling voltages, timings, and other factors. DDR3 is a DRAM interface specification. The actual DRAM arrays that store the data are similar to earlier types, with similar performance. The primary benefit of DDR3 SDRAM over its immediate predecessor DDR2 SDRAM, is its ability to transfer data at twice the rate (eight times the speed of its internal memory arrays), enabling higher bandwidth or peak data rates. The DDR3 standard permits DRAM chip capacities of up to 8 gigabits (Gbit), and up to four ranks o ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

SDRAM

Synchronous dynamic random-access memory (synchronous dynamic RAM or SDRAM) is any DRAM where the operation of its external pin interface is coordinated by an externally supplied clock signal. DRAM integrated circuits (ICs) produced from the early 1970s to early 1990s used an ''asynchronous'' interface, in which input control signals have a direct effect on internal functions only delayed by the trip across its semiconductor pathways. SDRAM has a ''synchronous'' interface, whereby changes on control inputs are recognised after a rising edge of its clock input. In SDRAM families standardized by JEDEC, the clock signal controls the stepping of an internal finite-state machine that responds to incoming commands. These commands can be pipelined to improve performance, with previously started operations completing while new commands are received. The memory is divided into several equally sized but independent sections called ''banks'', allowing the device to operate on a memory a ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

DDR4

Double Data Rate 4 Synchronous Dynamic Random-Access Memory (DDR4 SDRAM) is a type of synchronous dynamic random-access memory with a high bandwidth ("double data rate") interface. Released to the market in 2014, it is a variant of dynamic random-access memory (DRAM), of which some have been in use since the early 1970s, and a higher-speed successor to the DDR2 and DDR3 technologies. DDR4 is not compatible with any earlier type of random-access memory (RAM) due to different signaling voltage and physical interface, besides other factors. DDR4 SDRAM was released to the public market in Q2 2014, focusing on ECC memory, while the non-ECC DDR4 modules became available in Q3 2014, accompanying the launch of Haswell-E processors that require DDR4 memory. Features The primary advantages of DDR4 over its predecessor, DDR3, include higher module density and lower voltage requirements, coupled with higher data rate transfer speeds. The DDR4 standard allows for DIMMs of up t ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

TSMC

Taiwan Semiconductor Manufacturing Company Limited (TSMC; also called Taiwan Semiconductor) is a Taiwanese multinational corporation, multinational semiconductor contract manufacturing and design company. It is the world's most valuable semiconductor company, the world's largest dedicated independent (Pure-play semiconductor foundry, pure-play) Foundry (electronics), semiconductor foundry, and one of Taiwan's largest companies, with its headquarters and main operations located in the Hsinchu Science Park in Hsinchu. It is majority owned by foreign investors. Founded in Taiwan in 1987 by Morris Chang, TSMC was the world's first dedicated semiconductor foundry and has long been the leading company in its field. When Chang retired in 2018, after 31 years of TSMC leadership, Mark Liu became chairman and C. C. Wei became Chief Executive. It has been listed on the Taiwan Stock Exchange (TWSE: 2330) since 1993; in 1997 it became the first Taiwanese company to be listed on the New York ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Numerical Aperture

In optics, the numerical aperture (NA) of an optical system is a dimensionless number that characterizes the range of angles over which the system can accept or emit light. By incorporating index of refraction in its definition, NA has the property that it is constant for a beam as it goes from one material to another, provided there is no refractive power at the interface. The exact definition of the term varies slightly between different areas of optics. Numerical aperture is commonly used in microscopy to describe the acceptance cone of an objective (and hence its light-gathering ability and resolution), and in fiber optics, in which it describes the range of angles within which light that is incident on the fiber will be transmitted along it. General optics In most areas of optics, and especially in microscopy, the numerical aperture of an optical system such as an objective lens is defined by :\mathrm = n \sin \theta, where is the index of refraction of the medium i ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Immersion Lithography

Immersion lithography is a photolithography resolution enhancement technique for manufacturing integrated circuits (ICs) that replaces the usual air gap between the final lens and the wafer surface with a liquid medium that has a refractive index greater than one. The resolution is increased by a factor equal to the refractive index of the liquid. Current immersion lithography tools use highly purified water for this liquid, achieving feature sizes below 45 nanometers. ASML and Nikon are currently the only manufacturers of immersion lithography systems. History The idea for immersion lithography was patented in 1984 by Takanashi et al. It was also proposed by Taiwanese engineer Burn J. Lin and realized in the 1980s. In 2004, IBM's director of silicon technology, Ghavam Shahidi, announced that IBM planned to commercialize lithography based on light filtered through water. Immersion lithography is now being extended to sub-20nm nodes through the use of multiple patterning. Back ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Interuniversity Microelectronics Centre

Interuniversity Microelectronics Centre (IMEC) is an international research & development organization, active in the fields of nanoelectronics and digital technologies, with headquarters in Belgium. Luc Van den hove has served as President and CEO since 2009. In September 2016, imec merged with the Flemish digital research center, iMinds. Overview Imec employs around 4,000 researchers from more than 90 countries; it has numerous facilities dedicated to research and development around the world, including 12,000 square meters of cleanroom capacity for semiconductor processing. The imec headquarters are located in Leuven. History In 1982, the Flemish Government set up a program to strengthen the microelectronics industry in Flanders. This program included setting up a laboratory for advanced research in microelectronics (imec), a semiconductor foundry (former Alcatel Microelectronics, now STMicroelectronics and AMI Semiconductor,) and a training program for VLSI design engine ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Photolithography

In integrated circuit manufacturing, photolithography or optical lithography is a general term used for techniques that use light to produce minutely patterned thin films of suitable materials over a substrate, such as a silicon wafer, to protect selected areas of it during subsequent etching, deposition, or implantation operations. Typically, ultraviolet light is used to transfer a geometric design from an optical mask to a light-sensitive chemical (photoresist) coated on the substrate. The photoresist either breaks down or hardens where it is exposed to light. The patterned film is then created by removing the softer parts of the coating with appropriate solvents. Conventional photoresists typically consists of three components: resin, sensitizer, and solvent. Photolithography processes can be classified according to the type of light used, such as ultraviolet, deep ultraviolet, extreme ultraviolet, or X-ray. The wavelength of light used determines the minimum feature si ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Electron-beam Lithography

Electron-beam lithography (often abbreviated as e-beam lithography, EBL) is the practice of scanning a focused beam of electrons to draw custom shapes on a surface covered with an electron-sensitive film called a resist (exposing). The electron beam changes the solubility of the resist, enabling selective removal of either the exposed or non-exposed regions of the resist by immersing it in a solvent (developing). The purpose, as with photolithography, is to create very small structures in the resist that can subsequently be transferred to the substrate material, often by etching. The primary advantage of electron-beam lithography is that it can draw custom patterns (direct-write) with sub-10 nm resolution. This form of maskless lithography has high resolution and low throughput, limiting its usage to photomask fabrication, low-volume production of semiconductor devices, and research and development. Systems Electron-beam lithography systems used in commercial applicatio ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Static Random-access Memory

Static random-access memory (static RAM or SRAM) is a type of random-access memory (RAM) that uses latching circuitry (flip-flop) to store each bit. SRAM is volatile memory; data is lost when power is removed. The term ''static'' differentiates SRAM from DRAM (''dynamic'' random-access memory) — SRAM will hold its data permanently in the presence of power, while data in DRAM decays in seconds and thus must be periodically refreshed. SRAM is faster than DRAM but it is more expensive in terms of silicon area and cost; it is typically used for the cache and internal registers of a CPU while DRAM is used for a computer's main memory. History Semiconductor bipolar SRAM was invented in 1963 by Robert Norman at Fairchild Semiconductor. MOS SRAM was invented in 1964 by John Schmidt at Fairchild Semiconductor. It was a 64-bit MOS p-channel SRAM. The SRAM was the main driver behind any new CMOS-based technology fabrication process since 1959 when CMOS was invented. In 1965 ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |